-

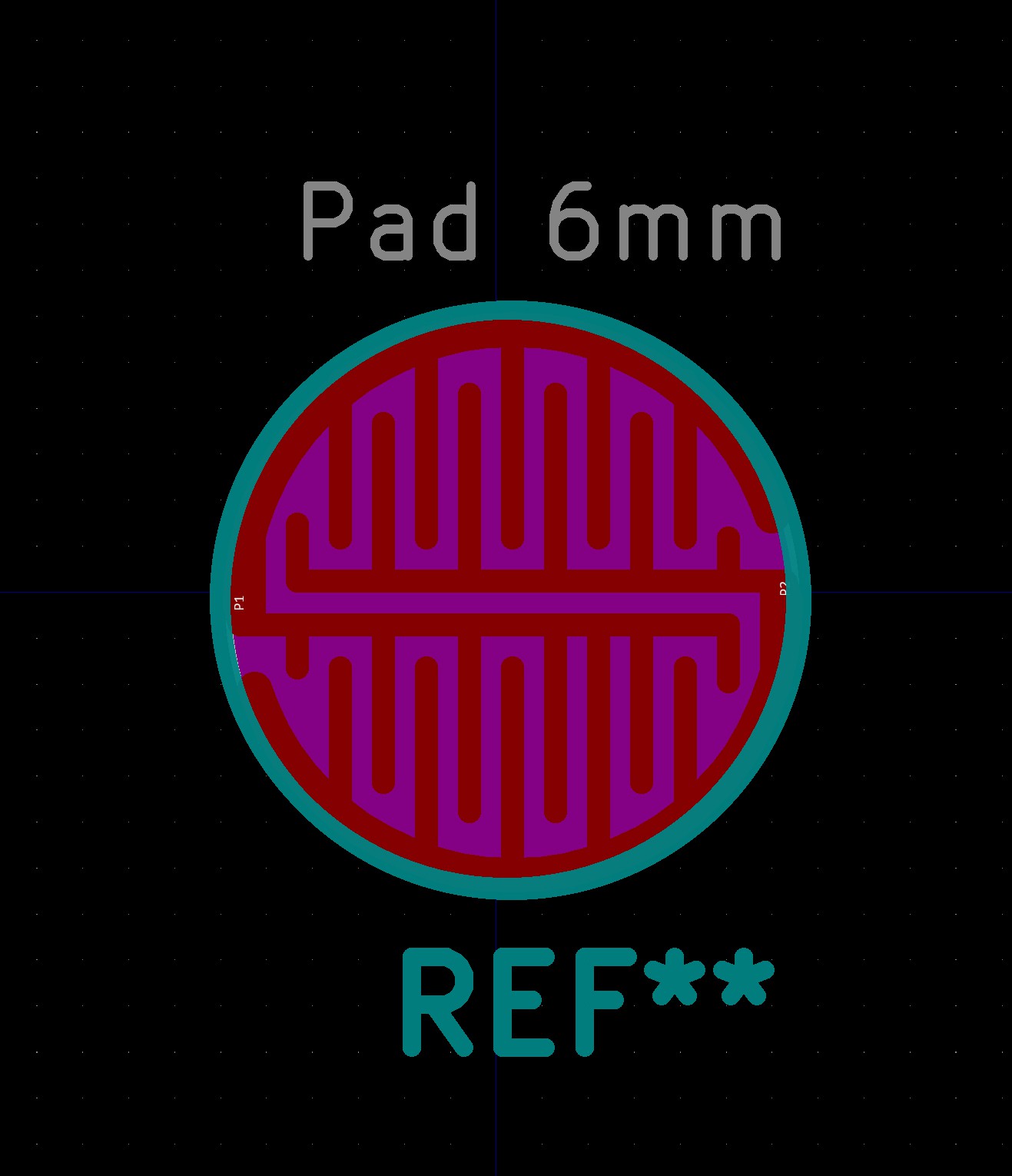

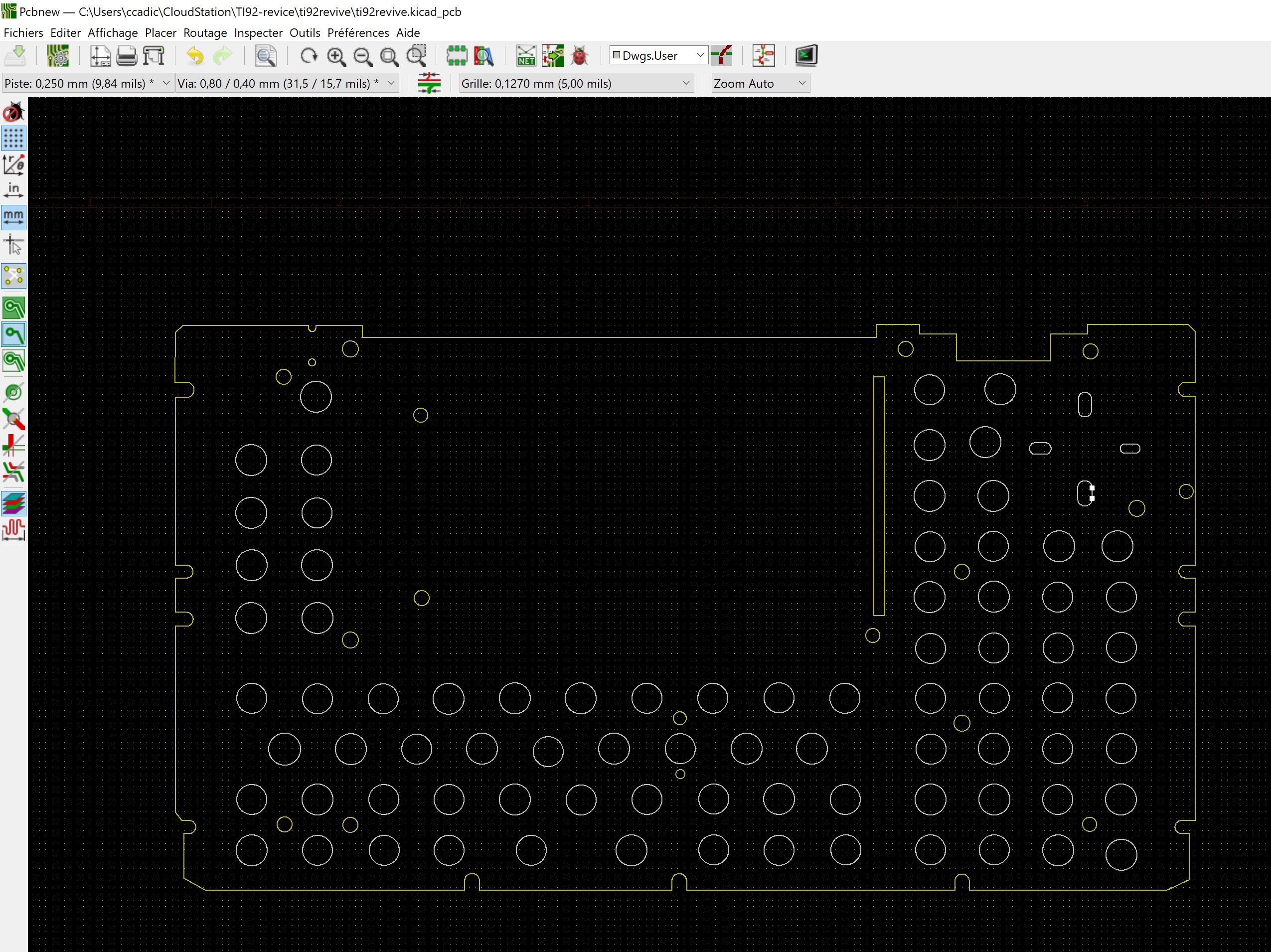

Conductive pads footprint for the keyboard

10/18/2020 at 20:13 • 1 comment![]()

I've updated the github file Kbpad.kicad_mod which is a pcb gamepad footprint. Fortunately I've made them in the past for another project. They can be reused with no problem.

![]()

-

The 4 inch ST7796 display seems to fit

10/18/2020 at 19:43 • 0 commentsIt is easy to replace the old liquid crystals display. The display is attached to a black sub board using a double sides sticker. A knife is required to detach it. I used another double side tape to attach the new color display. It fits well and it is possible to pack the all stuff together and insert the screws with no issue.

-

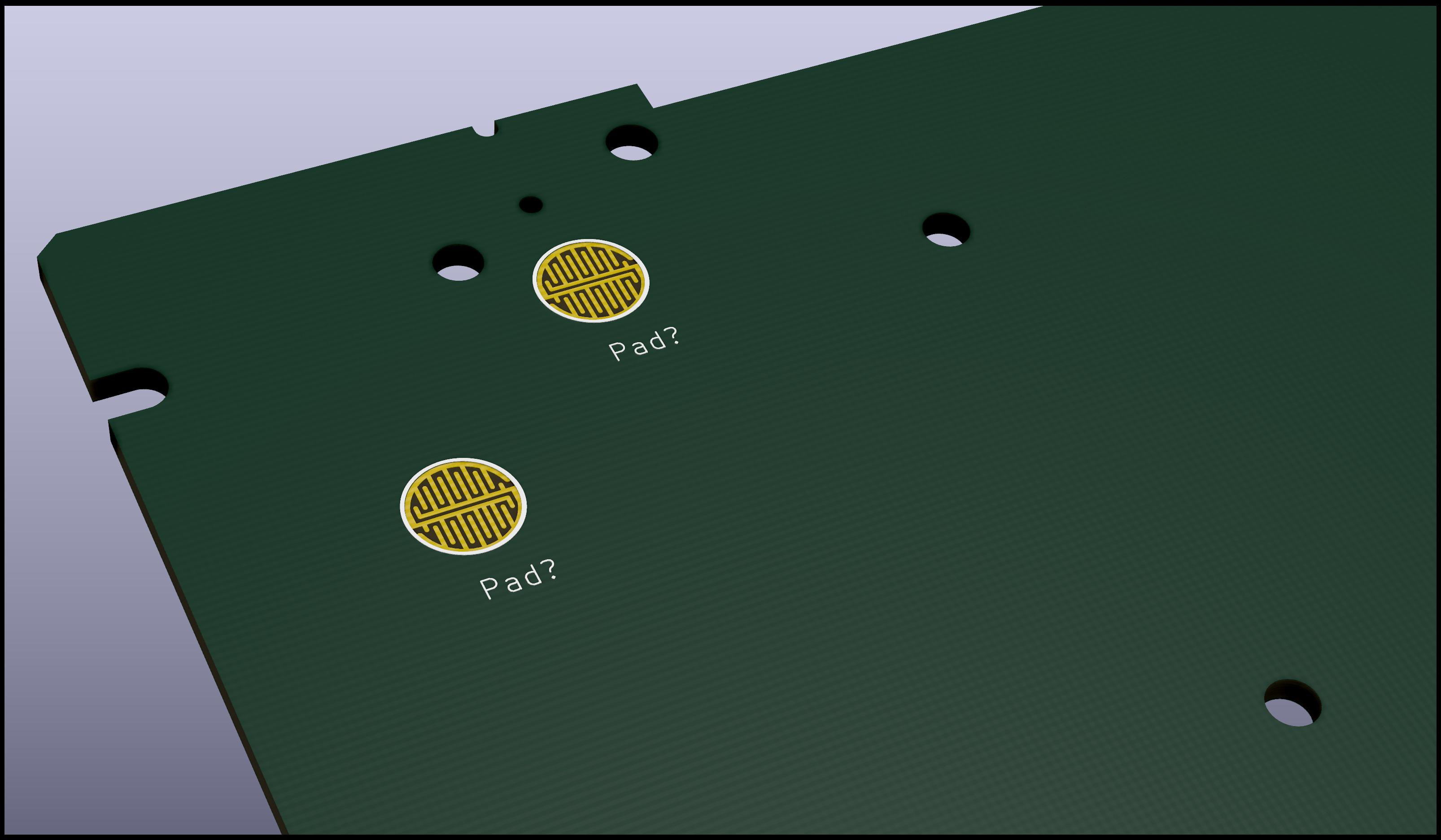

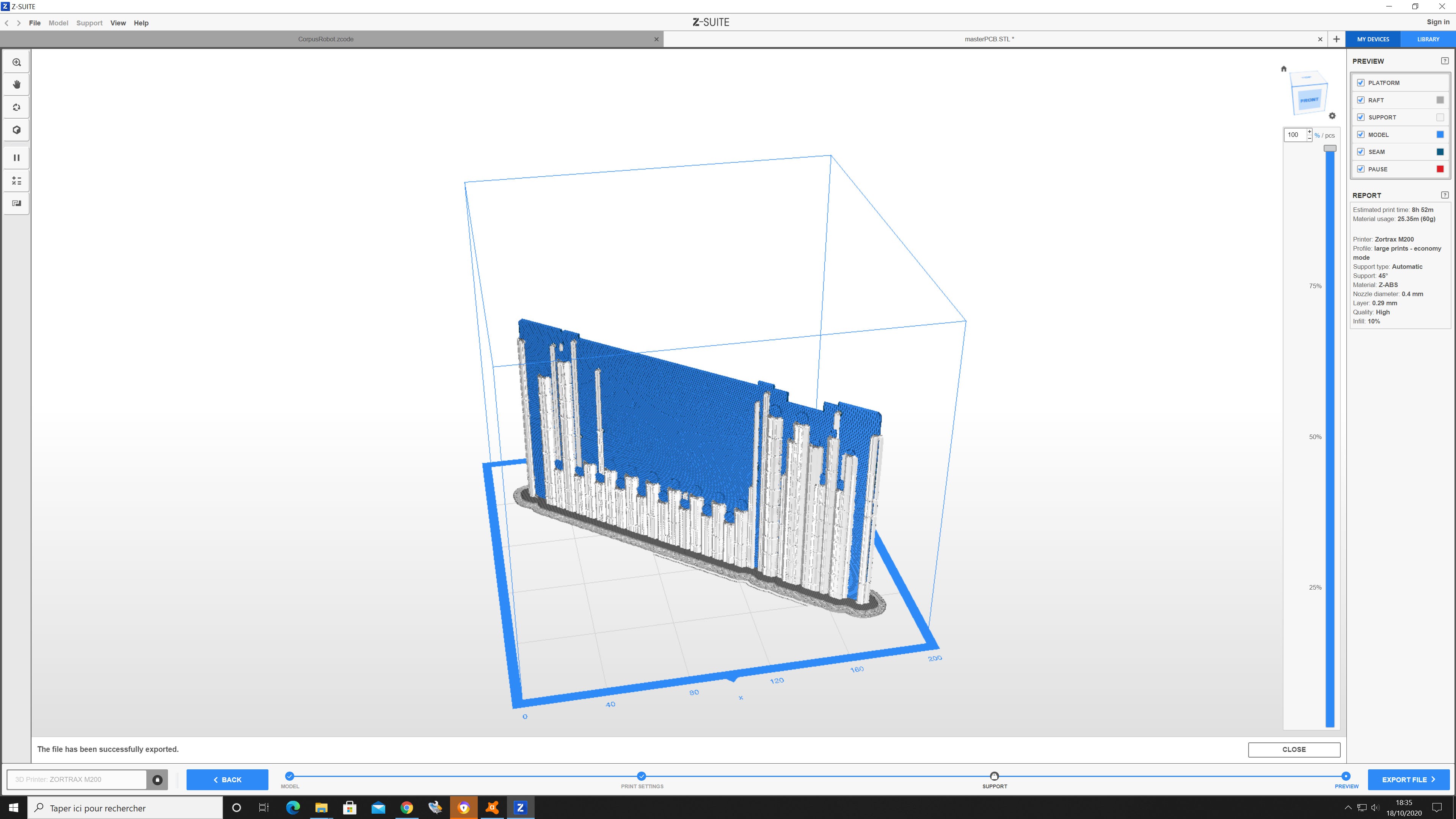

Testing the PCB (with 3D prints)

10/18/2020 at 16:39 • 0 commentsToday, we are testing to see it the designed PCB fits into the TI casing.

For this , we make a 3D printing of the board.

![]()

-

Genesis of the project

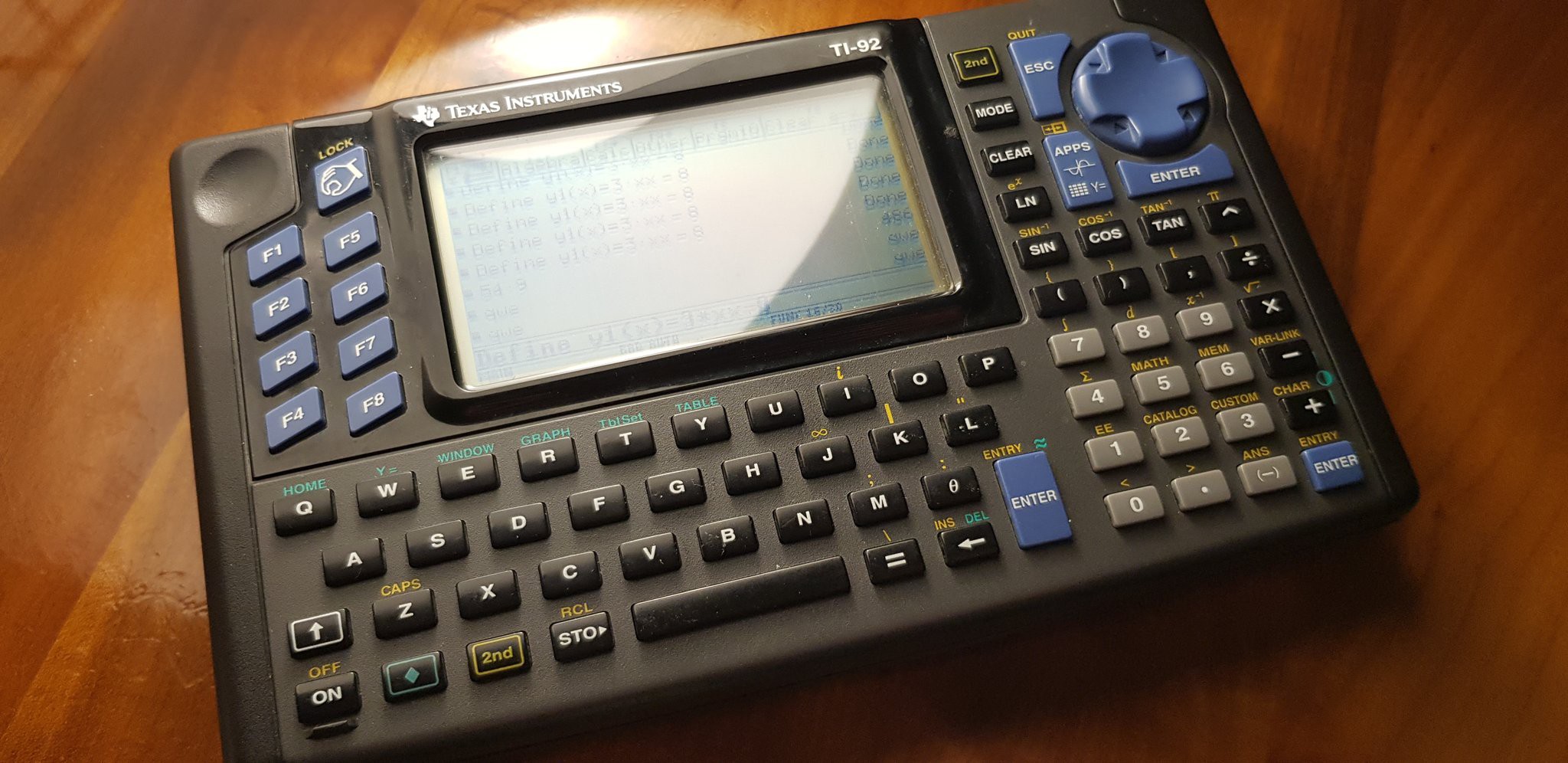

10/18/2020 at 14:25 • 0 commentsGenesis of the project.

This project started last week (10/10/2020) when I saw the tweet of @kongduino playing with an old calculator. I always wanted to design a PCB-clone to have the opportunity to replace the old board of a calculator. I wated to learn the technic to re-engineer a board.

Step 1: Choosing and getting the calculator. After a ling search over the internet , I found a strong old computer. I was seeking a device with a strong box, a strong KB, easy to open. I also needed to make sure the keyboard has enough keys to handle a true PC keyboard mapping. I also needed a joystick for the ones who will want to use retropie.

![]()

The calculator was found on ebay.fr for 39 € including shipping.

Phase 1

Finding the display. The old B/W display is crap. We want a good one with high rez and color. We found a ST7796s model with the exact same size on aliexpress.

Phase 2

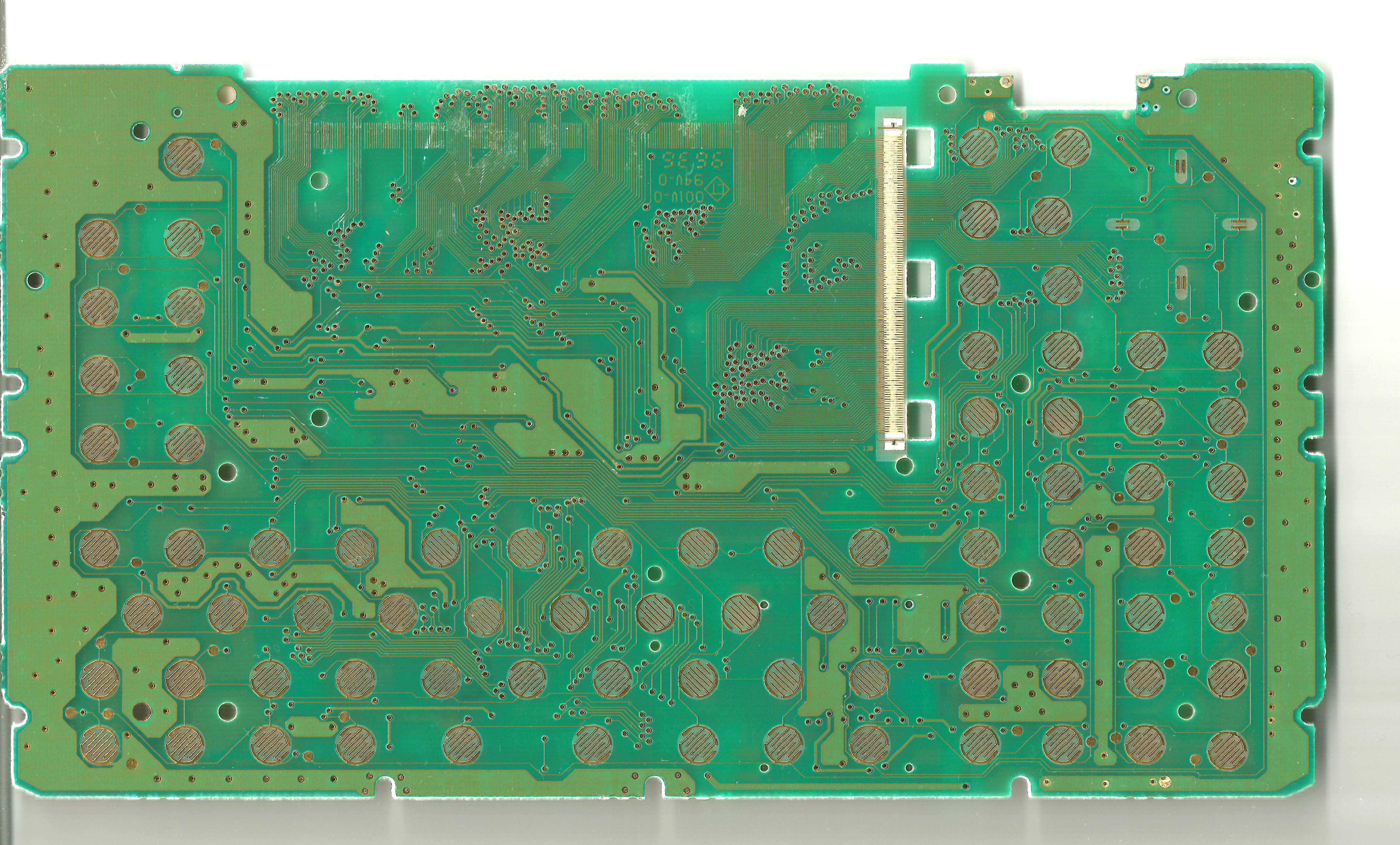

The next step was to be able to get a JPG scan of the original PCBoard. This was done opening the case, removing all the thick components to get a plane and easy to scan surface.

![]()

Once scanned, we imported the file into solidworks to resize, get the the contouring set, localize the key contacts, locate the drill holes. (You have all the files in our github) .

A cool feature of solidworks is to be able to save to DXF files. We did this and were able to import the DXF into KICAD PCBNEW software. Once done, the next step was to differenciate the EDGE.CUTS from the buttons footprints.

![]()

It is now super easy to re-use the template with your own project.

Reviving the TI-92 calculator into a RPI PC

We are re-engineering the old PCB board into a modern PCB for a simple swap. The goal is to get an up to date RPI computer

pcadic

pcadic