-

F-35 predecessor

12/20/2021 at 18:45 • 0 commentsInteresting predecessor to the F-35 nozzle built by the soviet union.

http://www.leteckemotory.cz/motory/r-79/index.php?en

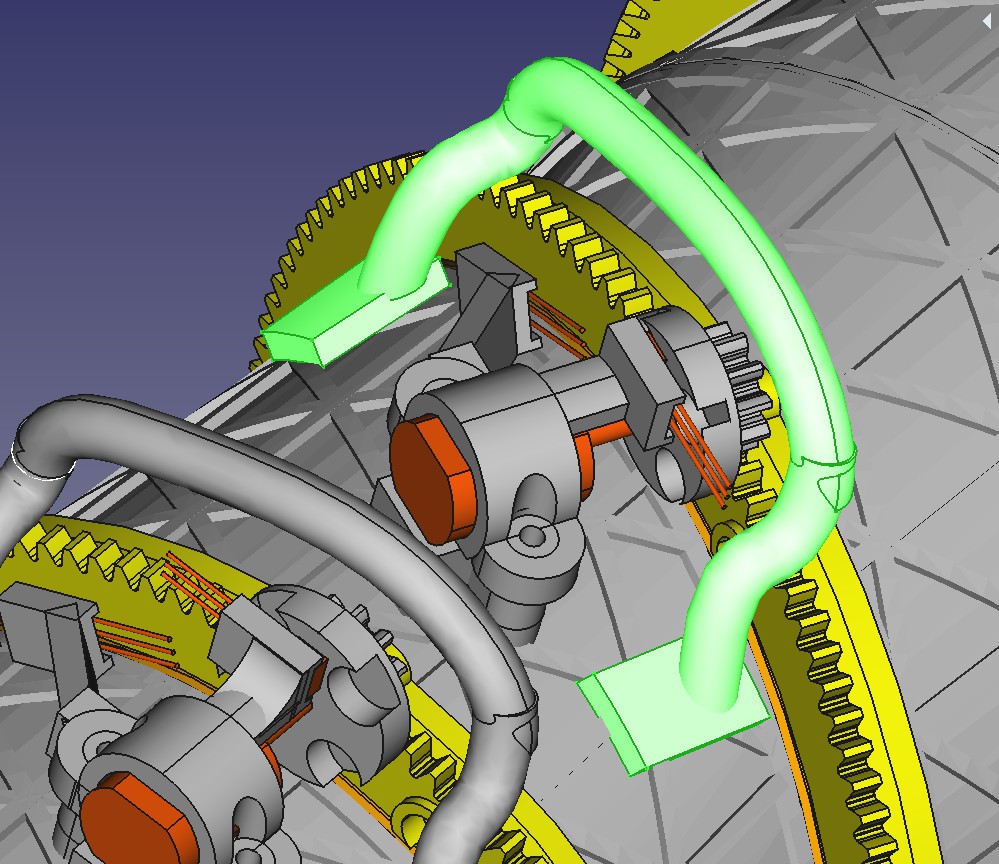

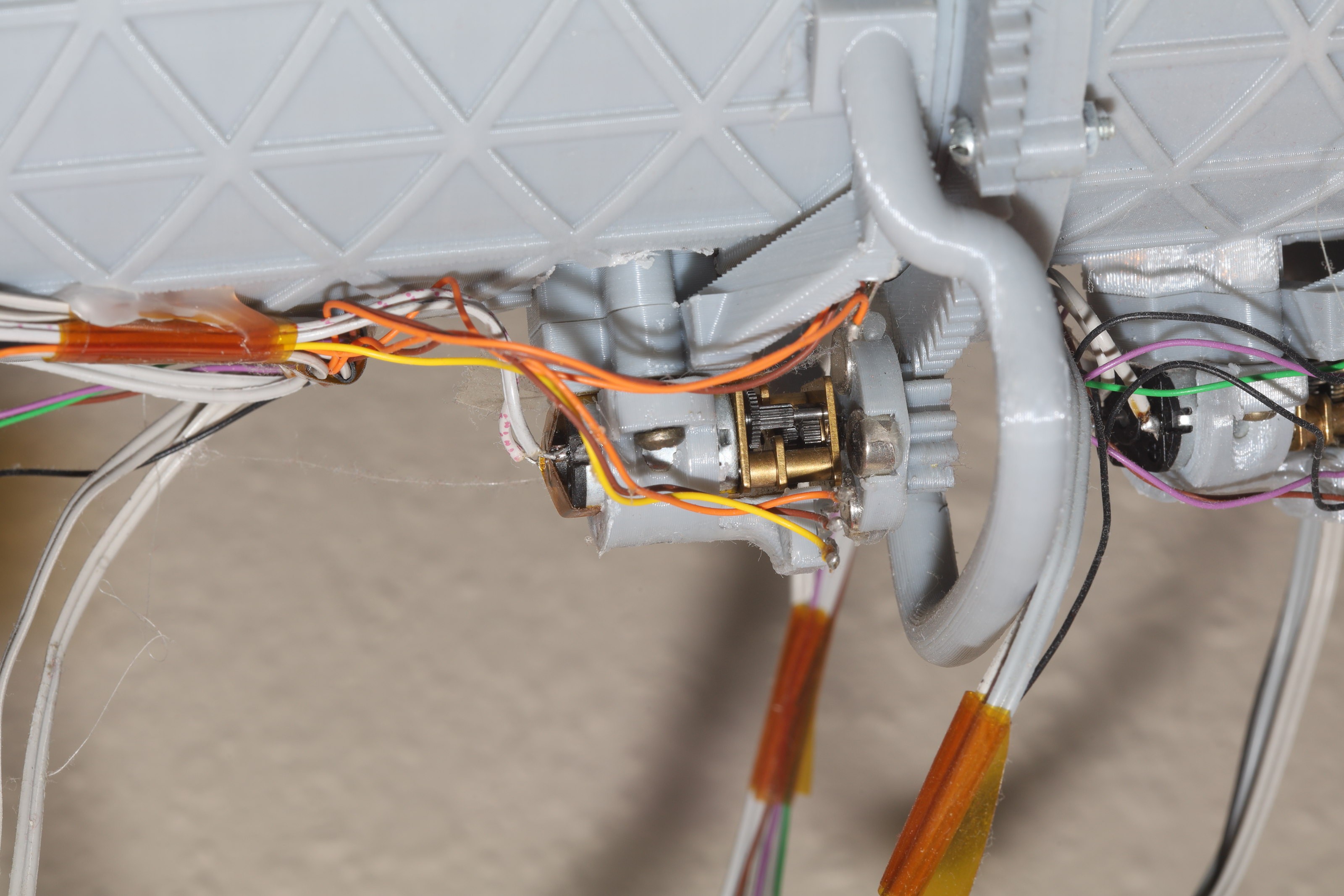

Of note for lions is the use of a torque tube & a complicated mechanism for nozzle opening. It has 4 swiveling sections & the exit doesn't rotate. It has a jig which keeps the exit from rotating, thus providing a rigid platform for the last actuator to push against. It has 3 motors with 1 freewheeling bearing. The lion version has 3 swiveling sections & the exit rotates.

It was used in the yak-141

https://en.wikipedia.org/wiki/Yakovlev_Yak-141

It had 3 engines. 2 vertically mounted, afterburning engines replaced the lift fan in the nose & only ran when hovering. Lockheed paid a certain amount for the nozzle design. It must have been envisioned as a hovering weapons platform.

![]()

1.5 years on, air vent model #F-35 has shown its age. The front motor no longer has enough brake torque to keep it in a sideways right angle. Once it slips, the encoders have to be reset. The brushes must have worn down or the friction in the bearing must have worn down. Farsteners have started falling off. It is now known that PLA is threadlock safe.

There would be some major redesigns. Quadrature motor encoding would be the biggest change. A new nozzle would be built before discarding the old one. It would have to be manually reset in order to access more range.

-

Wishlist

07/19/2021 at 08:57 • 0 commentsThe summer heat brought the nozzle's 1st real test. It definitely needs more range. The leading idea for adding more range is not using the boundary sensors for detecting runaway motors.

Experience has shown the nozzle never needs the boundary sensors & never has to be reset. It would be too much hassle to completely eliminate the boundary sensors, but they don't have to really stop the motors.

The fully automatic reset routine can be replaced with a manual reset of the nozzle angle. The confuser would reset the pitch as before, then the user would manually rotate the angle to within a few steps of the magnet, then resume the reset routine by searching for the precise angle boundary. It would require no hardware changes.

![]()

![]()

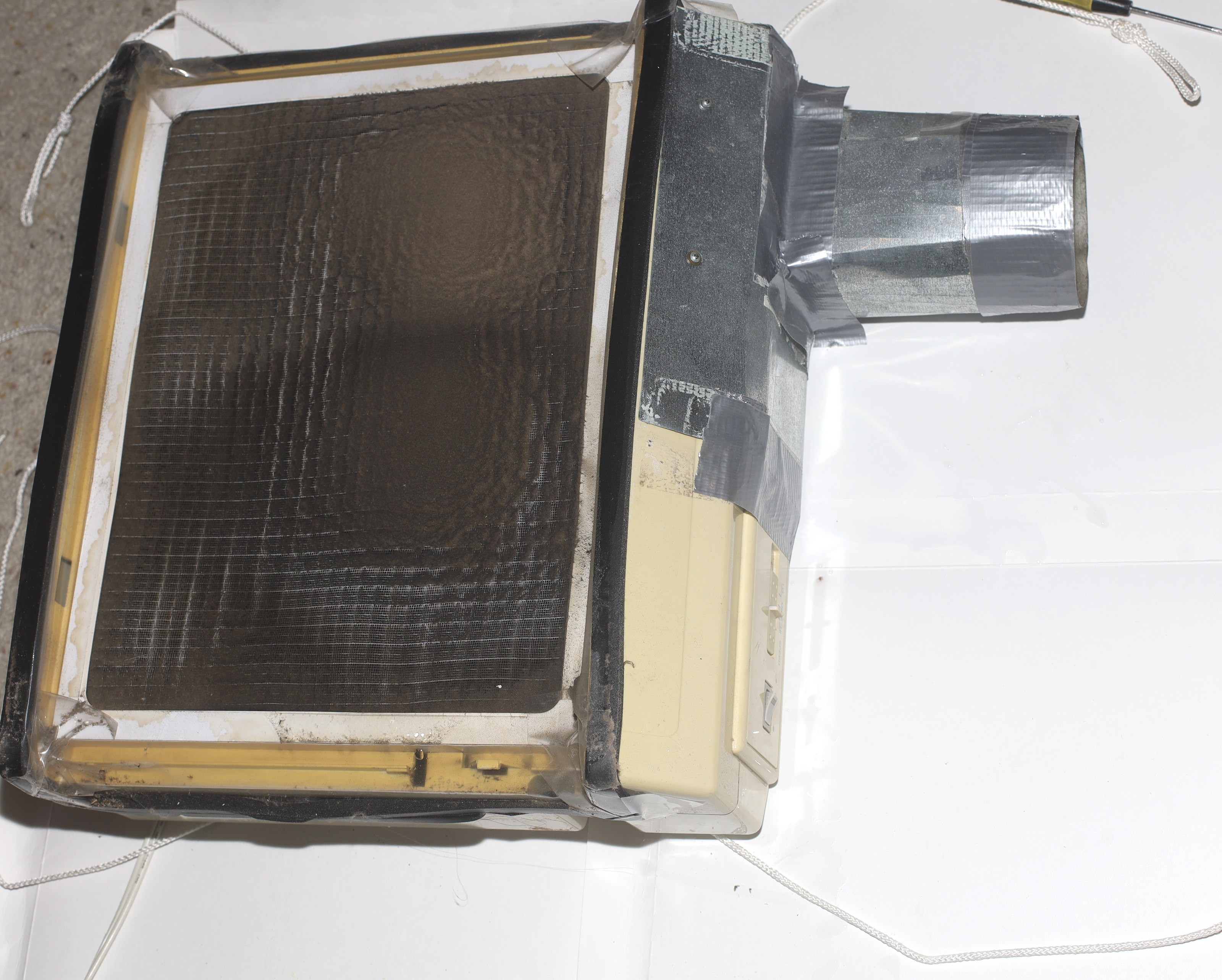

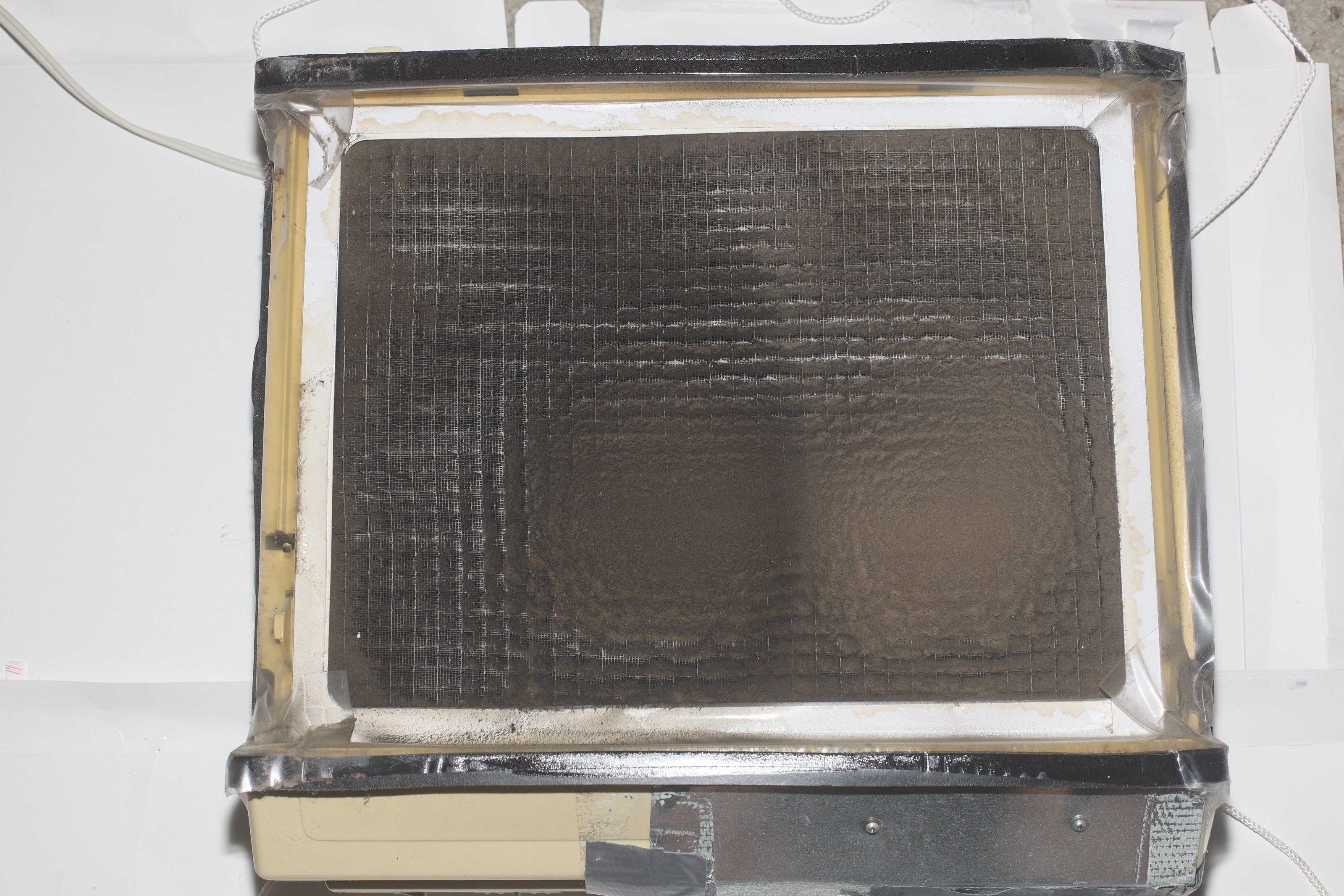

After spending 3 hours replacing another filter, ideas returned for making a complete blower, customized for easy cleaning. The filter would sit inside an inset notch, making it easy to seal the edges with tape. The edges would be flat, making it easy to scrape off all the critters. This one would be made of many smaller blowers that could be individually printed in 1 piece. The smaller blowers would still be the largest the printer could fit.

There's a slight benefit to having the exit nozzle change diameter. The leading plan is having interchangeable nozzle extensions. The interchangeable extensions just wouldn't be F-35 compliant.

The whole thing could be made lighter with a year of lessons learned about minimum tolerances for PLA. The mighty 300:1 N20 motor with encoder is still in stonk.

https://www.adafruit.com/product/4641

Being a much more precise encoder, it would be susceptible to losing count if it wasn't wired in quadrature mode.

-

Misting experiment

07/01/2021 at 21:35 • 0 comments![]()

![]()

![]()

![]()

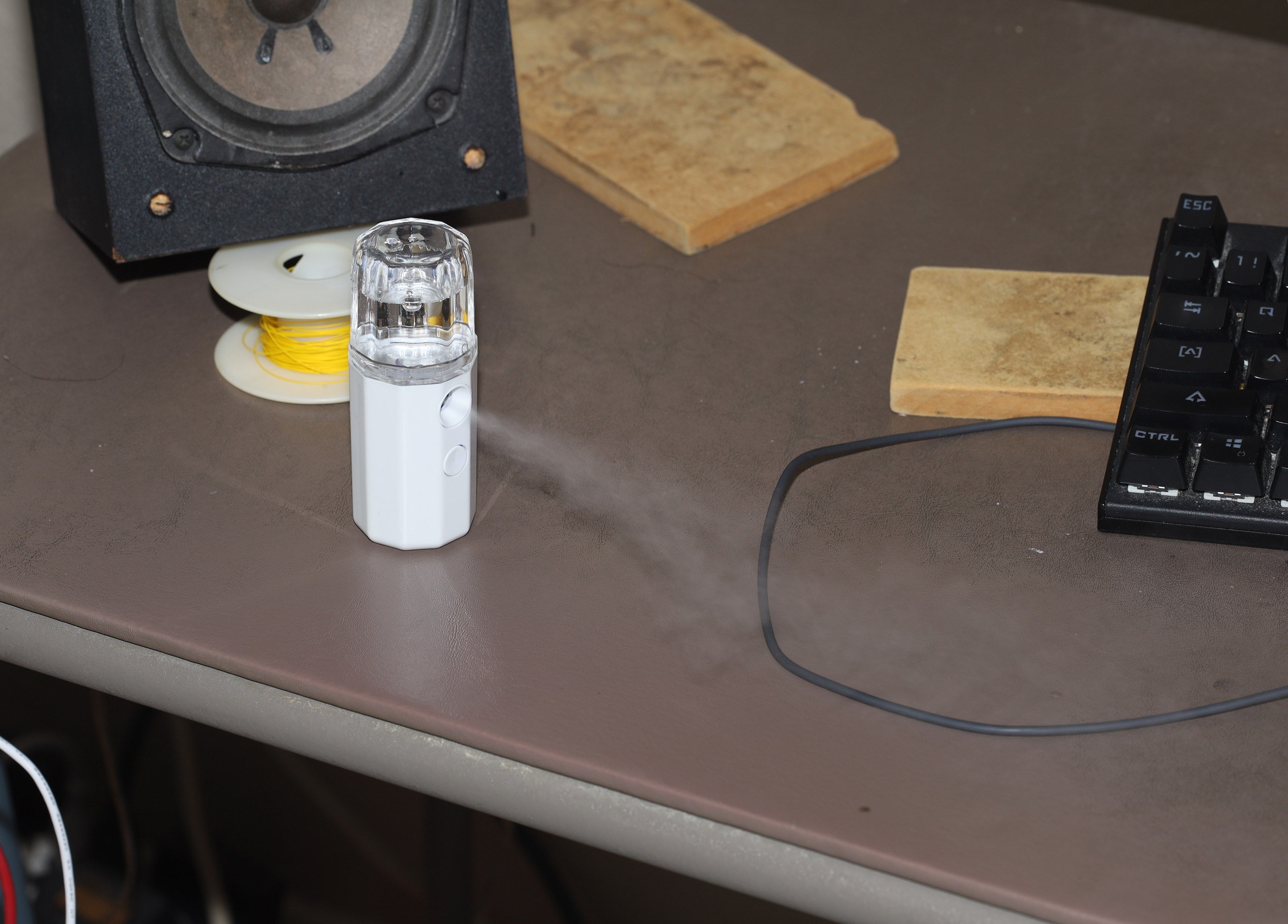

This thing does reduce a lion's temperature, when placed right next to an arm. It's based on early 2000's MEMS investments, a much more efficient solution than a pump with atomizer. The internet warned it doesn't last long. If the water isn't distilled, the MEMs atomizer clogs up quickly. If it runs dry, the MEMS atomizer burns out. Despite this danger of overheating, it does have a backflow of air to pressurize the tank. Instead of sensing the water level, it relies on a 5 minute timer to shut it off.

It runs for around 7 minutes per tank. It doesn't seem to leak when it's off. Only a matter of time before the seals start leaking. There's a high voltage, alternating current driving the atomizer. A better solution would have a filter & external hose. At least it's a starting point for a 3D printed mister using multiple atomizers.

MEMS atomizers seem to have appeared in 2009, near the end of the MEMS boom. MEMS were the self driving cars of generation X. They continued evolving into the vaping boom around 2015. The ideal application was short term use specifically with expensive purpose built fluids. Along with the essential odor, nicotine or whatever, the fluid could be guaranteed to be free of contaminants so the damn thing wouldn't clog up.

-

Nozzle presets

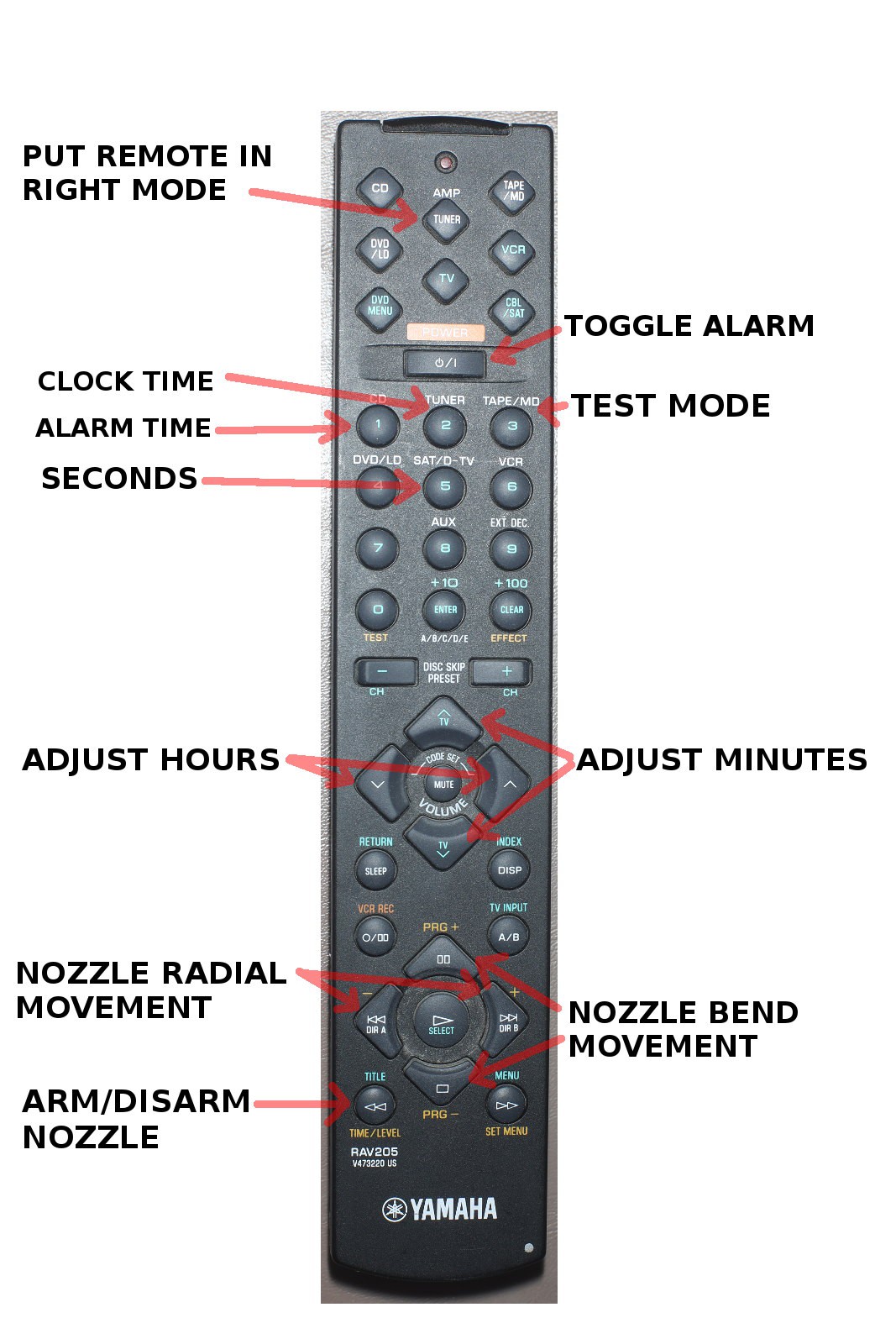

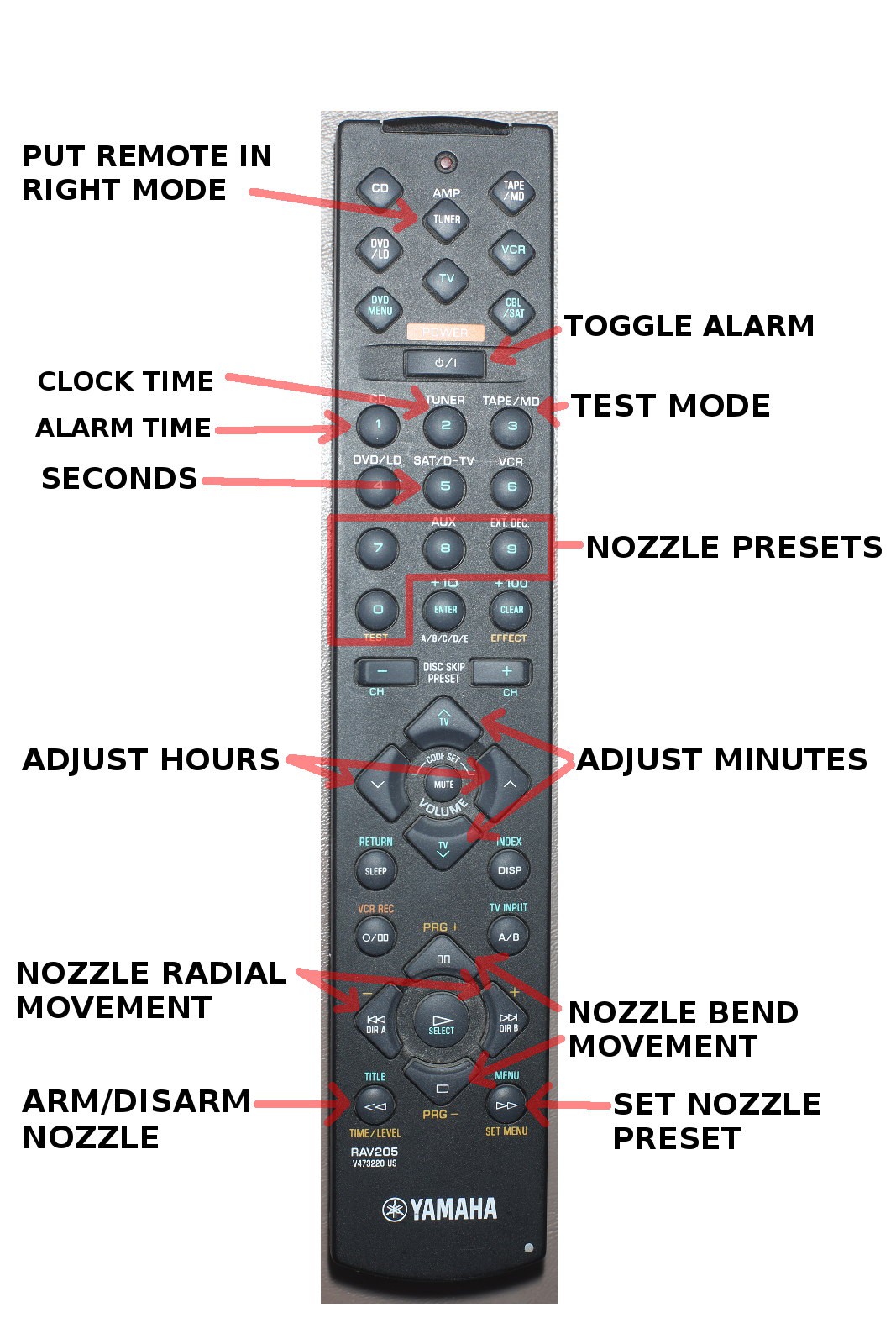

11/15/2020 at 21:02 • 0 commentsPositioning the nozzle by IR remote has grown into a pain in the mane. It would be money to have 3 preset positions.

![]()

![]()

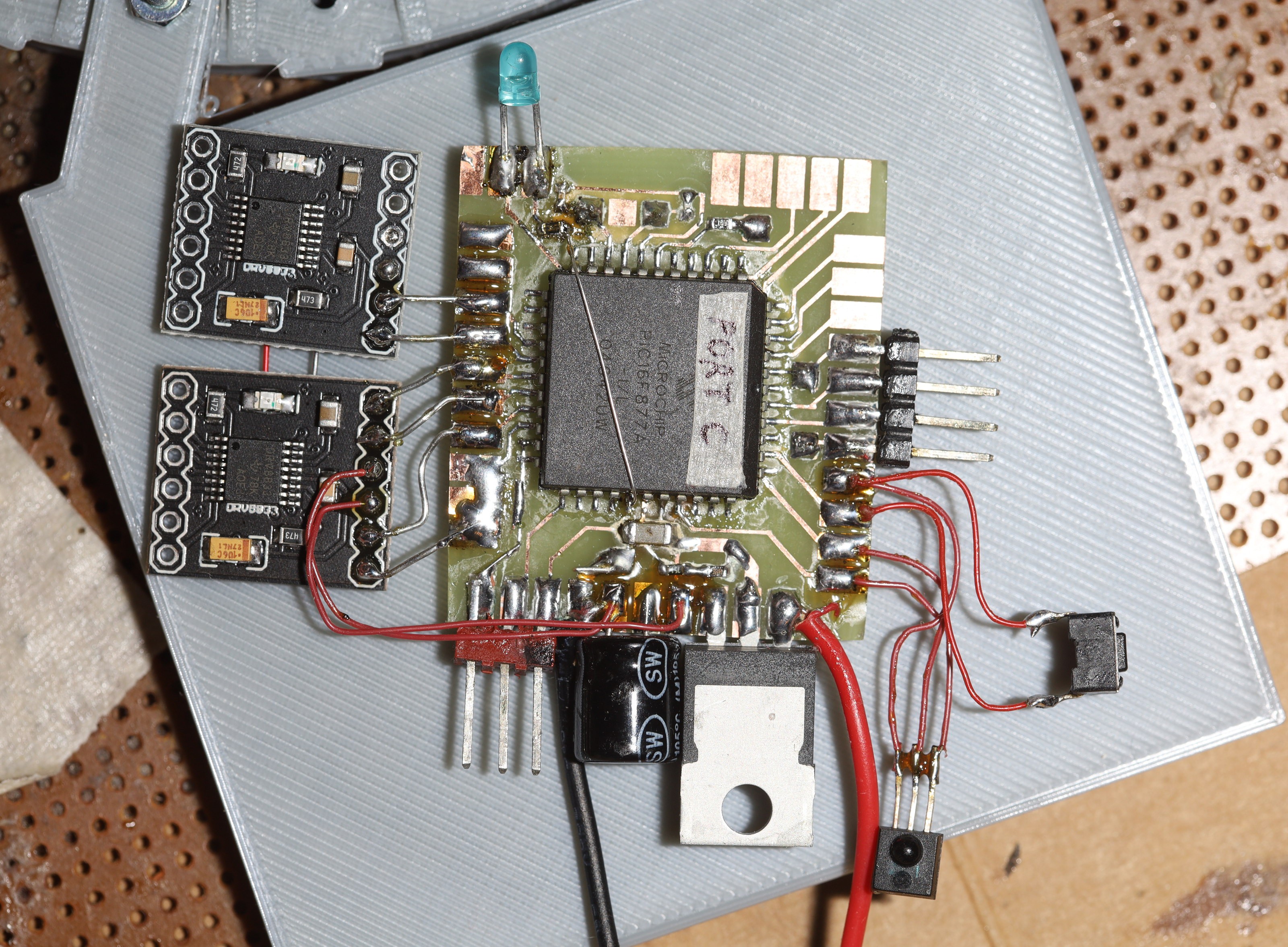

The mane problem with presets was supporting 5 more remote control buttons. The clockspeed had to be stepped up to 22.579 Mhz. This increased the standby current to 50mA. Having it on the bench again brought back the memories of the time it was created.

It's not the most efficient solution. It compares every IR code against 10 values in a table, as soon as it's received. It would probably save 20mA to store every IR code in a FIFO when it's received & process it when the CPU has enough time. The 20mA would just require a lot more programming & no-one ever got quizzed on the power requirement of a software change in a job interview.

![]()

The remote control is becoming a beast.

The accuracy of the motors is a pain in the mane. The motors were originally bought for a traction application, not suited for precision. The gear reduction possible with 3D printing is bad. No way to improve the accuracy without new motors presented itself. More accurate motors would be $40. The new motors have integrated encoders, so the boundary switches could be closer to the motors. That would entail printing new motor mounts. The gears would no longer have magnets but would have the same dimensions.

The nozzle could stand to be a hair larger in diameter, maybe 5mm.

There is a slight advantage to printing a new nozzle, buying new H bridges, magnets, & motors.

-

Polar vs XY coordinates

09/21/2020 at 18:20 • 0 commentsControlling the nozzle in polar coordinates proved to be a real pain. XY coordinates presented the problem of dead areas where an XY position corresponds to multiple polar positions or multiple XY positions correspond to a single polar position. An idea emerged whereby dead areas could be avoided. The key is the fact that the user only moves the nozzle 1 step in 1 direction at a time.

For every polar position, we calculate either 4 or 8 adjacent polar positions by adding & subtracting 1 angle & 1 magnitude step. Then, we manetain a master XY position which updates X if the user presses a horizontal arrow or updates Y if the user presses a vertical arrow while fixing Y if the user presses the horizontal arrow or fixing X if the user presses a vertical arrow. It picks the next adjacent polar position based on what's closest to the fixed master axis while moving the variable master axis in the right direction. If 2 polar positions have the same fixed master axis, pick the variable master axis which is closest.The next problem was improving the encoders. It turns out, they actually sense the rising & falling edges of the magnets instead of the magnet centers. With braking enabled, they actually stop on the rising & falling edges. The trick is to space the magnets 1 magnet apart & detect 2.5V crossings instead of 0V & 5V levels. What they can't do is detect the centers of the magnets. Sensing edges increases the accuracy to 8 steps per turn.

Also, the boundary switches don't need to be polled anymore after it's initialized, which could increase the accuracy further.

The mane problem is the motors are still too fast & reprogramming the encoders would entail making new position tables by paw. Reprogramming the encoders is just a bandaid for what really needs to be done. It needs expensive 300:1 motors with built in encoders. The more lions live with an F-35 air vent, the more reasonable the extra cost becomes.

https://www.adafruit.com/product/4641Further random ideas:

remote control for the power.

Aquarium pump powered mister

LEDs for afterburner effect with the mister. Mounted on the inside of the nozzle, they could make a straight flame. The problem is the nozzle rotates, so the water pipe & any wiring would have to slip inside the nozzle.

-

F-35 nozzle air vent

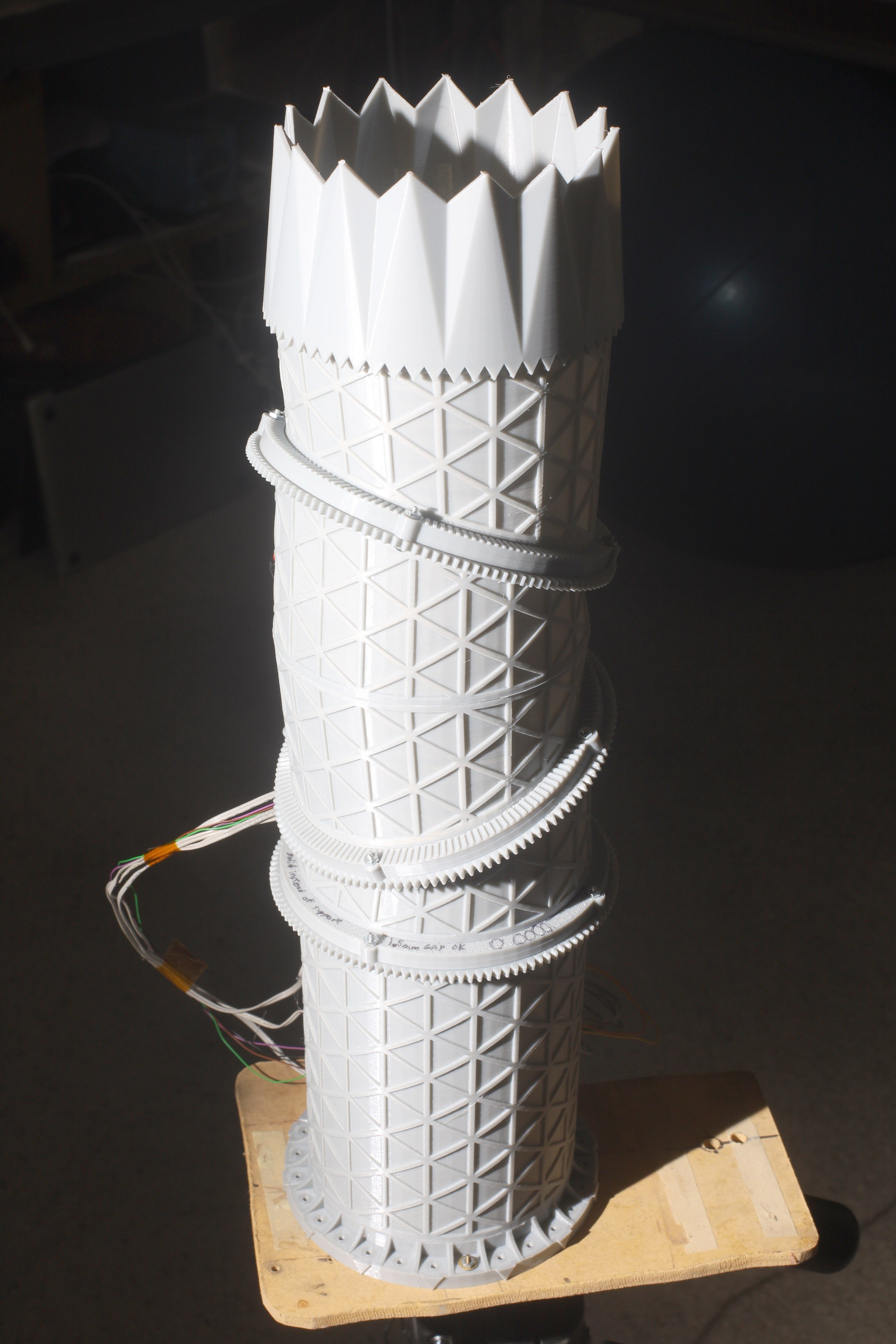

09/20/2020 at 06:09 • 0 comments![]()

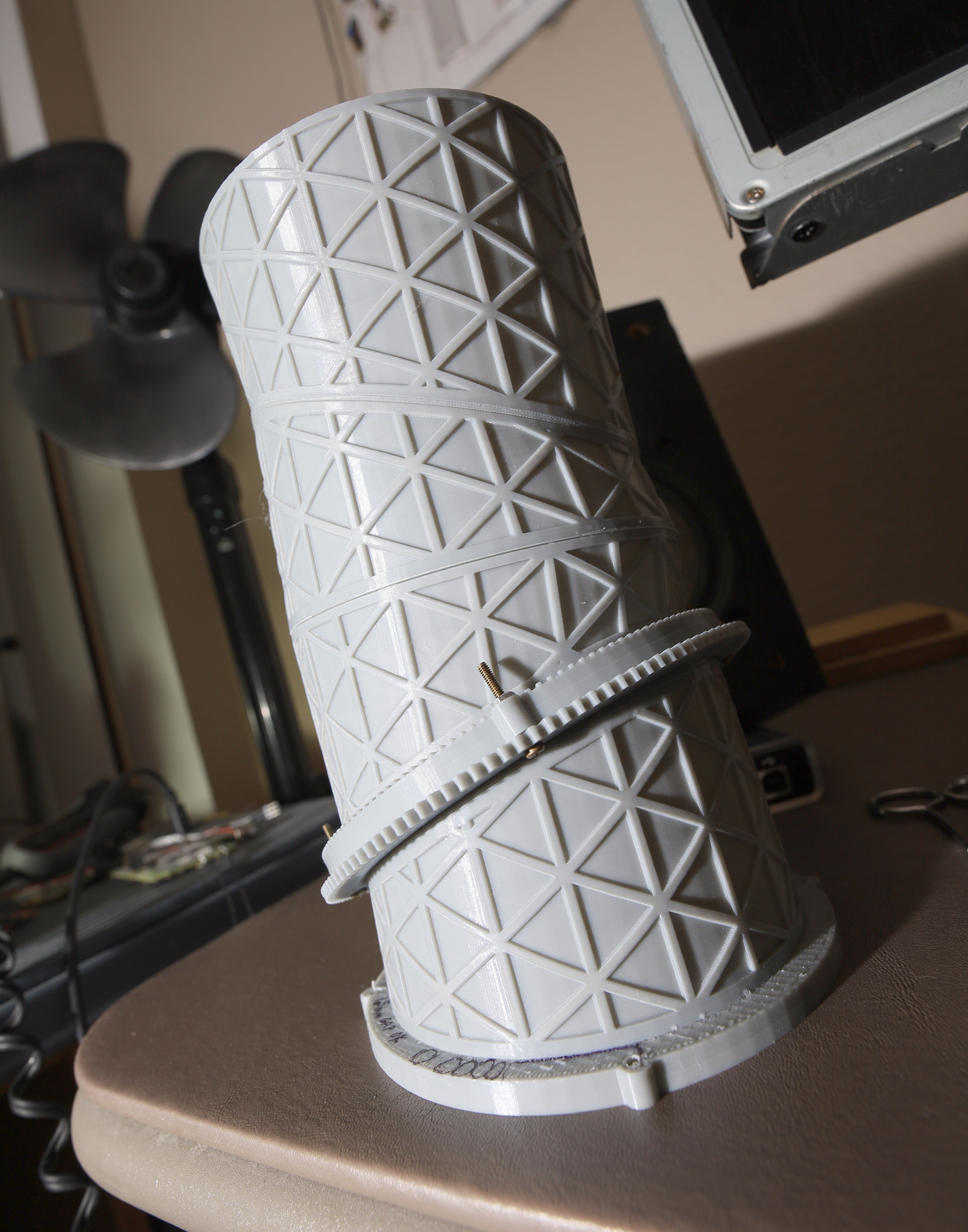

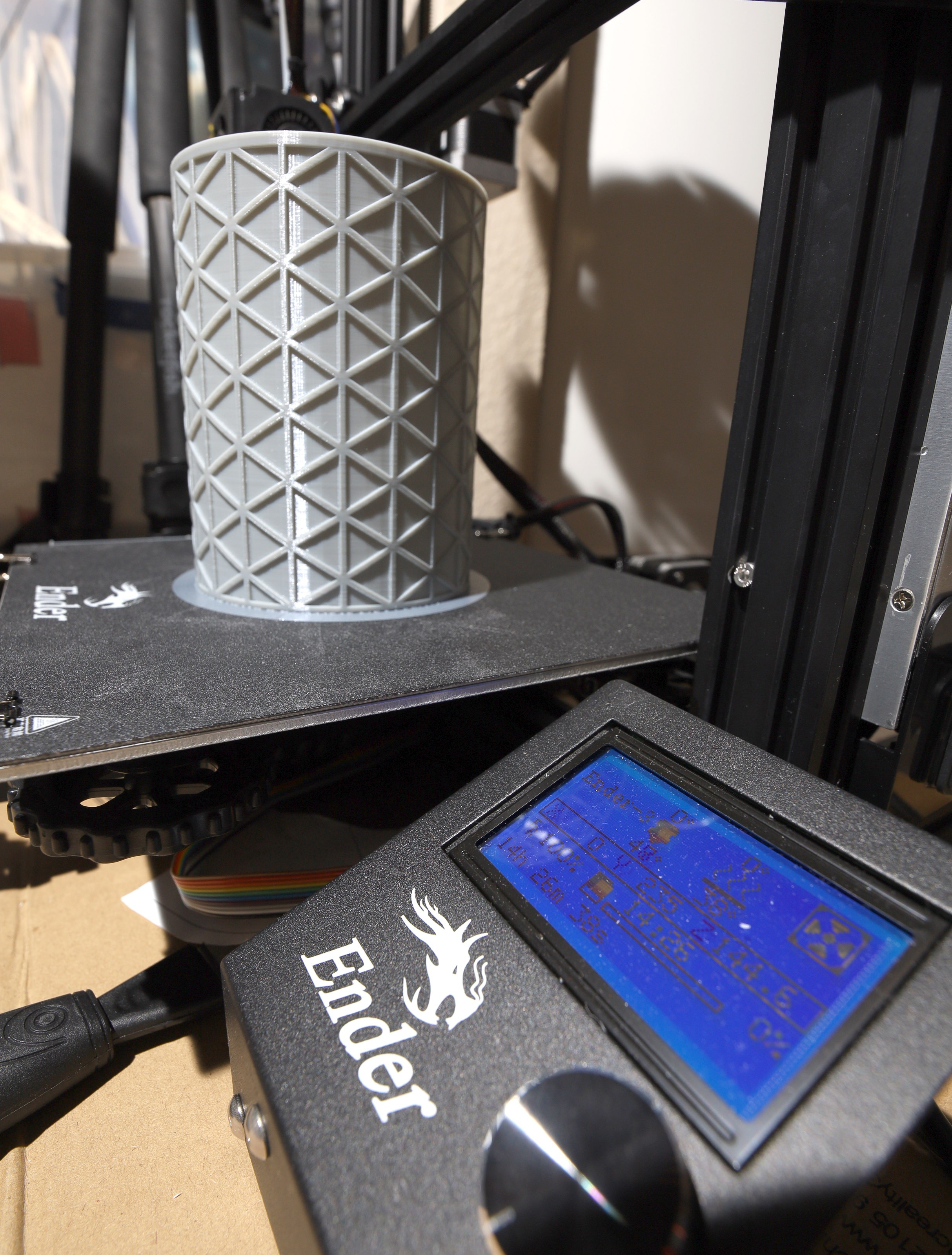

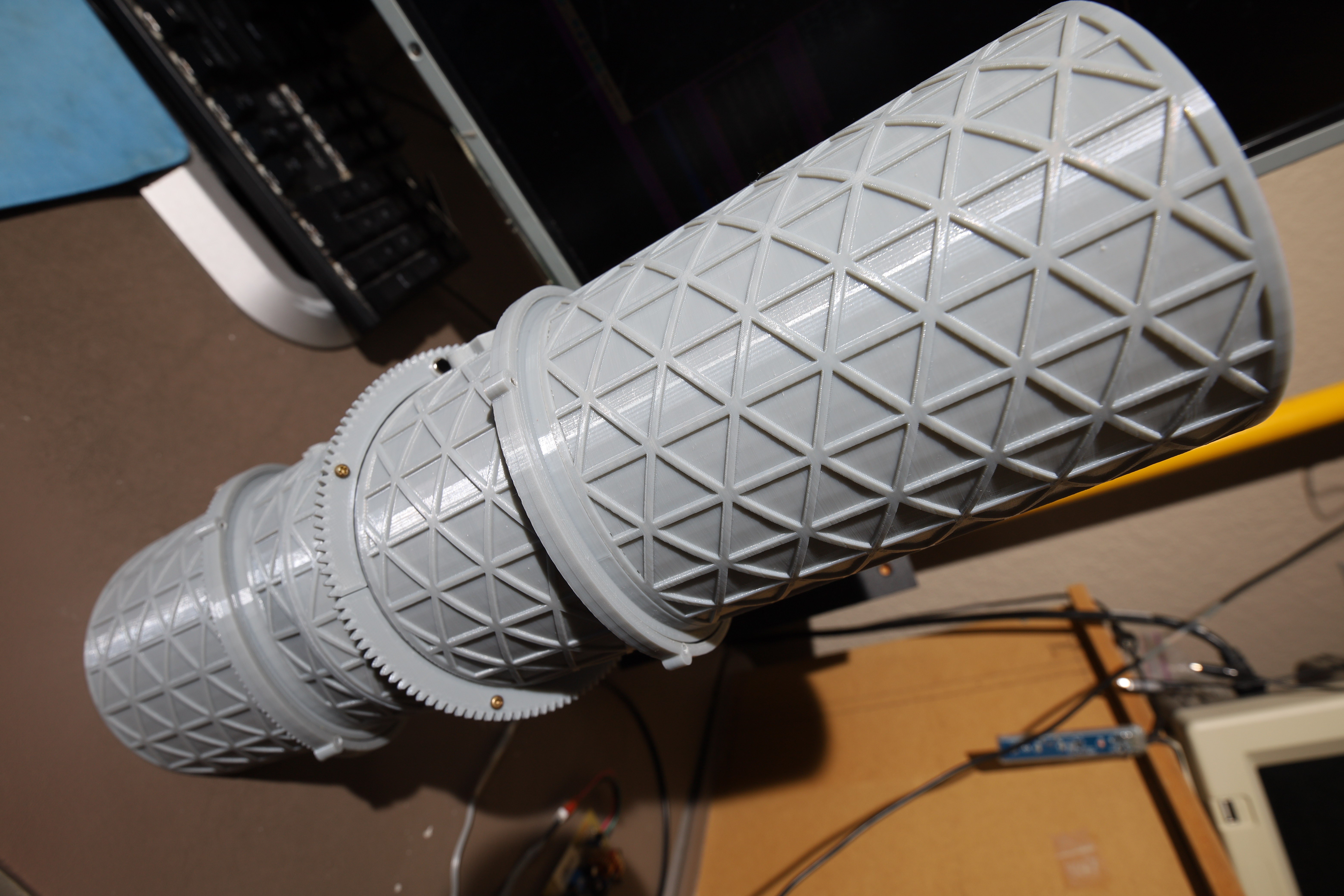

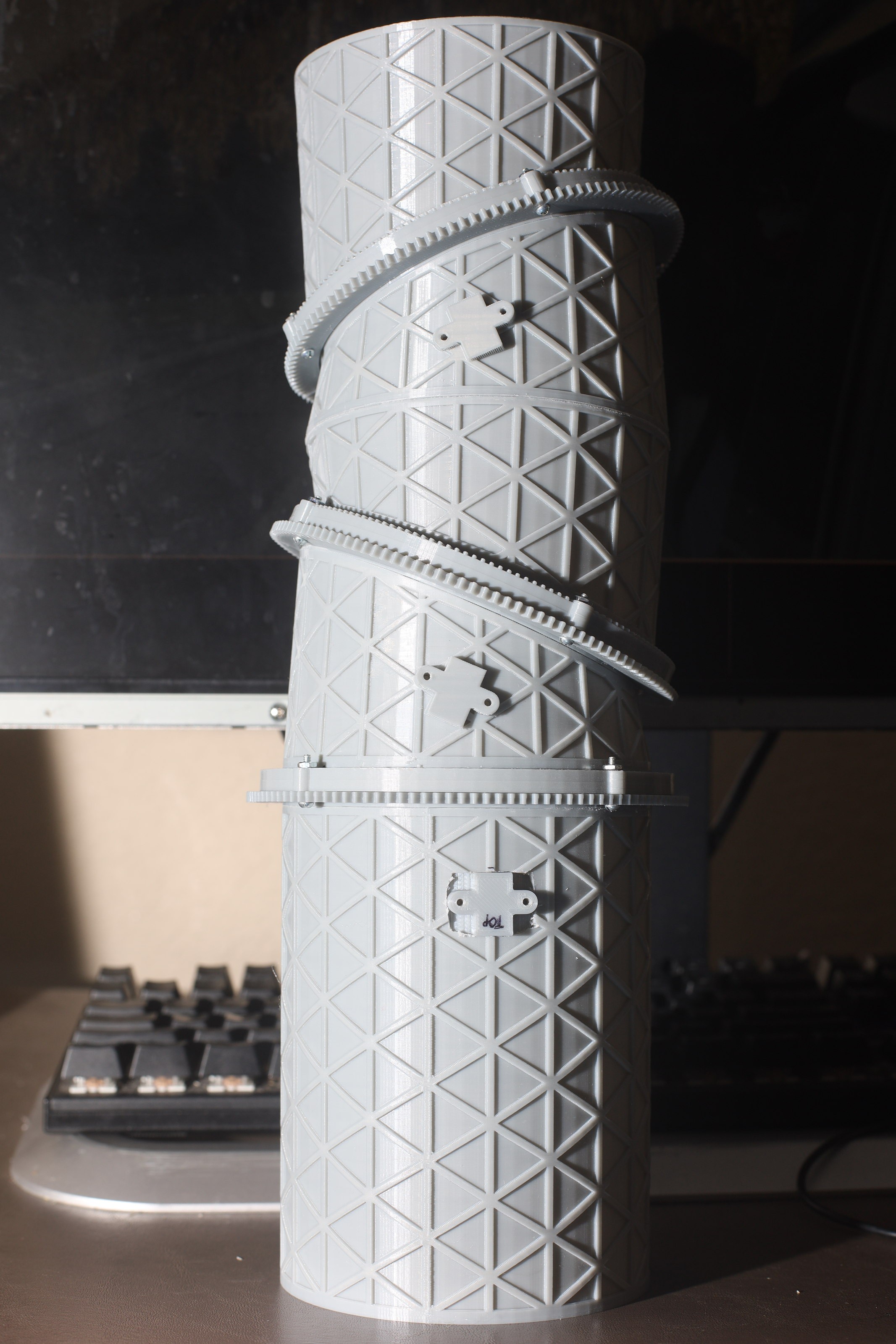

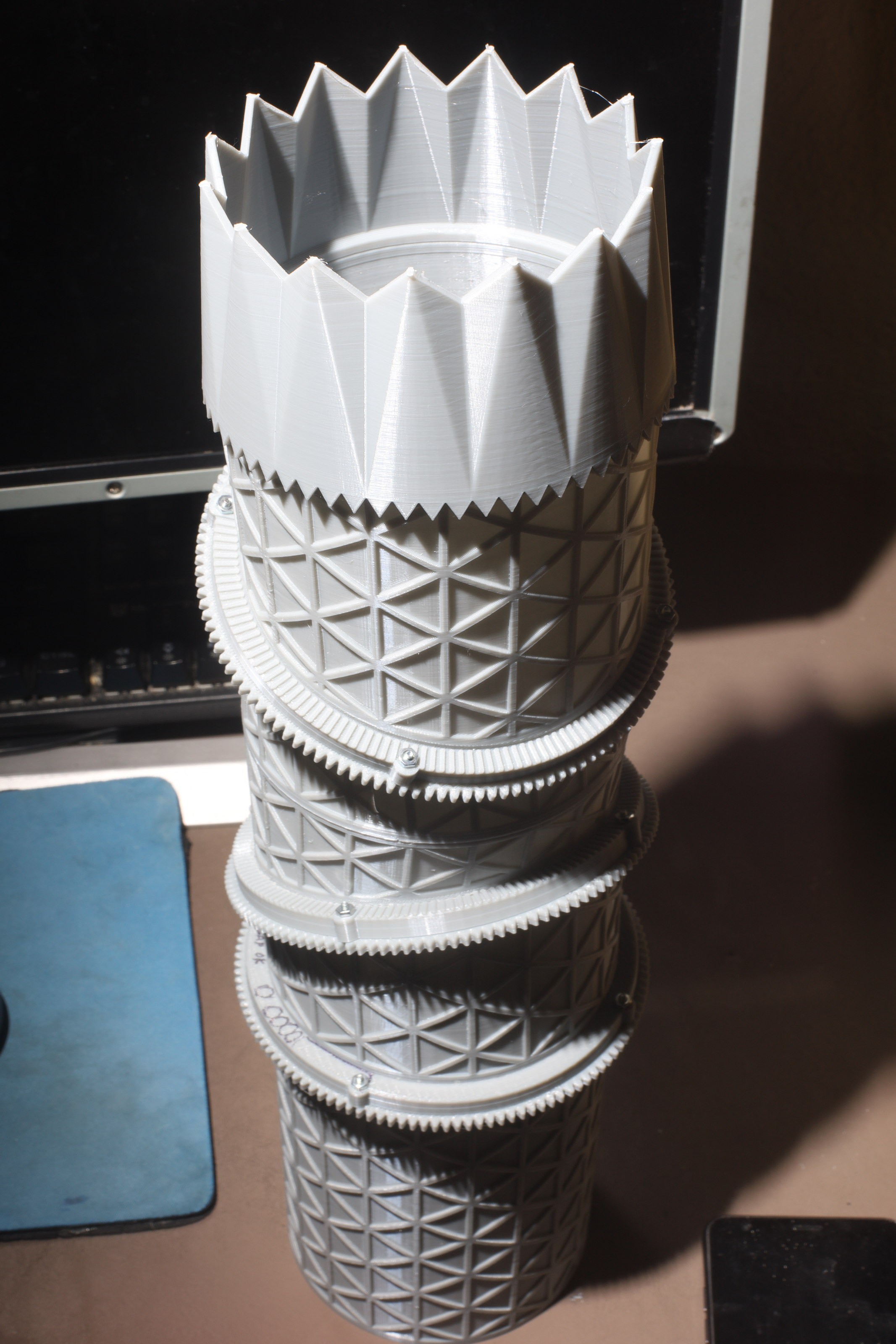

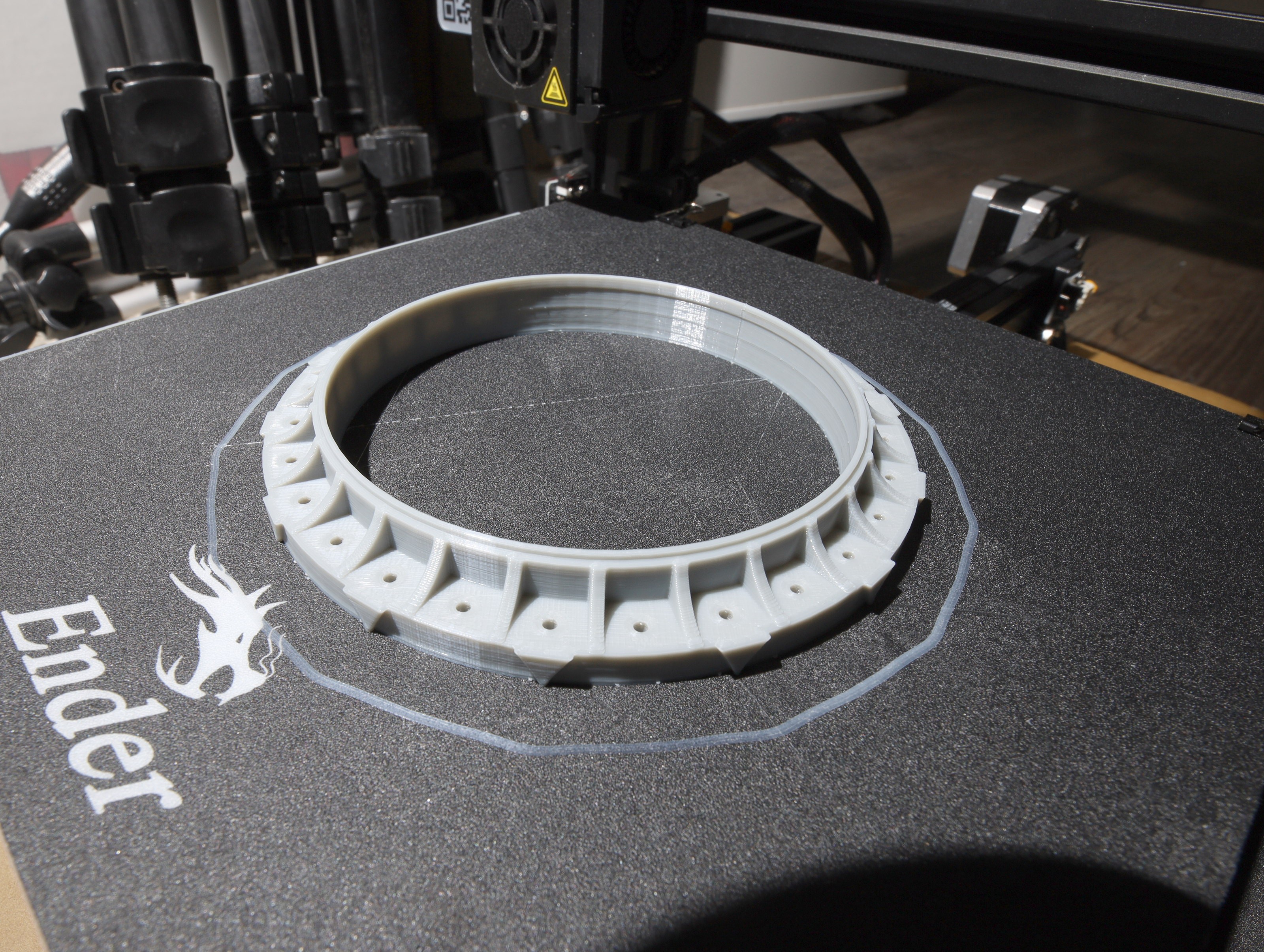

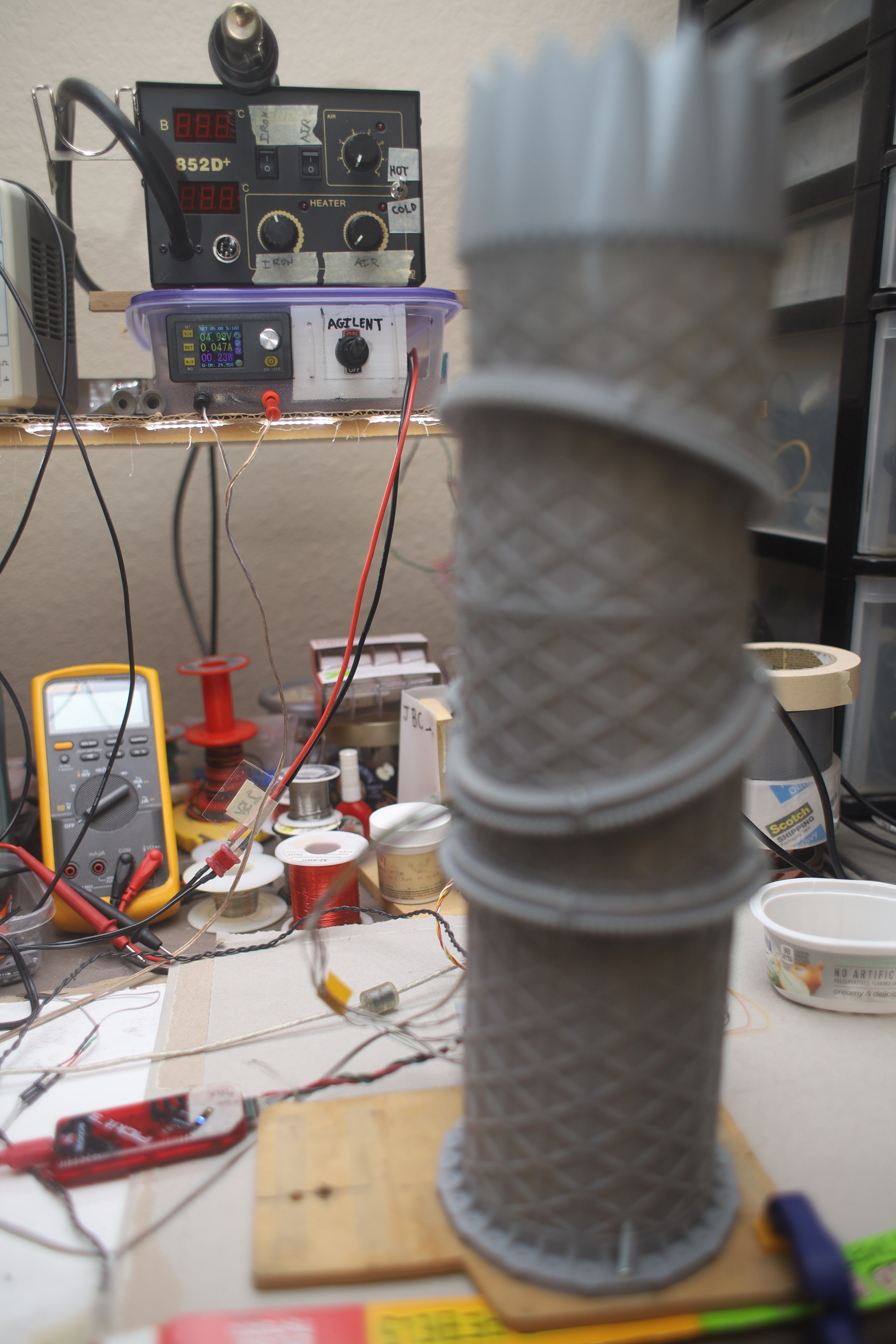

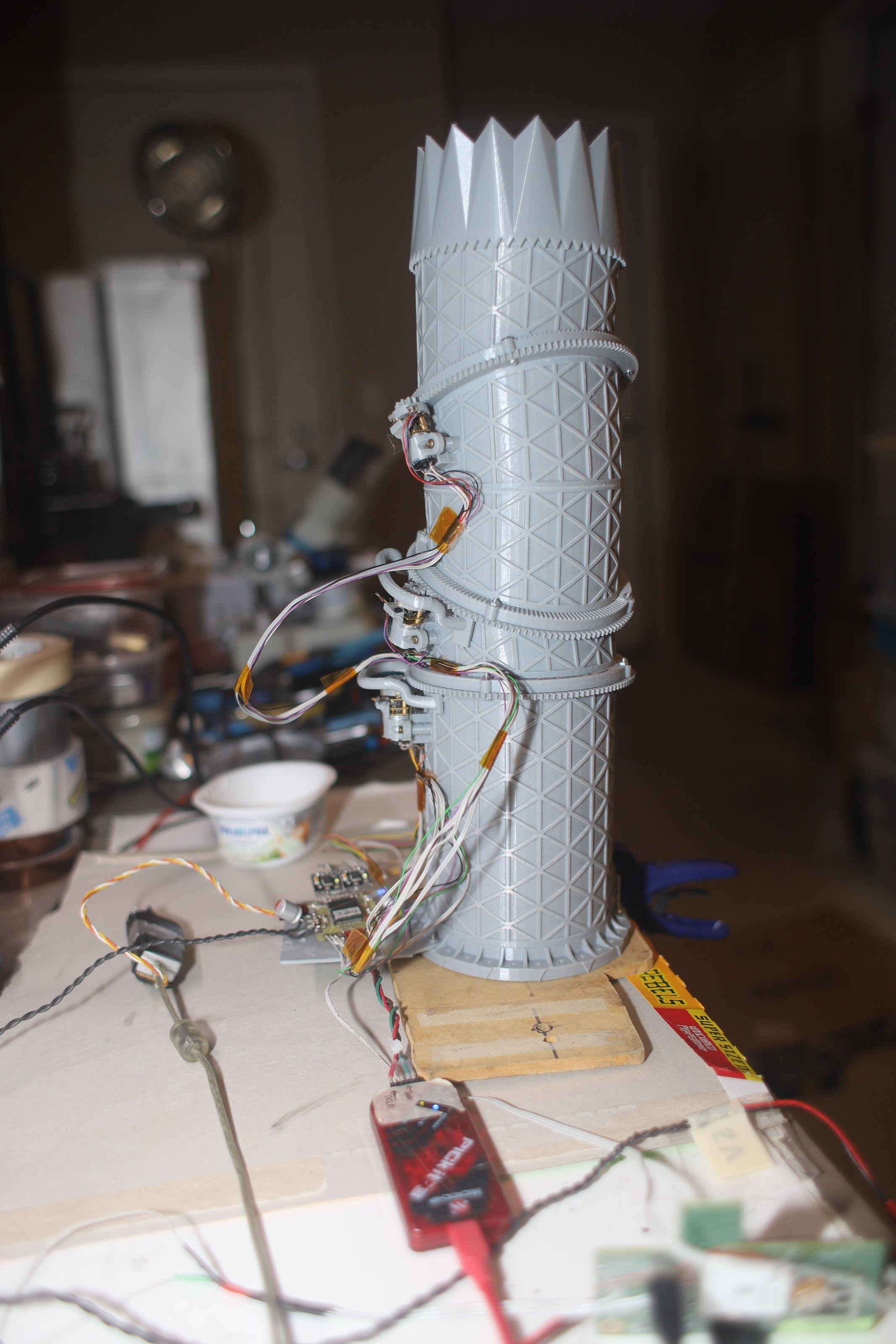

It was the lion kingdom's 1st 3D printing project. The journey began with much CAD modeling that would later be refined. Custom C programs made isogrid segments that were too slow to model in Freecad. The mane limitation in 3D printing is the CAD software. The whole thing was printed on just the baseline $170 Creality Ender 3 & $20 of filament. It printed & printed over 7 days while the tower of isogrids grew.

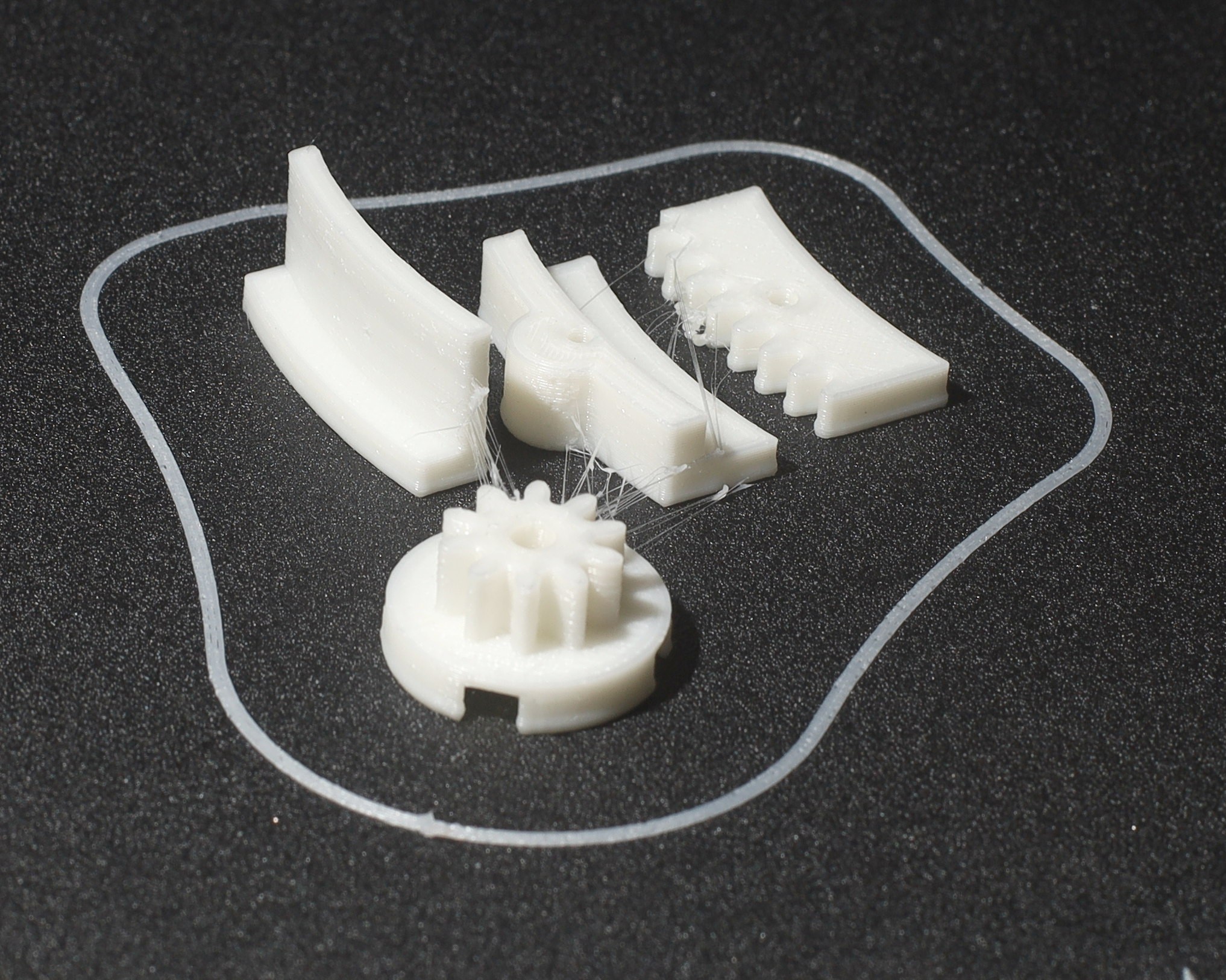

![]() The 1st part printed by lion was this pinion gear.

The 1st part printed by lion was this pinion gear.![]()

![]()

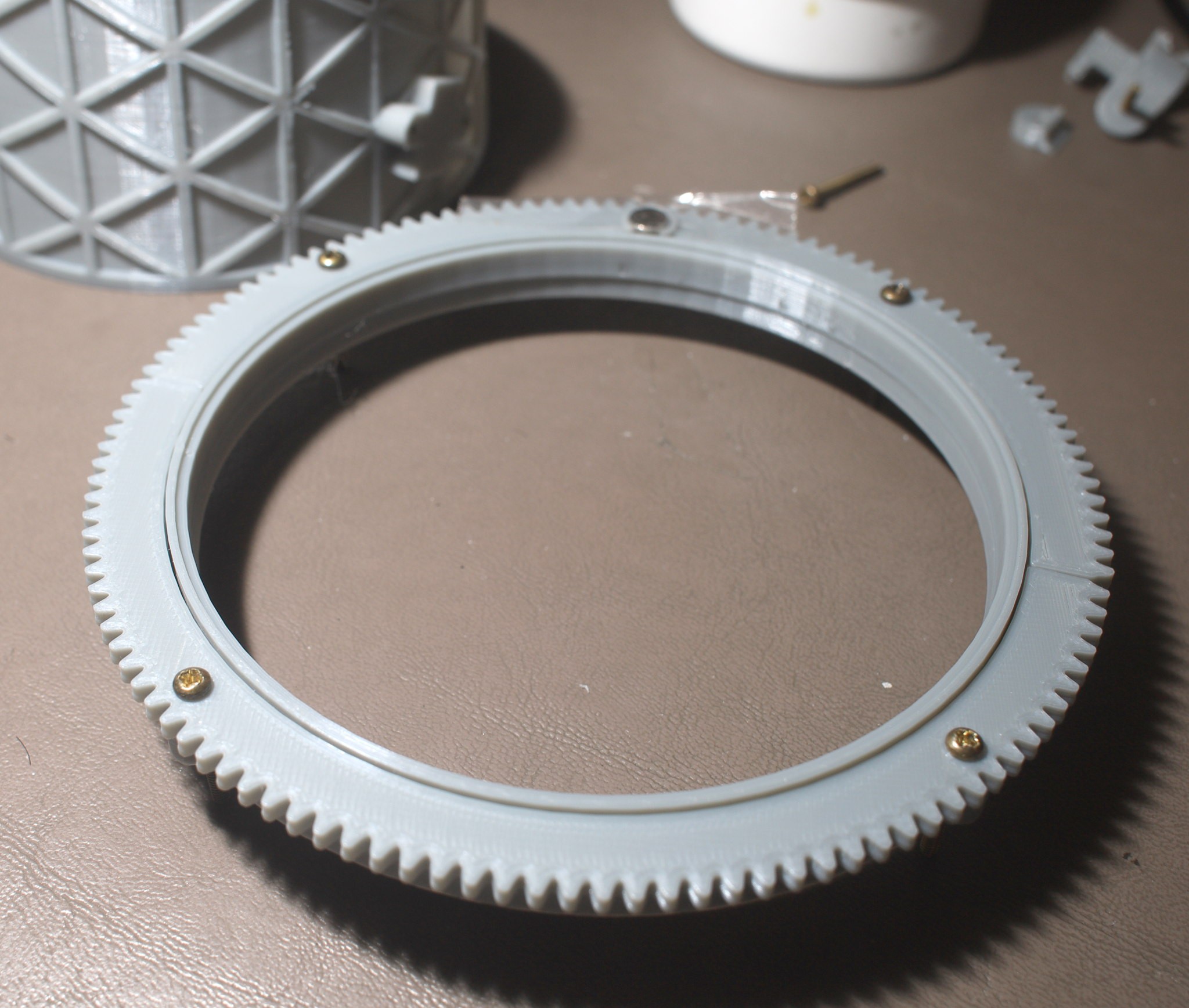

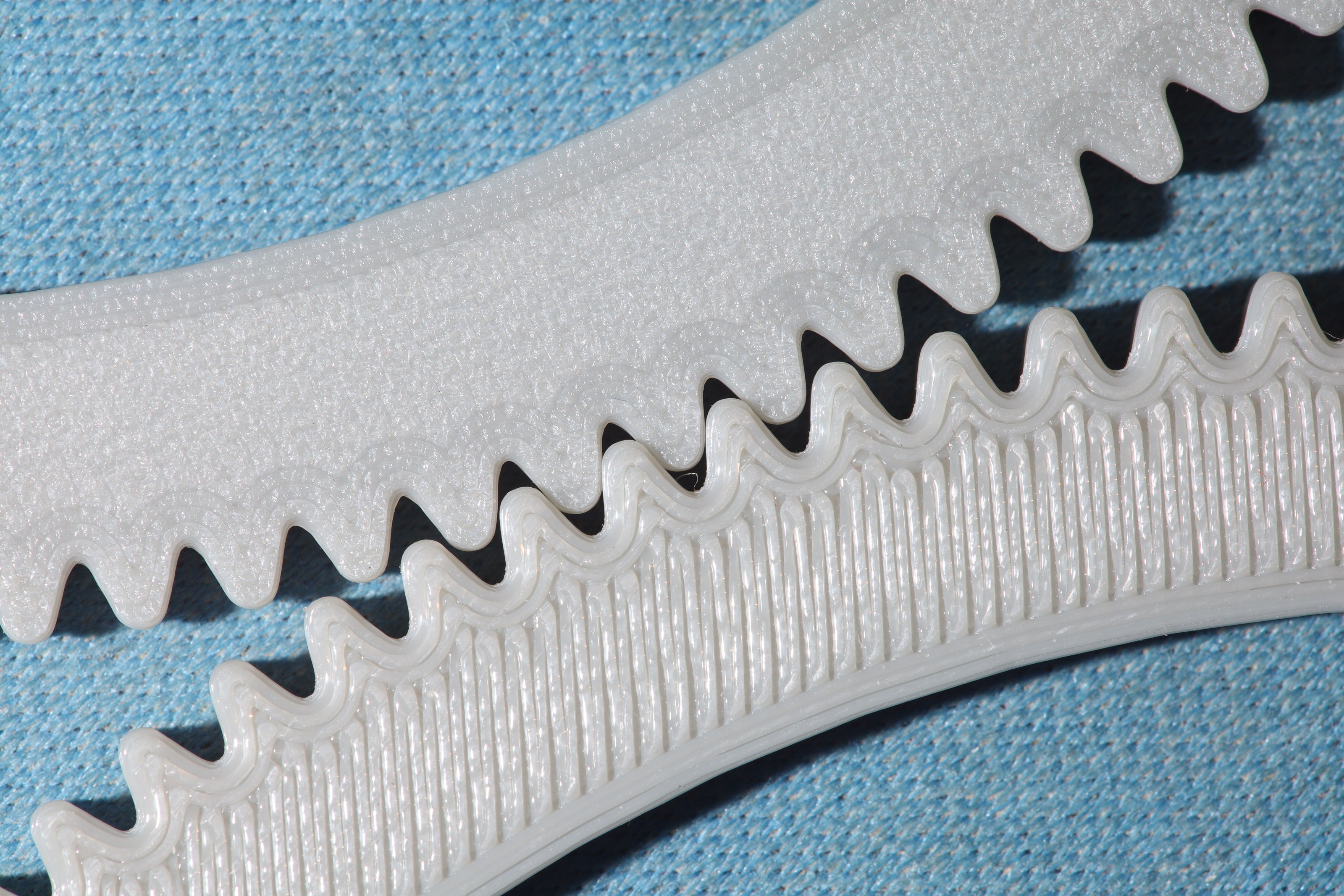

Printing subsections was key to determining the required clearance & minimum gear sizes. 3D printed parts expanded by 0.2mm per side. 2 3D printed parts needed 0.4mm between them to slide past each other. A structure of this size could get by with 3mm deep gears.

![]()

![]()

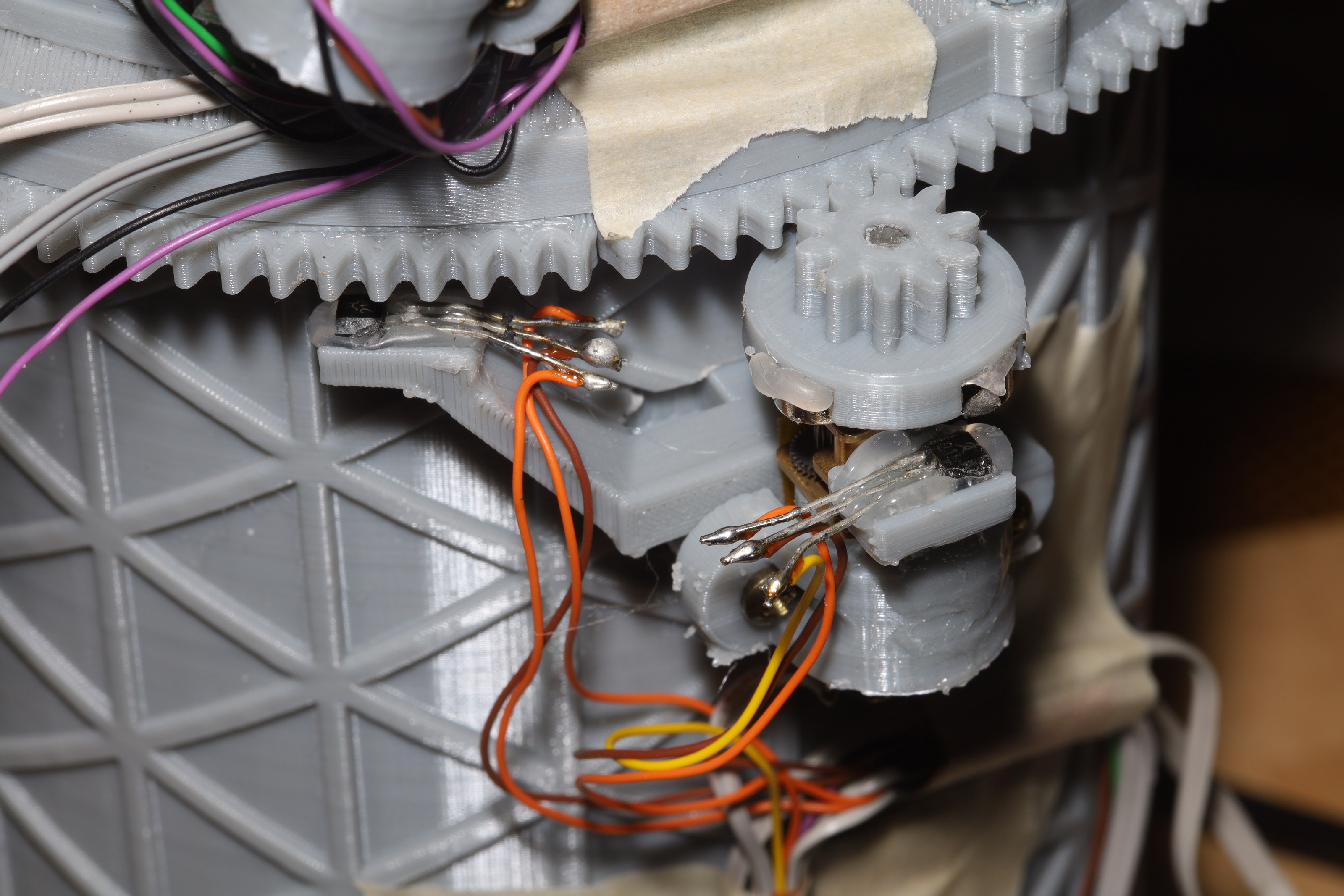

The bearings & gears were the 1st parts printed. It was remarkable to see 122 tooth gears like this pop out of the printer after being just dreams for home fabricators for all time. The bearing parts got 0.5mm of separation to guarantee they wouldn't bind. The most loaded bearing still needed silicone grease.

![]()

![]()

![]()

![]()

Printing without support or a raft yielded a much smoother bottom side.

![]()

![]()

![]()

The longest printout was 14 hours for the longest isogrid tube. Sadly, it lacked a motor mount which later had to be bodged on.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

The boundary sensors used hall effect sensors instead of limit switches.

Attention then turned to the electronicals.

![]()

So the lion kingdom uses vintage microcontrollers because they look cool, there's an abundant supply in the apartment, the current task needs hardly any computing power, & modern C compilers don't tie your program to a specific chip. It wasn't that way 20 years ago when these microcontrollers 1st arrived. They all have dead pins which are normally labeled.

![]()

![]()

![]()

![]()

Mocking up the cables outside the robot was key. Wrapping the cable in captain tape & hot gluing the captain to the plastic proved to be the best way to farsten it. Cable guards were hot glued on to keep the cables out of the gears. A 6mm diameter proved to be the narrowest PLA worm size before it crumbled. A revision would definitely involve screwing them onto the tubes instead of gluing them.

Much firmware development followed, manely impacted by the motor control algorithms & the IR code processing. It suffered from lack of encoder precision & motors that are too fast. It used leftover polulu #2365 & #2366 motors. It would have been better with 200:1 gear ratio motors with integrated encoders from adafruit.

Inferior motor encoders caused it to be not as smooth as the gootube videos, but good enough to be functional. Another problem is the IR remote can only move it in steps. A smaller pinion with no hole for the shaft might have bought more accuracy. Never tested the minimum wall thickness for a 3D printed gear.

![]()

![]()

![]()

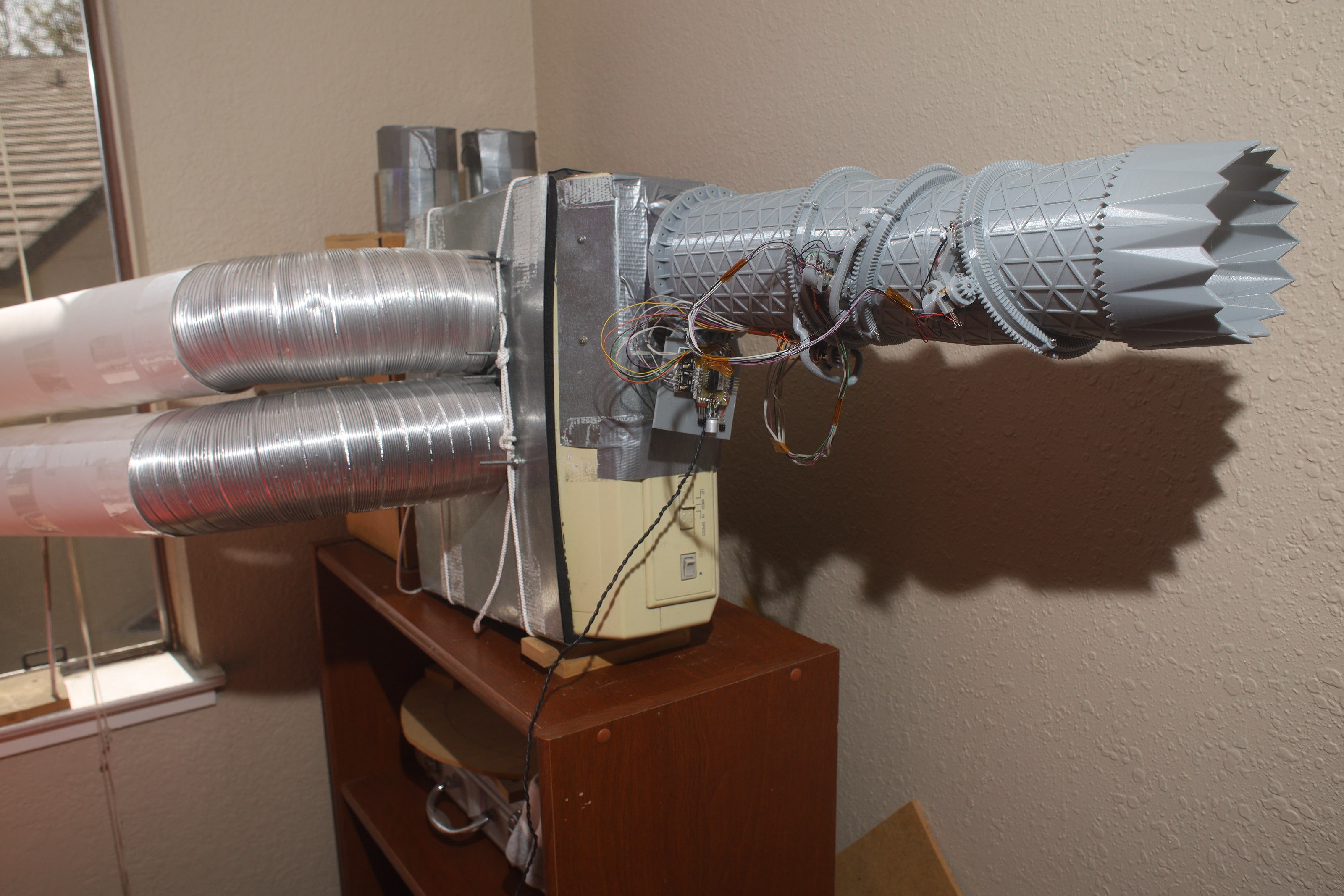

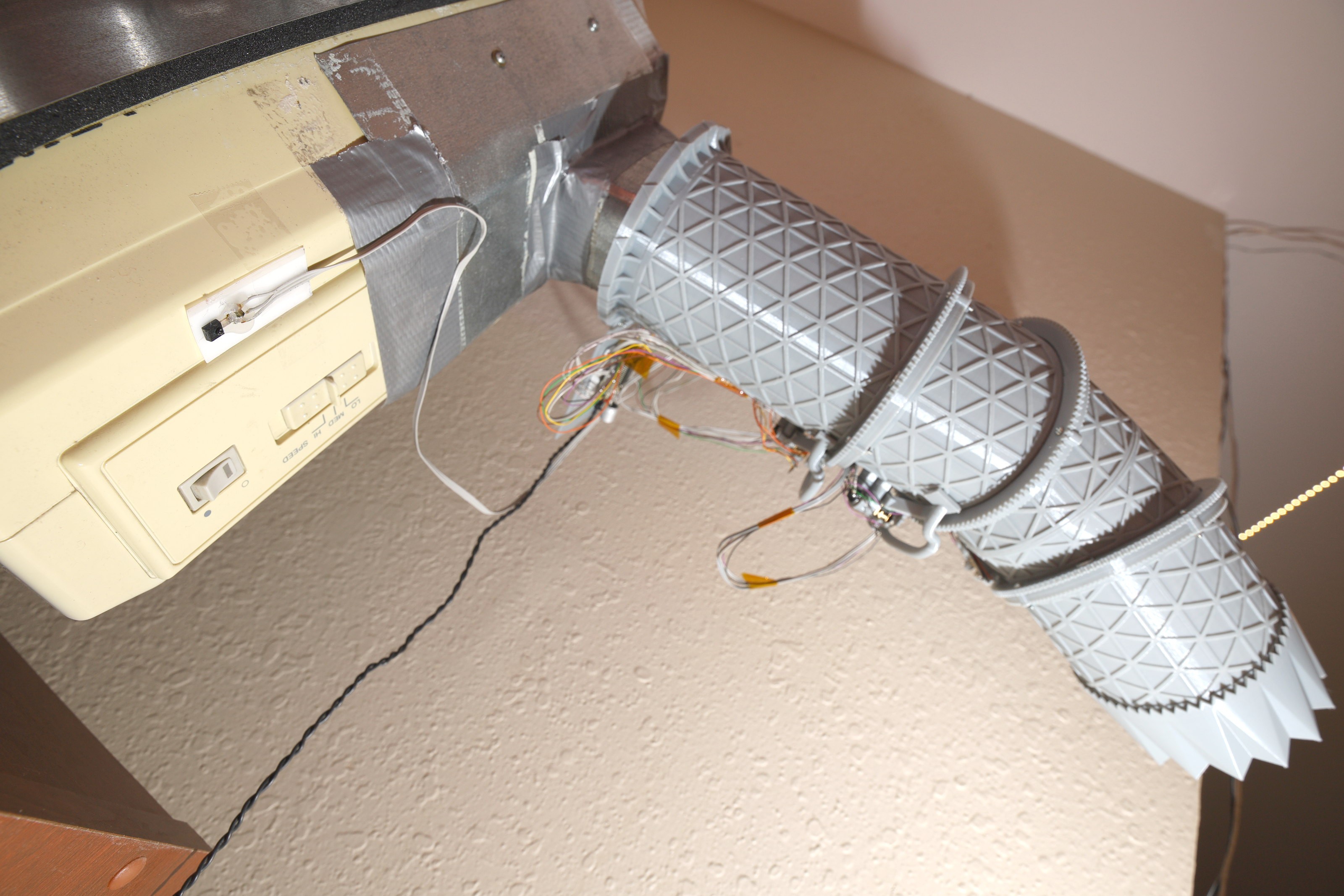

Mounting it sideways tested the maximum load. The ideal power supply was a raspberry pi 5.2V. The motors have very high transient loads when all 3 fire at the same time. USB phone chargers couldn't manetain the minimum 4V during the transient loads.

![]()

Once installed on the blower, the blower didn't entirely fit in the nozzle, but going halfway seemed to be enough. It would need to blend into a rectangular isogrid to entirely fit on the blower.![]()

![]()

![]()

The IR receiver was repositioned away from the cables.

![]()

The heroineclock remote control got a few more buttons for moving the nozzle.

It worked as required on the blower. 15 years of wishing for a remote controlled nozzle finally came to an end. The bearings & contortions didn't impede the airflow as much as expected, but that's why it's a fighter jet nozzle.

-

Practical uses of F-35 nozzles

08/11/2020 at 09:28 • 0 commentsThe search for a better air vent has lasted as long as the fans have been blowing. Lions have been using semi rigid dryer ducts for 15 years, but they wear out after a year. At least $200 has been spent on new dryer ducts. The ultimate vent points in any direction, is aimed remotely like a Tesla Model 3 vent, never wears out, & doesn't rattle.

Lions found self supporting air ducts on portable air conditioners insanely expensive & heavy. Louvered air vents only move on 1 axis & are heavy.

F-35 nozzle designs are 1 of the search requests time forgot. They give a few videos of home made ones, but not enough to build your own without a lot of suffering. The current online generation just doesn't care.The nozzle is simply an elbow joint from homeless despot.

![]()

It's the most efficient way to get a directable air nozzle that doesn't wear out & which can be motorized.

The problem is getting it to rotate smoothly, use servos, & not rattle. The homeless despot version is intended to be fixed. It has conical sections which rotate against each other without leaking. Conical sections are not circular. They use an oval duct & 3 joints instead of 2, specifically to reduce the eccentricity of the oval shape.There are some videos about home made nozzles but no downloadable designs.

The F-35 nozzle absolutely requires 3D printing. 20 years ago, lions would have written off a project like this as unattainable. Nowadays, 3D printers are quite cheap, but it will take quite an effort to free up enough space to store one. The printer's mane task would be printing the F-35 nozzle, but then it would make replacement robot parts, stencils, sandal farsteners, camera mounts, areas which have been stymied by lack of plastic fabrication.

At least 2 F-35 nozzles will be made, 1 for injecting outside air & 1 for next to the confuser later on. An F-35 next to the confuser should take less space than a fan.

The gootube F-35 nozzles use a magnetic encoder to determine the nozzle position, but this requires persistent storage of the servo position. They get away with only using it for a 10 minute flight. If the apartment ventilation always has power, it should work.

They use a boundary sensor to reset the encoder.

Apartment ventilation system

The 25 year battle to get fresh air in tiny apartments

lion mclionhead

lion mclionhead

The 1st part printed by lion was this pinion gear.

The 1st part printed by lion was this pinion gear.