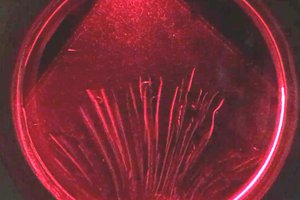

UV sterilization is provided by a 3W GTL3 UVC bulb which may also produce small amounts of ozone (depending on envelope coatings). This is ballasted by a capacitive dropper which provides the bulb ~10VAC at a couple hundred milliamps.

GTL3 bulbs have an interesting self-ignition design, they initially operate as a thermionic emitter using a filament with a negative thermal coefficient until a sufficient mercury plasma is generated in the envelope. The plasma cloud then conducts the majority of the current once the filament reaches a high-resistance state. AC operation is preferred over DC to prevent premature erosion of one end of the filament.

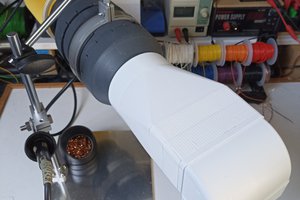

Airflow is provided by an inexpensive computer case fan operating at 12V. Due to the simplicity of the circuit and inherent safety of a fully enclosed device another capacitive dropper is used, followed by a full bridge rectifier and zener for rough regulation.

Both capacitive droppers have bleeder resistors in parallel with the class X capacitors to prevent shocks off the end of the cable. The 120VAC input is protected with a fuse, MOV and inrush current limiter. I chose to install an in-line switch into the power cable but this is optional.

In order to maximize the exposure of the air-stream to UVC radiation the area immediately surrounding the GTL3 bulb is sheathed in aluminum foil which will reflect the radiation through the chamber multiple times as well as protect the plastic from degradation. Other surfaces of the baffle are painted with white (titanium dioxide) interior house paint for protection. According to the scientific literature TiO is an efficient absorber of UVC radiation and should reduce the amount which escapes through the baffle via reflection. It also photocatalytically destroys VOCs but I'm not clear on if a paint coating has this ability or if it requires special preparation of the TiO particles.

Jeremy Ruhland

Jeremy Ruhland

Jeroen Brinkman

Jeroen Brinkman

Vitaly

Vitaly

Sebastian Lenartowicz

Sebastian Lenartowicz

M. Bindhammer

M. Bindhammer