Please Note: Before I get any further into this; this is a research project. I would love to have a finished product at the end of this, but I am aware from the start that this is not likely to work.

What am I doing?

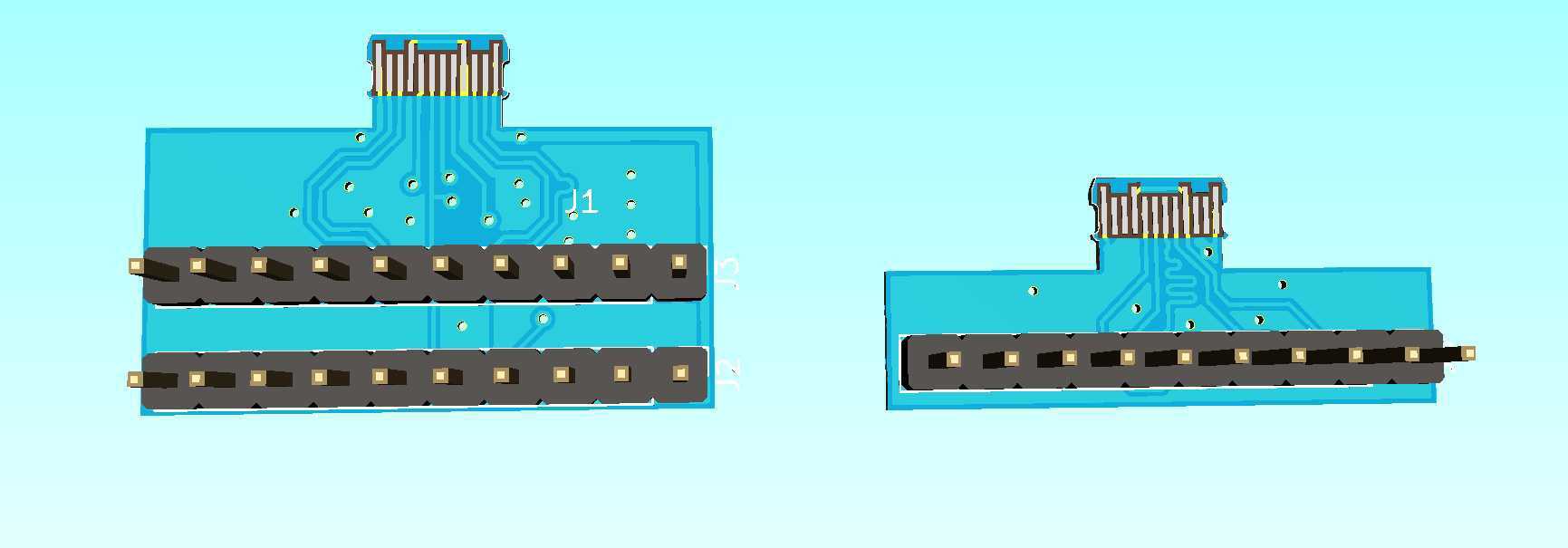

In this project I want to answer once and for all. "Is it possible to create a USB-C socket with PCB material to remove the need to use a USB-C socket (which can be quite expensive in some cases)?

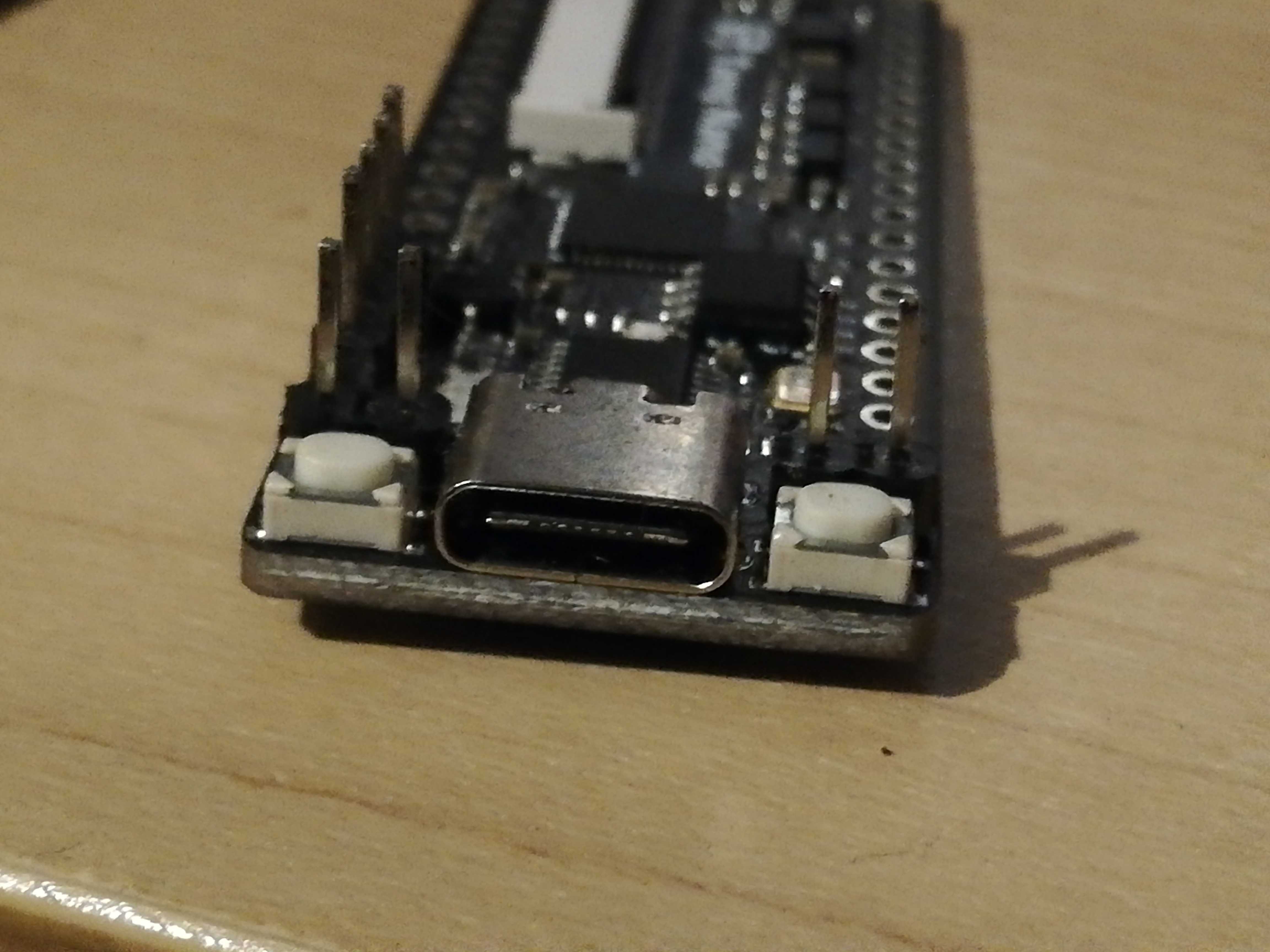

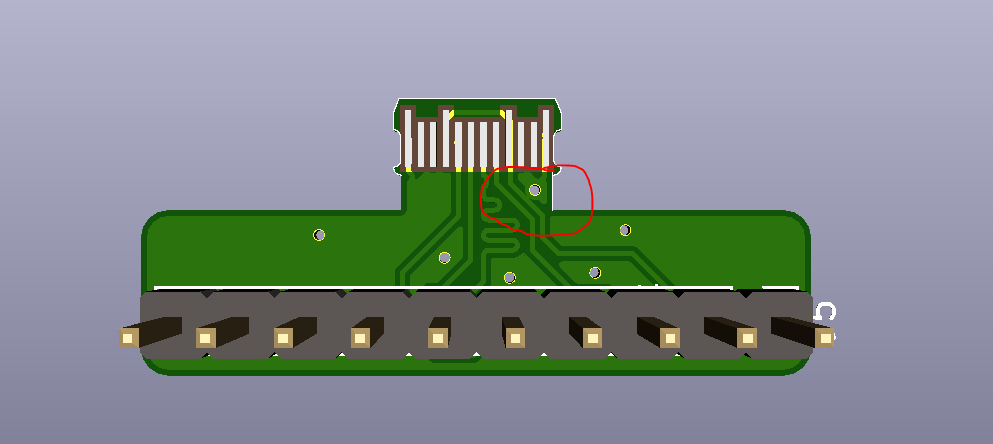

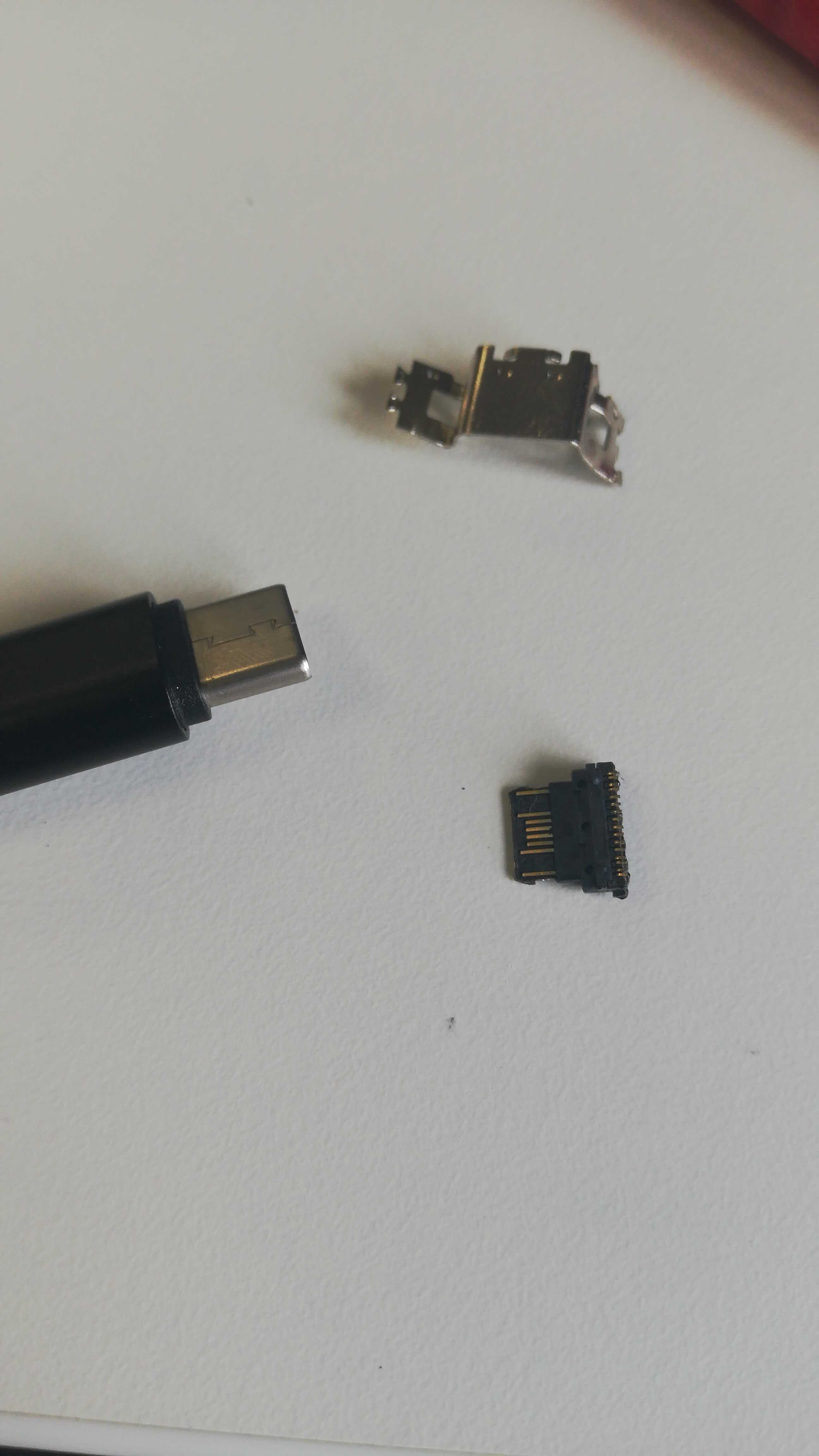

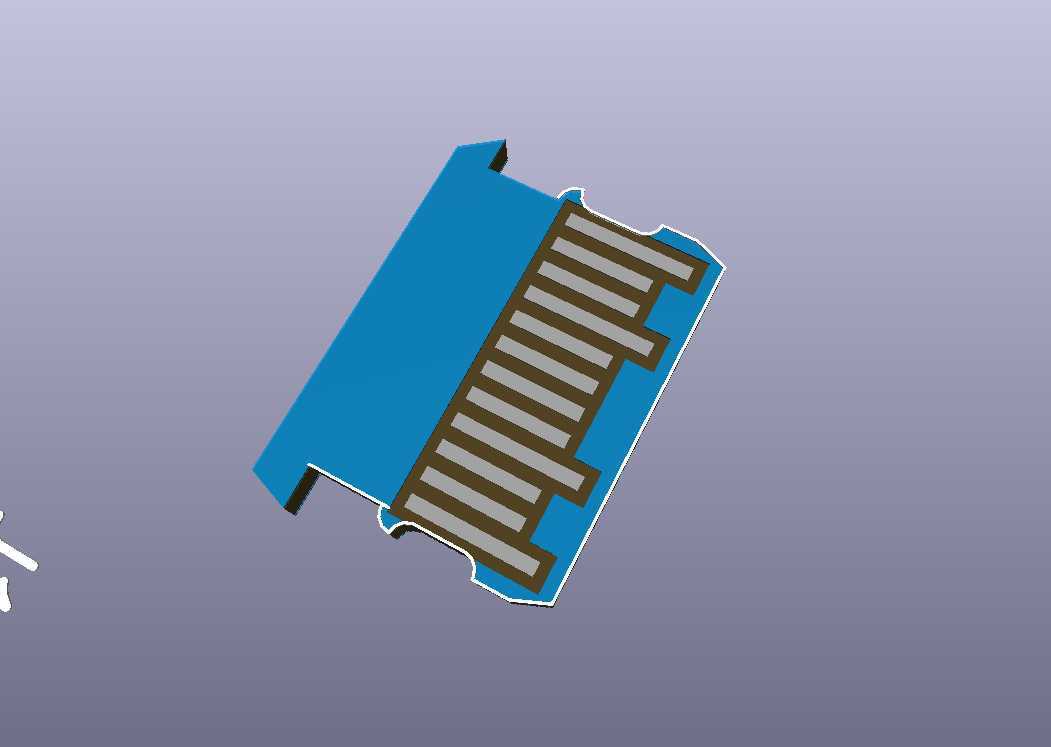

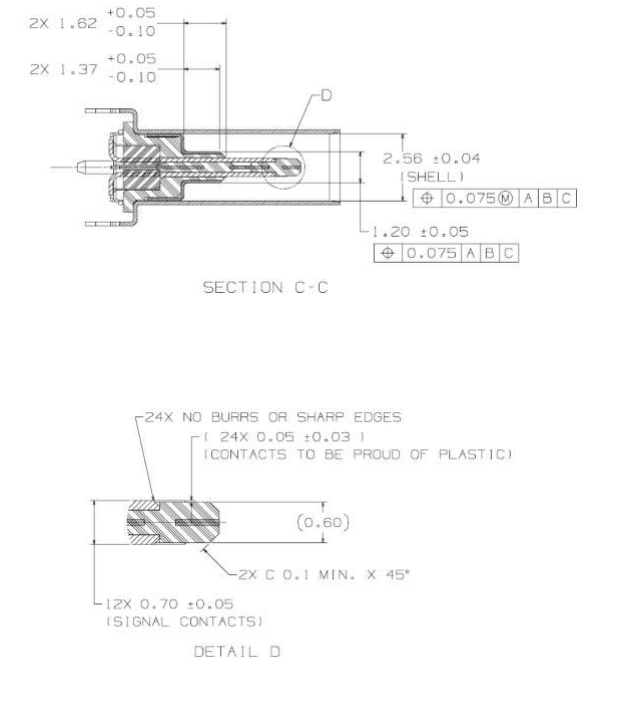

USB-C sockets use a thin tongue to connect with up to 24 contacts inside the USB-C plug, i'm hoping this can be recreated using a PCB.

Why am I doing this?

When I first thought of using this method the first thing I did was go to google and ask if anyone had ever tried this before. I have seen plenty of examples of using PCB pads as a USB-A plug and even an example of a Micro-USB socket mimicked on a PCB. But there was no obvious examples of this before.

I was intrigued that there was so little information available especially as USB-C is starting to become a staple of the engineering and maker communities.

Has this been done before?

After talking about my first initial PCB prototypes on twitter, it was brought to my attention this in fact, had been tried by a few engineers and designers on some of their own boards.

This is a design by Jan Henrik Hemsing. He states that he had connection issues and had to use an outer casing

The EFM8UB1 Breakout seems to be able to use it quite effectively which can be found here

There was also attempts by Bobricus

And also by Deshipu

But unfortunately not much success in those cases.

Disclosure: I'm sorry if there are others, the above are the only ones brought to my attention.

SO, (once again) Why am I doing this?

I feel most of the people who have tried this method have been taking the approach of adding it to a product design. Which is creative and astounding work and I am very grateful for the insight it provides. Adding it to a product can be difficult because if it doesn't return a satisfactory result then the whole thing is normally dropped for a more tried and tested method. Honestly, I would do exactly the same in those cases. But I would like to take a deep dive into the question of is this method possible, given material cost and manufacturing constraints.

What am i trying to achieve?

What I want to achieve from this is:

- answer the question of 'Can this work?'

- Find what the constraints are.

- Fully document what happens at each stage of this investigation.

- Provide all my working files during and at the end of this process.

- If this doesn't work, explain in detail why it doesn't work.

Wish me luck :) I hope I can do this Justice.

Gee Bartlett

Gee Bartlett

that's so neat, looking for more