-

Working leg prototype

08/29/2020 at 00:45 • 0 commentsLeg prototype

Key updates:

- Single arduino can control 2 servo (my plan for 4 per arduino) - 0.7 ms per update now

- Leg Kinematic seems like ok

- Python test app

-

Leg prototype

07/25/2020 at 19:33 • 0 commentsLeg kinematic prototype

Upper and lower links are 150mm each

-

Electronics update

07/14/2020 at 18:05 • 0 commentsUpdate:

I switched from L298N to TMC2130 SPI stepper drivers.

TMC2130 biggest advantages:

- Size

- SPI mode to control coils directly via XDIRECT

- Less wires - now i can control 4+ motors/servos with single arduino nano

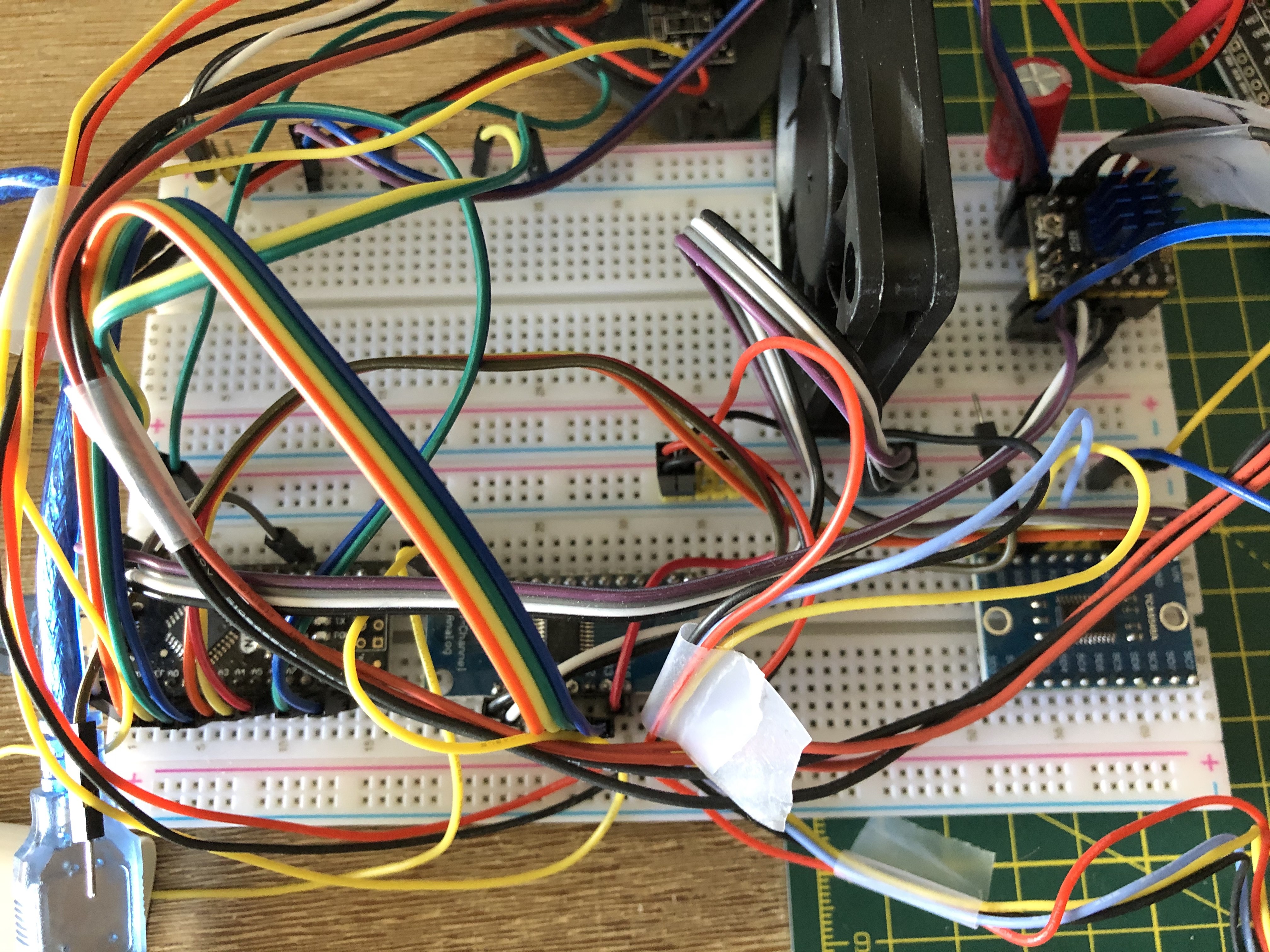

My current setup:

![]()

- Arduino Nano

- 16CH A/D MUX HP4067 - to get values for up to 16 hall sensors (up to 8 motors 2 halls per motor)

- TCA9548A - to get data from 8 absolute encoders (AS5600 i2c devices)

- TMC2130 SPI drivers

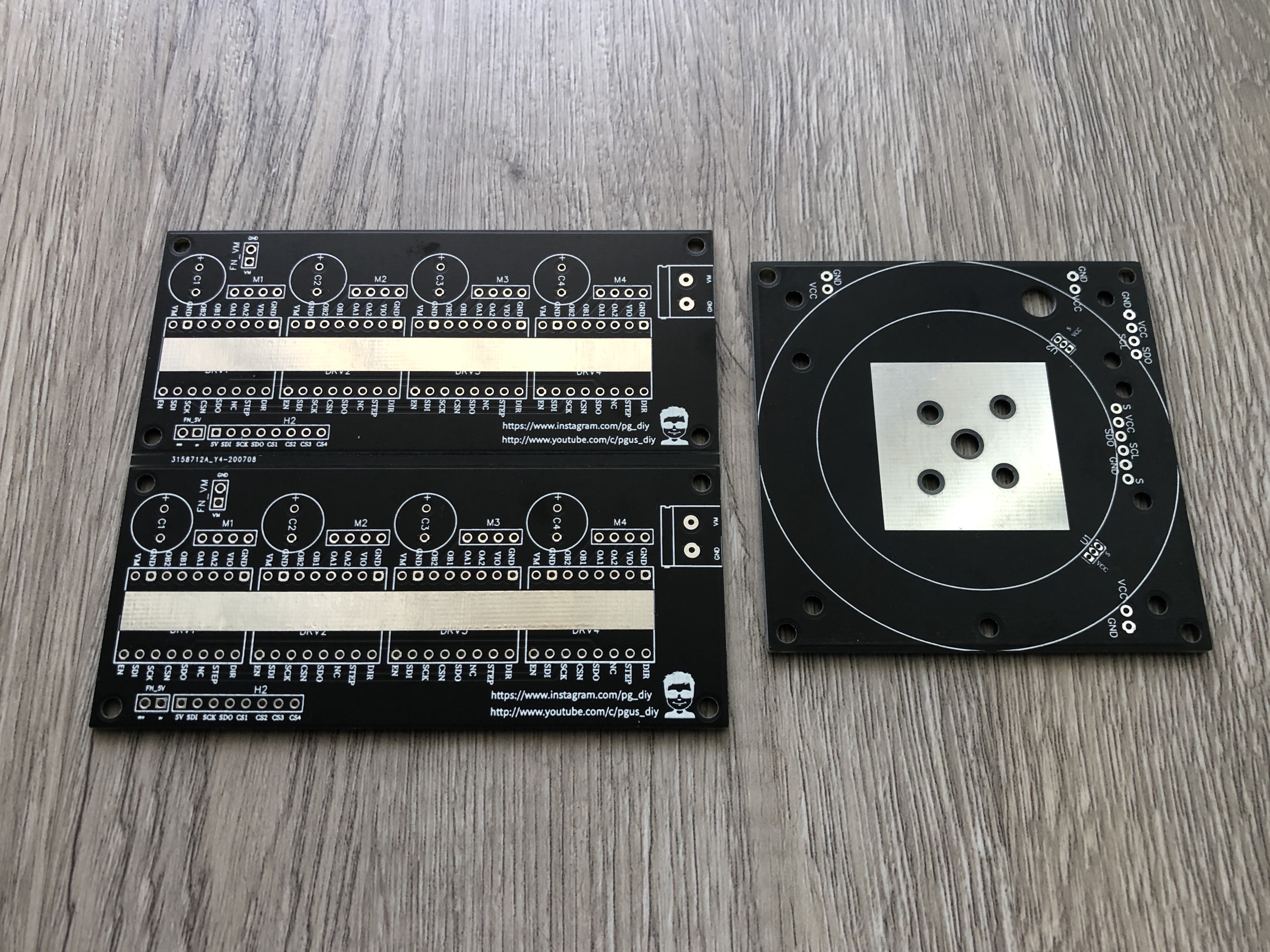

Experimental PCB's

Left PCB for 4 motors drivers, right PCB is a base for motor with hall sensors and mounting holes

Auto calibration finalized, calibration results saved to EEPROM

-

Stator wiring machine

06/26/2020 at 19:06 • 4 commentsTo rewire motors(very boring process if done by hands) i made a simple machine.

Details:

- Marlin+Ramps 1.6 as electronics

- RepitierHost as software

- Python g code generator - https://github.com/pavlog/RobotUtils

Final result:

![]()

-

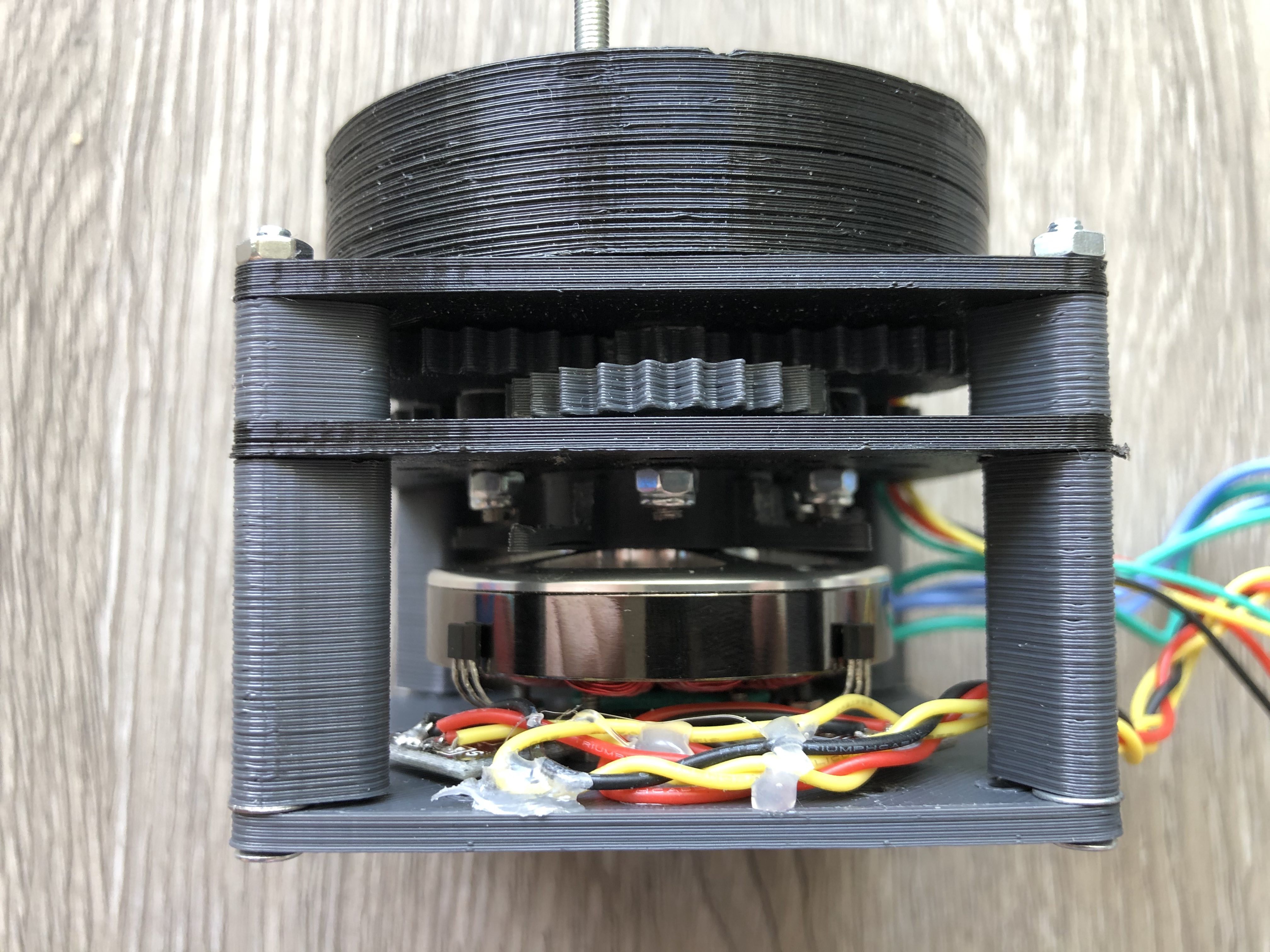

Gearbox v.1.1

06/07/2020 at 23:08 • 0 comments2 Weeks spent for Gearbox V 1.1

Whats new:

- Dowel pins

- Herringbone gears used

- Ratio 1:30.8148

More updates coming soon...

-

Gearbox

05/07/2020 at 23:58 • 0 commentsGeneral

I decided to develop gearbox with ratio from 1:25 to 1:35 to archive 180 degrees per second with full torque (i hope).

Small backlash is acceptable (at least for robot leg actuator)

All designs will be created in Openscad.

Design

I had a few experiments in the past: So my favorite designs are:

1) Spur Pinion double gears organized in 3 gears per stage (each stage is a 3 spur-pinion gears at triangle corners) with ring gear as output: Openscad drawings and visualization will be uploaded soon.

This type of gearbox have 1:33 ratio (can vary, but not limited at max)

2) Cycloidal - i experimented in past, I got 1:25 ratio (strong limit for 70x70 cm footprint), but my past experiments had some Issues (mostly because of missing bearing at critical places)Best ideas for Cycloidal you can see here:

https://hackaday.io/project/165653-3d-printed-robot-joint-with-active-compliance

https://hackaday.io/project/167855-simple-cycloidal-robot-leg-for-quadruped

Gearbox exploded view concept

Key features:

- Ratio: 1:33.1852 (1st stage 1:2.66, 2nd 1:2.666 output is a 1:4.66)

- Output gears module can be bigger then stage modules

- Gear height can be different for each stage

- Place to embed as5600 i2C absolute rotary sensor (2$ on aliexpress)

- Extra stage can be added without problems (1 extra stage and you can get 1:88 ratio)

- Only output stage is rotate (all double gears are rotates on the static common shafts)

- Each stage have 3 points of contact (less backlash and more torque)

Gearbox disassembly video

Assembled gearbox

![]()

Actuator test without absolute encoder

Gearbox test with absolute encoder

-

Motor

04/29/2020 at 08:10 • 0 commentsMotor theory and practice

I use brushless 5010 motor rewired as stepper motor with 28 steps per revolution, controlled by L298N module, arduino and 2 hall effect sensors

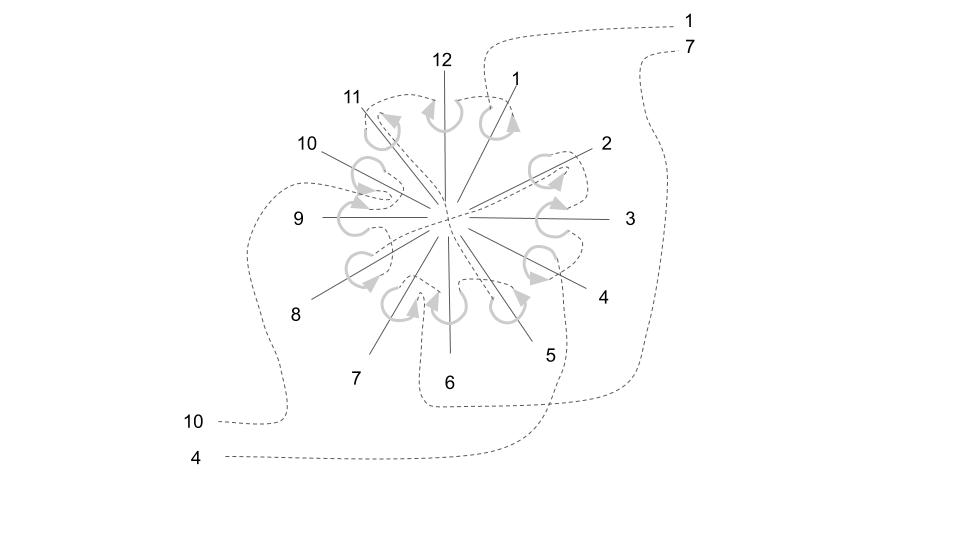

Image bellow is a 3 phase brushless motor (5010 model) with 14 magnet poles and 12 stator poles, this motor need to be rewired as stepper motor with 28 steps per revolution

![]()

Motor wiring diagram (14 magnet poles, 12 stator poles) converted to stepper motor (top view)

NOTE: Arrows lines is always on top of stator lines

![]()

Motor phases animation with wiring above visualized in video bellow

Disassembled motor ready for rewire

![]()

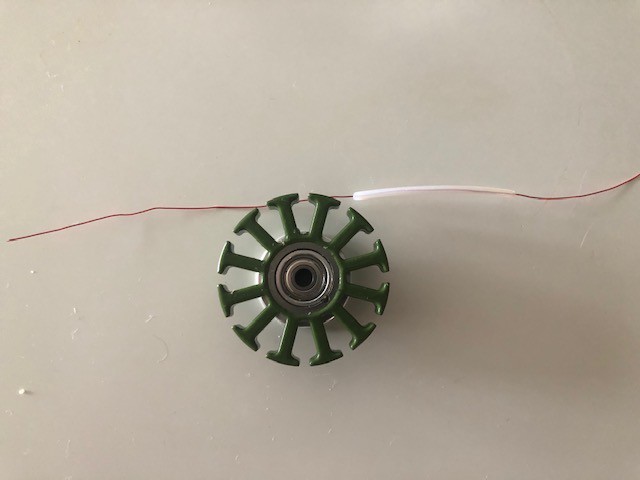

I use small radius PTFE tube as a helper for rewiring

![]()

100 turns per pole by 28 AWG wire (very challenging process)

Final resistance 3.7 Ohm per phase

![]()

Assembled motor (wires covered by nail polish (pole 1 marked by blue)

![]()

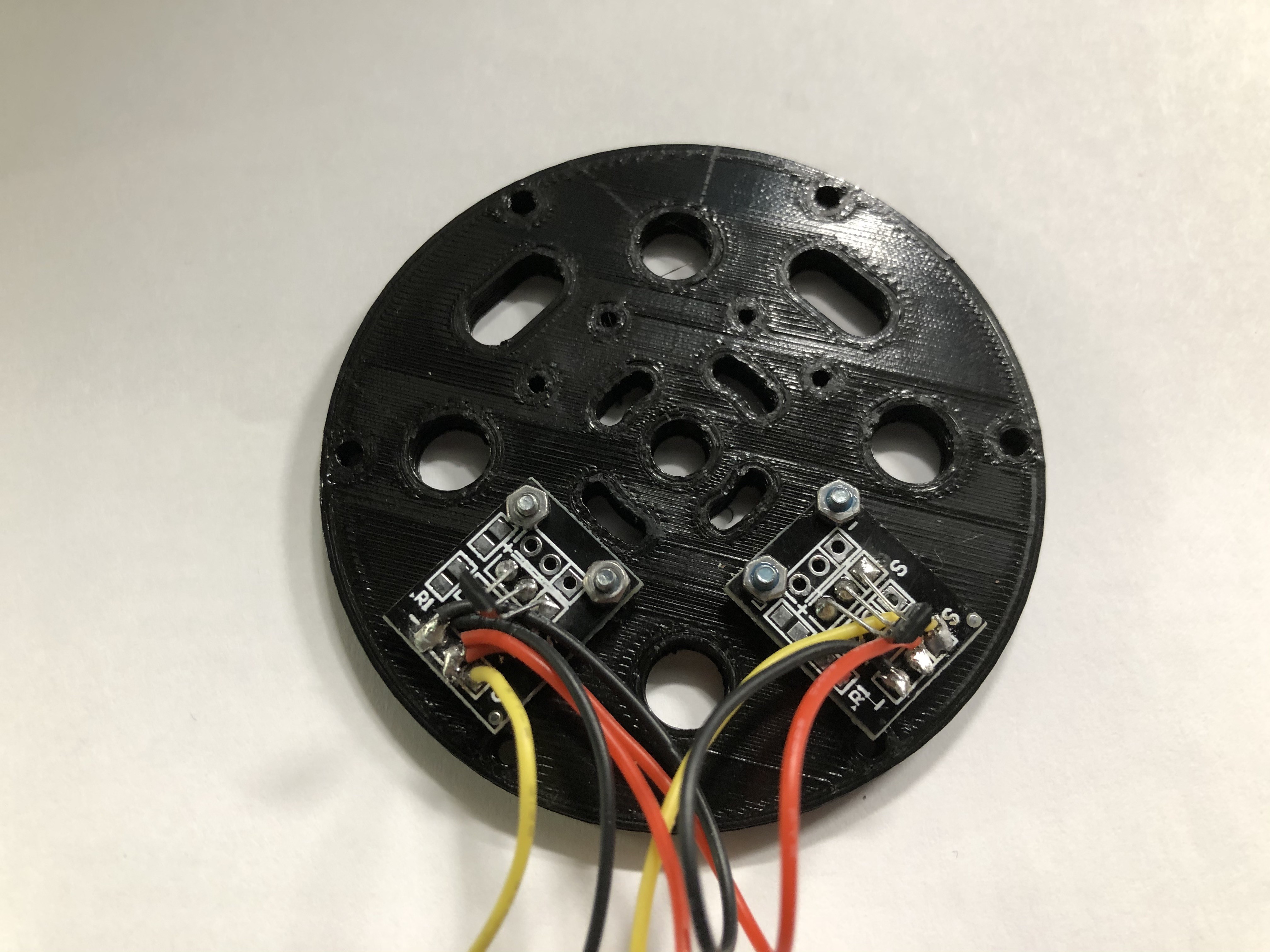

Motor base plate 3d Printed (small holes for hall effects sensors mounting)

![]()

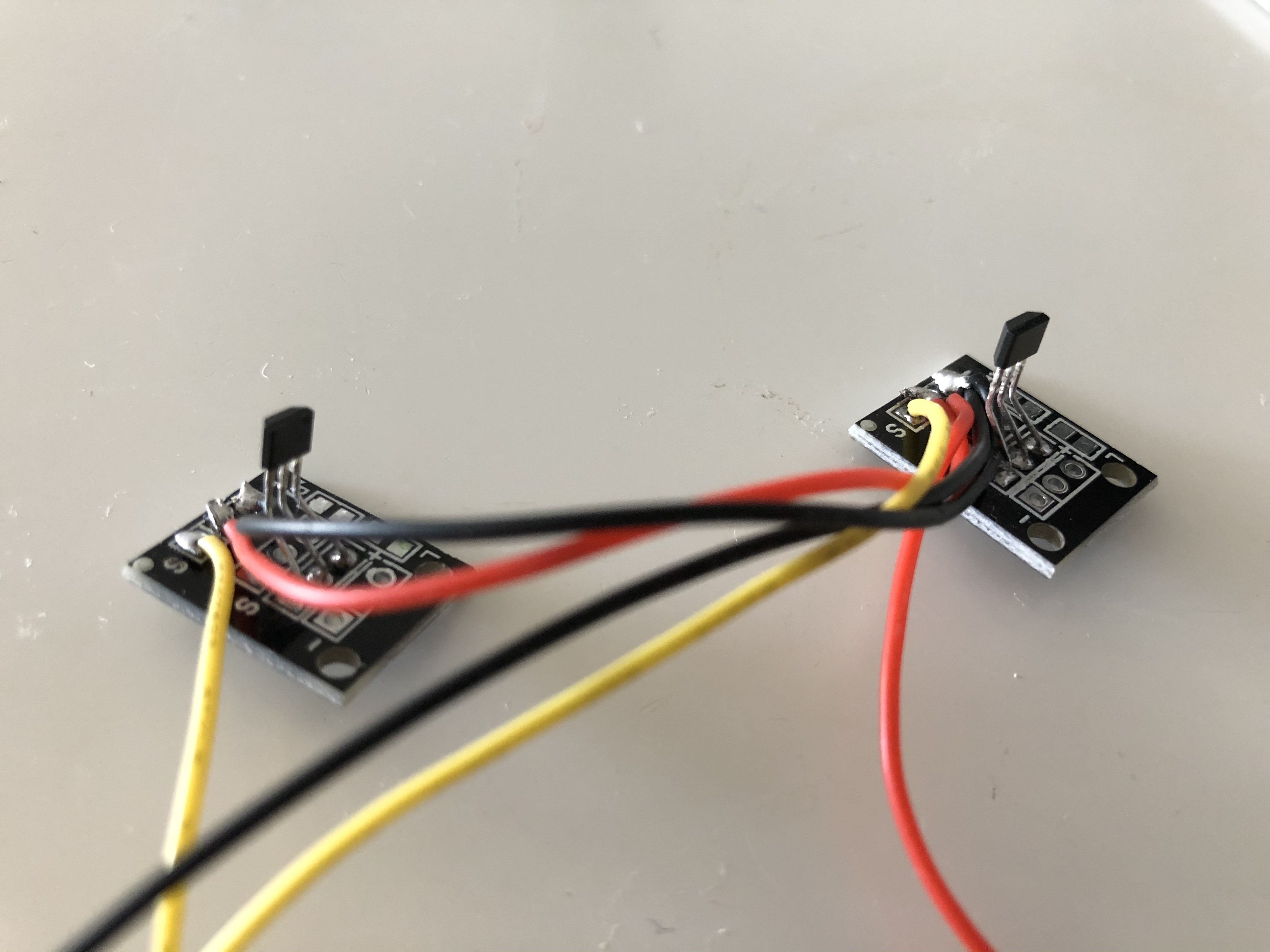

2 Hall sensors ready to be mount on base plate (49E 9148G sensor)

![]()

Sensors mounted to base

![]()

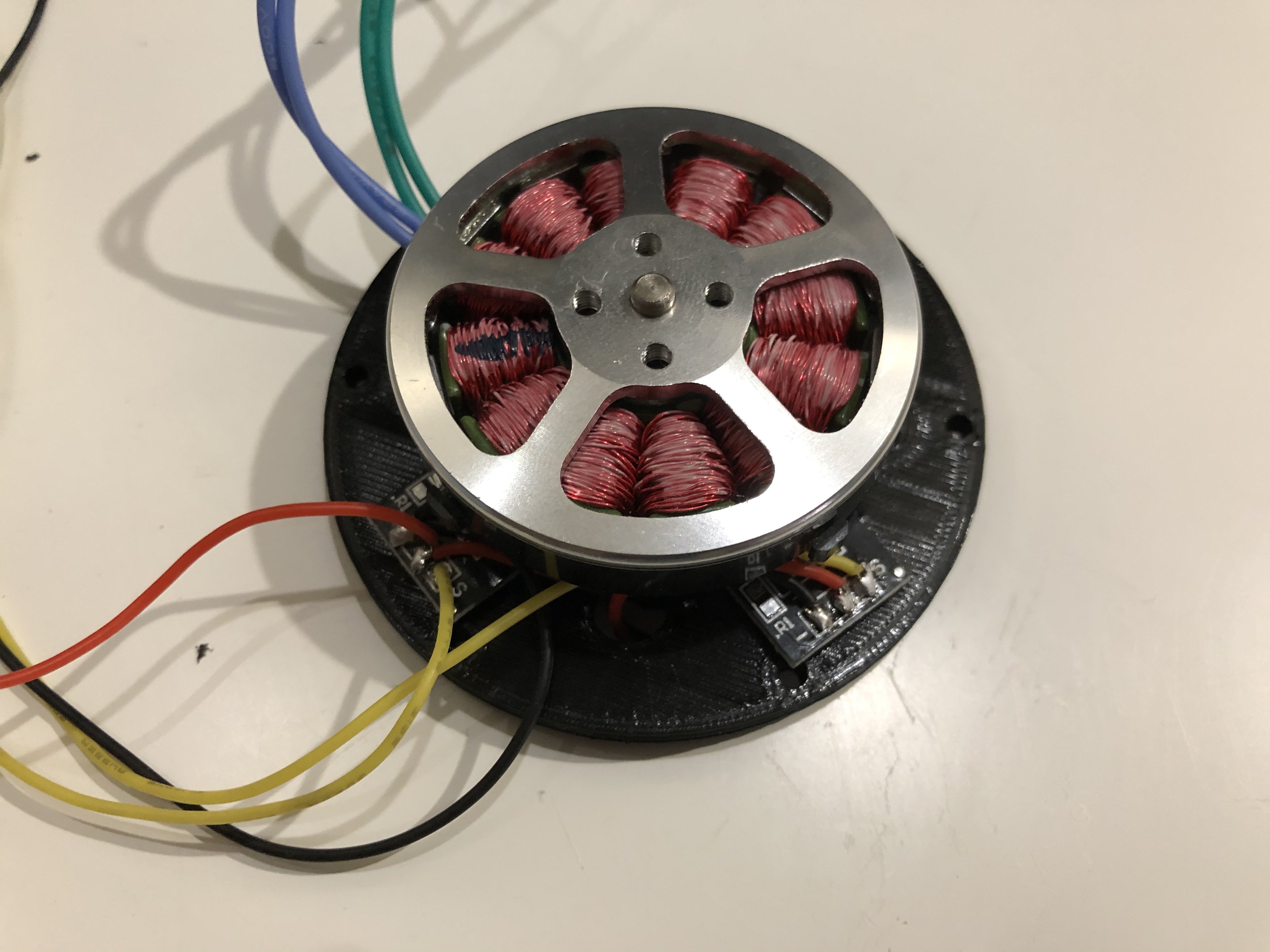

Motor mounted to base plate 1st hall sensor look at stator pole 12 2nd to 9 (it should be 90 degrees)

![]()

Sensorless motor test run

Sensored test run

Motor torque test

- 160 PWM - 70g/10cm or 700g/cm

- 255 PWM - 160g/10cm or 1600g/cm

Hi torque 3d printed cheap robot actuator

Cheap 3d printed hi torque robot actuator with electronics

Pavel G.

Pavel G.