-

Side project: Soldering iron stand

09/24/2020 at 11:27 • 0 commentsAs I was going to design the station housing, iron handle etc. I thought I might as well design a proper stand for the tips as well.

The result is a soldering iron stand that works with RTP, RTM and RTU tips. To my surprise, the stand works very well with the TS80 and TS100 too! I am sure the later two in the compatibility list would make this design appeal to a large audience, so I decided to publish the design on thingiverse as well, which is my first time.

The iron rest can be tilted within a 25 degree range, and is printed in PPS, a wonderful FDM material that is wayyyyy underrated. I believe this is the highest temperature resistant plastic that can still be printed with an open-frame FDM printer, unlike filaments like PEI and PEEK. You could print PPS on a stock Prusa i3 MK3 and the resulting part would work in temperatures upwards of 200 deg C. Perhaps I'll share the print settings if there are interest in the material. Oh and did I also mention PPS is reasonably priced at 27USD per kg? I love PPS.

Link to the thingiverse thing here: https://www.thingiverse.com/thing:4605456

(It might take 24 hours from the time of publishing of this article before you can access the thing, I am a new thingiverse user)

![]()

![]()

![]()

![]()

![]()

-

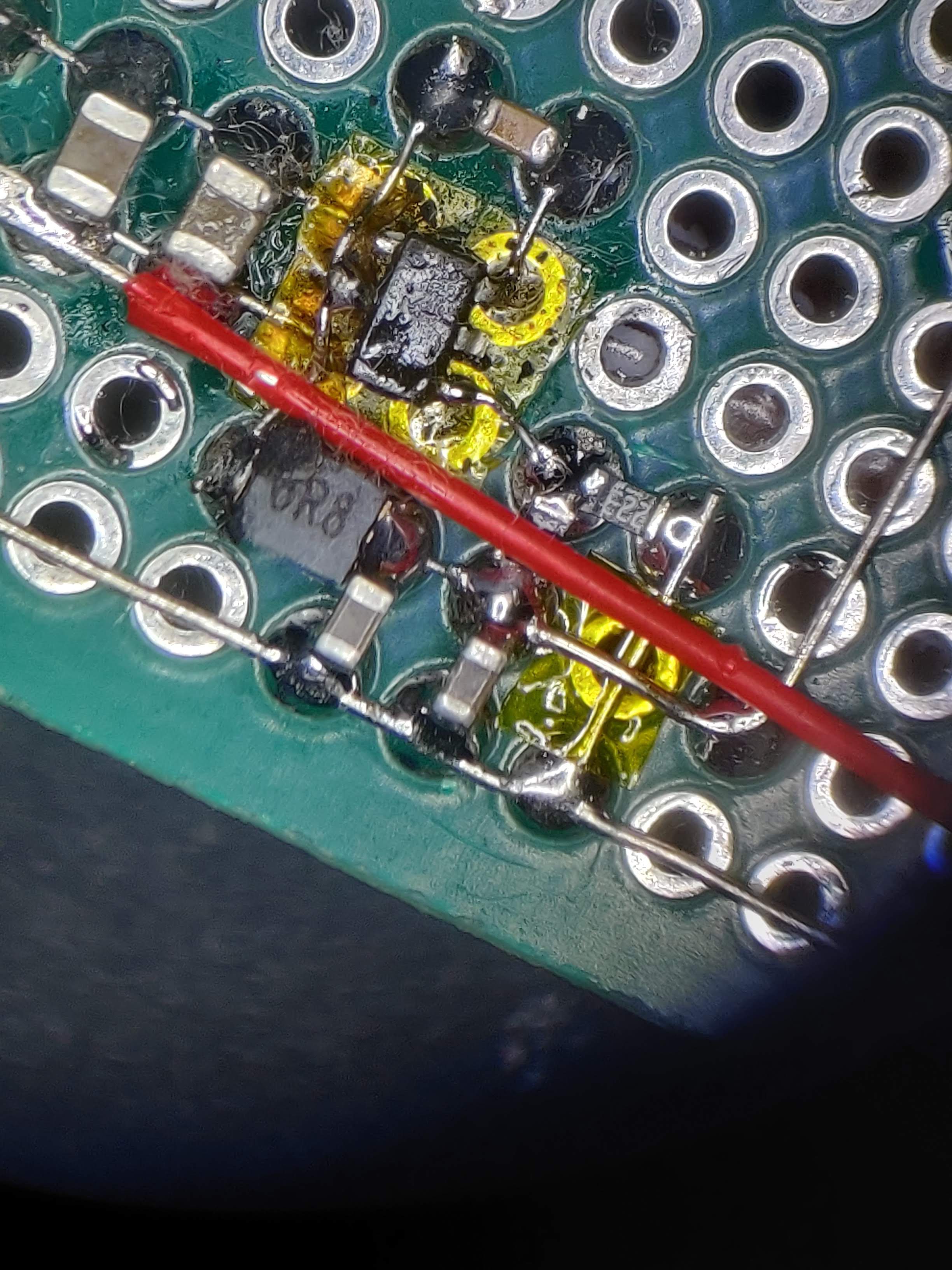

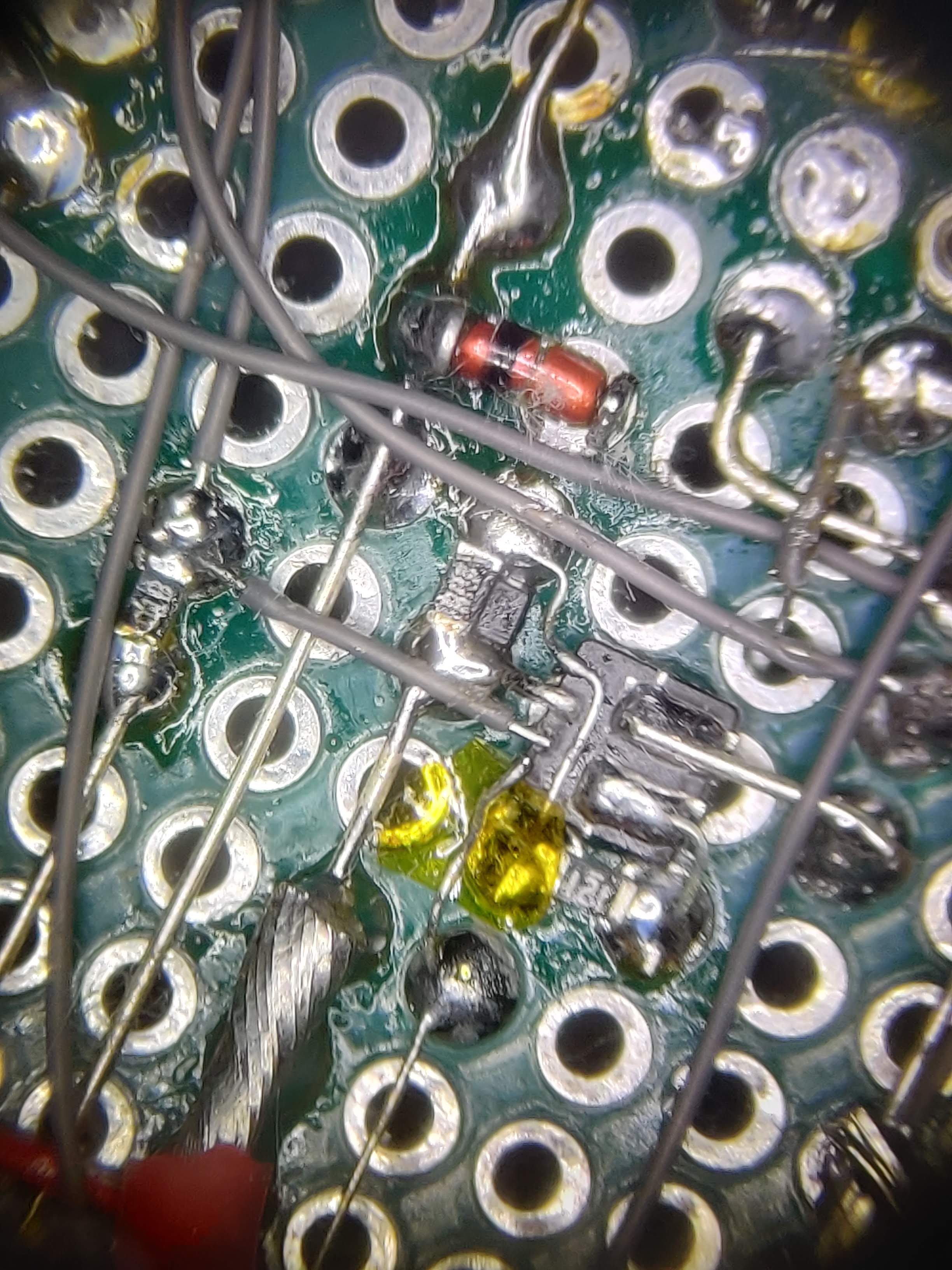

Perfboard prototype

09/01/2020 at 15:26 • 0 commentsAs I've mentioned in the project description, I started the project with a pen form factor controller in mind. So when I started to build the perfboard prototype, I decided to construct the prototype with exactly the same components as I would in a compact pen-sized PCB. This resulted in tiny components glued into a perfboard and soldered dead-bug style. Some of the more extreme circuit sections included the DC-DC buck converter and the power switch for the iron. The DC-DC converter was constructed to minimize the AC loop, and the resulting size of the converter circuit would not be much smaller on a proper PCB layout.

![]()

The soldering iron tip power switch was a p-ch and n-ch dual fet squeezed in to a 3x3mm dfn-8 package, and as you can imagine, it was a pain to solder. At this point you may wonder how bad would reworking this circuit construction be, and the answer would be surprise you. I once accidentally revered the power input and fried the DC-DC converter chip, and rework only involved cutting off the IC pins, and resoldering the chip in the same position. The process was not that much worse than working on a proper PCB.

![]()

After testing the perfboard prototype I decided to go for a desktop station form factor, where using larger parts would not be an issue, so this self-inflicted microsoldering hell is a bit moot.

Soldering station for Weller RTP/RTM/RTU tips

A soldering station designed to work effortlessly with Weller RT pico, RT micro and RT Ultra tips.