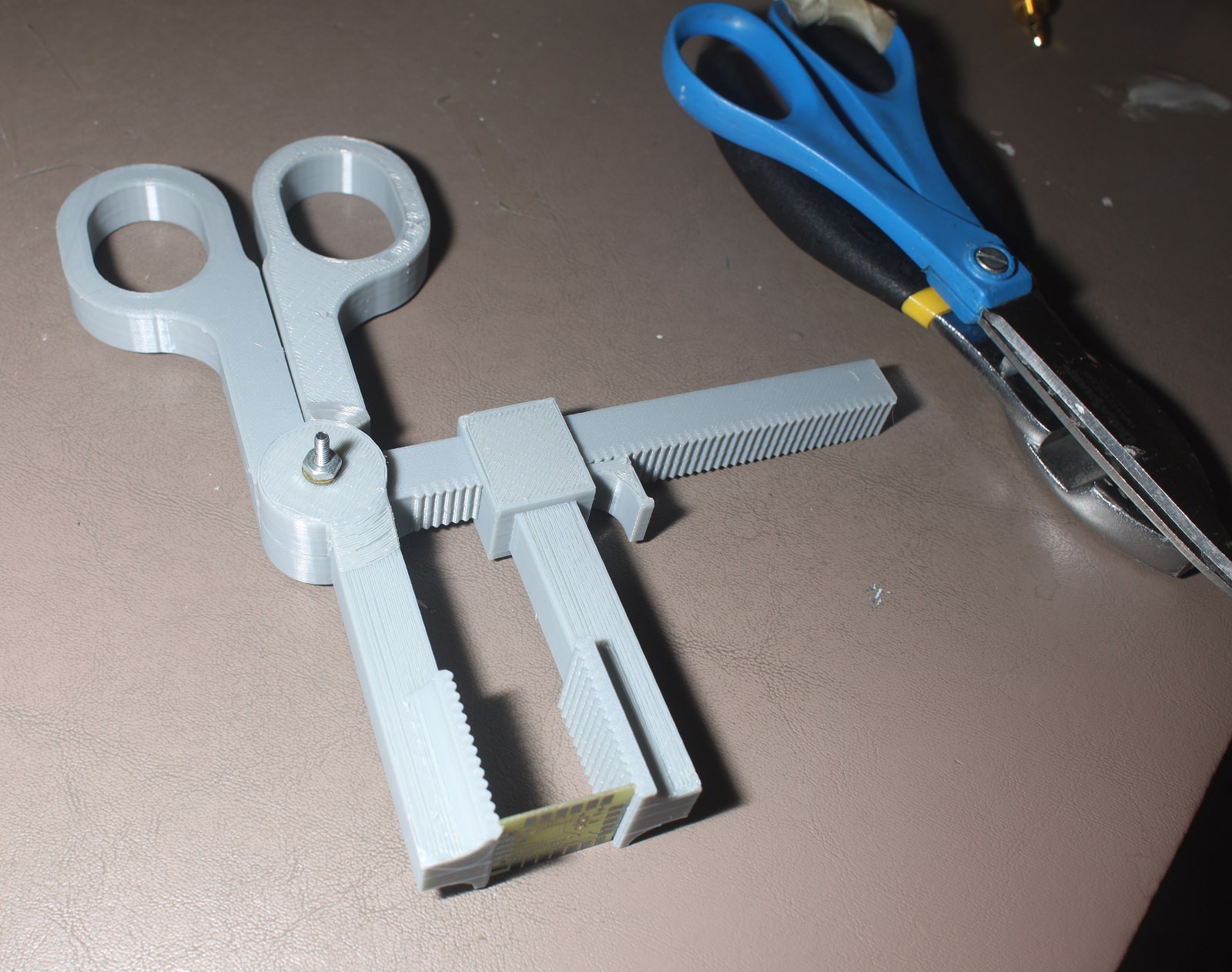

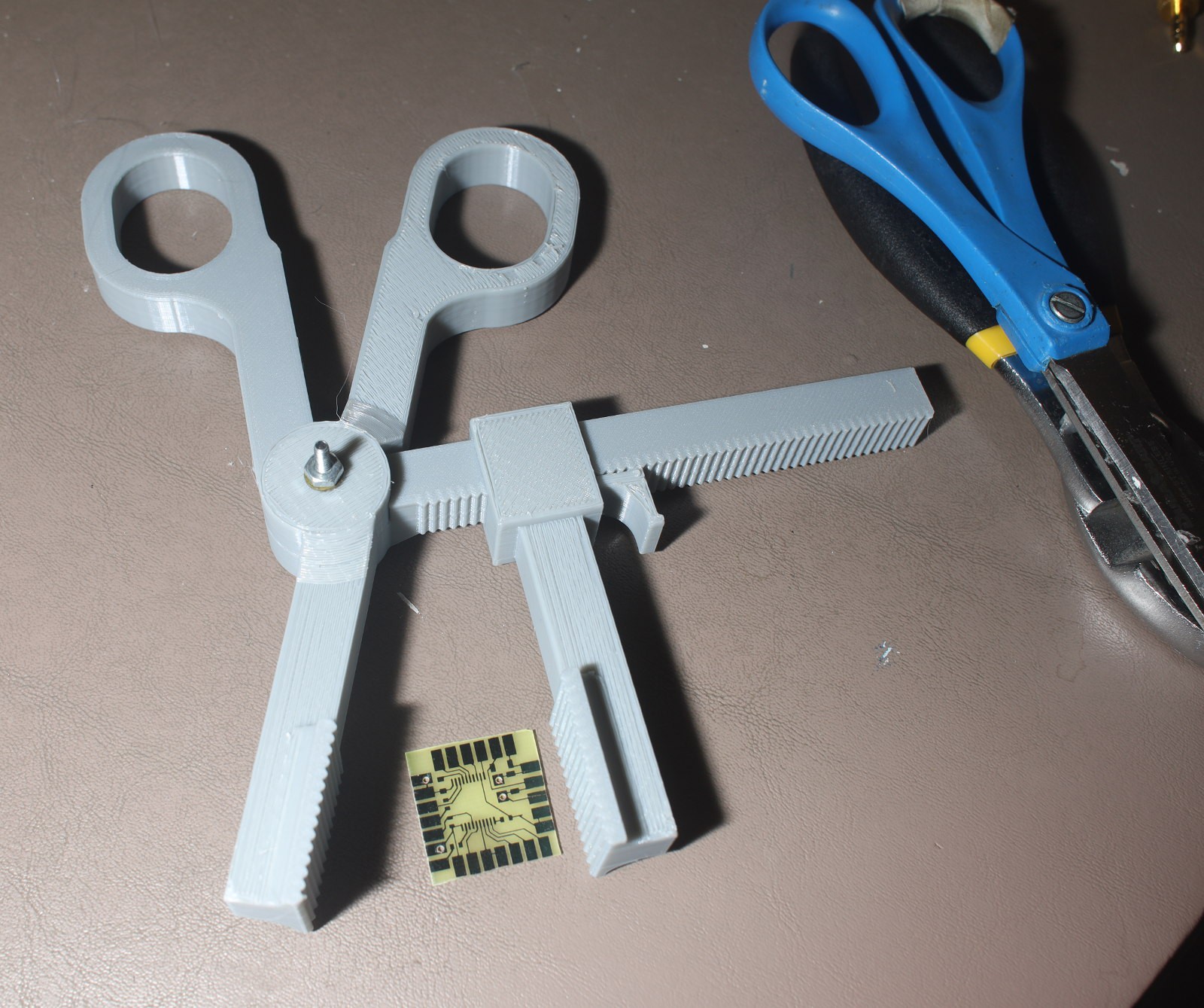

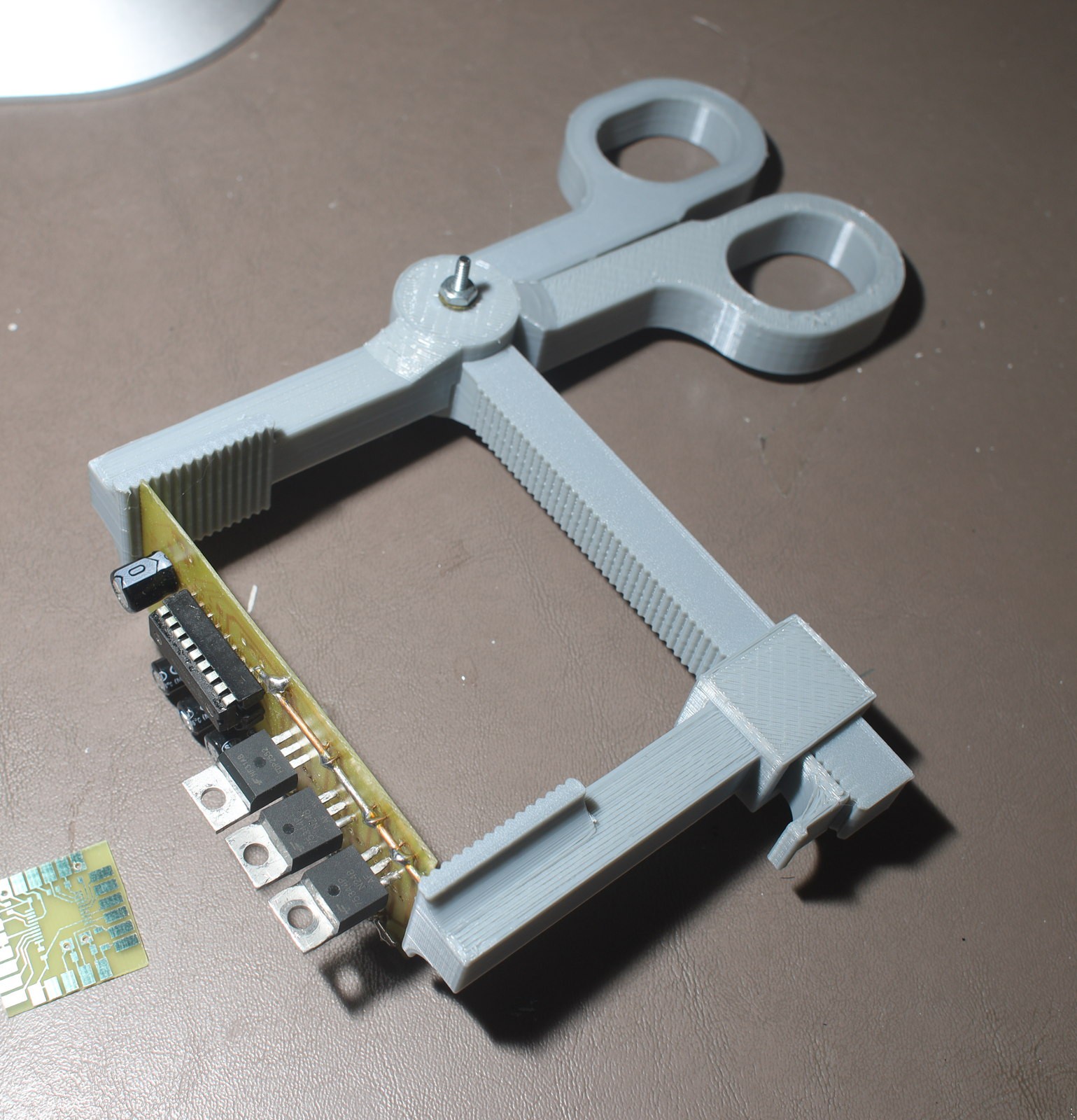

These PC board etching pliers should make the process a lot easier & allow bigger boards.

They were based on the size of normal scissors to keep the operator's paws away from the chemicals. The range of the slider motion & the size of the largest boards dictated 2 dimensions. Maybe the scissor handle could be smaller & the rods thinner.

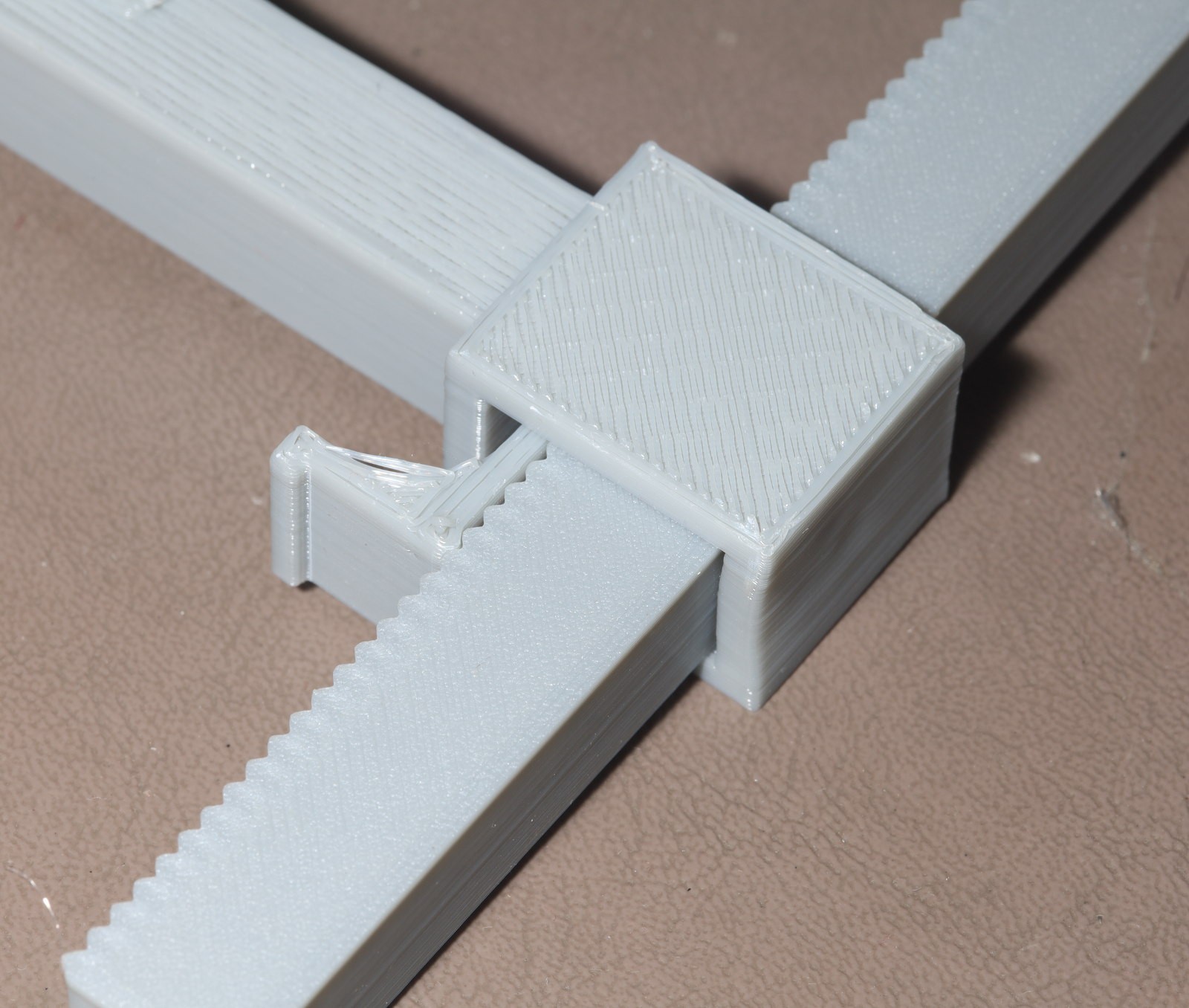

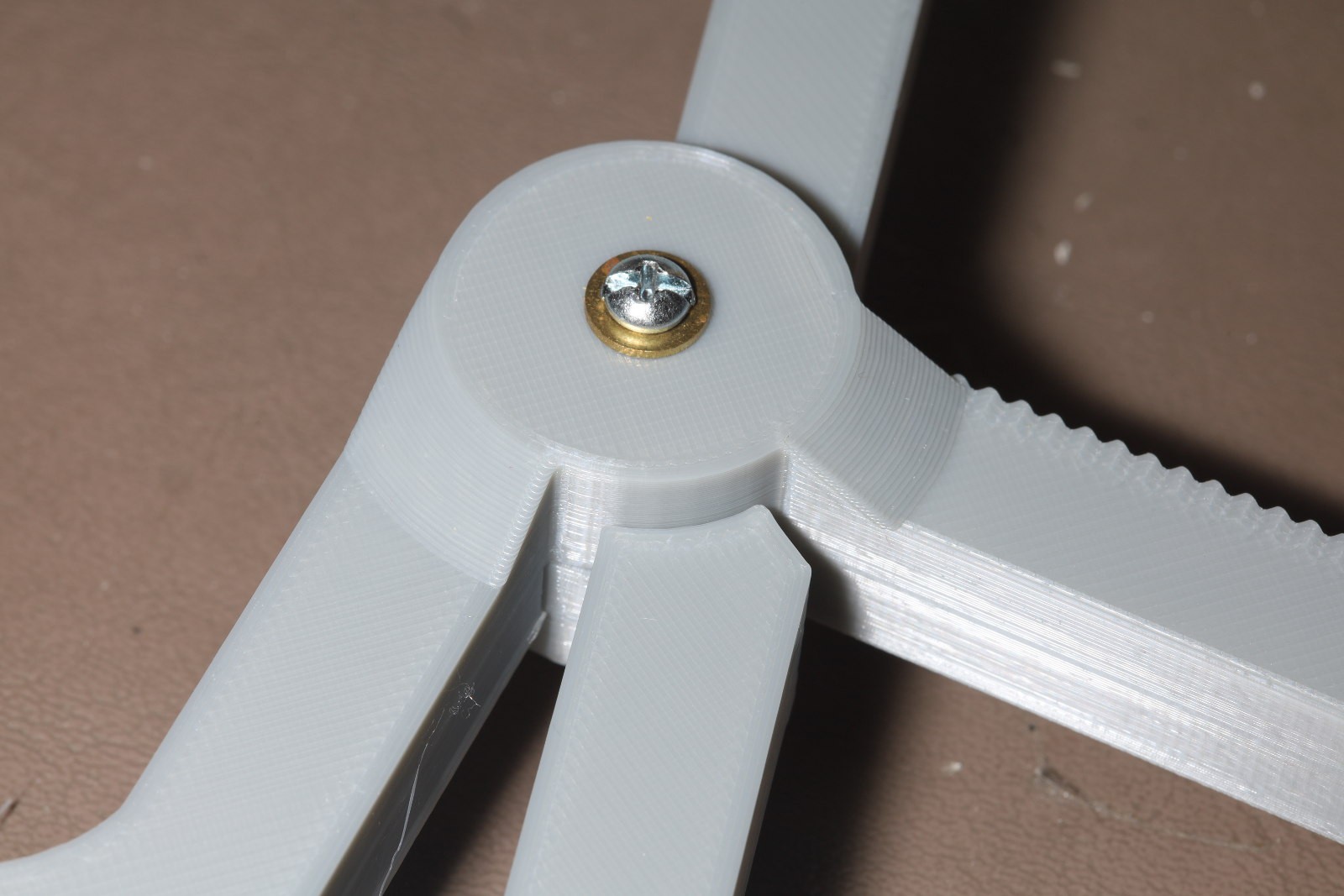

The key challenge was the ratchet mechanism. It could be improved with sawtooth teeth & a slightly smaller spring handle. Making it snug enough required heating the PLA & nudging it just a mane hair. In CAD, the solution would be not providing any clearance between the teeth while providing a 0.2mm expansion clearance between the sliding parts.

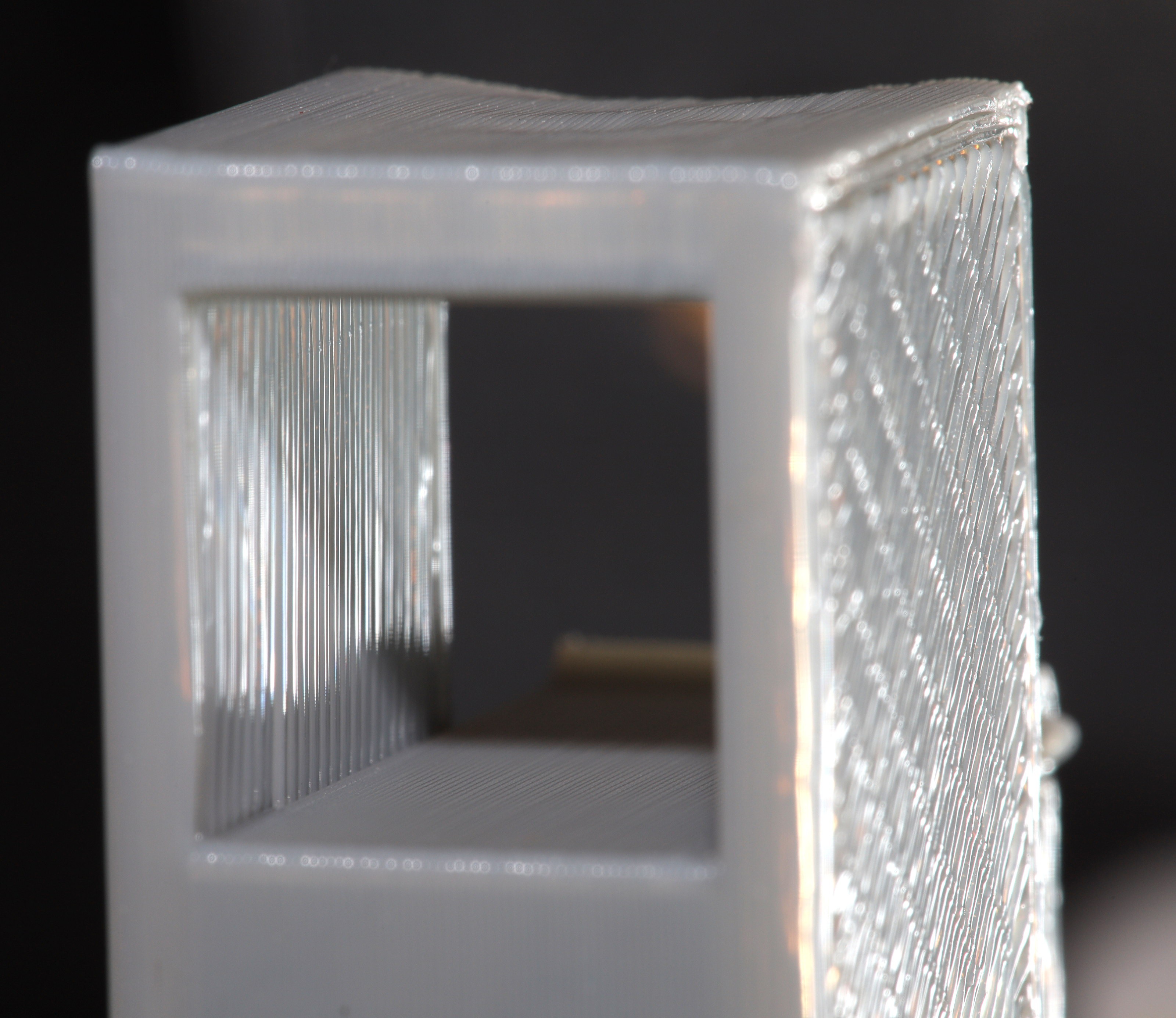

The printer managed to span the sliding part without supports.

The hinge worked well.

TODO:

Taper & round the grabbing ends so they slosh less fluid

Use sawtooth ratchets

Shrink the spring handle

Shrink the ratchet clearance

Add a ratchet to the scissor handle. Just tightening the mane bolt may be good enough.

Thinner sliding rods that taper into the same ratchet surface.

Make the bottom completely flat instead of using fillets with support to make it smooth & prevent chemicals from leeching into the spagetti.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.