I designed something like this a while back but there were just too many parts to consider it. Well, now I have time! I restarted the design from scratch with a different solid as the focus. Then I saw the Making Tech At Home contest, and had to make some extra changes before cutting.

The cloth I was going to order for the diffuser material was replaced by tissue paper originally intended for shipping earrings and Xmas ornaments on Etsy.

The rotary power switch and knob I was going to order were replaced by the power switch from an old dead ATX power supply.

The 3 meter extension cord I was going to order to cut and use as a power cord was replaced by the cord from an old TV spliced into some wire from an old extension cord to get the total length I needed.

The light bulb was from my pantry; we keep extra bulbs on hand. It's one of the cheap GE ones; nothing fancy.

The light bulb socket was a leftover from a 4-pack that was only a few cents more than a 1 pack. One went into a table lamp, another into version 2 of that lamp, and now a third is in this...maybe a 4 pack will end up having been too small.

The wood was all stuff I had on hand; back in the good old days when going to Home Depot was something sane people did I bought as much of it as I could fit on my shelves and I still have a good amount left. I also have tons of this wood as scrap from other projects. One feature of this project is that many of the parts are small, so I got to use those scraps. I think getting rid of the scrap was a higher priority than reducing use of new sheets of wood; my scrap buckets are no longer overflowing! It's 4.5mm thick birch plywood, stained with Minwax Crimson stain.

Cutting took the better part of a day. It would have been a lot faster but I spent a lot of time trying to fit pieces onto bits of scrap. Assembly took something like 30 hours. Didn't really mark times or anything but it was most of three days used on assembly. Staining all the pieces also took a long time, but it's hard to say how long since a lot of them were already stained.

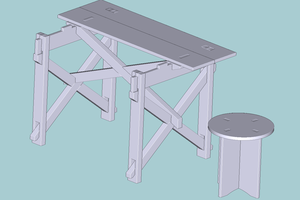

The design is parametric, with variables for things like wood thickness, minimum material thickness, and even a built-in kerf offset (because RD Works gets confused sometimes so it's easier to just do it in SolidWorks). Basically just put in a material thickness and a kerf, press regen, and then save a DXF containing all the parts with a very light press fit that can be assembled without tools.

As far as releasing files: I don't want to release the original SolidWorks file because it would only help people with SolidWorks 2019 or newer...even other software that can import it will likely drop all the parametric stuff that makes it work. I think that maybe the best way would be to turn off the kerf compensation, set the material thickness to 4mm, and export that...then repeat for 4.1mm, etc, etc up to 6.1mm...but that's 20 DXF files to make and it's getting late so maybe in the morning.

Cedric Anné

Cedric Anné

Pinomelean

Pinomelean

Øystein

Øystein

mclien

mclien