Nowadays, lots of chip has QFN or BGA shape, those are "impossible" to solder by soldering iron. Actually I know lots of personal engineer and hardware hacker has reflow oven and utilise them with solder paste stencil. Also in my case, I encounter this type of chip (gyro sensor and temp/pres/humi sensor) and found out soldering them is NOT so hard. Here I would introduce my own way.

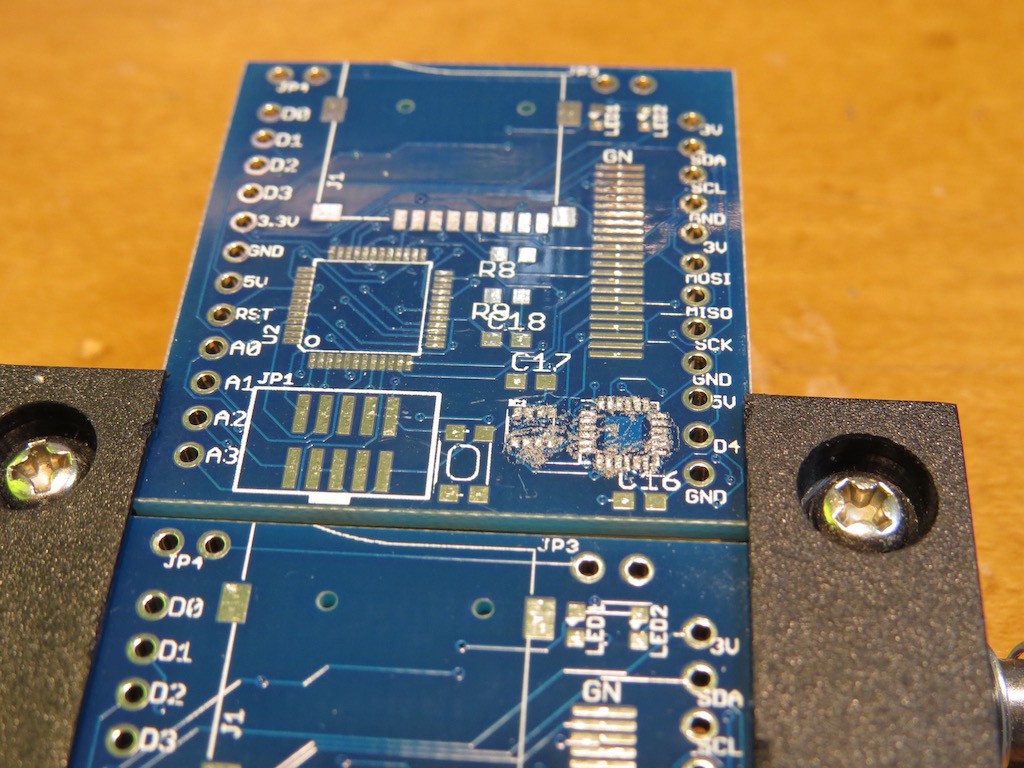

First of all, we need to paste solder paste on the destination pattern. Common sense says we should mask between electrode but indeed, surface tension of melting paste clearly separate electrode each other. Of course too much paste will put additional electric connection between patterns and we need some experience how the amount is proper....

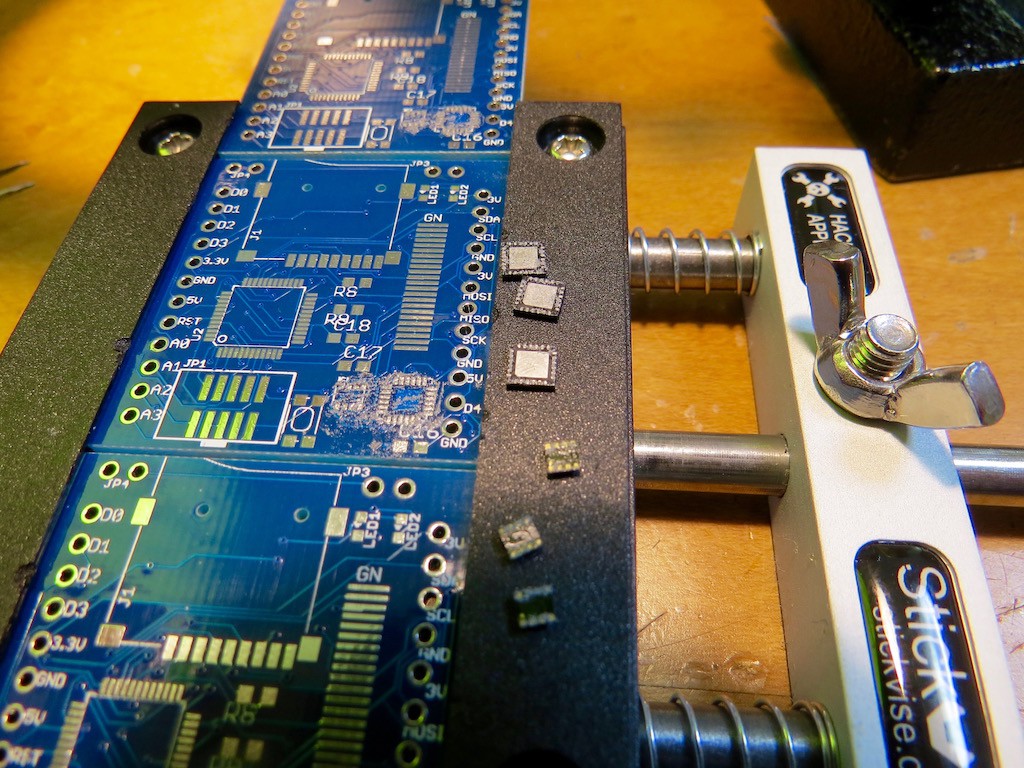

As same as PCB, in my experience, I put very small amount of paste on the electrodes of chips. Just on PCB sometimes bad connection so this is just to make it more sure.

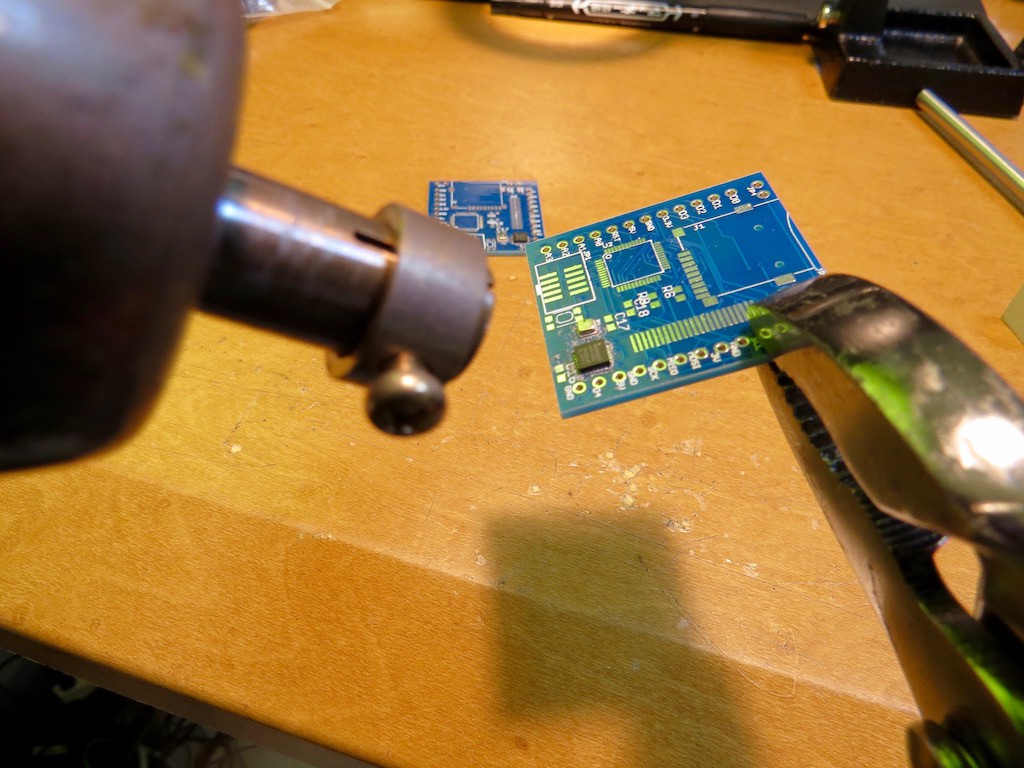

For heating soldering paste, I use "heating gun", a kind of big blower for engineering purpose.

Lastly, putting hot air blow on PCB. The pressure of air flow easily blow out tiny chips so we need some care. This requires some experience. After certain amount of air flow, the color of soldering paste will change from gray to silver (glittering), carefully heat all of electrode and everything is done! (As we know, too much heat will break parts and burn PCB, some experience is required...)

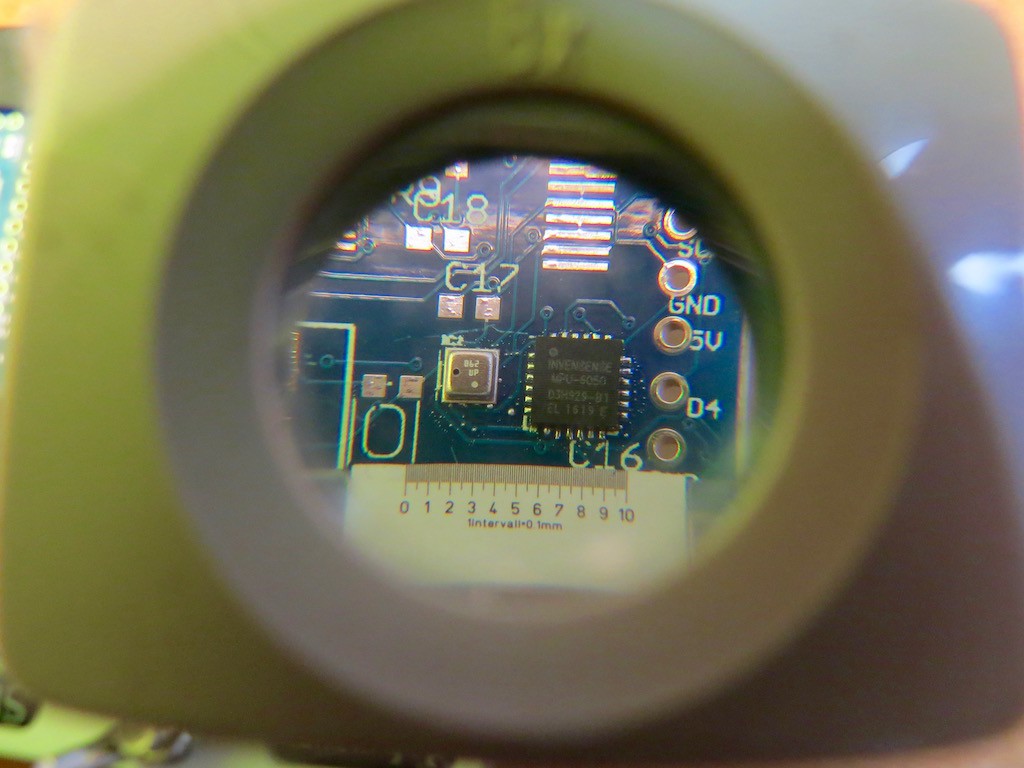

This is the final shape of soldering by hot air. As we see, some solder ball are around chip and we need to remove them carefully (no need but for cosmetic). Also we need to check solder bridge (if we can see electrode). This case, the electrode of BME280 is completely below chip and we cannot see and check "solder bridge" by our eyes but I took this way more than 100 PCB and I have not met error.

Actual "live" soldering can be found in the following movie.. Have fun!

kodera2t

kodera2t

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Very helpful

Are you sure? yes | no