Construction

I found 1M x 100MM copper foil on aliexpress and also got some 100MM Kapton tape as the plastic backing. I simply cut about 100MM x 100MM of each and stuck the copper to the Kapton tape.

Etching

As a quick test, I wanted to see what would happen if I tried to print directly on to the copper surface. After the print was done, most of the printed but some of the parts did not. I will need to see if there is a better way to print on these flexible PCBs.

Since the printing method needs work, I decided to use the direct transfer method to get the PCB image onto the copper.

I used Sodium Persulfate etchant to etch away the unwanted copper. it had been a while since I last did this and the PCB did not come out 100% great. I will need more practice at it before doing a production run of the Flexible PCBs.

The biggest problem I had with etching when the PCB was getting close to being finished, the PCB started to float. This made some areas under etching and other over etched. Over time, I can get all the methods correct.

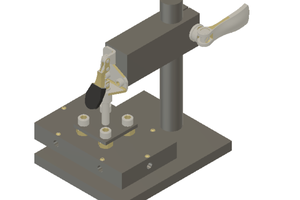

Soldering

I tried to solder to the PCBs and it was alright. The Kapton tape deformed a little. I was not sure if this was because the Kapton tape was cheap. I tried a different type of Kapton tape that I have had for a while and this tape did not deform. So the tape I got for making these flexible PCBs was fake Kapton which was very annoying. I will be trying different things to get it working

I tried to use hot air to reflow the solder, the fake Kapton just stated melting and shrinking like heat shrink but the better stuff did work. The only problem I had with the better Kapton tape is the tracks would get lifted off the tape very easily. I will try gluing the copper first to get the tracks to stay in place.

Conclusion

The PCB works but I think I can do better. I will be trying some other methods to see what else could work. I'm waiting until I finish my vinyl cutter to try to cut the PCB tracks. I will also try gluing the copper dow with epoxy.

I want to try doing a similar method with FR4 fiberglass PCBs but that will have to wait until I have time.

If more testing is successful, I want to use it for LEDs. I think these will work great with LEDs.

Tinkers Projects

Tinkers Projects

Lithium ION

Lithium ION

Andrey V

Andrey V

Jayken

Jayken

deʃhipu

deʃhipu

Very nice idea, this will change DIY PCB-manufacturing in a major way. Getting a good tape will be crucial. Keep on it!