-

1Details from the Build Process

This is not the complete build instructions, perhaps I will add that in the future. This is more to show some of the details of the project.

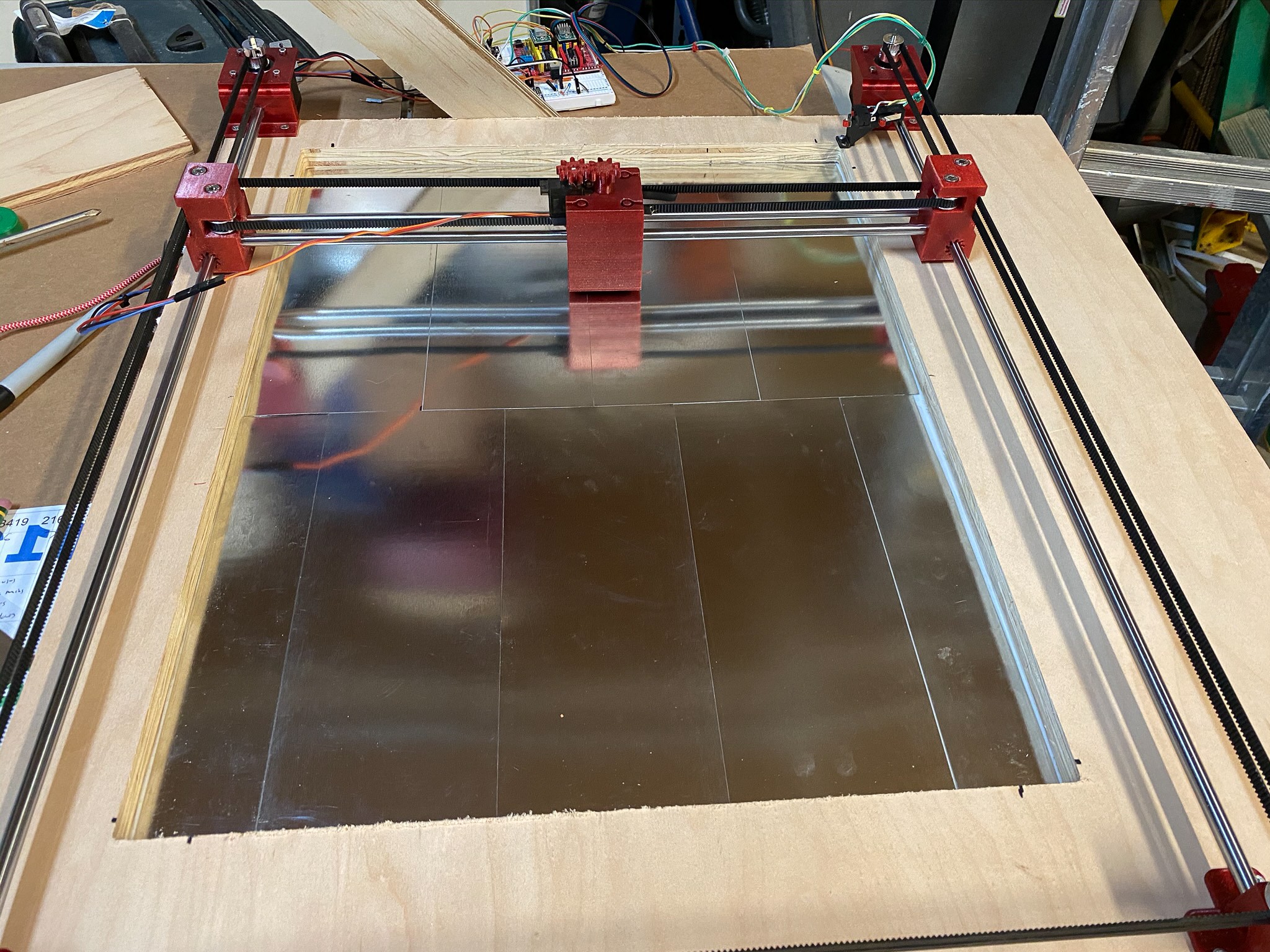

The plywood xwas cut using a CNC router to make a 1/16" deep pocket for the Plexiglas. The CNC makes a rounded corner (1/8" when using a 1/4" bit). So I cut the Plexiglas on a laser cutter to get a nice fit.

![]()

![]()

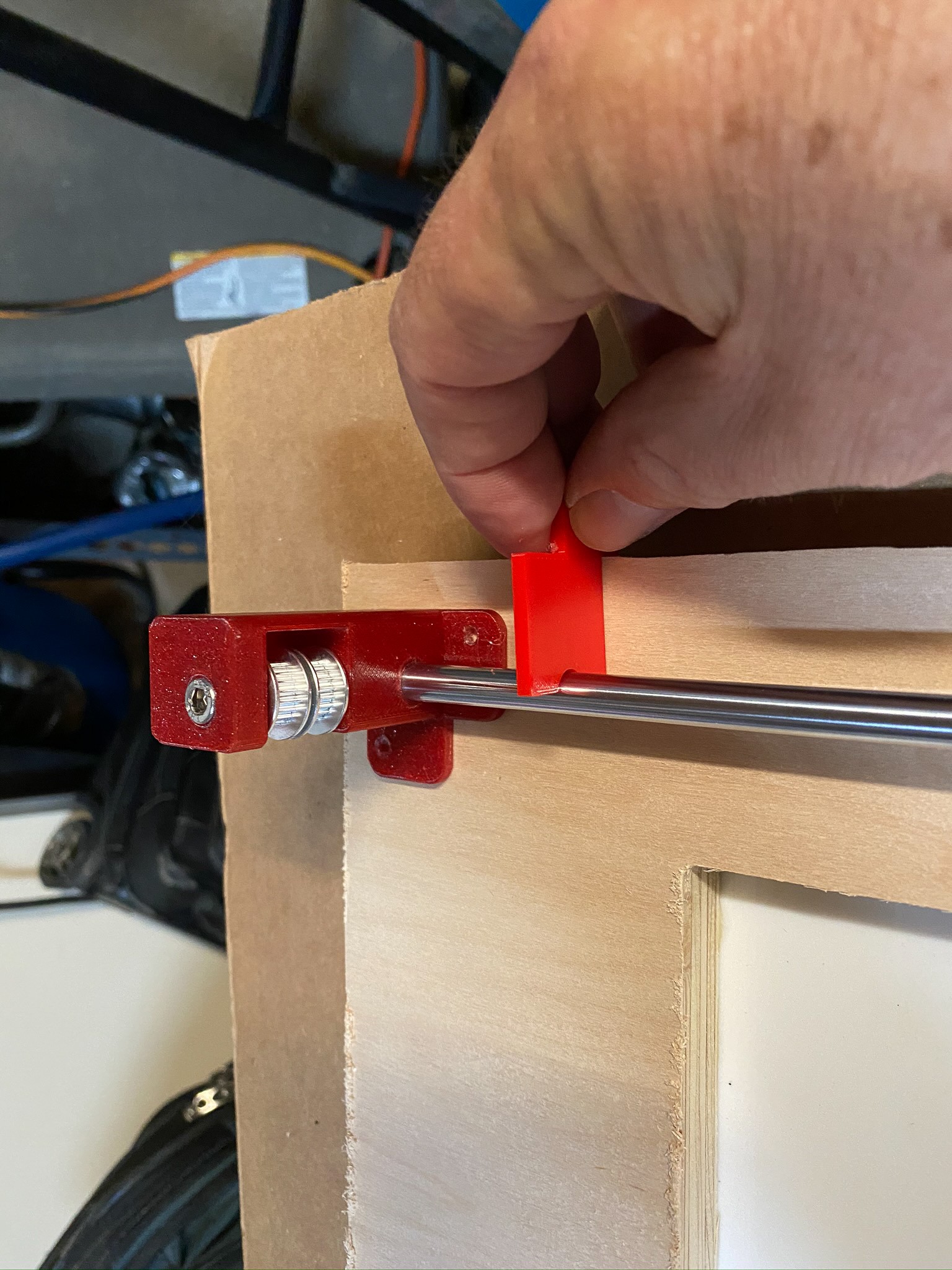

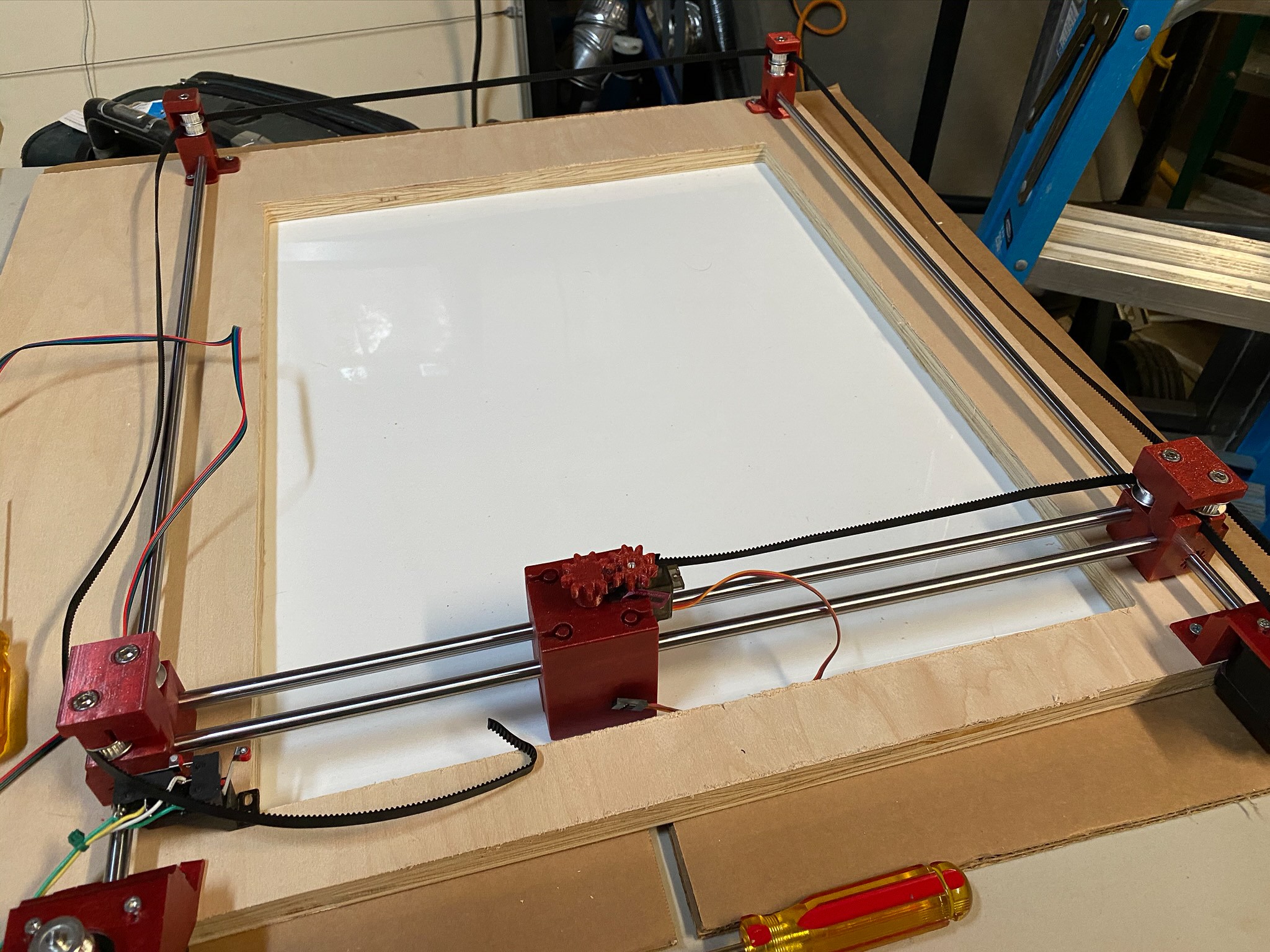

When mounting the CoreXY components onto the plywood I needed to make sure the guide rods where parallel. So I 3D printed a gauge to make sure the first rod was parallel to the edge of the plywood.

![]()

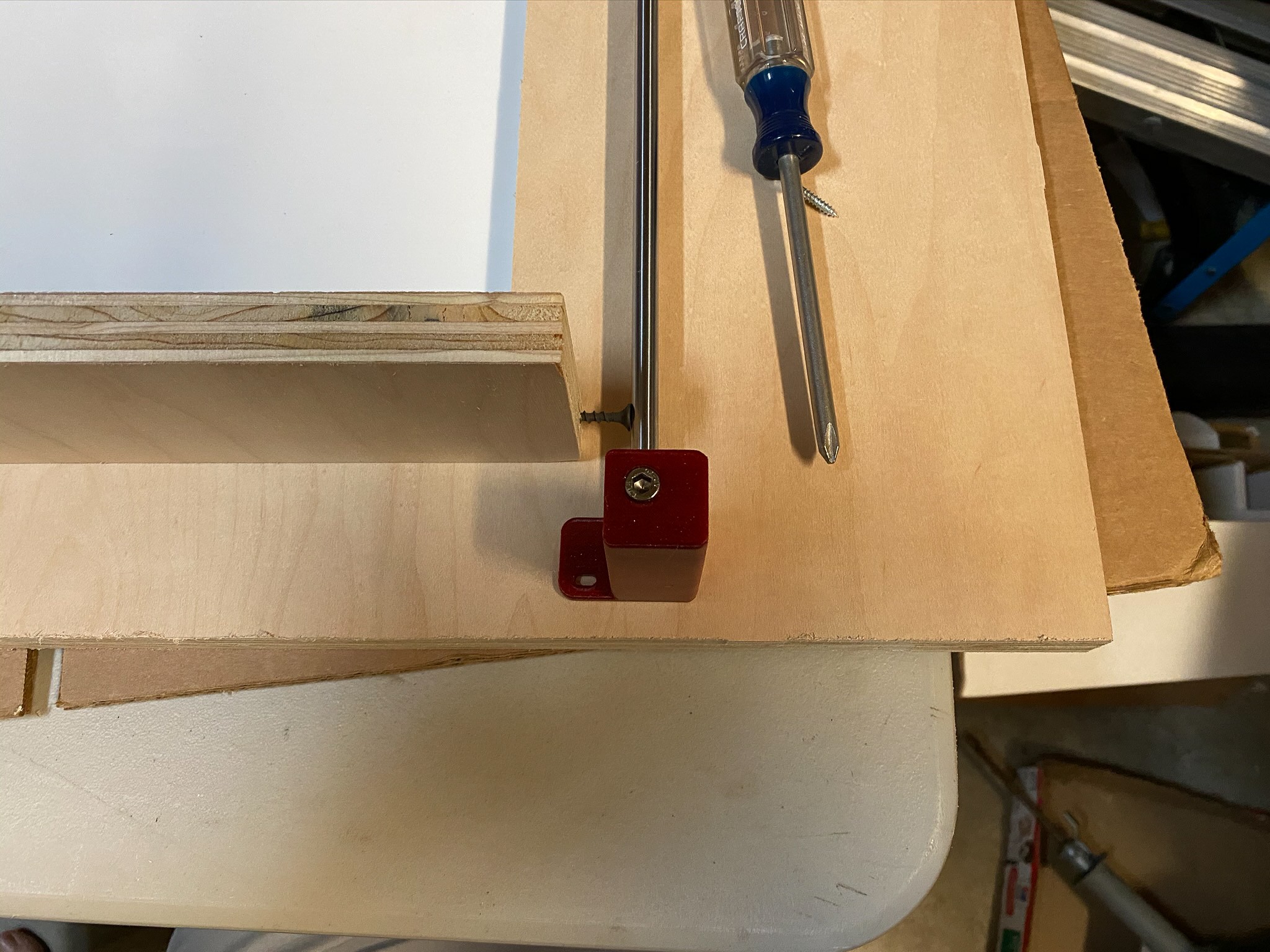

For the 2nd rod I took a scrap of plywood and put a screw into it so I could make precise spacing between the 1st and 2nd rods and to make sure they were parallel.

![]()

![]()

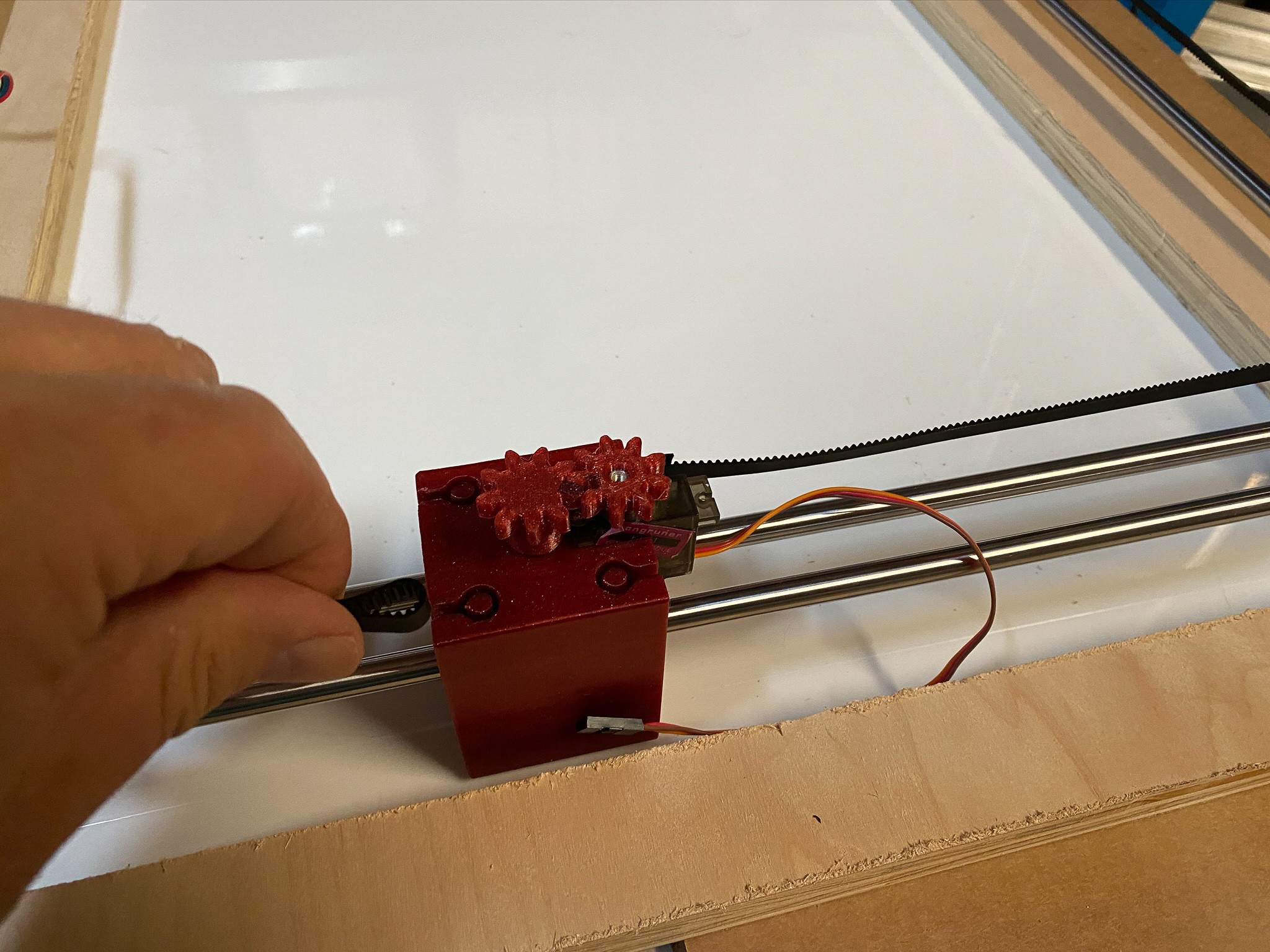

Next came the timing belts.

![]()

![]()

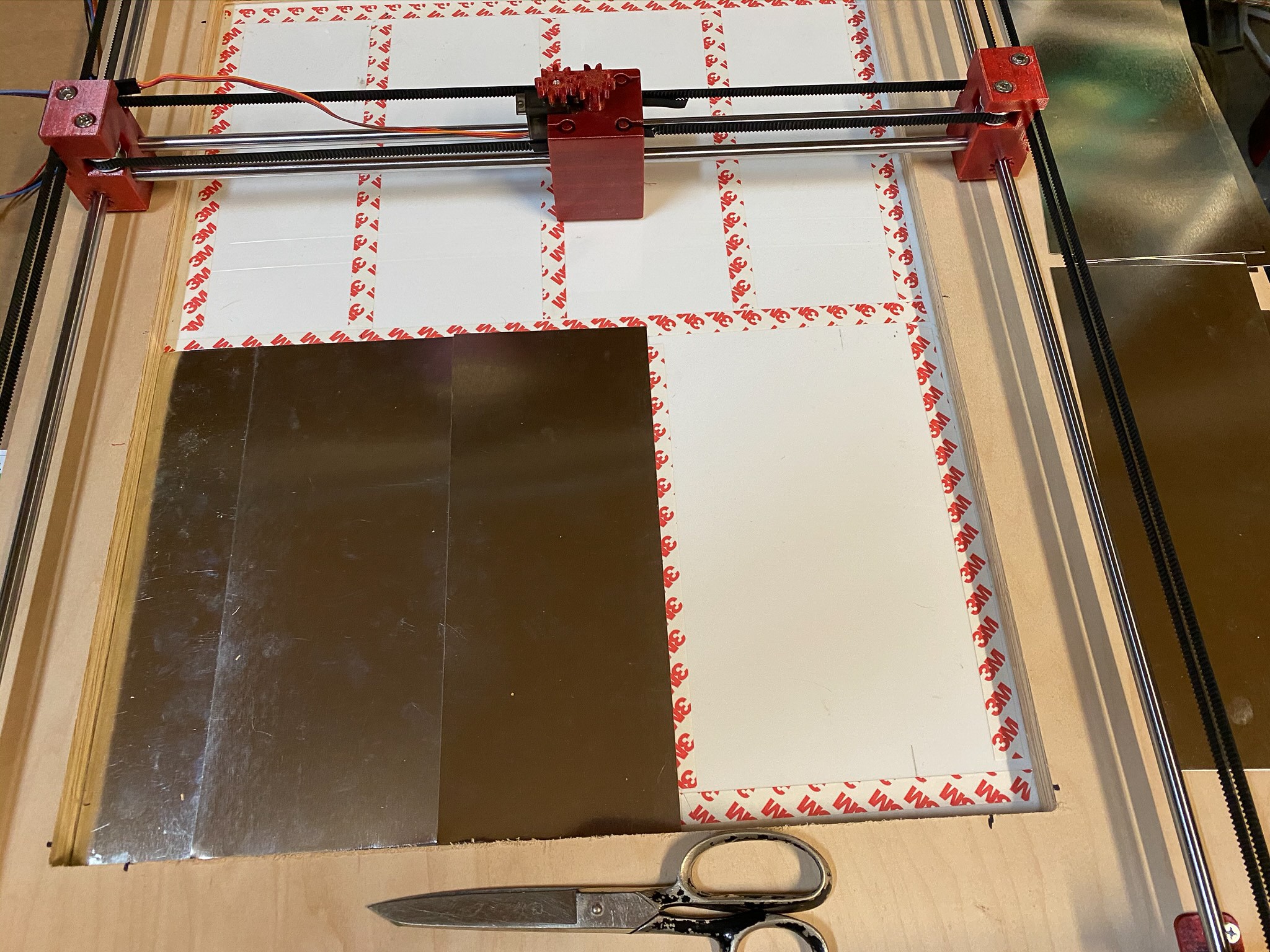

I had difficulty sourcing a large sheet of 36ga sheet metal so I used a bunch of 10" x 4" pieces which I attached with 3M double sided tape.

![]()

![]()

The numbers are all 3d printed and I used Super Glue to attach the 6mmX3mm magnets

![]()

Refrigerator Magnet Clock

A clock that uses children's magnetic alphabet numbers to display the time.

Craig Colvin

Craig Colvin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.