Anybody with a bit of sense for environment and owning a filament printer will sooner or later look for ways to reuse failed prints or upcycle plastic bottles. My first approach is to shred plastics and print the granule with a direct extruder. That result already has been published on Hackaday (thanks, Dan).

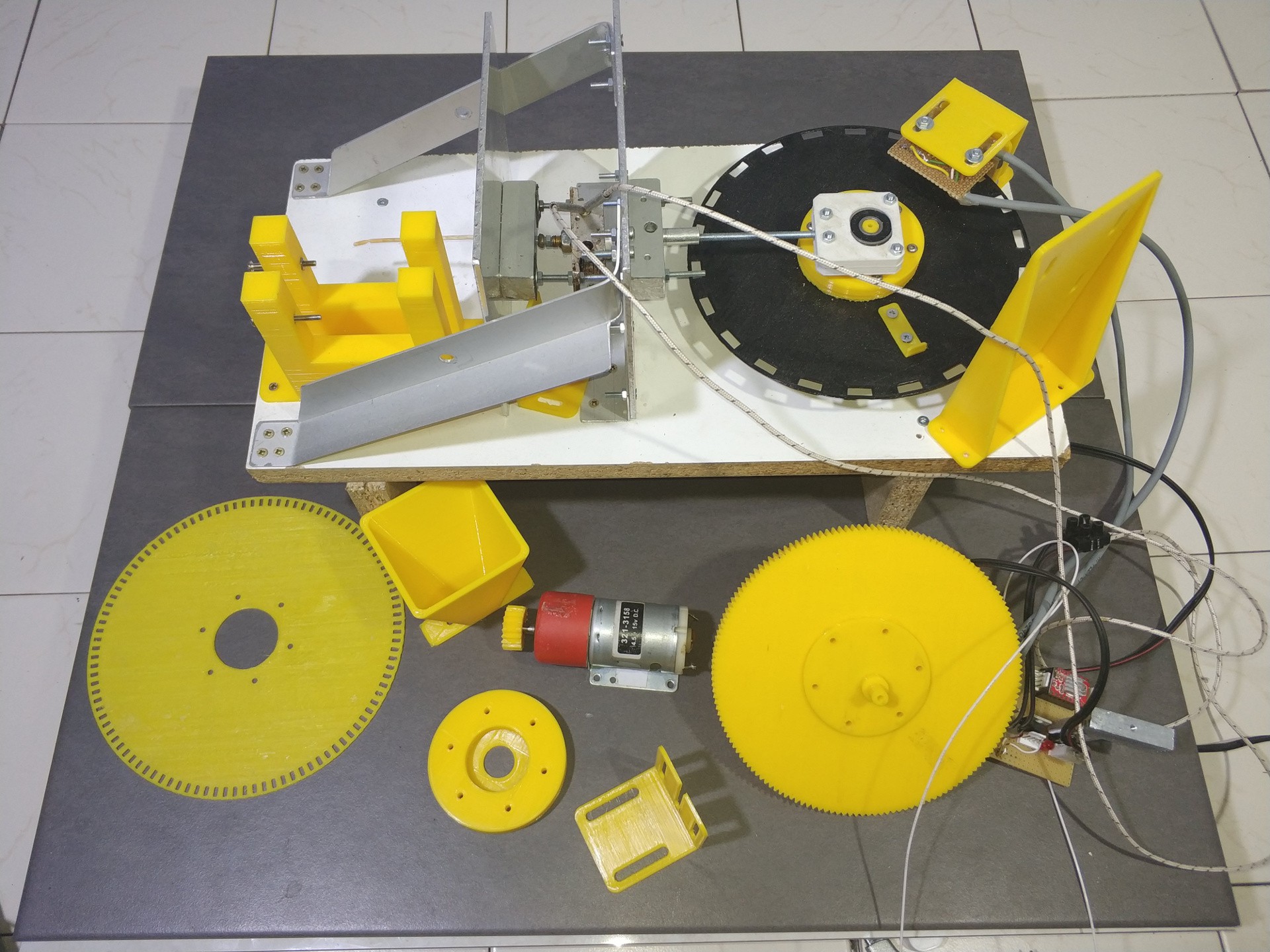

My next step is to build a filament extruder:

This one won't be a continuously working extruder. The raw material is pressed into a hotend by a piston that is driven by a crank shaft. The non continuous forwarding of raw material means the filament is extruded in intervals. That in turn requires the plastics to be solidified before exiting the extruder. This is achieved by a Teflon tube that is long enough to cool down the plastics. The problem with traditional filament extruders is that they are very sensible to extrusion parameters. That's what my setup can solve. You can extrude filament whenever it is needed, forwarding the plastics wire directly to your 3D printer while it is working. I have gone through a couple of iterations and the hardware has now reached a level that allows to dive into fine tuning...

Norbert Heinz

Norbert Heinz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.