-

Second design

08/25/2020 at 15:20 • 0 comments[To be added]

-

Servo Motors Options

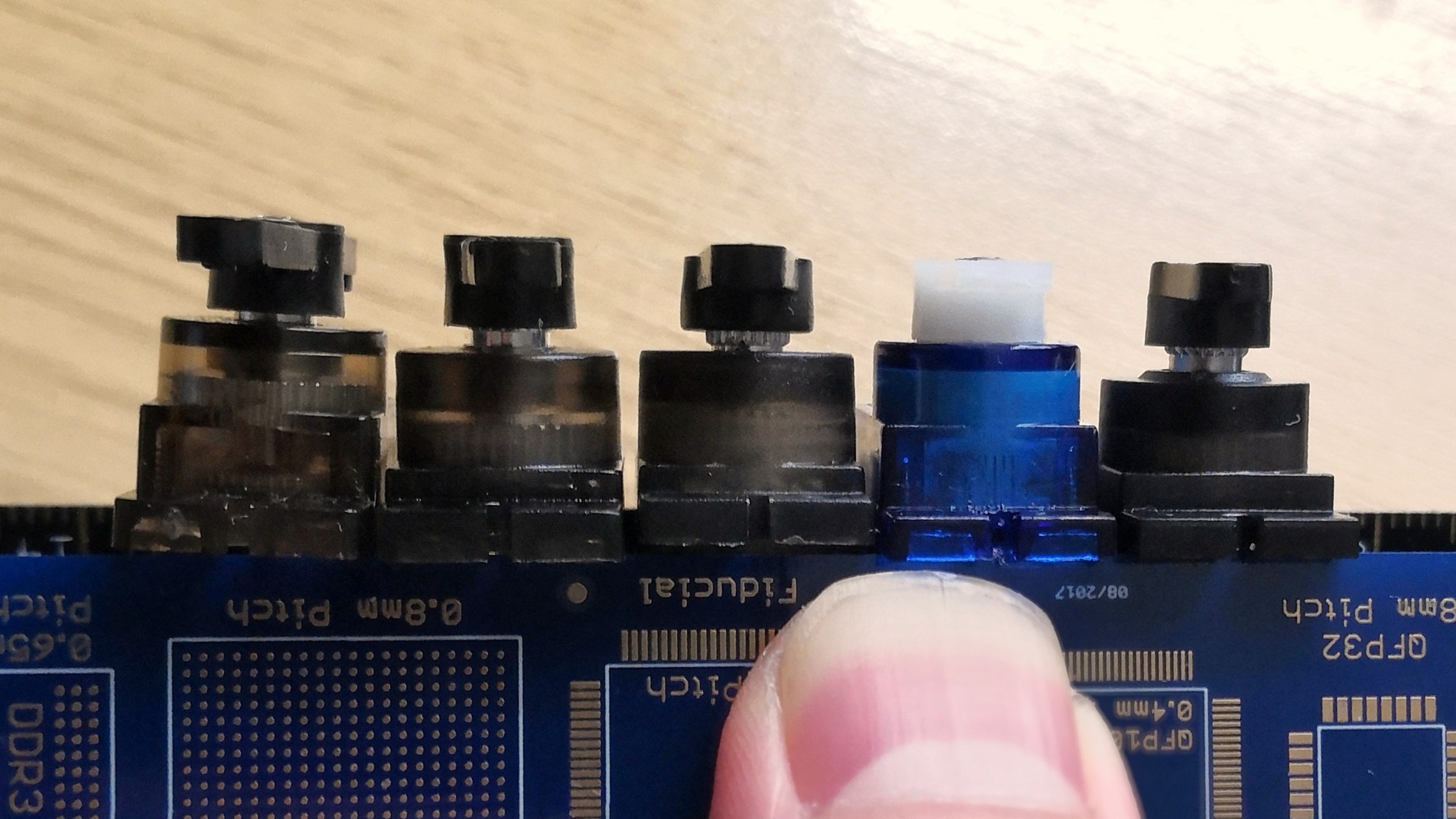

07/10/2020 at 15:56 • 0 commentsFor now, I'm aiming for the design to use the more common SG90 or MG90S servo motors. These servos are fairly popular for their small size and affordability, and can be purchased for a few dollars each. Unfortunately, with the popularity of these servos, many manufactures create similar looking servo motors under the same naming but with subtle differences in how they're made. Some SG90/MG90S servos have different casing, horn height, horn dimensions, potentiometer construction and some even used a digital control system instead of an analogue system. Adapting the design to suite all different variations would be quite difficult but they still at least maintain roughly the similar dimensions of around 12x23mm.

For servo case gear height from mounting, the variation between same models can vary quite drastically between vendors (or even same vendors). Horn height also has slight differences which adds to things to work around.

![]()

-

temp

04/30/2020 at 18:25 • 0 commentstemp

-

Temp

02/03/2020 at 01:02 • 0 commentsTemp

-

First Servo Based Prototype

01/23/2020 at 11:43 • 0 commentsFirst experimental servo prototype derived from the ARK MK0 prototype. This prototype used 5 SG90 servos that I had purchased a few years back that I never got around to using. The servos aren't of great quality, so I would recommend using modern MG90S servos which are more durable with the metal gears and has a digital system. Overall initial impressions weren't that great with the use of the SG90 servos due to lack of torque and feedback, however, it does show a promising development for an educational/development tool. I will be developing some methods of improving feedback along with using some slightly more powerful servos in the next version.

Features:

- Servo based design

- Easy control with servos

- 5 actuation motors

- Low cost at around $30

- Added experimental geometry features to help with assemblySpecs:

- 5 SG90 servos

- Used a PCA9685 PWM driver board for easier control through an Arduino.Further Work:

- Adjustments needed for screw locations for swap able fingers

- Subtle changes needed for cord location and overall adaptability for different servos

- Possible additions of new elastic cord system

- Better cable management for servo wires

- Use of higher torque servos

- Use of feedback for servo position and load

Supercell

Supercell