-

Finished V1

10/27/2020 at 06:44 • 0 commentsOpen LRC Log 2

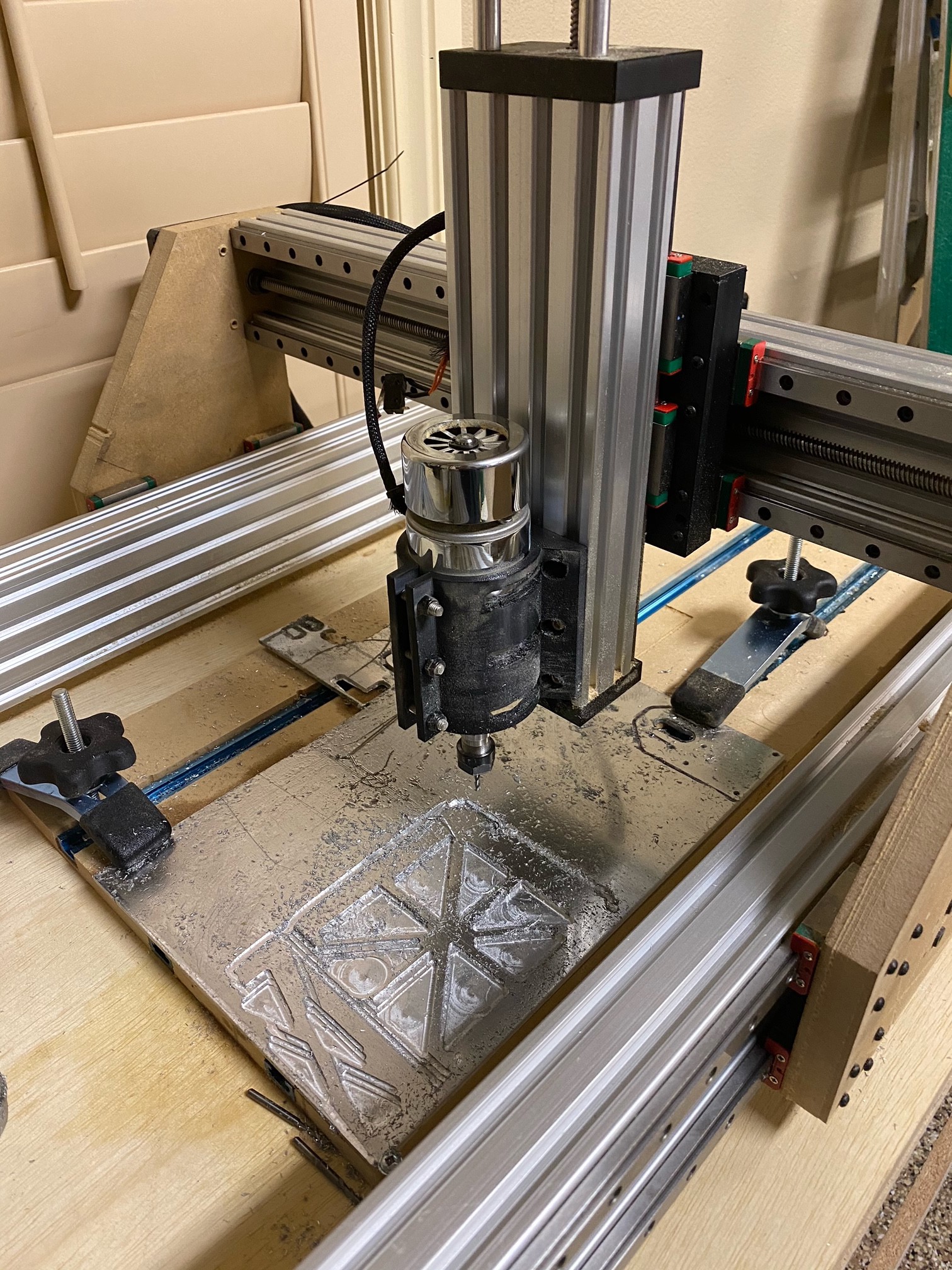

After a while with no updates, I finally have finished the first version of the project! While it still has many flaws that need to be sorted out before I can release files and instructions, it does in fact work. For Right now the CNC is mounted to a poorly made temporary table. A much more stiff table and enclosure have yet to come. Here are some pictures of the machine.

![]()

![]()

![]() Electronics

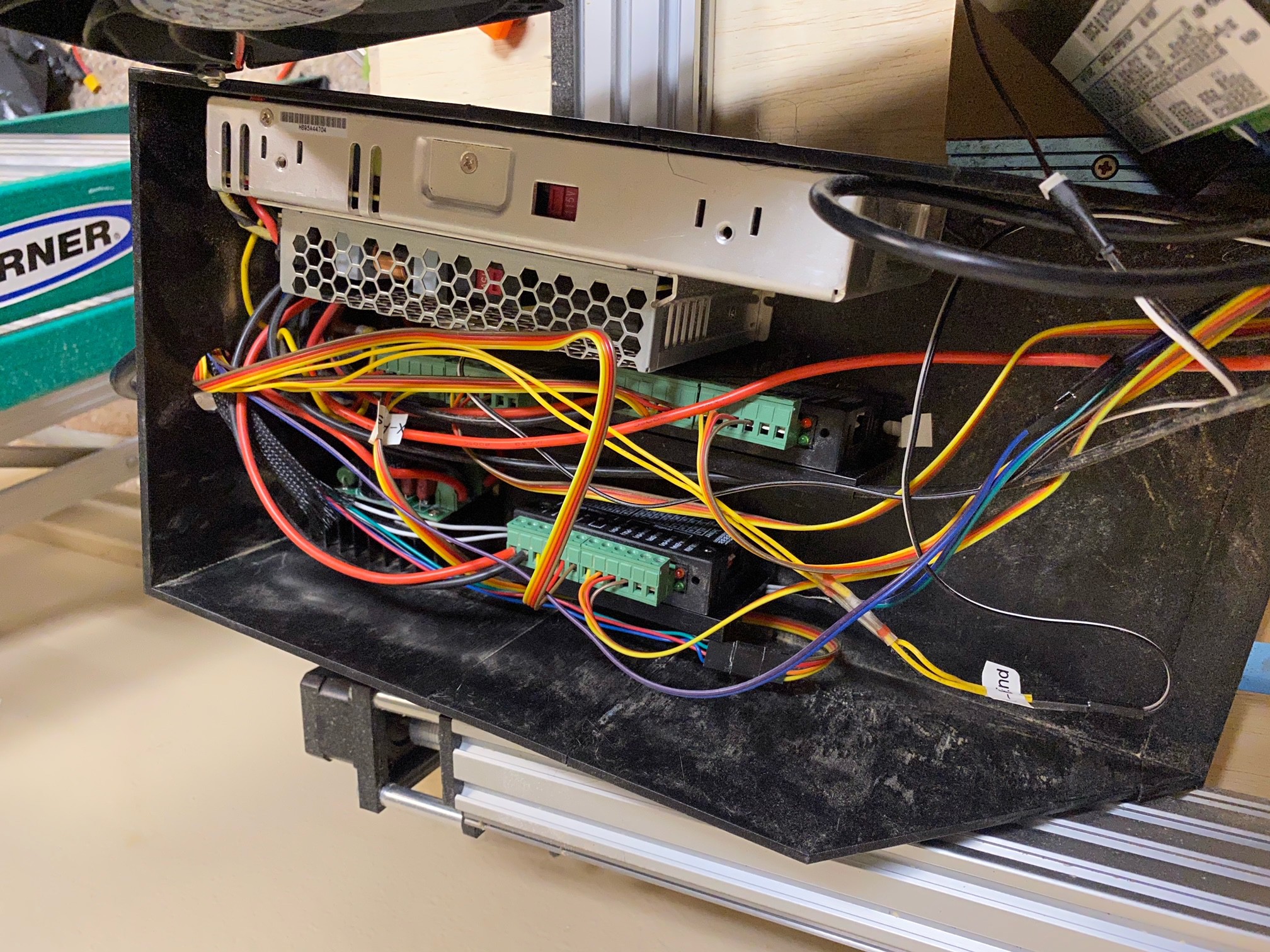

ElectronicsThe main controller I have chosen to use for this build is the DDCSV2.1. While the price of this controller is more expensive than most at $160, it has full offline capability's meaning it does not have to be tethered to a pc in order to function. You simply put the GRBL Gcode files into a usb thumbdrive, plug it in, and hit start. This controller has a ton of features including + and - endstops for all 3 axis, toolpath simulation, pendent compatibility, and digital rpm control for spindles that support it. It is also extremely simple to wire up and get going with. A full wiring guide will be released with the files. Here are some pictures of the controller box.

![]()

![]() Issues and Changes

Issues and ChangesAn issue you guys probably noticed in the earlier pictures are the screws all coming out due to vibrations of the machine. I did not use thread-locker on any screws which was a massive mistake that will be reprehended when I reassemble it into version 2. Another issue holding the machine back is skipped steps. This is when the force required to be issued by the stepper motor is more than it can handle and it "skips" a step. This is only apparent while milling aluminum as can be seen below. There could be 2 underlying causes for this. 1). The stepper motors are too weak. Many who have built similar platforms have opted to use the larger nema 23's for their higher torque. These motors are also a lot more expensive and require a larger psu adding more cost. 2). The spindle is to weak. I opted to go with a 300w spindle, as it is the absolute cheapest one can buy. One of the limitations is that the spindle does not have enough torque at lower rotation speeds, meaning you have to move it faster with a shallow depth of cut for optimal chip load. Moving the spindle fast strains the steppers and applies more force to the entire machine. This can, and will be remedied by either a cheap Chinese 1.5kw spindle. Or a cheap wood router. Both options have pros and cons and I have not decided which to go with yet. A router is cheaper and easier to setup, but is limited by power and the rpms can not be controlled as precisely. A Chinese spindle is more expensive and requires a separate controller, but is more powerful and has less runout. Before I add a new spindle, I have chosen to mill a new Z-Axis Plate and Side Plates out of 3/4 thick 6061 aluminum. I have refined my design with better tolerances and shape. This should help stiffen up the entire machine. The next update will be in a few weeks when these changes are complete. I expect final files to be released by the end of the year. Until then see yah

-Peter

![]()

-

X-Axis

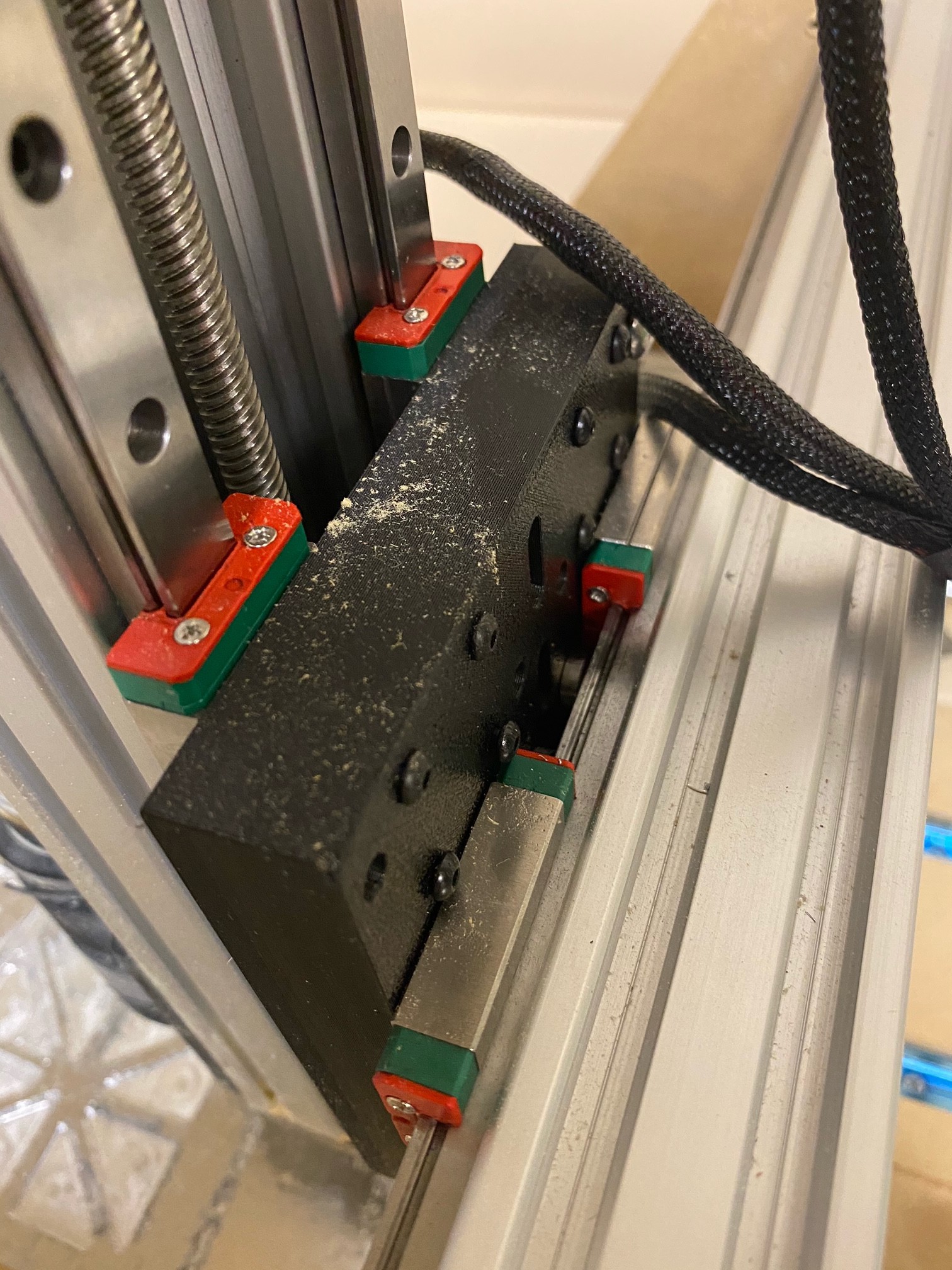

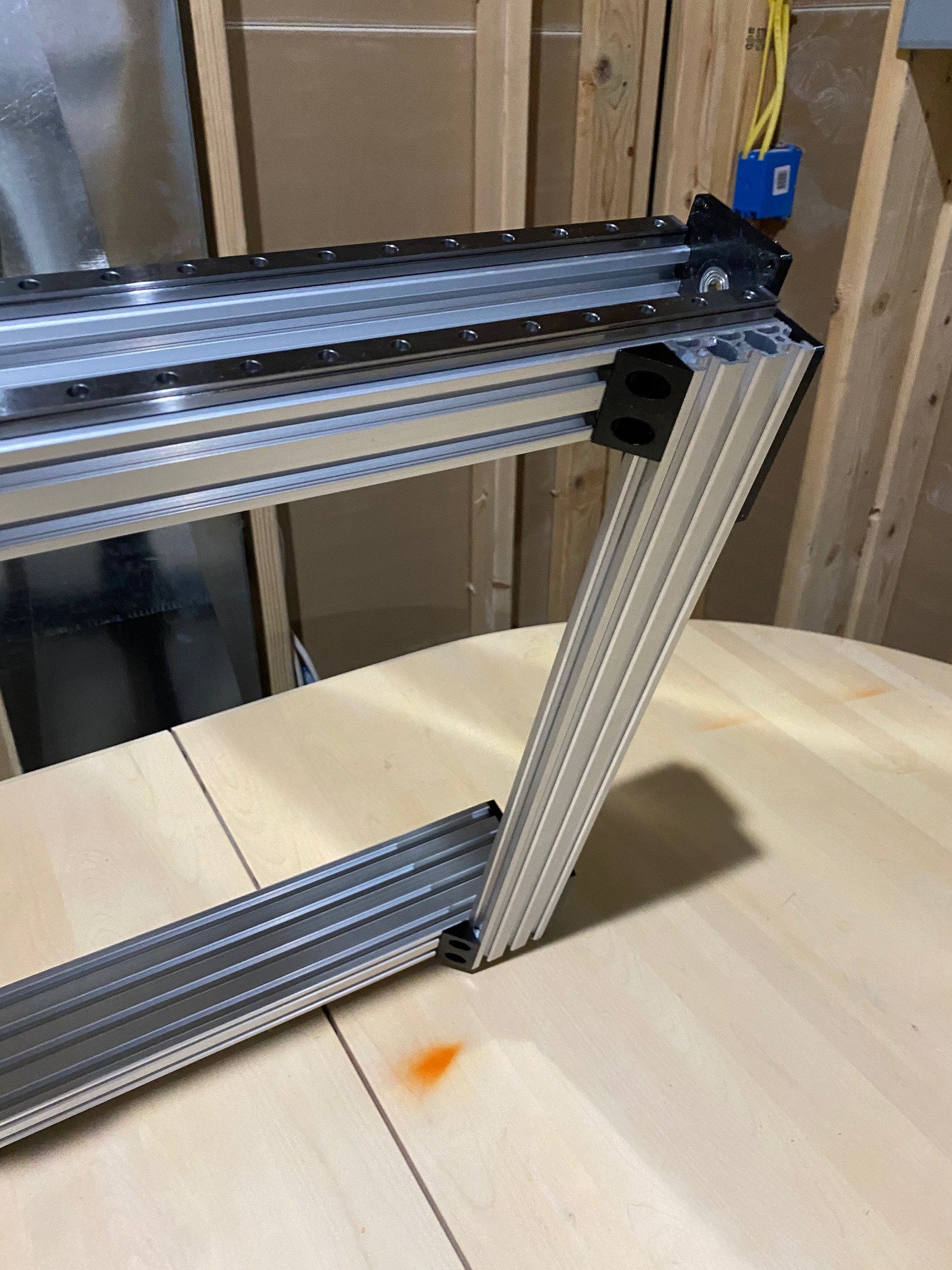

05/22/2020 at 03:42 • 0 commentsThe x Axis is the exact same as the regular Spinx. I printed the plates in Black Amazon basics Petg with 5 perimeters and 100% infill.

![]()

![]() I used 3d printed rail aligners to temporally install the linear rails. Im using MGN12H knockoffs off alibaba. They are each only held on with 4 screws for now as i am waiting for more to arrive. The lead screws are not installed because i mistakenly ordered them all far to short. Right now i am designing the plates for the y and z axis. And will add nother log when those are complete.

I used 3d printed rail aligners to temporally install the linear rails. Im using MGN12H knockoffs off alibaba. They are each only held on with 4 screws for now as i am waiting for more to arrive. The lead screws are not installed because i mistakenly ordered them all far to short. Right now i am designing the plates for the y and z axis. And will add nother log when those are complete.

OpenLRC - The low cost linear rails CNC

Open source CNC project which uses cheap linear rails from china, and aluminum C profiles for modularity and rigidity.

Peter Buckley

Peter Buckley

Electronics

Electronics

Issues and Changes

Issues and Changes

I used 3d printed rail aligners to temporally install the linear rails. Im using MGN12H knockoffs off alibaba. They are each only held on with 4 screws for now as i am waiting for more to arrive. The lead screws are not installed because i mistakenly ordered them all far to short. Right now i am designing the plates for the y and z axis. And will add nother log when those are complete.

I used 3d printed rail aligners to temporally install the linear rails. Im using MGN12H knockoffs off alibaba. They are each only held on with 4 screws for now as i am waiting for more to arrive. The lead screws are not installed because i mistakenly ordered them all far to short. Right now i am designing the plates for the y and z axis. And will add nother log when those are complete.