-

First Grow!!

08/31/2020 at 05:05 • 0 commentsIn order to try and simplify the process, I planted the seeds directly into the system instead of doing a separate process and transferring them in later. For the time being, they have to be watered by hand until the roots grow long enough. I wanted to test doing it this way, hoping to reduce the amount of human interaction required. One problem that may arise is whether or not the roots will find their way through the gaps in the net pots; if not, I will have to see if I can find another method to directly plant them. Now that the seeds have sprouted, I set the light on 8 hour intervals. There is also a fan that circulates air to both reduce tip burn and help the sprouts grow stronger.

The next step will be to get the gantry mounted to the frame and get it moving. Once it's moving between all the growing spots, I can start automating tasks.

-

Gantry

08/31/2020 at 04:52 • 0 commentsUsing more 1"x1" aluminum extrusion, I made a frame for the y and z motion of the gantry. The y motion is similar to the x motion; a pair of linear rails with bearings will allow it to slide freely with the motion being controlled by the motor(s). The z axis is using a lead screw to control the motion, with a linear rail to help guide everything. For simplicity, I used a 3D printer bed for the main plate that mounts to the bearings for the y direction. This frame will mount to the bearings on the x-axis linear rails and slide freely within the system. The linear rails will need to be cut to length, but the hardened material will require me to find a different way to cut it aside from the band saw I've been using up to this point.

-

System Plumbing

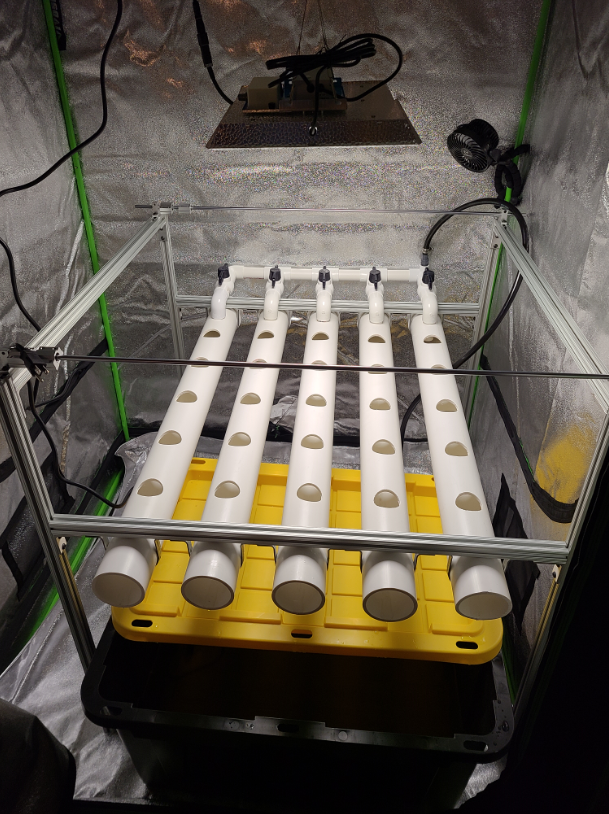

08/31/2020 at 04:43 • 0 commentsAs I planned on using 2" net pots for growing the lettuce, I decided to use 3" PVC tubing for the main tracks. This size of tubing, combined with the dimensions of the frame, allow for and even 5x5 grid for the net pots. The net pots are evenly spaced from each other at 6" in both the x and y directions, allowing for easier setup with our program later. I used 1" PVC for the end where the water flows into the system with ball valves to allow for flow control.

The main difference with the plumbing in my current system is that the tracks are not all connected together. In most system of this size, the tubes would be positioned in a way that water flowed into the system from one track and traveled through all of them before being deposited by the last track. There are a couple of reasons that I chose to feed each track individually, primarily for the gantry and flow control. The current layout allows me to put all the tracks at the same heights, making it easier for our gantry to interact with each position. In addition, I put valves on each track to control their flows individually. The reason I want to control the flows individually is because the track closest to the water inlet will always be stronger than the one farthest. Also, if someone wants to stagger the grow period of each track (to have some lettuce each week as opposed to a lot of lettuce all at once, for example), they can cut the flow to the tracks currently not in use. -

Aluminum Frame Completed

08/31/2020 at 04:30 • 0 commentsI ordered 8' lengths of 1"x1" aluminum extrusion and 2"x2" L-bracket to cut down into parts for the aluminum frame. The frame was designed to be a 3' cube, so there wasn't much to be done to the aluminum extrusion besides cutting it to length. The L-bracket required a little more work as it had to be cut down into 1" thick brackets, then have two holes drilled in each side for screws. The process wasn't difficult, but it took a while to make all of the needed brackets with a few extra just in case.

The reason I chose aluminum extrusion is because it is readily available, relatively cheap, and easy to use. Assembly is simple once you have the brackets, requiring just 1/4-20 T-nuts and screws to put it all together. I also set up the linear rods for the x-axis motion along the top of the frame.

Automated Hydroponic Garden

An NFT hydroponic setup integrated with a gantry to allow for automated processes.

rgleason92

rgleason92