I am using a: Shopbot PRSalpha 96-60

Let me know of any additions, corrections, or clarifications that you might suggest or need!

Ear Saver Router CNCing

Protect your ears from face mask ear loop burn!

Protect your ears from face mask ear loop burn!

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

I am using a: Shopbot PRSalpha 96-60

Let me know of any additions, corrections, or clarifications that you might suggest or need!

EarSaverShopbotSetup_26inches.crvcrv - 29.74 MB - 05/19/2020 at 00:17 |

|

|

EarSaverShopbotSetup_20inches.crvcrv - 22.31 MB - 05/19/2020 at 00:17 |

|

|

EarSaverSingle_Spacer_Text.dxfAutoCAD DXF - 767.42 kB - 05/19/2020 at 00:17 |

|

|

EarSaverSpoilboardSetup_18x26inches.crvcrv - 33.00 kB - 05/19/2020 at 00:17 |

|

|

EarSaverSheet_20inchMaterial_24parts.dxfAutoCAD DXF - 13.94 MB - 05/19/2020 at 00:16 |

|

FYI - I had several issues exporting a fully correct Surfacing File from Vcarve. But eventually got it, just make sure to check your code before you get infront of the machine.

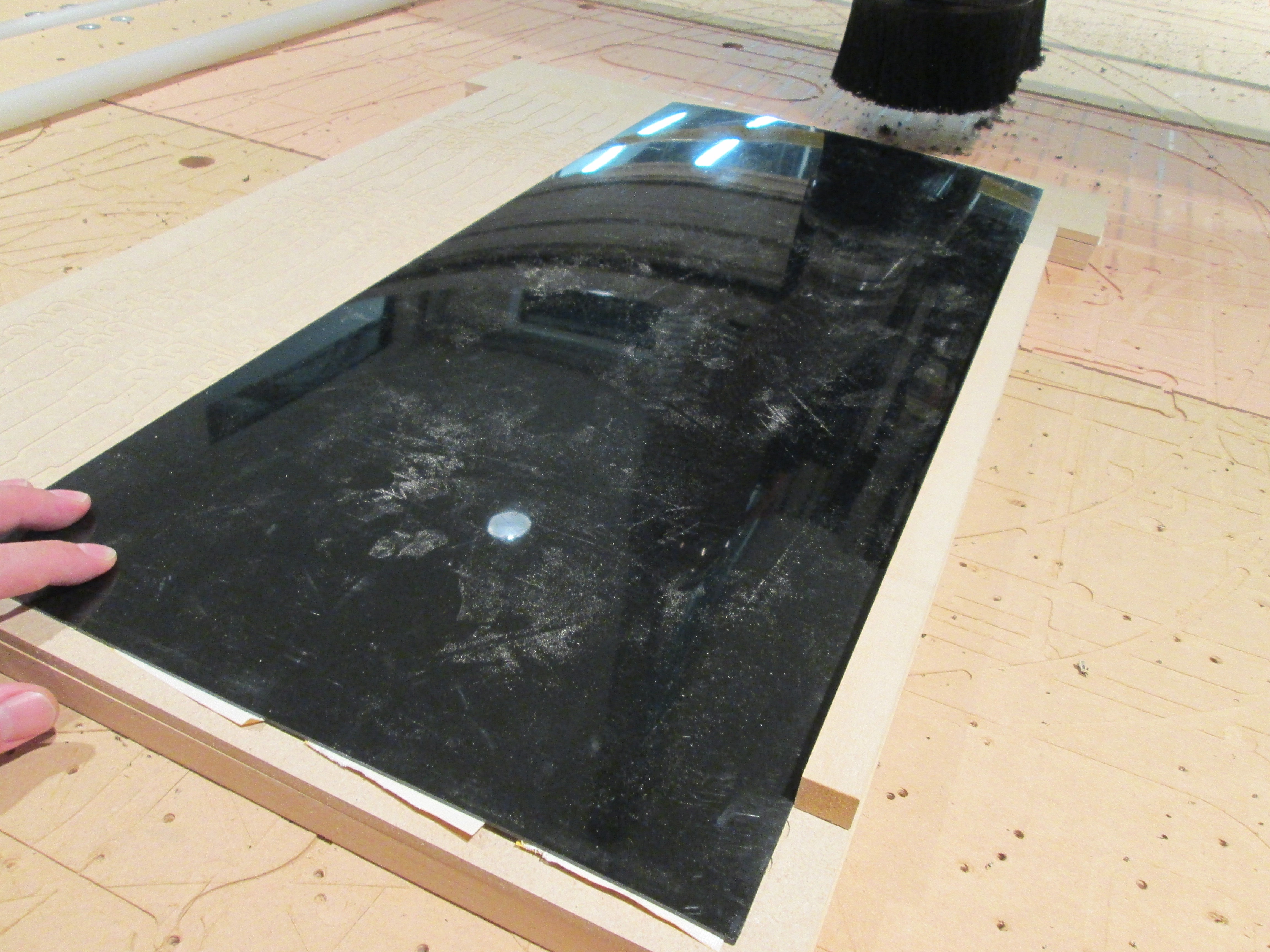

Use a Sanding Block on the surface of the Spoilboard after each sheet.

The Scotch tape DID work! But only on a clean spoilboard surface.

Cut through all the columns of your parts; 8 minutes

Cut only one column at a time, to remove any tape residue from the endmill, and incase something goes wrong...; 2 minutes

I usually get through three sheets before I've needed to surface the board

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates