-

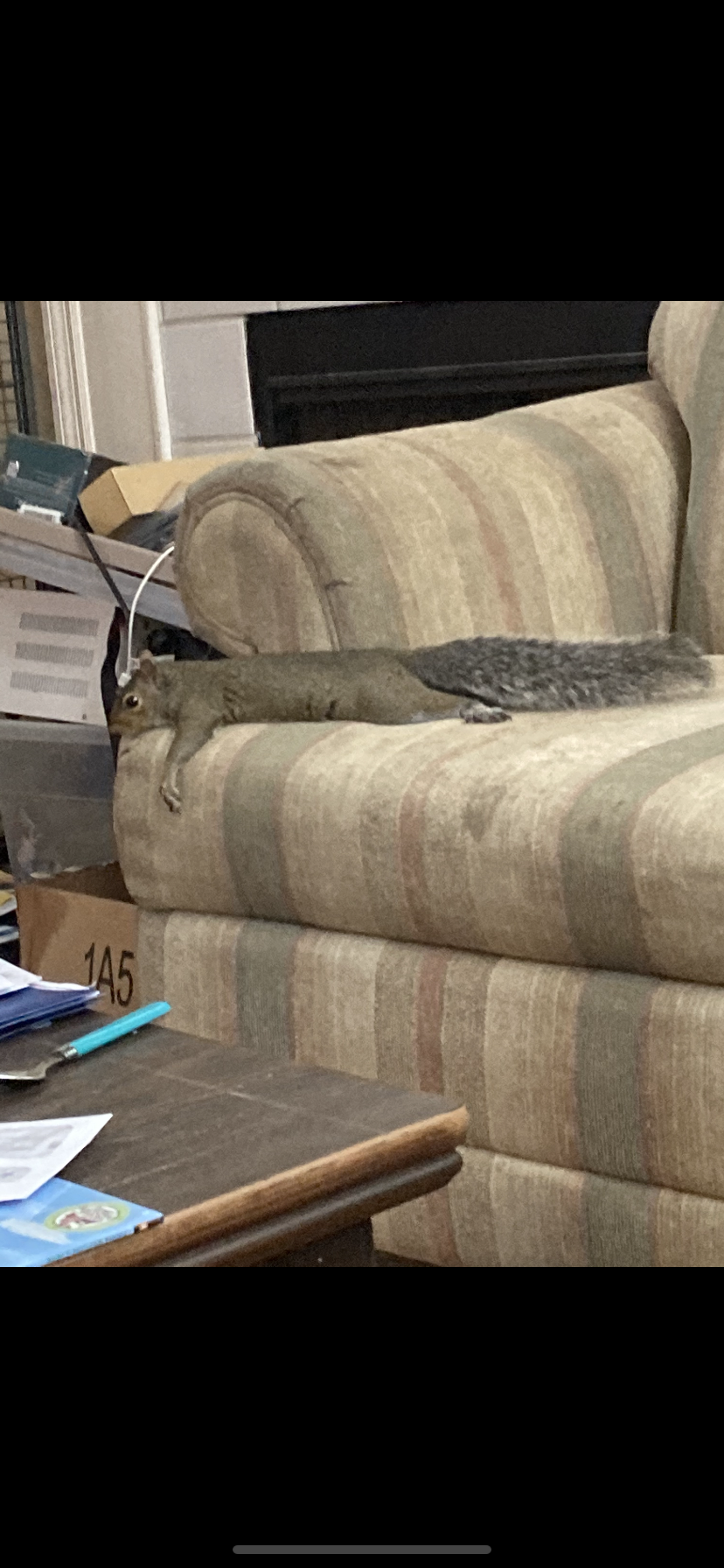

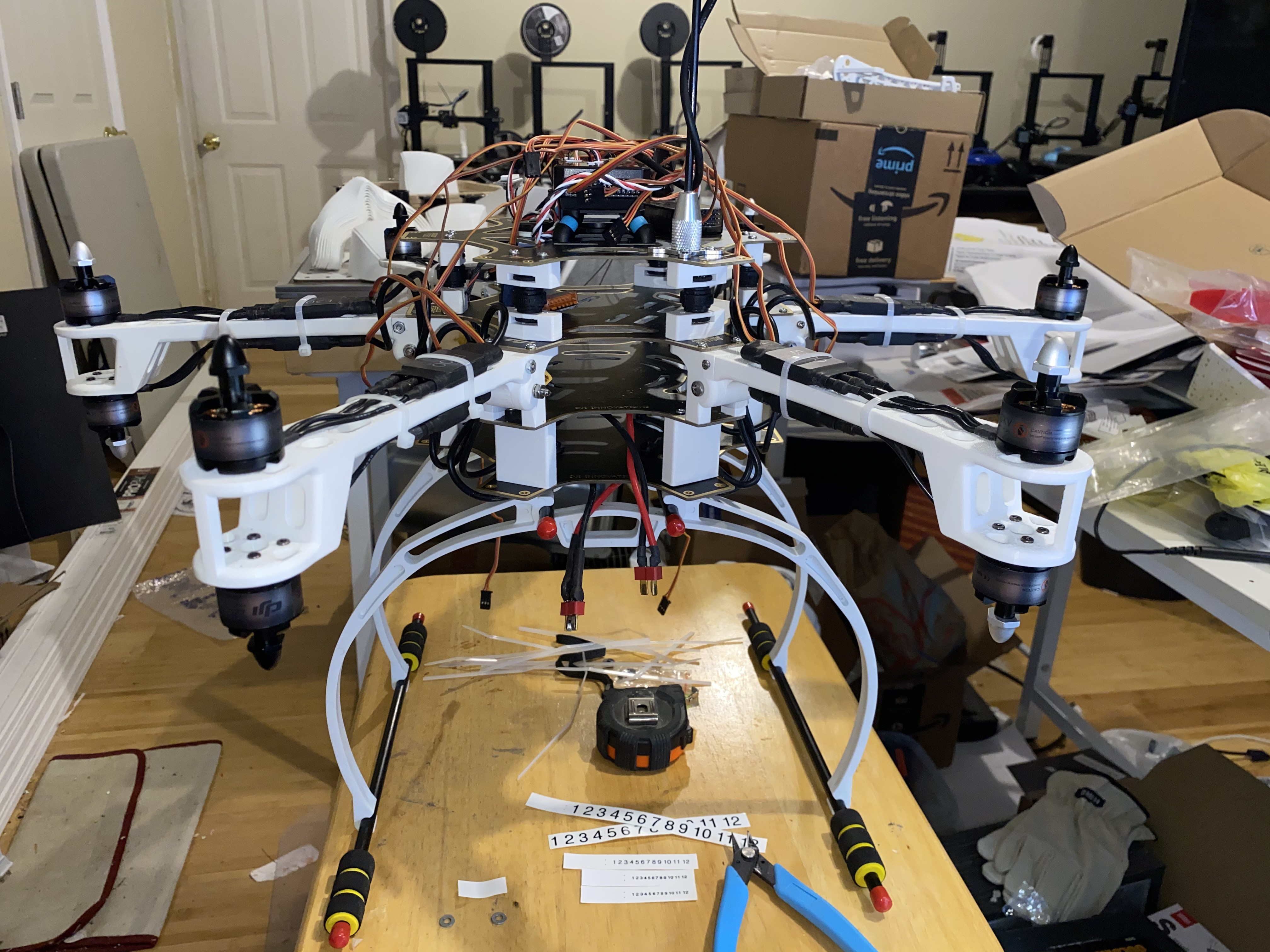

Getting our assembly on!

08/13/2020 at 00:56 • 3 comments![]()

![]()

![]()

![]()

![]()

![]()

-

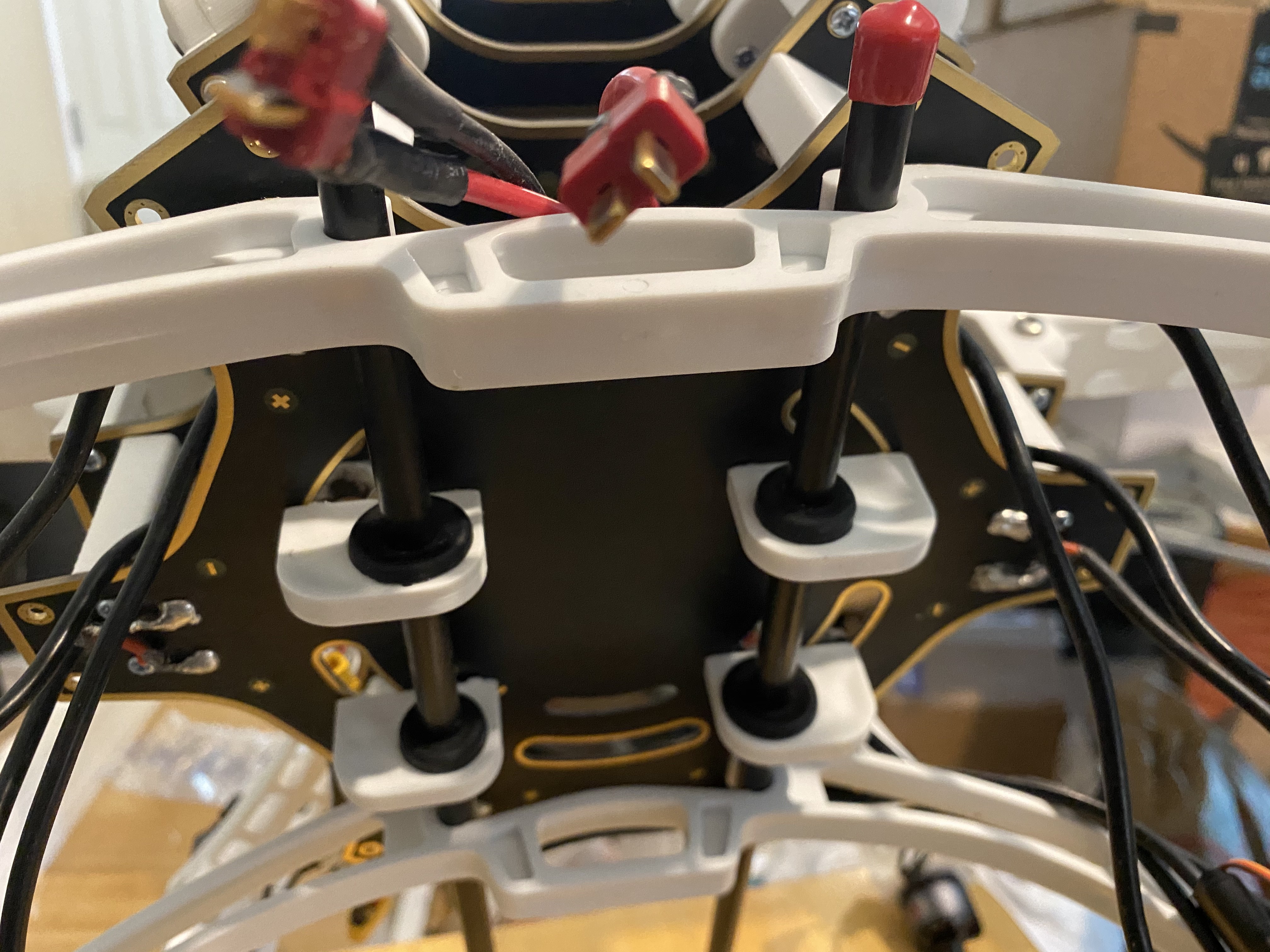

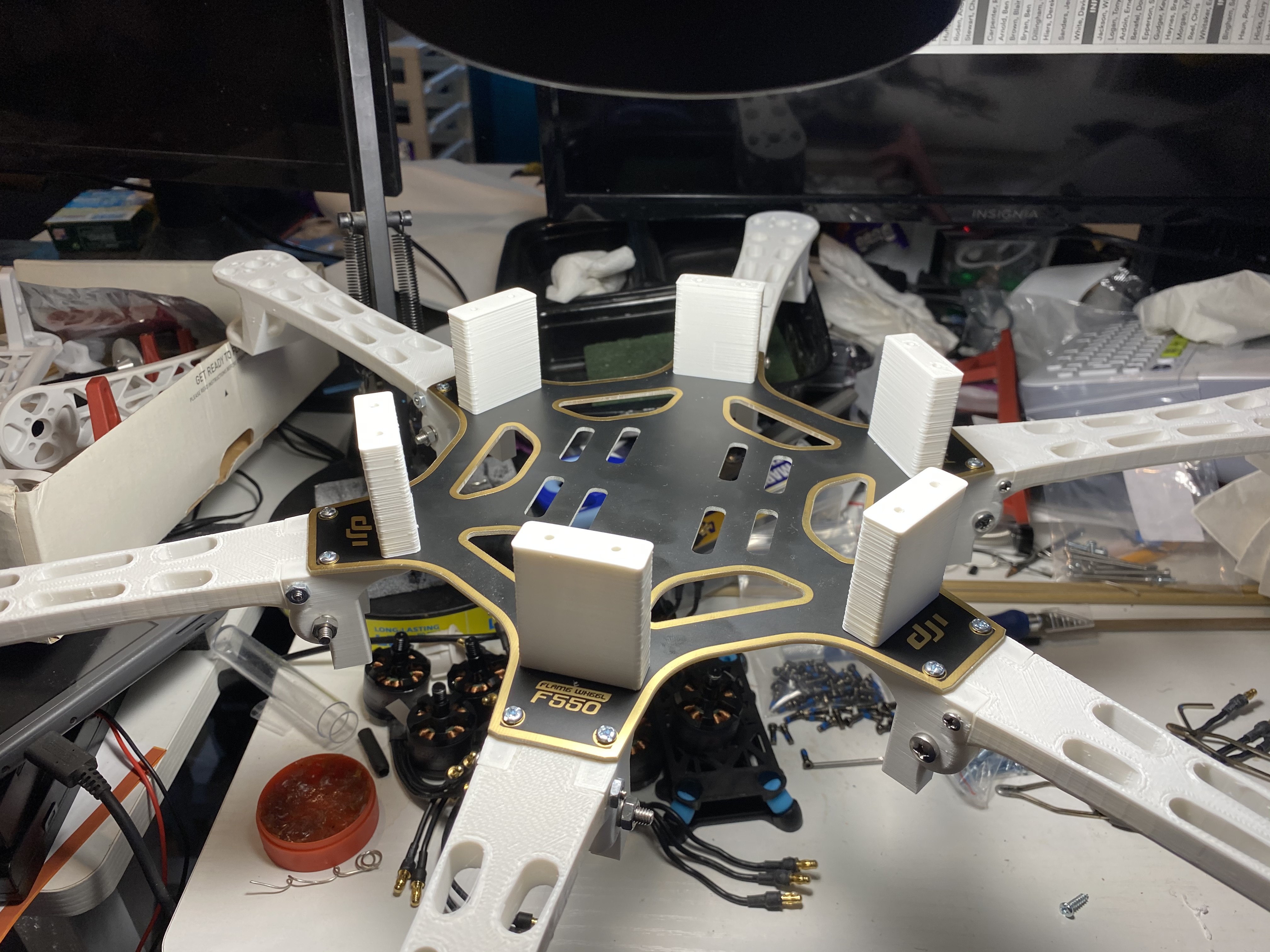

Vibration isolation installed

08/10/2020 at 03:10 • 0 comments![]()

![]()

![]()

-

6 custom vibration isolators done

08/09/2020 at 14:12 • 0 comments![]()

-

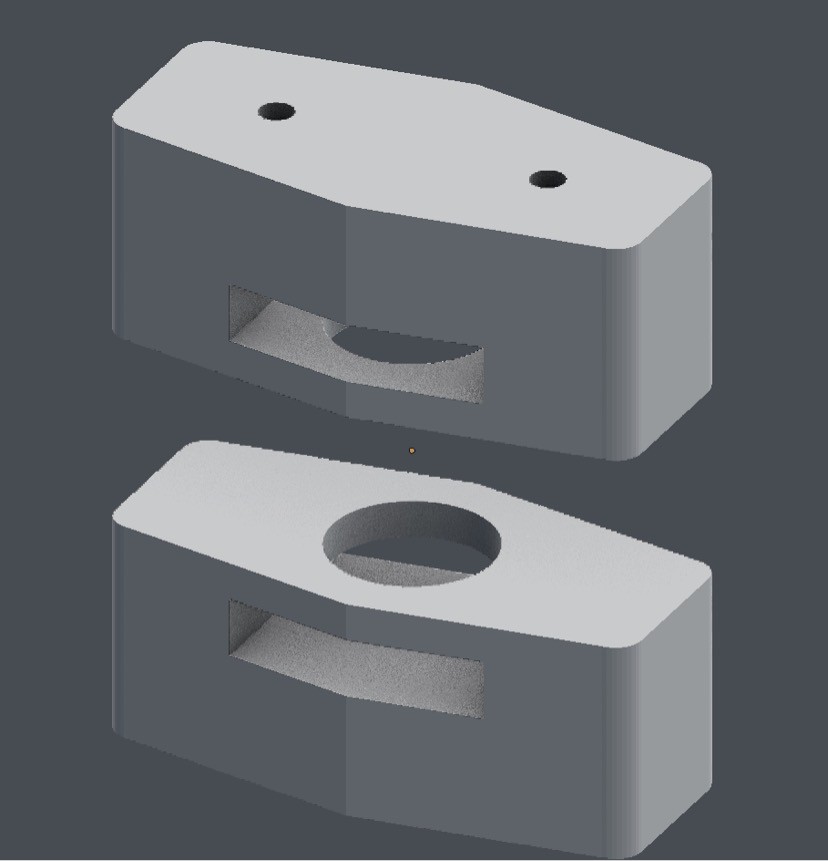

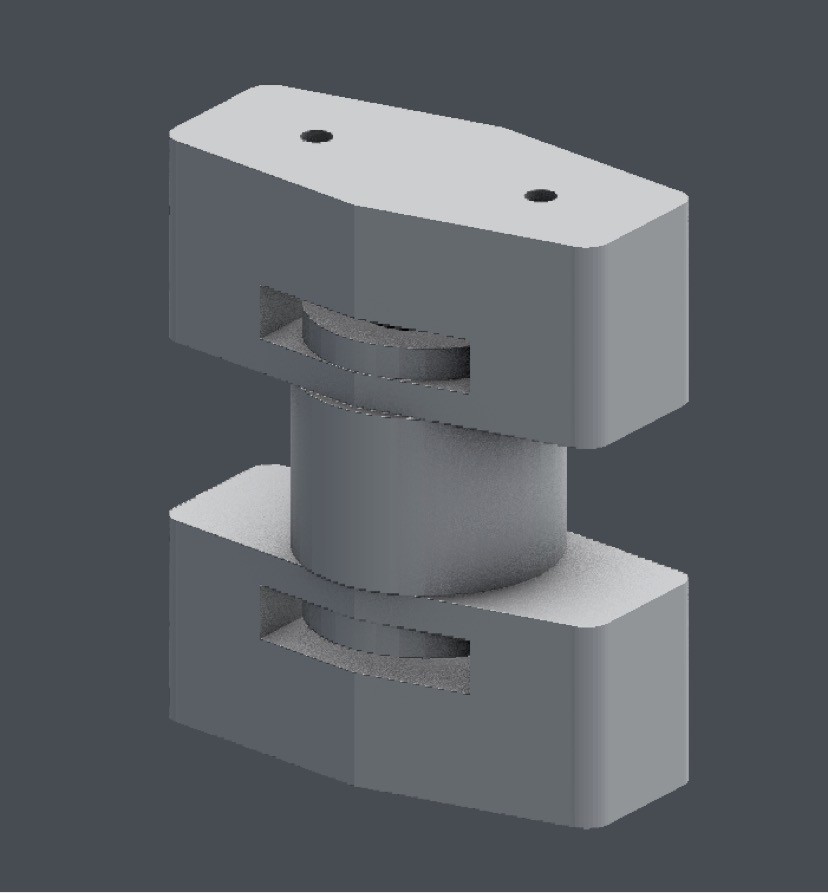

Top plate vibration isolation solution

08/09/2020 at 05:05 • 0 comments![]()

![]()

![]()

ok , so as I was previously indicating, I will use the second plate I have to make a raised platform. The temporary spacers will be swapped for custom vibration isolators normally used for camera gimbals. This also raises the sensors and gps module higher and farther away from DC ESCs the DC power wires and the 110v /220v wiring as well to reducing any possible interference. Here is the 3D model and I am printing 12 pieces to make 6 vibration isolators now.

-

Stacking the frames

08/08/2020 at 14:07 • 0 comments![]()

![]()

![]()

-

Kudos to a kids project for flying wifi router

08/06/2020 at 22:59 • 0 comments![]()

So this is a bit smaller of a project and does not involve long term flying, but it really is a tiny version of what I am doing. I found this kids paper and he has a website from a couple years ago. I think this was an engineering project for school. I will review his findings to see if there is anything out there useful.

https://garethnunns.com/wp-content/uploads/Flying,-Autonomous-WiFi-Gareth-Nunns.pdf

Web page and you tube video

-

ESC Jelly Fish, 12 ESC soldered

08/06/2020 at 22:12 • 0 comments![]()

-

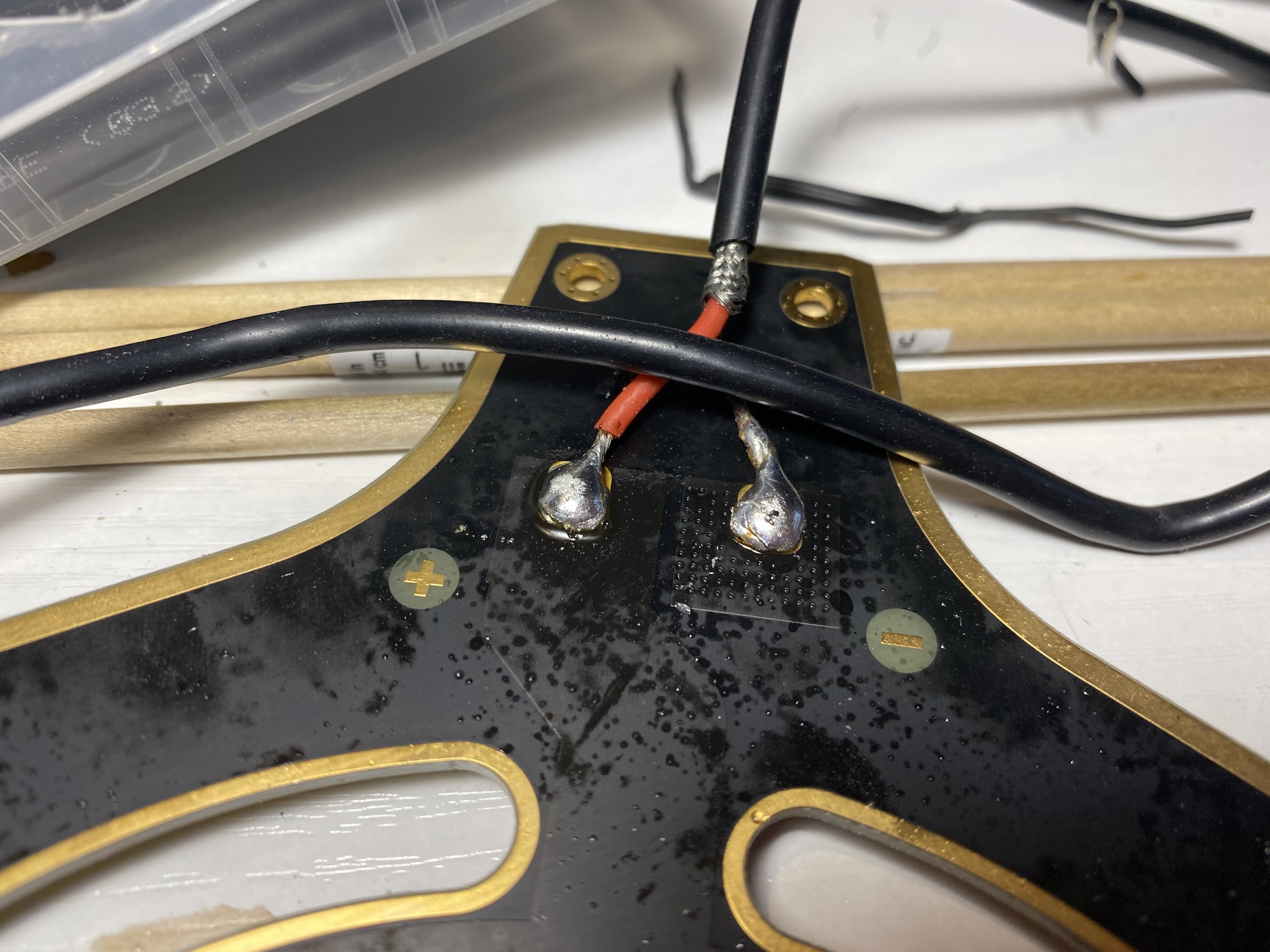

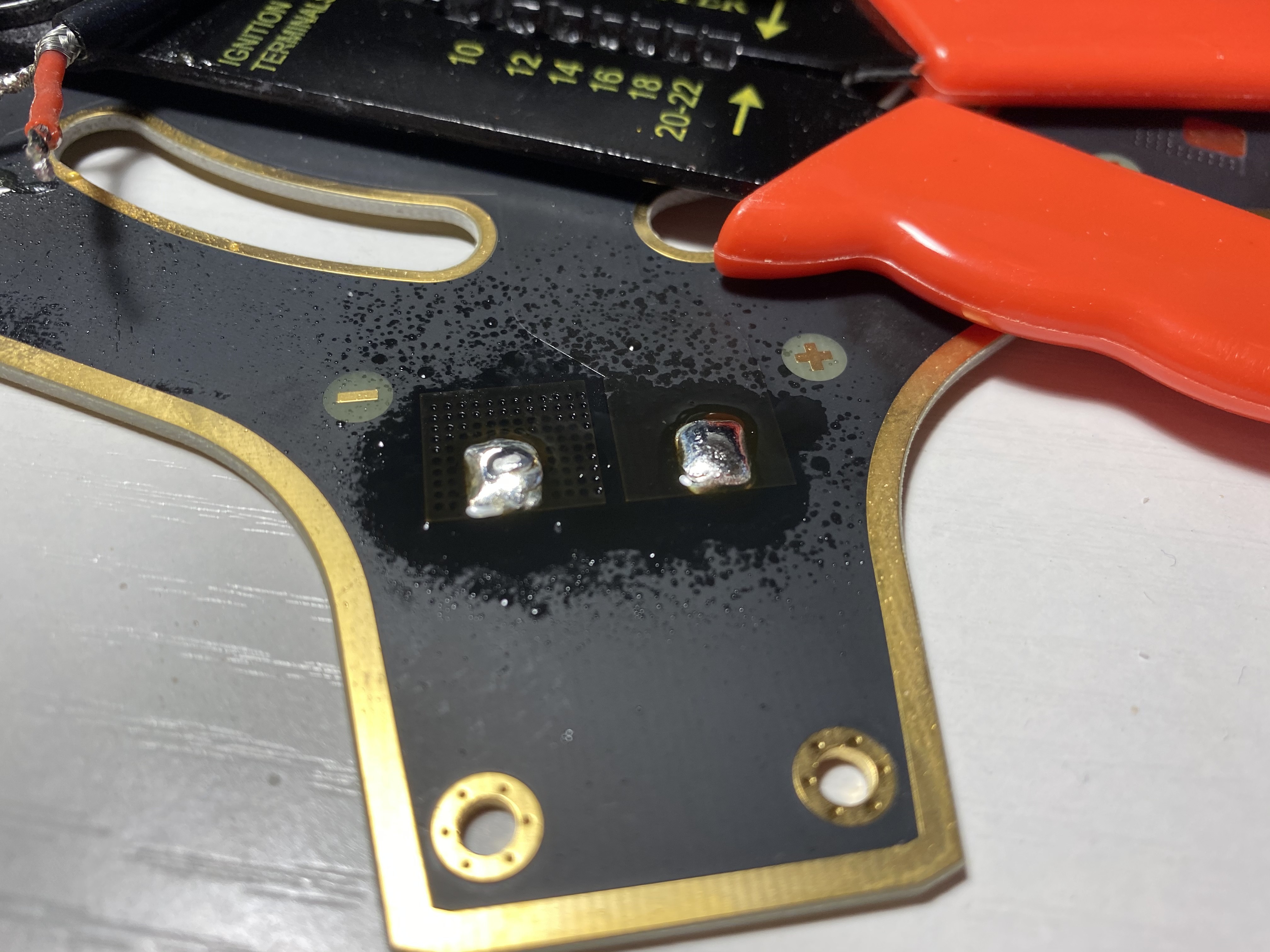

Soldering the power distribution

08/06/2020 at 09:41 • 0 comments![]()

![]()

![]()

![]()

I really am not sure if I have the worlds worst solder or this soldering gun is giving up the ghost. I went through three tips and a bunch of flux. As far as looks go, this is not my best looking soldering job, but I went through and reheated each connection to molten and then cooled again to prevent any cold joints.

-

Bending Arms for Storage

08/05/2020 at 23:13 • 0 commentsThis is the fold down mount for the new arms. We already needed to design a new arm to mount two motors and props on each arm , so adding a folding feature would make it easier to store and transport as well.

![]()

![]()

![]()

![]()

-

Reaming the props for perfect fit

08/02/2020 at 04:00 • 0 commentsThis is sort of uneventful, but there are tedious tasks you need to do when prepping any aircraft. Reaming custom props to match your motor shaft perfectly with no play is one of them. I picked up a reaming tool typically used for wood from Great Planes. The shaft of a DJI 2212 is just shy of 8mm thick when measured by a micrometer. Because of the motors that will be pointed down in operation, there are no DJI self tightening props that will work. I actually need to Ream the props and mount them in reverse to be in the correct orientation. Also moving from 9.4 in x 4.5in to 10 in x 5 inch provides a bit more thrust over the original props.

I have finished reaming and matching props to the motors. Next I need to balance then on both blades as well as the hub. More on that soon...

Open Sky Anchor WiFi Drone Brings The GIG

Mission "Wifi" Impossible > Bring Long Range 5G and 2.4 G WiFi Backed By A 1 Gigabit Fiber To The East Brainerd EF-3 Tornado Disaster area.

Josh Starnes

Josh Starnes