ARX MK0S

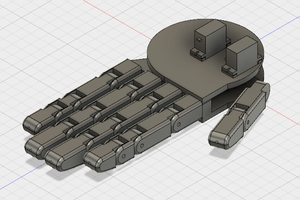

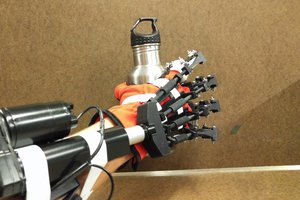

This is the servo variant of the ARX Hand Project which focuses on being an easy to develop robotic hand using common RC servos that can be easily sourced and controlled.

ARX MK0 Variants

- MK0 - https://hackaday.io/project/167785

Main variant which focuses on a bringing a fairly advanced low cost robotics hand that's compact in design.

- MK0M - https://hackaday.io/project/169585

An advance fully mechanically driven design with wippletree actuated fingers and 3 or 2 times mechanical advantage pulley system

- MK0F - https://hackaday.io/project/173565

Figure variant which is non motorised and static design. Mainly focused for artistic uses such as in stop motion, display purposes, sketching, scale modelling, etc.

Design Intentions

This design is more of a fun low cost design I made that may be used in STEM education for inspiring future engineers and makers. I may work further on the design for other possible purposes.

Design Aims

- Uses commonly available servos

- Can be printed in with only PLA or PETG

- Easy to print - No supports needed nor any fancy materials to be printed

- Easy to assemble - Roughly 15-30 mins to assemble without the need for drilling, tapping or part cleanup

- Materials are easy to source - Uses common screws, fishing line, elastic cord and 3D printer filament

- Maintain good balance of functionality, ease of assembly and aesthetics

Design Overview

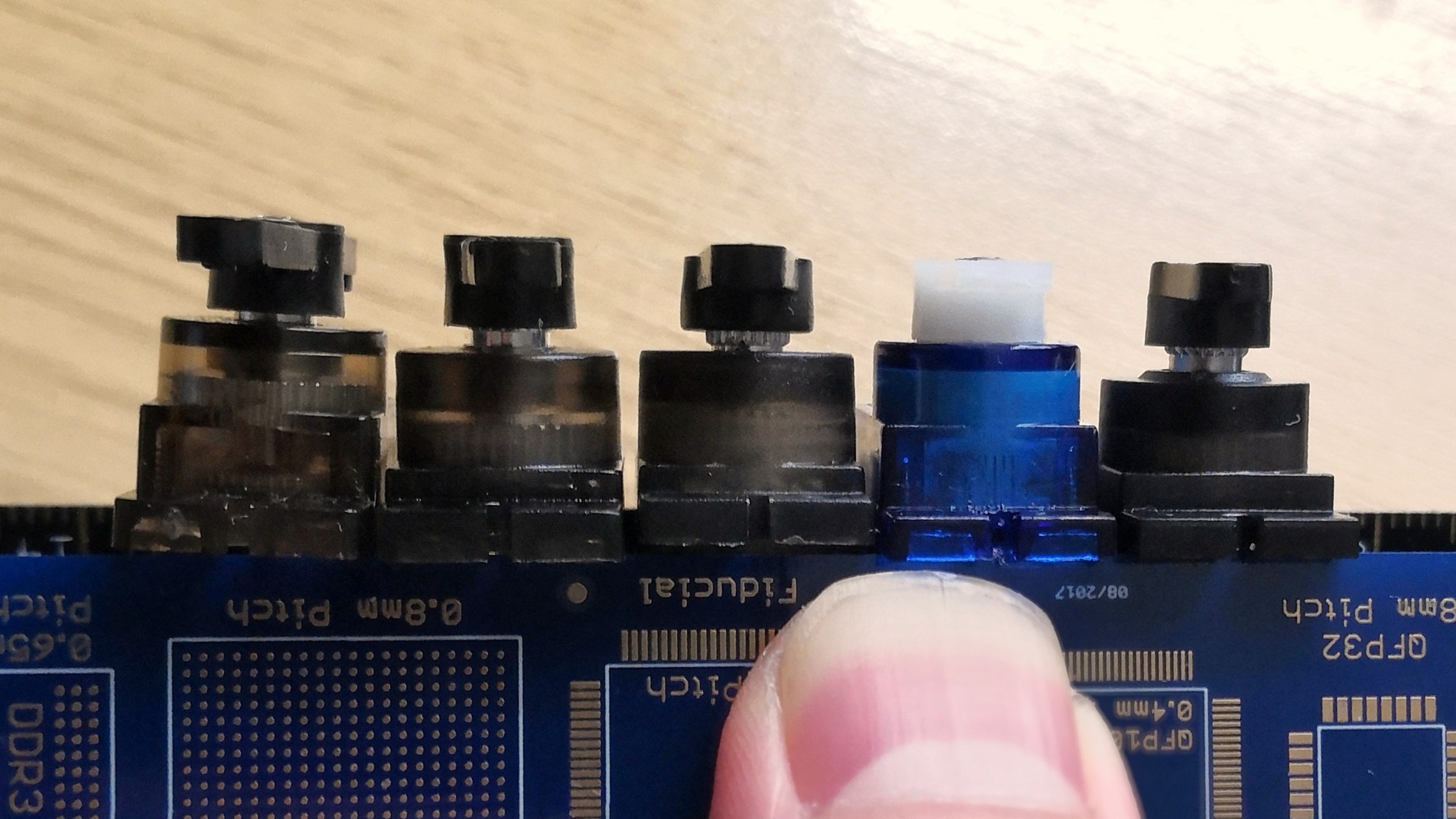

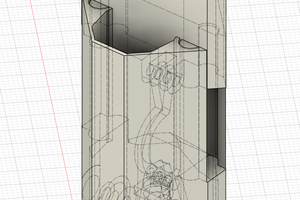

The design brings 5 degrees of actuation using servos along with 11 degrees of freedom in joints. It uses 5 micro/mini RC servos which can be controlled using an Arduino, a PWM driver or any servo driver. The use of servos brings the ability to have the fingers actuated to a set position through standard servo control. The servos can also be modified if there's a need for greater control and feedback of the fingers. Lifting and holding capabilities are dependent on the servos used, so ideally a high torque servos should be used if possible. Currently, the design will be compatible with the SG90, MG90S or any similar sized servos. Hand parts can be printed using any printer capable of printing PLA, and can be printed with or without supports. Additional materials required are some self tapping screws, 3mm nylon filament, 1mm diameter elastic cord and 0.5mm to 0.8mm diameter braided fishing line.

Hand Design

- V3.4 Finger Design

V3.4 builds on top of the initial design for V3 finger design. The aesthetic design remains the same, but many optimizations have been made to the design to improve overall printabilty and assembly.

Subtle features have been added within the model to reduce effects of 3D printing imperfections from impacting the fitting of joints. Rounding to edges have been added to reduce overshooting artefacts on surfaces from ghosting, ringing and nozzle pressure build up. Seam adjustments have been added to avoid seams being placed between joint surfaces. Clearances on the joints are still fairly lenient to allow for easier printing, but clearances may be reduced down to 0.1mm if required.

For a two joint finger, fingers require the use of 1.75mm and 3mm nylon filament to act as pins between joints. Nylon should ideally be used as it provides a low friction, low wear joint. The flexibility of nylon also allows for a compliant spring effect of joints, as well as to aid with friction fit joints through deformation of the material.

For closing actuation, fingers are actuated through a single cord of 0.5mm to 0.8mm diameter braided fishing line attached using a screw. For opening actuation, fingers are opened using an elastic material attached on the back side. The method of attachment of the elastic material allows for a number of options that available or easily accessible. Elastic cords can be used through tying knots at ends, and elastics can be printed or made through casting/injection moulding. Detachable cords also allow for easy replacement or disassembly of fingers. Currently, 1mm...

Supercell

Supercell

Andrew Bahls

Andrew Bahls

Chad Paik

Chad Paik