What is a RC Servo motor?

RC Servo motor is a motor with low speed, high torque, and comes in many different sizes. Unlike DC motors and Stepper motors, RC Servo motors usually do not rotate at 360 degrees. Instead, it is limited to 180, 270 or 90 degrees.

A control signal is sent to the servo to adjust the axis at the desired angle. With a single signal makes it simple and widely used in Arduino applications .

Control Servo Motor with PWM

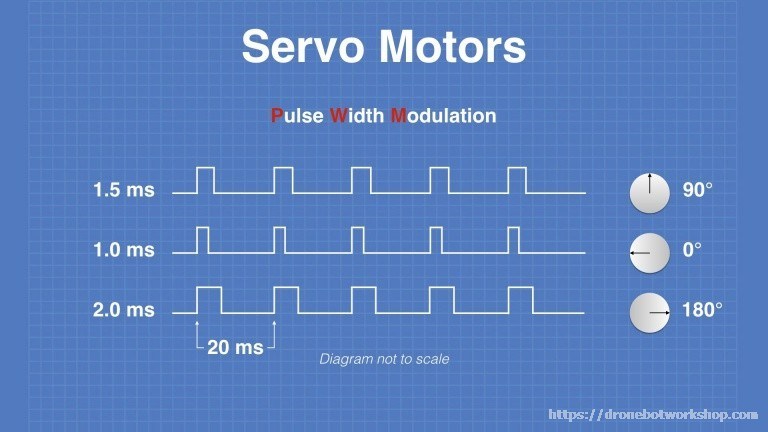

In Analog Servo motors, a PWM signal for 20ms is used to drive the motor.

A 20ms signal has a frequency of 50Hz.

The width of the pulse is changed from 1 to 2ms to control the motor shaft position.

- Read the article PWM: Posts 4: PWM | Change the light of the LED on the Arduino

- The pulse width of 1.5ms will make the servo axis stay in the 90 degree position.

- The pulse width of 1ms will cause the servo axis to be in the zero position.

- The pulse width of 2ms will make the servo axis stay at 180 degrees.

Changing the pulse width between 1ms and 2ms will move the servo axis through the 180-degree limit angle. You can adjust any angle you want by adjusting the pulse width accordingly.

Time Servo motor rotates continuously

The RC servo motor rotates continuously, sending the same PWM signals that will cause the motor to operate differently.

- The pulse width of 1.5ms will cause the servo to stop rotating.

- The pulse width of 1ms will cause the servo to rotate at maximum speed counterclockwise.

- The pulse width of 2ms will make the servo axis rotate with the maximum speed clockwise.

Changing the pulse width between 1ms and 1.5ms will cause the motor to rotate counterclockwise with a shorter pulse width that makes the motor spin faster.

Changing the pulse width between 1.5ms and 2ms will cause the motor to rotate clockwise with longer pulses resulting in faster speeds.

Speed

The speed of the RC servo motor is determined as the time required to move the axis of the servo by 60 degrees.

For example, 0.25 seconds / 60 degrees, it means that it takes a quarter of a second to move to an angle of 60 degrees .

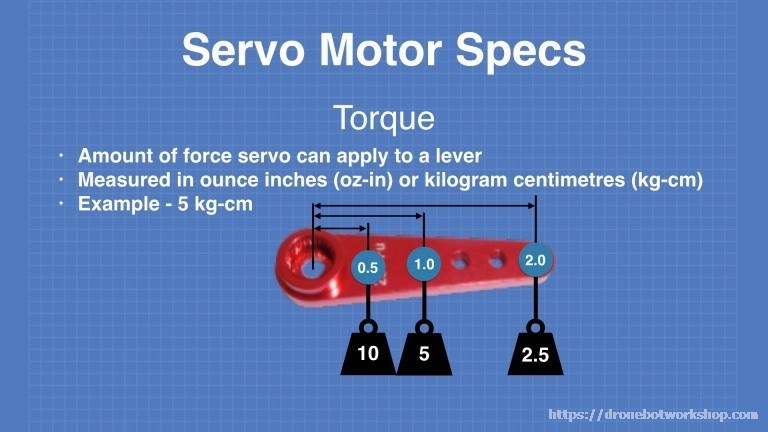

Torque

Torque is a very important quantity, used to determine the strength of the engine.

Units in ounce-inch or kilogram-cm. You can redeem as follows:

- Multiply the number of kilograms by 13.88 to get the ounce-inch.

- Divide an ounce-inch 13.88 to get kilograms-centimeters.

To understand the torque figures, see the following example:

A servo motor withstands a load of 5kg-cm. This means it will withstand 69.4 oz-in (5 x 13.88 = 69.4).

The servo motor can withstand 5 kg loads at a distance of 1 cm from the center of the shaft.

When doubling the distance, the load will be halved, thus 2cm from the shaft and withstand a load of 2.5kg.

Half the distance doubling the load can withstand 10kg.

The bigger the servo motor tends to be the larger the torque and the bigger the motor torque is, the higher the price.

Operating voltage

Most motors have operating voltages between 4.8 and 6 Volt.

Also on the market today there are many servos with operating voltage from 7.5 to 8.5 volts. And more and more popular due to the appearance of 7.4 volt Lipo battery to meet the needs of playing: model aircraft, boats, quadcopters ...

Foot diagram of RC Servo Motor

Normally RC servo has 3 pins. The color of the string is different depending on the manufacturer. However, the position of the pins is homogeneous in the design process.

- Ground: Ground pin (Mass).

- Power: Chan powers the servo.

- Control: Chan send control signal.

Arduino KIT

Arduino KIT

Aishat

Aishat

Huang Jin

Huang Jin