-

Warmup: 10-year "flashlight"

11/07/2016 at 19:38 • 0 commentsI decided to throw this together to get some experience and think through some of the issues while I wait for parts to arrive. For a flashlight, it's pretty dim, but still useful. I can easily read with it once my eyes are dark-adapted. I expect it to run for about 10 years, just based on battery capacity and current drain. There is, of course, no power switch.

![]()

Even though I don't trust 3D-printed materials to last 10 years (the QCL will use a metal case), I couldn't help throwing this into one. I used one of the #TritiLED V2.0 boards, a 1/4W 100-ohm resistor and a 2AA battery holder. I don't really trust a plastic battery case to last 10 years, either, but I had the stuff here, so I figured I'd throw together a prototype.

I don't have the time to run a bunch of serial experiments if I might have to wait a decade or two to see if each one worked - the only thing I can do is try a bunch of stuff all in parallel.

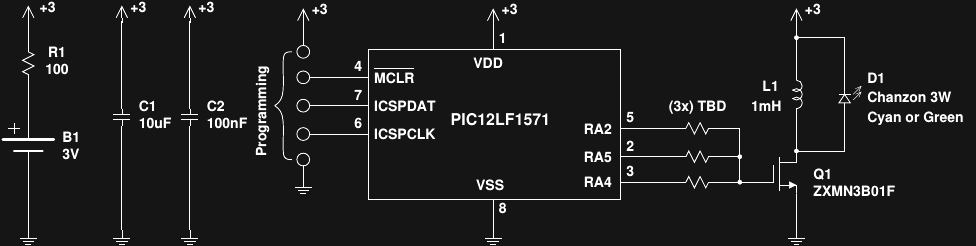

The circuit is essentially the one proposed in the last log, repeated here:

![]()

The TritiLED V2.0 PCB I had available uses only two I/O's to drive the MOSFET gate, and doesn't have sites for gate resistors, so those were omitted. I modified the code to generate 6 LED pulses per wakeup, which put the current drain in the right ballpark, then tweaked the result by changing the OSCTUNE register to get the current right. with At the 3.6V nominal voltage from 2 LiFeS2 AA batteries, I measured 39.8 uA current drain. A simple estimate of the run-time divides the 3500 mAh capacity of the cells by the current drain:Of course, as the battery voltage drops (only slightly with this chemistry at these drain rates), the current consumption also decreases, extending the battery life somewhat. If everything goes according to plan, it will run for a decade.

The assembly-language code is shown at the end of this log. The basic loop is driven by the watchdog timer, waking the PIC every 16ms to output six sawtooth LED current pulses near the peak efficiency point for the LED.

I don't know about the reliability of the WDT, and whether I can trust it to wake the part consistently for 10 years (1.97 x 10^10 times). On one hand, 20 billion times seems like a lot, but then again, the CPU in my desktop executes 20 billion instructions every few seconds. It just sounds different spread out over a number of years - but what to do? I've been thinking of external watchdogs, but then how do you ensure they don't reduce reliability? A malfunctioning watchdog could hold the PIC in continuous reset. I'll be devoting a log to the issue shortly. There don't seem to be any easy answers.

A defensive feature of the code is to reset the PIC with a software reset instruction every 256 wake-ups (4.096 seconds). This should reset any RAM values that get randomly corrupted. Finally, the entire unused program space is filled with reset instructions - if program execution somehow gets to one of those locations, the part gets reset. I'm still thinking of possible improvements to the code. As with this whole project - if you see other ways this could fail, please let me know. The more things I can consider now, the better the chance of meeting the ultimate goals.

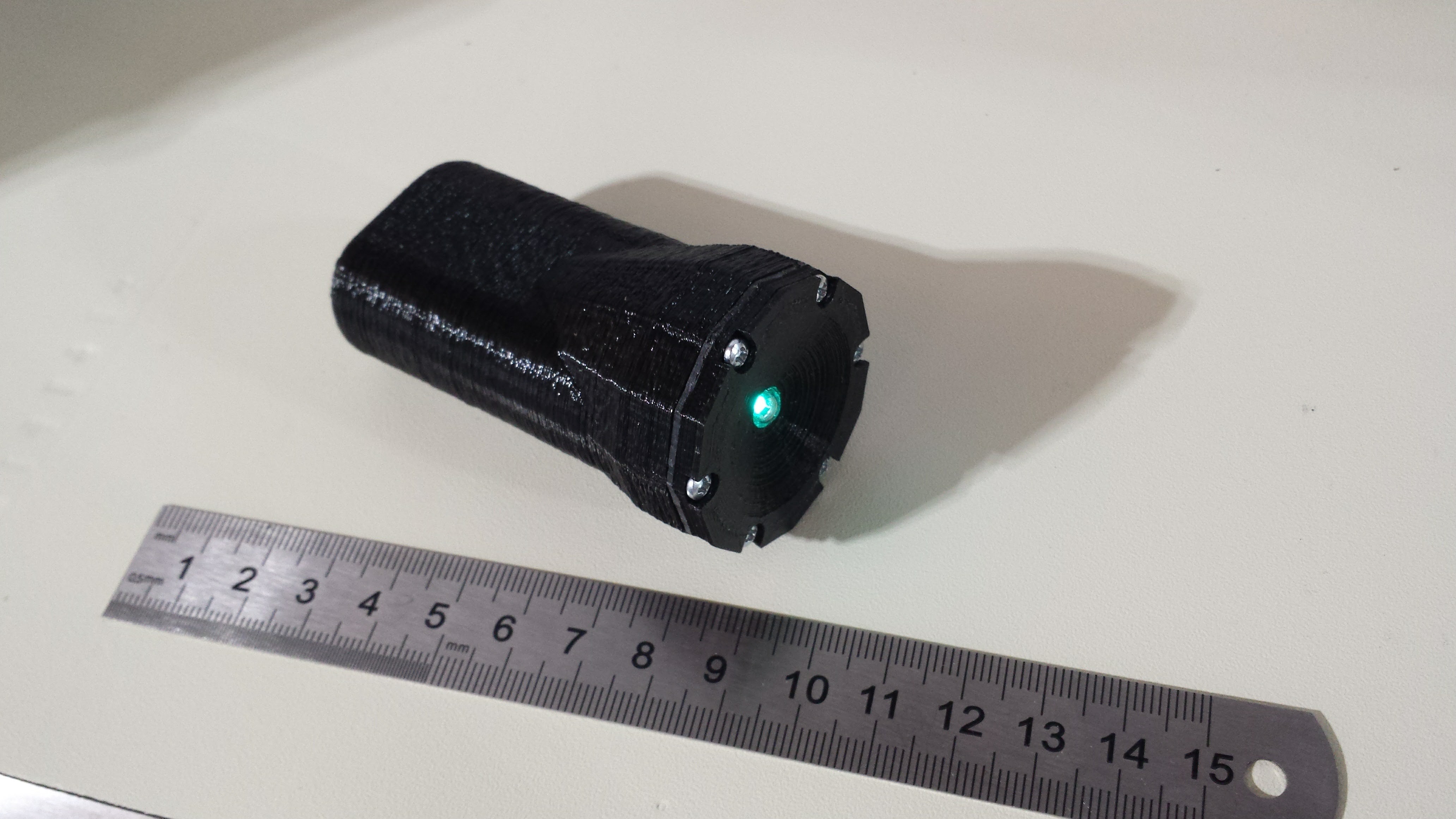

Here are some pictures of the build (printed in PLA). I'm going to print another case or two in ABS or PolyMax, which should be a little more durable. I'll probably wait until some LED lenses and reflectors I ordered arrive, though - it would be nice to narrow the beam on this thing a bit. I thought of adding some heat-shrink tubing around the battery case once they were installed, but thought that this might keep them from sliding inside the case if the plastic holder relaxes over time (especially the positive contact without the spring). I have some steel battery holders on order for the QCL build.

![]()

Here's the finished product. I added a note in the battery compartment with today's date and the expected run-time. When I showed the light to my wife, it was the first thing she asked about - she's seen too many times I wished I had dated some project from years ago.

![]()

Here's the code:

;;; ;;; ten_year_lamp.asm : ;;; PIC12LF1571 code for (2x) LiFeS2 AA-powered LED glow marker ;;; ;;; 20161106 TCY LIST P=12LF1571 #include ERRORLEVEL -302 ERRORLEVEL -305 ERRORLEVEL -207 ;;; ;;; OSCTUNE_VAL: set to fine-tune current draw for compensating for ;;; component tolerances ; OSCTUNE_VAL equ 0 ; OSCTUNE_VAL equ b'00100000' OSCTUNE_VAL equ b'00011111' ;;; ;;; number of LED pulses per WDT timeout loop ;;; N_PULSES equ 6 LED_PULSE macro variable i i = 0 while i < N_PULSES - 1 movwf LATA ;start inductor ramp-up clrf LATA ;end inductor ramp-up nop ; 2 nops here - tuned for minimum current nop i += 1 endw movwf LATA ;start inductor ramp-up clrf LATA ;end inductor ramp-up endm ;;; ;;; I/O pin configuration ;;; GATE_DRIVE_A equ 4 GATE_DRIVE_B equ 5 __CONFIG _CONFIG1, _FOSC_INTOSC & _WDTE_ON & _PWRTE_OFF & _MCLRE_OFF & _CP_OFF & _BOREN_OFF & _CLKOUTEN_OFF __CONFIG _CONFIG2, _WRT_OFF & _PLLEN_OFF & _STVREN_OFF & _BORV_HI & _LPBOREN_OFF & _LVP_ON ;;; ;;; variables in Common RAM (accessable from all banks) ;;; CBLOCK 0x70 reset_counter ENDC ORG 0 RESET_VEC: nop nop nop nop INTERRUPT_VEC: BANKSEL OSCCON movlw b'00111011' ; 500 kHz MF osc movwf OSCCON BANKSEL OSCTUNE movlw OSCTUNE_VAL movwf OSCTUNE movlw .255 movwf reset_counter BANKSEL ANSELA movlw b'00000000' ; all digital I/O movwf ANSELA BANKSEL LATA clrf LATA BANKSEL TRISA clrf TRISA ; set all lines as outputs BANKSEL WDTCON movlw b'00001001' ; WDT 16ms timeout movwf WDTCON BANKSEL LATA movlw (1 << GATE_DRIVE_A) | (1 << GATE_DRIVE_B) MAIN_LOOP: LED_PULSE sleep decfsz reset_counter goto MAIN_LOOP reset ;; fill remainder of program memory with reset instructions fill (reset), 0x0400-$ END -

First Circuit Ideas

11/03/2016 at 03:10 • 5 commentsSo, here's the first circuit idea; it's a modified version of the latest TritiLED design:

![]()

The battery is a pair of Energizer L91 "1.5V" lithium cells, which are actually 1.7-1.8 V when very lightly loaded. R1 limits the battery current in case the PIC gets stuck for a while and holds Q1 in a conducting state. Without R1, the full battery voltage winds up across the coil, which has a DC resistance of a few ohms at most (exact inductor not chosen yet) - enough power to cause burns or ignition. With R1 in place, the current is limited to 3.6/100 = 36 mA, and the dissipated power (mostly in R1) is limited to 3.6^2/100 = 130 mW - a small resistor can dissipate this all day if needed. 100 ohms in the power supply wires sounds like an efficiency killer until you realize that the whole circuit will draw around 15 uA (exact value TBD). At 15 uA average current, the drop across R1 is 150 uV, for an efficiency loss of only 0.05%. Not bad for keeping the inductor from possibly catching fire. In practice, I might want to use a 47-ohm resistor in each of the battery leads for redundancy - although they usually fail open, so this might not be the best idea. Of course C1 keeps the reserve power needed for the LED current pulses so the pulses aren't reduced by the inclusion of R1. I might add some extra capacitance at C1, which is a ceramic capacitor - there's no place for electrolytics in this type of application.

In the TritiLED circuit this is based on, two output pins are directly paralleled to provide more gate drive, and no gate resistor is used. This sounds OK unless the software goes awry (cosmic ray strike) and doesn't switch the two output lines at the same time - then, they "fight" outputting different levels, drawing lots of current, and possibly damaging the internal drivers. In this version, the outputs are again paralleled for greater drive, but each has its own resistor to mitigate problems if they somehow switch separately. Additionally, the resistors limit the peak current the drivers need to output, reducing stress on the PIC. The exact values are TBD.

I have the particular MOSFET at Q1 since it's the one currently in the TritiLED design. I have previously built these circuits with low-Vce(sat) BJTs, but the MOSFETs are a little more efficient. Unfortunately, I haven't yet found comparable low-Vgs(th) MOSFETs in through-hole packages. I'm strongly considering doing the whole circuit on a through-hole PCB, because I see many references that claim through-hole is more durable. I don't particularly care about size (the batteries will dwarf the circuit, anyway) or cost (only building a few) so through-hole is probably a better bet. The biggest reason to avoid SMD, however, is my lack of a proper reflow oven. While reflowing boards on an electric skillet might be OK for prototypes, it's completely inappropriate and untested for high-reliability devices. On the other hand, I have soldered tens of thousands of through-hole connections, and am confident that my through-hole joints will not be an issue, especially if I inspect each one under the mircoscope. I will be using eutectic 63/37 leaded solder (tin whiskers are for cat robots).

There's no mode switch like on the latest TritiLEDs - a mechanical switch is likely to fail (especially the crappy SMD ones), or conduct ESD or mechanical stress to the board. Maybe worst of all, the internal "weak" pullups on this part consume 80uA when shorted to ground. Weak pull-ups, my ass.

I'm thinking about a die-cast powder-coated aluminum enclosure with a little machining to let the photons out. I love 3D printing as much as the next guy, but expecting some case I printed to last 25 years? Nah.

Ted Yapo

Ted Yapo