-

1Assemble the XJW01 kit

The XJW01 kit comes with a bunch of resistors and capacitors that need to be soldered in. Also note that the kit comes with a small ziplock bag with 'calibration resistors'. You won't have to use these in the build, that will come later when calibrating.

Use ribbon cable to connect the display and keypad to the main circuit board. I've used around 15 cm of ribbon cable for the display and around 10 for the keypad.

After you're done, you can test the kit with a 12V bench power supply to make sure it turns on. Don't worry too much about the values it shows, it might not be calibrated properly.

-

2Print the case parts

Print the attached case parts. I've used 0.2mm layer height with a 0.4mm nozzle with 35% infill, printing PLA. The pieces can all be printed flat on the bed, but you might need to rotate them in your slicer.

-

3Calibrate the meter

It's time for calibration. It's not a super-obvious procedure, but it is fairly easy.

First, measure the included resistors as accurately as possible. There should be a 40R, 1K, 3K, 9K, 10K and 100K resistors. Go nuts with 50 power line cycles, averaging, 6,5 digits, 4-wire measurements and all that. We will use the measurements you've done to calibrate the meter to.

Once you've measured the resistors to an accurately enough degree, it's time to start the calibration procedure:

- Turn the unit on

- Perform a short test lead calibration. Clamp the Kelvin clips together and press the "Zero" button

- Perform an open test lead calibration. Disconnect the kelvin clips and press the "Zero" button

- Hold down MENU for approximately 3 seconds, this will bring up the options menu

- Press RNG to enter calibration mode, the display should now show "Z0"

- For the calibration, we will adjust the instrument to exactly match the previously measured resistor values (as well as some other parameters). Use the CLR (up) and SP/ESR buttons (down) to adjust the values. Use FREQ to go to the next parameter and QTY to go back.

- Set the values of the different parameters as follows:

Step Target Value Notes Z0 Z=0 Short the Kelvin clips Z1 Z=0 Short the Kelvin clips Z2 Z=0 Short the Kelvin clips R1 40R resistor Connect the resistor and try to match what you previously measured with your multimeter R1X θ=0 Leave the resistor connected R2 1K resistor Connect the resistor and try to match what you previously measured with your multimeter R2X θ=0 Leave the resistor connected R3 10K resistor Connect the resistor and try to match what you previously measured with your multimeter R3X 0 pF Leave the resistor connected R4 100K resistor Connect the resistor and try to match what you previously measured with your multimeter R4b 100K resistor Connect the resistor and try to match what you previously measured with your multimeter R4X 0 pF Leave the resistor connected G1 3K resistor Connect the resistor and try to match what you previously measured with your multimeter G1X 0 pf Leave the resistor connected G2 9K resistor Connect the resistor and try to match what you previously measured with your multimeter G2b 9K resistor Connect the resistor and try to match what you previously measured with your multimeter G2X 0 pf Leave the resistor connected PhX θ=0 Connect the 1K resistor After calibration, make sure to save your changes with the Hand/Auto button!

-

4Mount fuse holder and power socket

Attach the power socket and fuse holder to the back plate. The power socket will screw in with M4x8 screws

-

5Mount display, keypad and power button to the front plate

Using M3x10 screws (self-tapping), mount the display and keypad to the front plate

-

6Assemble the bottom part of the case

Attach the front and back plate to the bottom of the case with M4x16 bolts and M4 nuts. The screws should be able to not slip under the torque of tightening them, but if you want to be extra secure, add a drop of super glue

-

7Add the transformer and power supply and wire it up

Add the transformer and the linear regulator to the case with M3 and M4 screws. Make sure the transformer is tight against the pedestal as it's relatively heavy.

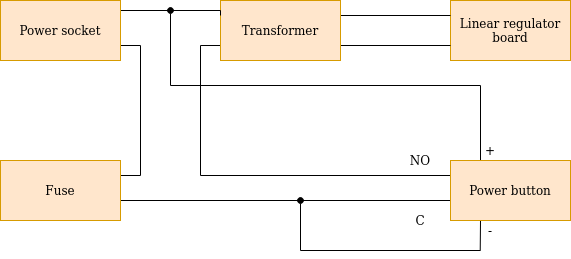

Wire everything up according to the following diagram:

![]()

Add a 0.2A (or smaller) fuse to the fuse holder.

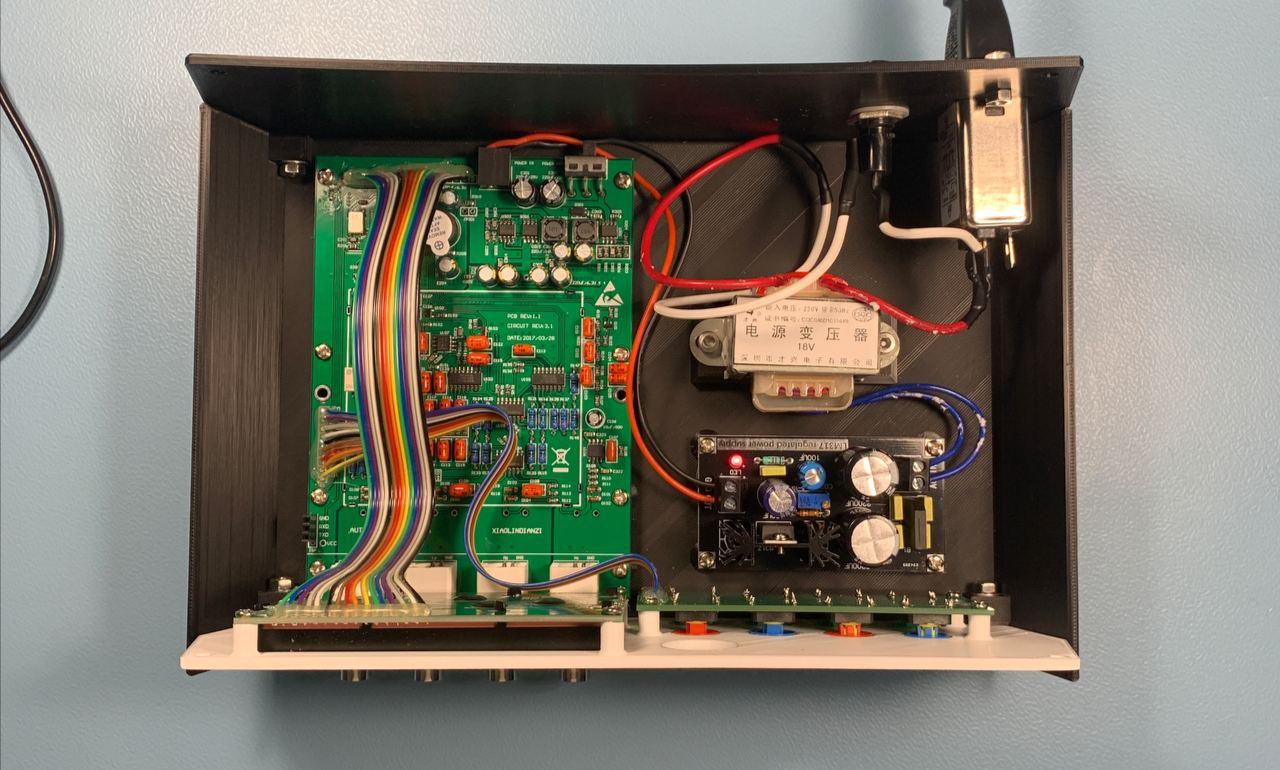

It should look something like this (minus the switch):

![]()

-

8Attach the top part of the case

Use superglue to glue the nuts in their recesses and attach the top part of the case with 4 M4x16 screws.

-

9Done!

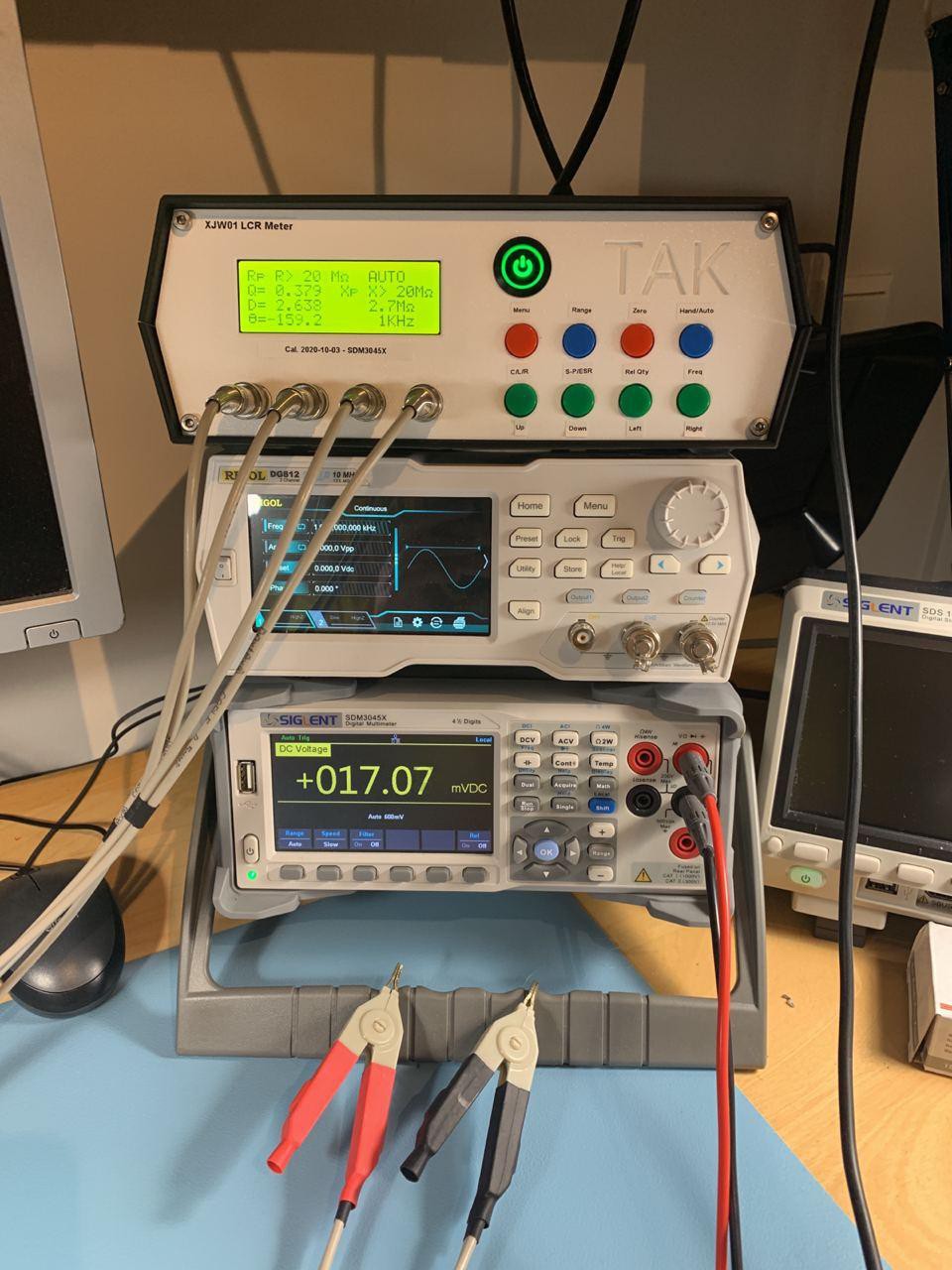

Add 20mm diameter rubber feet to the bottom of the case (probably needs a bit of superglue to stick properly) and add it to your already awesome stack of bench meters!

![]()

Merijntje Tak

Merijntje Tak

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.