Purchased from Craigslist out of a barn, not in horrible shape, but a little rusty and non-functional.

I have since cleaned up all surfaces, and applied oil.

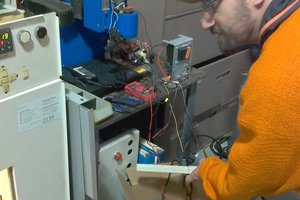

What is is: A Bridgeport Series I vertical mill (9x42" table) with a three-axis Anilam Crusader II CNC controller. Originally, the main components are:

- Servo "amplifier" box, made up of the main power supply and three servo amplifiers

- Control box, which is the Crusader II, including its own power supply (which is bad)

- Per-axis DC brushed motor, originally with a tacogenerator for RPM feedback

- Per-axis Acu-Rite 10 um glass scales, with quadrature output

- Not specifically part of the CNC package, but a three phase AC induction motor for the spindle

This project is to remove the Crusader II, and upgrade it:

- Main control to be Grbl, or similar, to produce step/dir pulses

- Servo drives to be Machdrives' BRA controllers, which consume step/dir pulses

- Spindle drive to be a Toshiba VFS7S VFD

- Keeping the glass scales and servo motors

- Rotary encoders to replace the analog tach in the servo motors

Ross Bochnek

Ross Bochnek

Benjamin Prescher

Benjamin Prescher

Brian Brocken

Brian Brocken