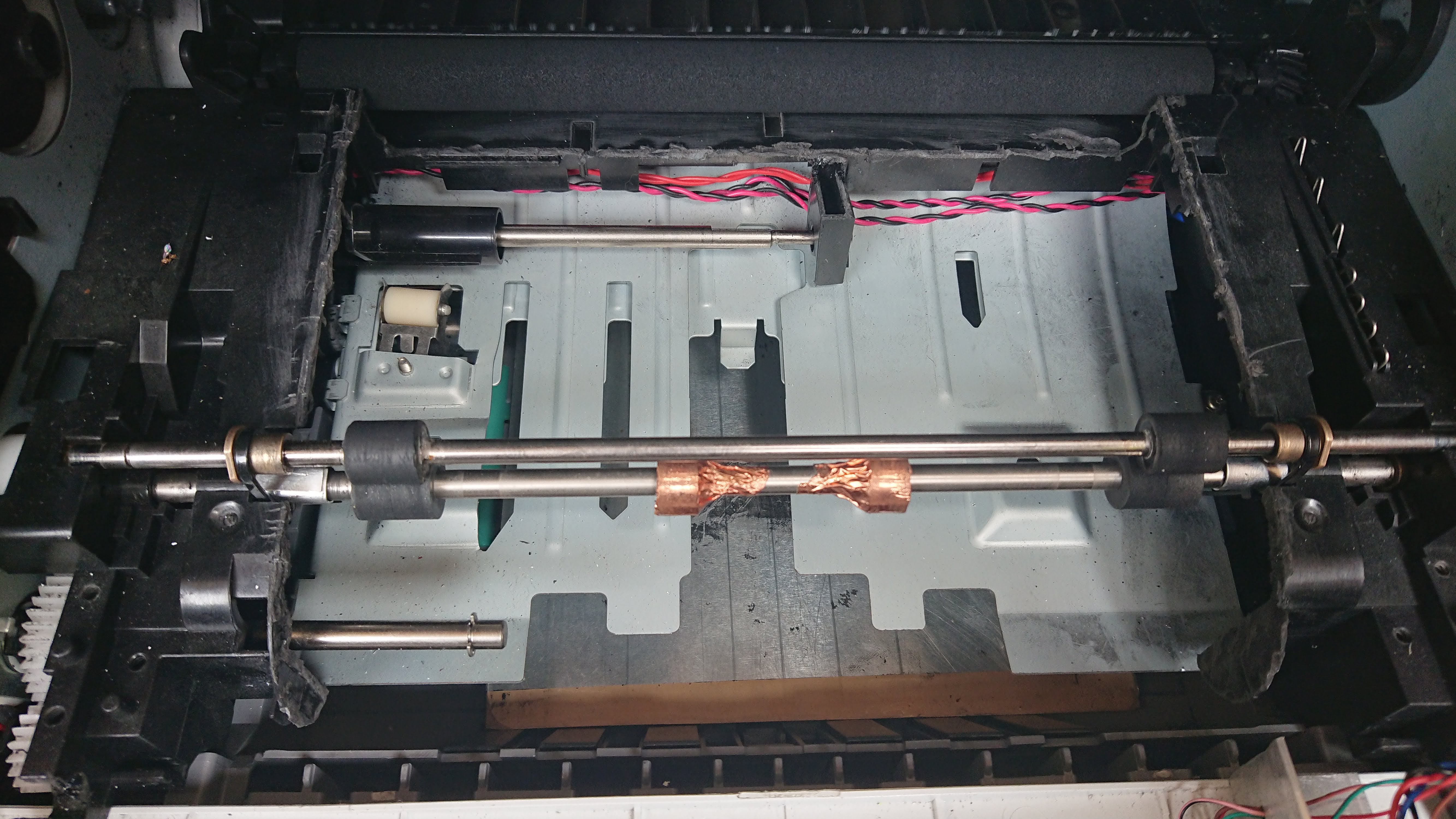

This project was based on the haxmark project and this instructable. These projects describe the modification of lexmark e360 and e260 printers.

I encourage you to read them, as they provide many details that might be elucidating. The modification seemed a bit dauting to me at first, but I assure you that it's not so.

Motivation

Most local PCB services take a week to make your board + shipping time (4 days). The cheaper ones start at $50 BRL for 3-5 boards, 2 layers max, but quality is great to be fair.

For comparison, the used lexmark e460dn for this project was about $350 BRL.

There are international PCB services too, but you either wait a long time or pay a high price for fast shipping + customs taxes. That's a problem that extends to electronic parts as well. We don't have any local Mouser or DigiKey warehouse to supply us the brand new IC of the week at a couple bucks (that's something I very much hope that will change soon by the way).

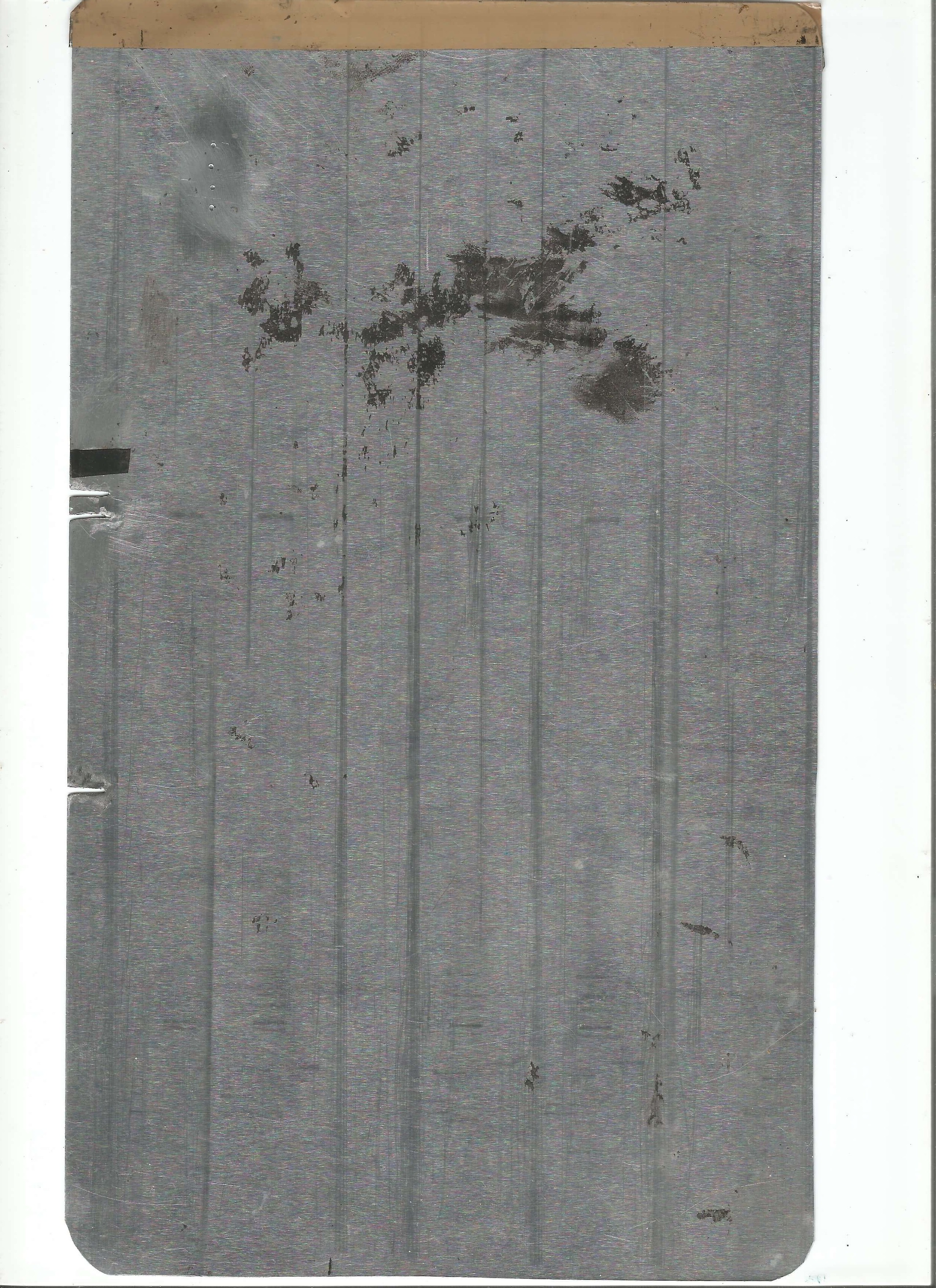

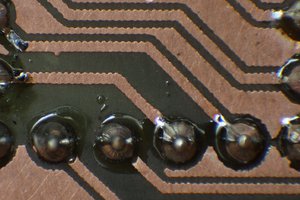

The goal of this project is to provide a decent way for quick PCB prototyping in regions where commercial solutions aren't quite there yet. Every hobbyist should be able to roll out his or her own design quickly!

Printing Settings

Always print at 1200DPI native resolution, or the timings won't match and you will get a paper jam.

Configure your printer to use the maximum toner amount.

I print my PCBs using the attached PPD file in Manjaro. I suggest you to use this same PPD with your prefered linux distro.

The following video shows it printing a small PCB.

Vítor Barbosa

Vítor Barbosa

fruchti

fruchti

Bhavesh Kakwani

Bhavesh Kakwani

Intelligent Minds

Intelligent Minds