-

First G-Code Stacked Print Test

04/13/2020 at 00:30 • 0 commentsFirst test of printing using a g-code print without any manual intervention in changing temperature and speed. Separation of the bands was fairly easy without the need excessive force. Delamination layer parameters were entered into the start and end of the layer using PrusaSlicer. Parameters were mainly to turn on fan, lower the temperature of nozzle and lower the printing speed. Once the layer was completed, the printer resumed normal operation.

Printed using a 0.8mm nozzle, 0.3mm layer height, 30-40mm/s speed, 1mm line width at 240C nozzle temperature for PETG. Parts are separated by a 0.3mm Z gap

Slicing and delamination parameters done in PrusaSlicer

Delamination layer parameters:

Start layer -

M106 S255 ;Turn on fan at max speed

M104 S210 ;Hotend set to 210C

M220 S60 ;Print speed set to 60%End layer -

M106 S100 ;Set fan to normal speed

M104 S240 ;Hotend set to 240C

M220 S100 ;Print speed set to 100%Special thanks to Augment Bionics for providing a spool of Fiberlogy PETG Burgendy for testing

-

Stacked Print Success

04/09/2020 at 22:12 • 1 commentThis might not be a new idea but I remembered that whilst I was printing PETG at 240C, I had horrible delamination problems between layers and had to turn up to 250C to get reliable prints. So considering that we wanted to stack prints, I wondered why not use this to our advantage.

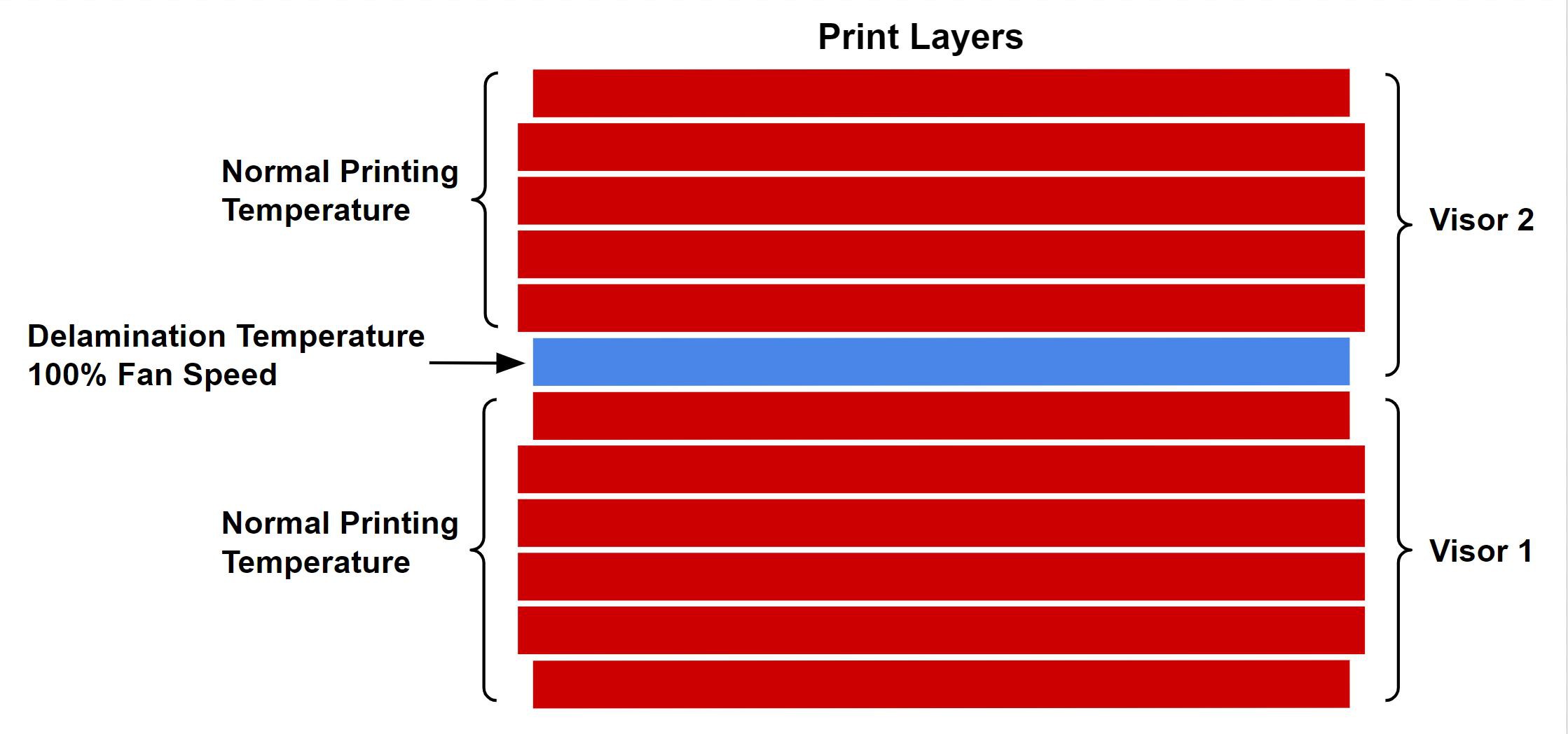

Here's a depiction of what I'm thinking:

This method really depends on how well you are able to control the hot end temperature, what temperature the material delaminates at and what material is used.

I've experimented with PETG and it shows promising results that we can reliably get stacked prints that can be split apart easily by hand.

Left print shows the bottom of visor 2 and the one next to it is the top of visor 1. The surface finish is quite good with minimal drooping of layers as the layer was fully supported with 0mm separation distance between each band. This is only one test print but it could be possible to repeatably create stack prints that are easy to remove using this method. This method does vary from printer to printer and material to material so do be aware. If the temperature difference between normal printing temperature and delamination temperature is too great, you may need to make some compromises on certain layers so that the hotend can reach the target temperature quickly.

Currently, I haven’t yet seen a slicer implement a delamination layer operation but hopefully it will be added soon. There are workarounds with slicers like Cura but the effect may not function as well, due to how the nozzle takes time to change temperature.

Special thanks to Augment Bionics for providing a spool of Fiberlogy PETG Burgendy for testing

-

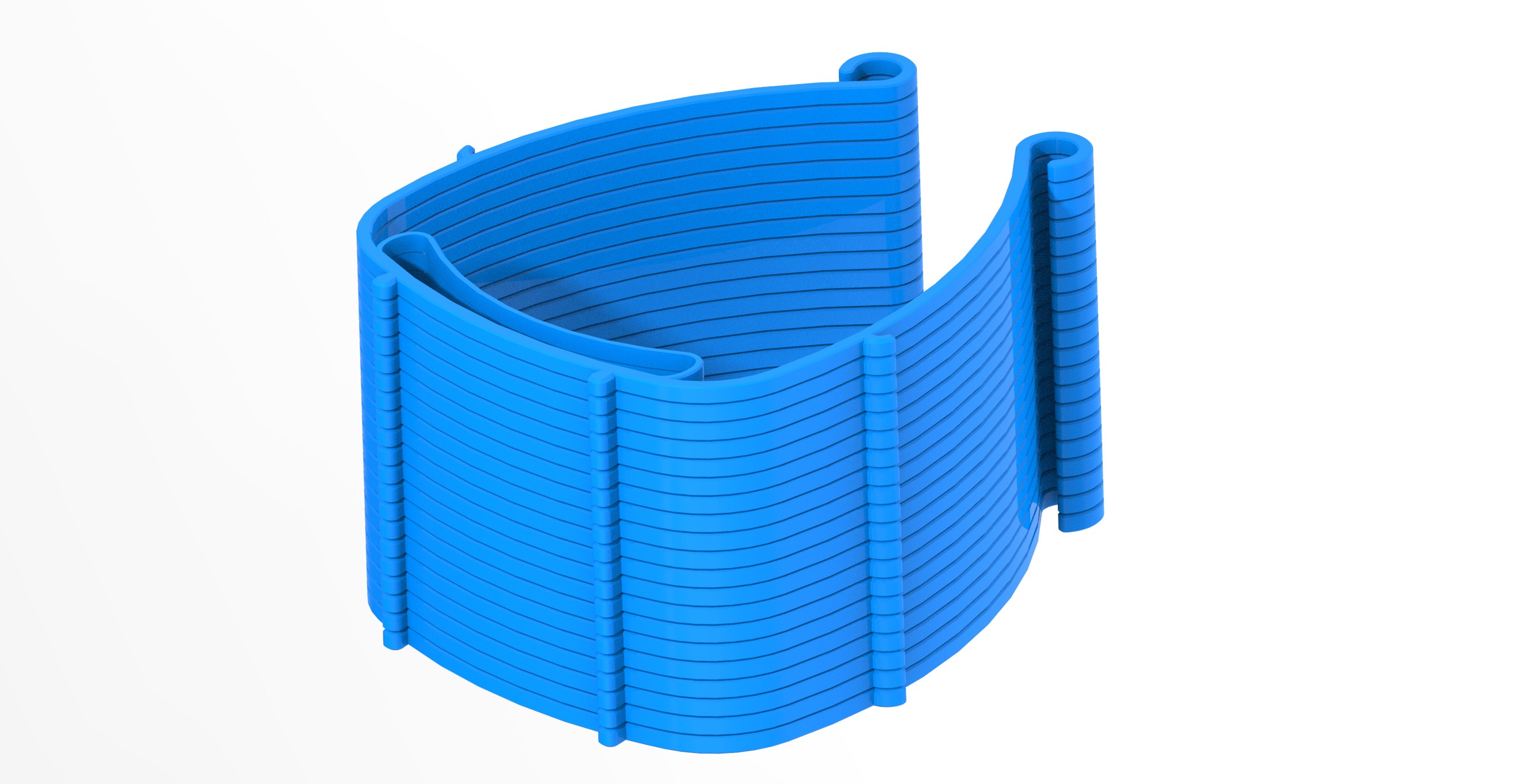

Experimental stacked version available

04/09/2020 at 01:58 • 0 comments -

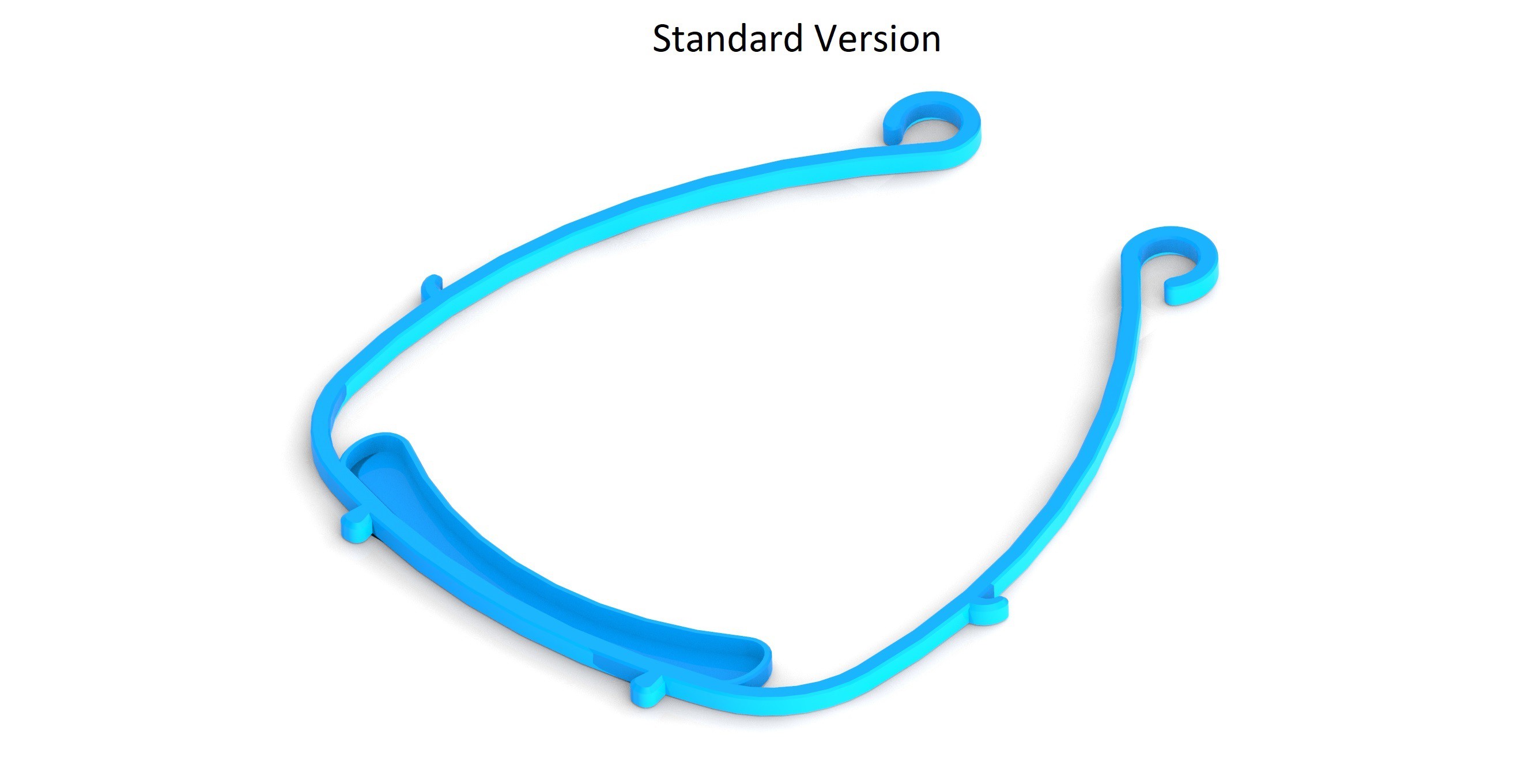

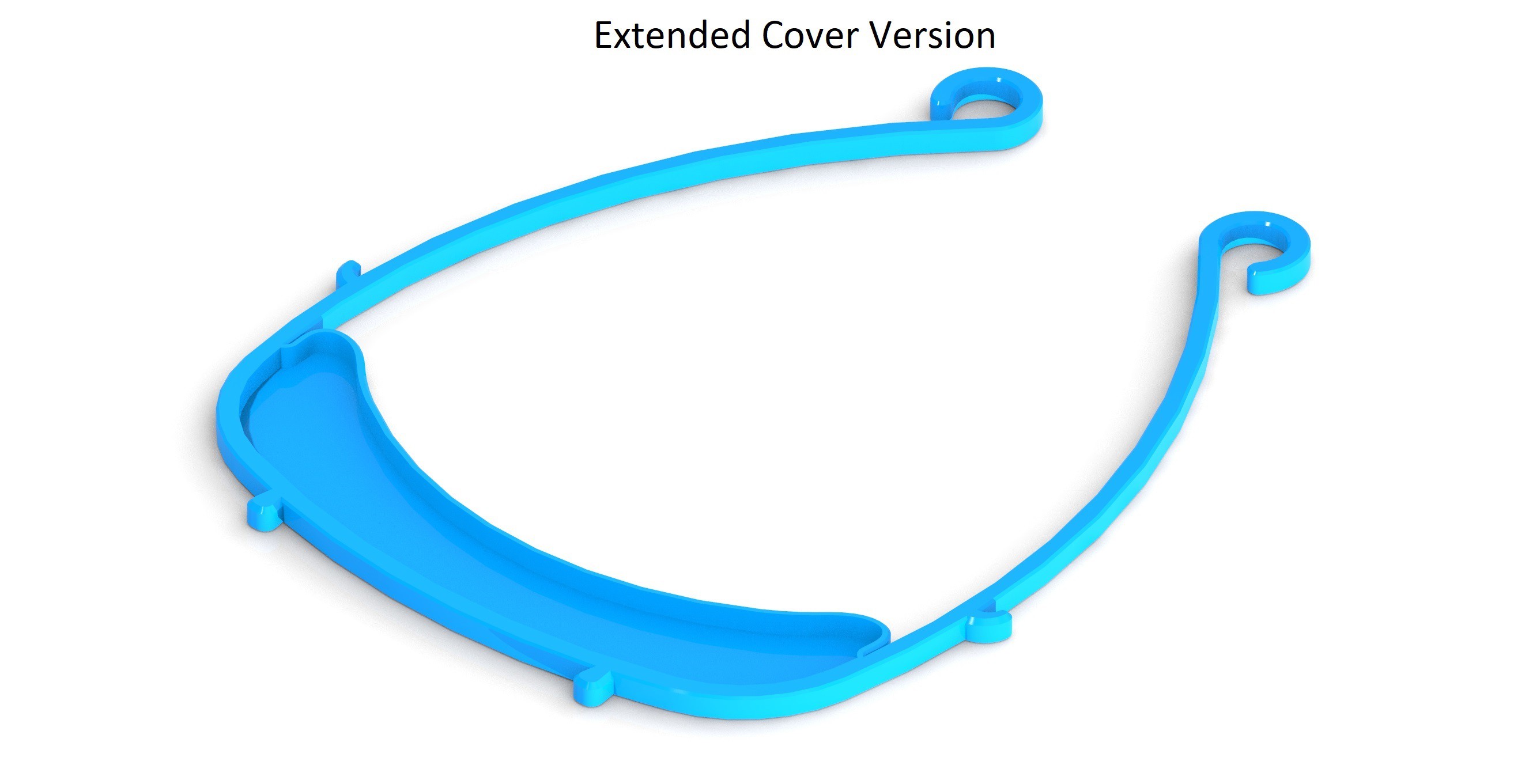

Current Design Version Options

04/08/2020 at 00:02 • 0 comments

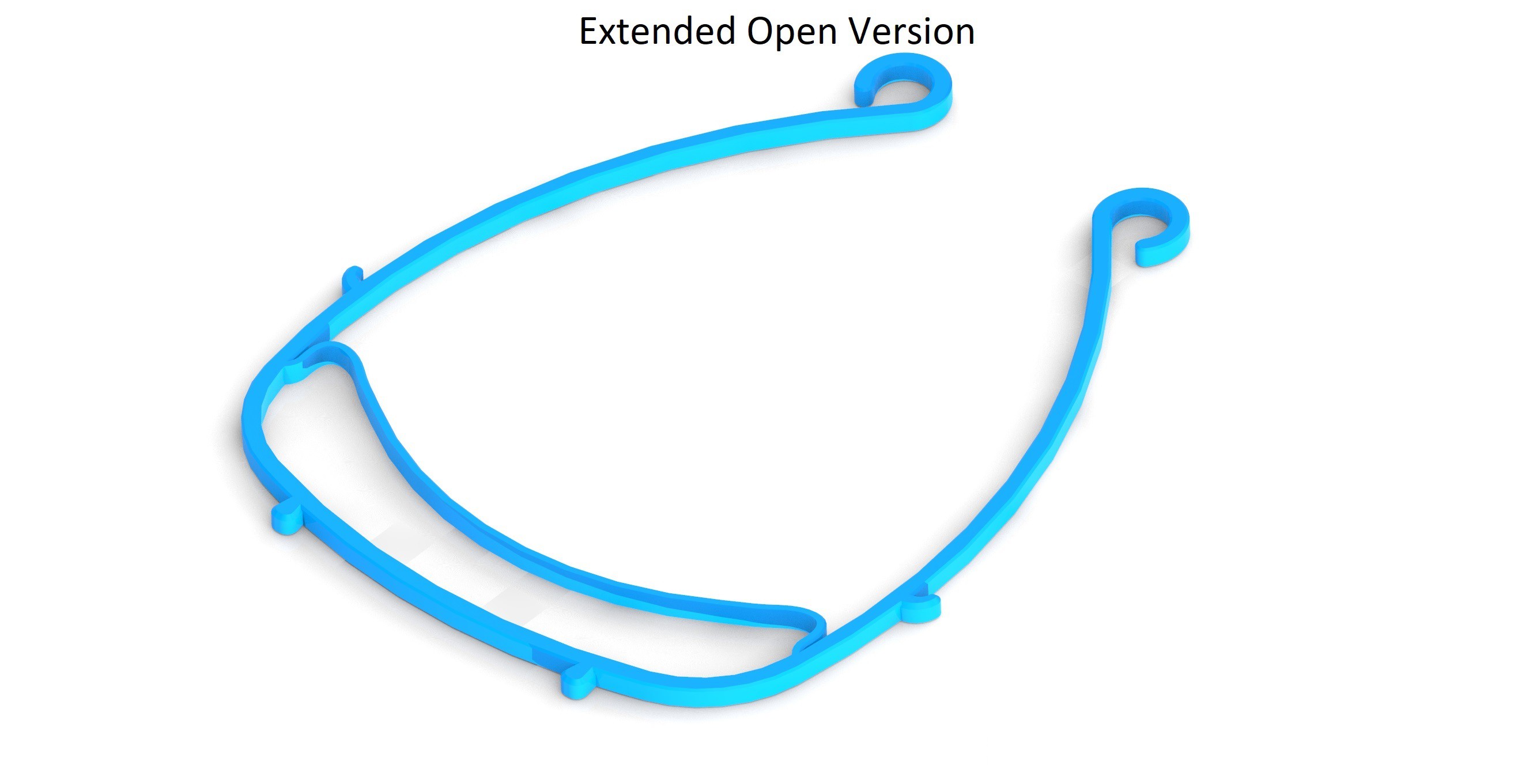

3DVerkstan Based Face Shield - Supercell Remix

Custom designs based on 3DVerkstan face shields.

Supercell

Supercell