My projects are all documented here https://sites.google.com/site/nodemcu12e/.

For two reasons.

1. Many people assisted in helping me to get all the microcontroller functions working. I put links to all their help in one location for others to use. Pay it forward.

2. To assist myself in the future when I forget how I got one of the functions working.

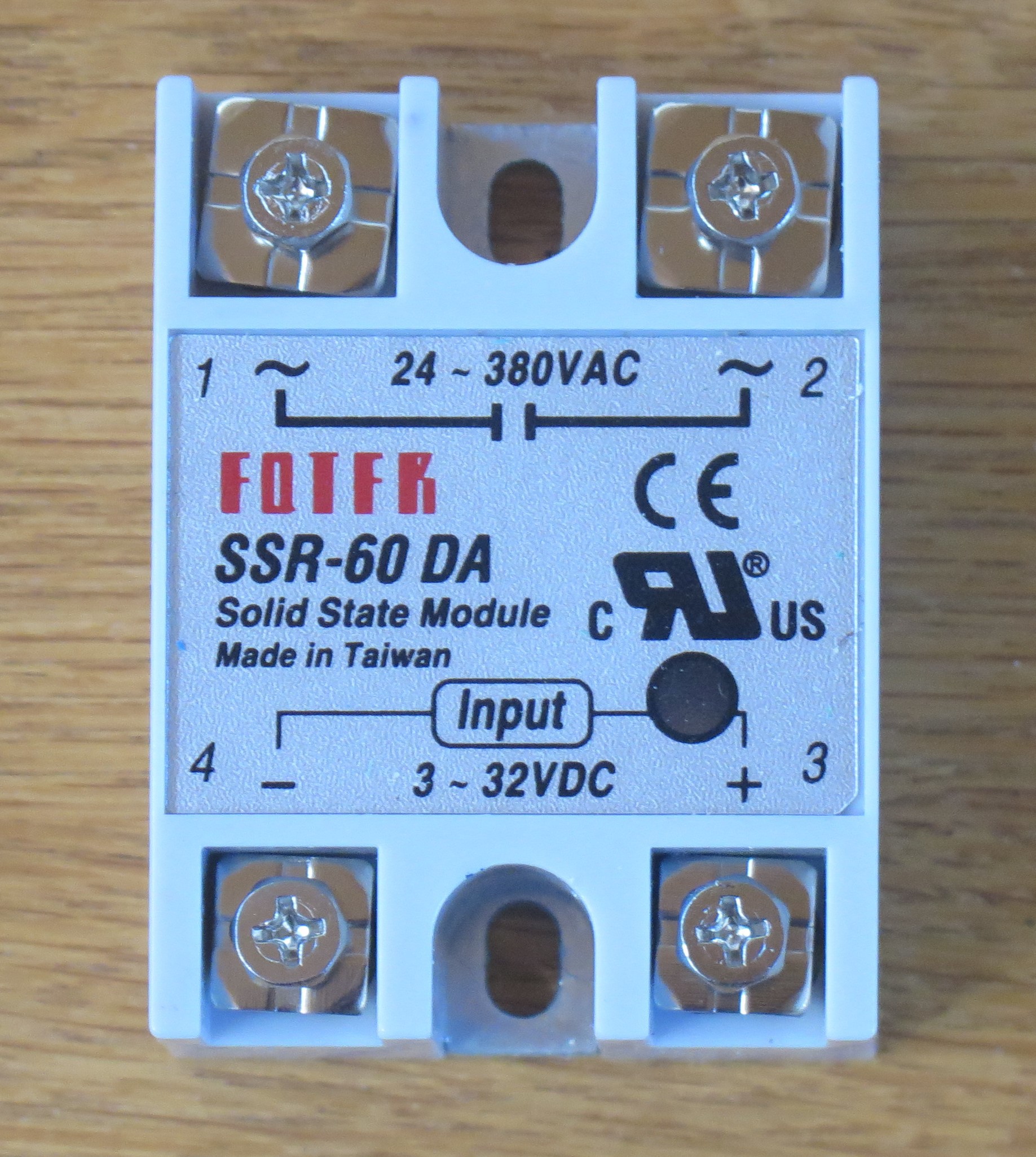

The gas furnace and water heater mods are set up with normally closed relays. The new functions open the relays. If you unplug the microcontroller the relays close and it goes back to the original thermostat and hot water control. The gas furnace thermostat mod only prevents furnace operation for up to an hour in any case so it will not prevent the furnace from operating for any great length of time.

vybhav-nag

vybhav-nag

Thomas

Thomas