So I decided to fix up my new laser engraving bed and see if I could not make it even better.

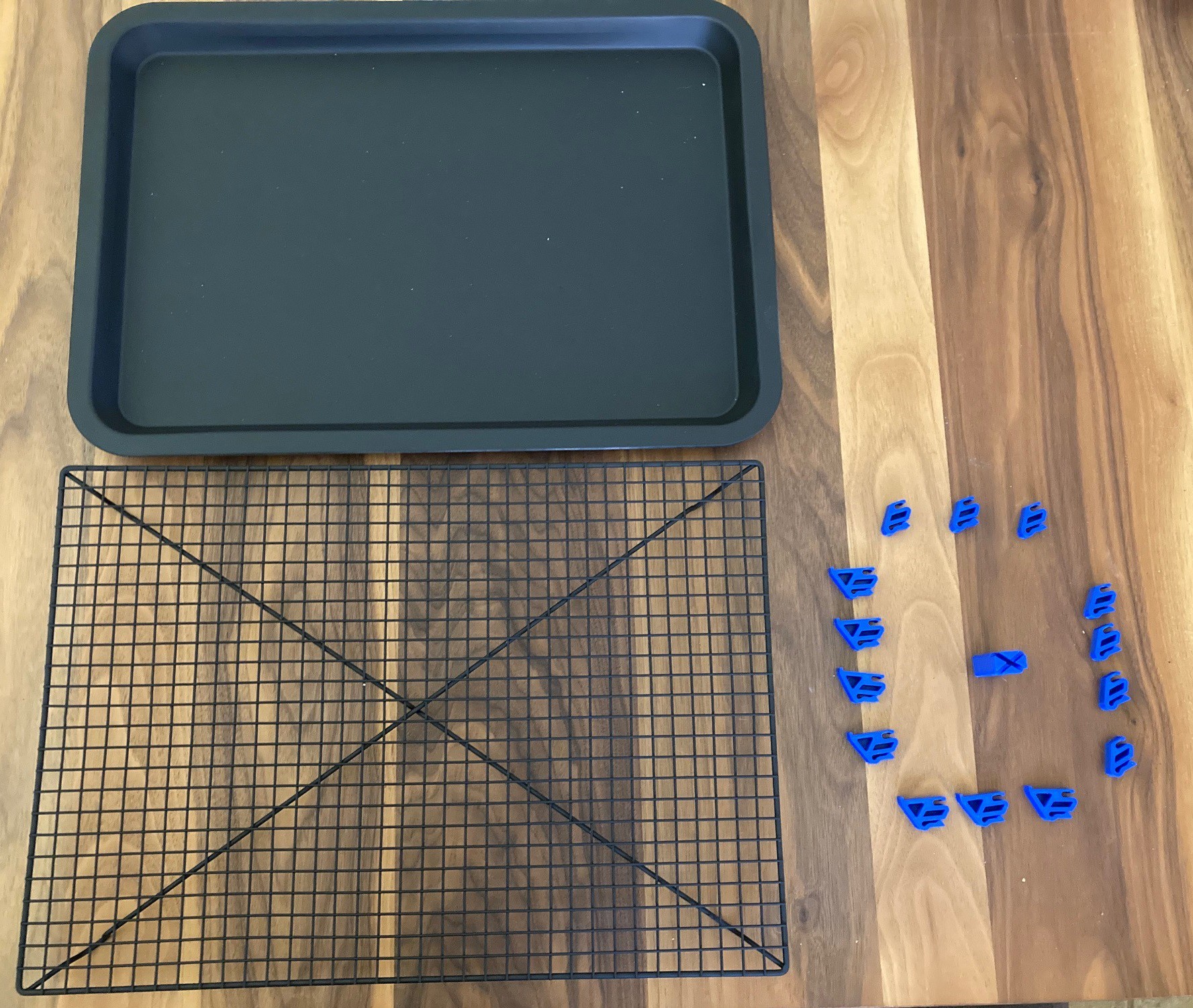

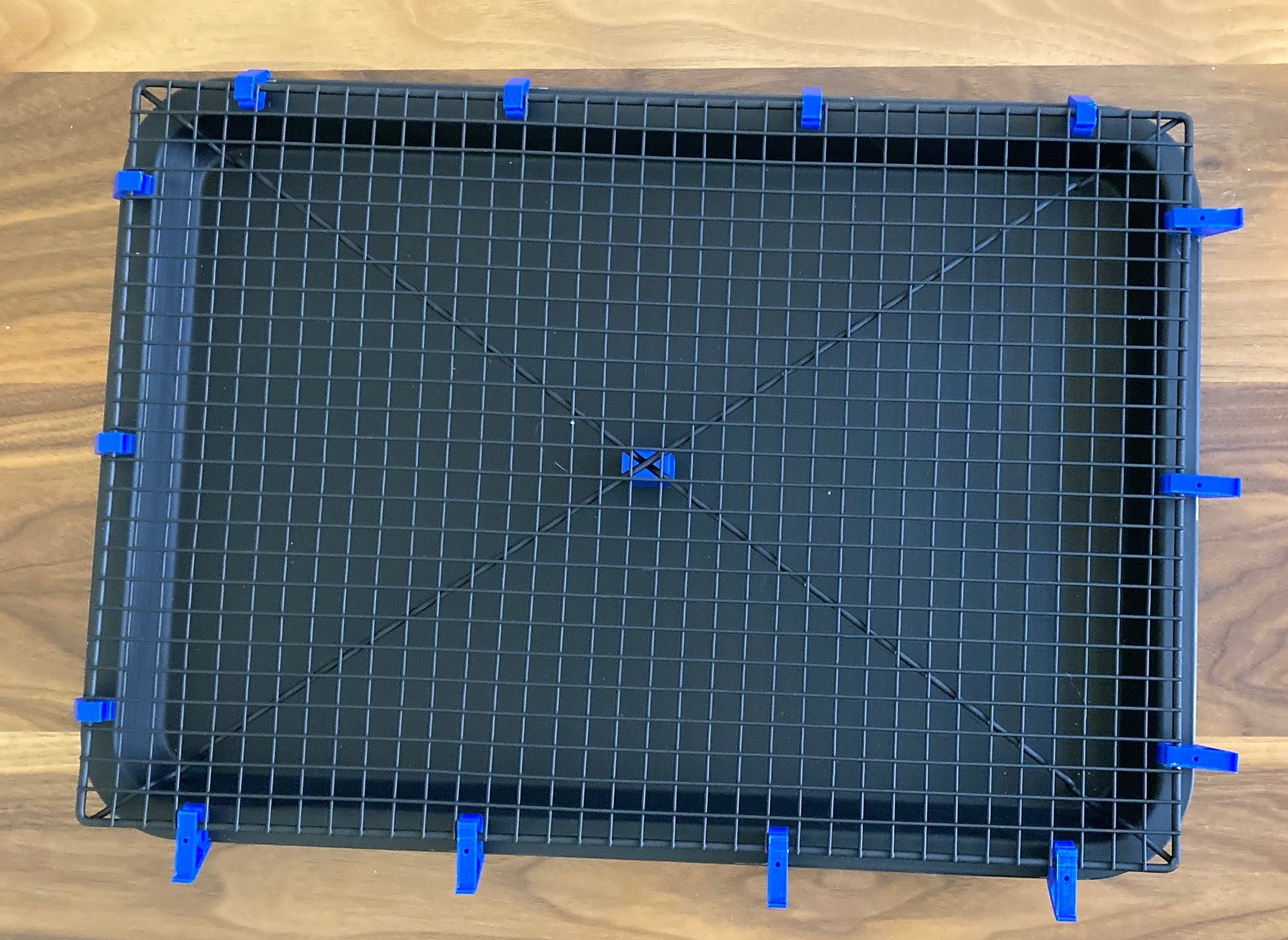

I wanted to stabilize it, and make it flatter and also provide a way to consistently lay out parts on it. To help that along I painted everything matt black to reduce the flashback and printed out little standoffs to hold the wire rack at a fixed height above the base so the smoke is not trapped below. I added a center standoff to help fight some sag in the bed and further stiffen things up as well.

It is a bit tight but once you snap it all together the structure is very solid.

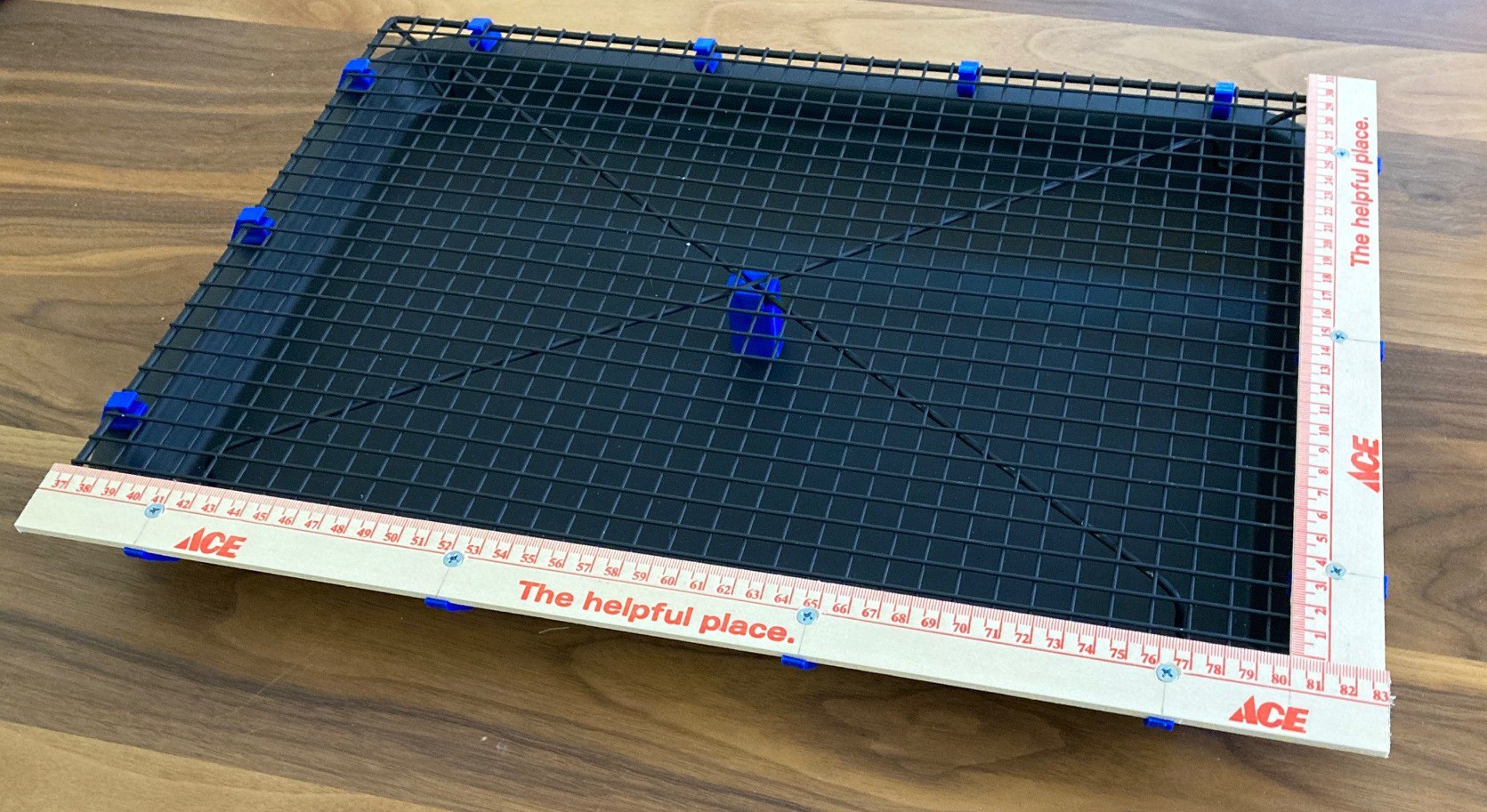

I printed half the standoffs with a little extension so I could use a yardstick as a reference edge to hold the material square to the bed.

Finally since the pan was not perfectly flat on the bottom I added in some rubber feet to stop it from rocking and to provide a more solid grip on the bed.

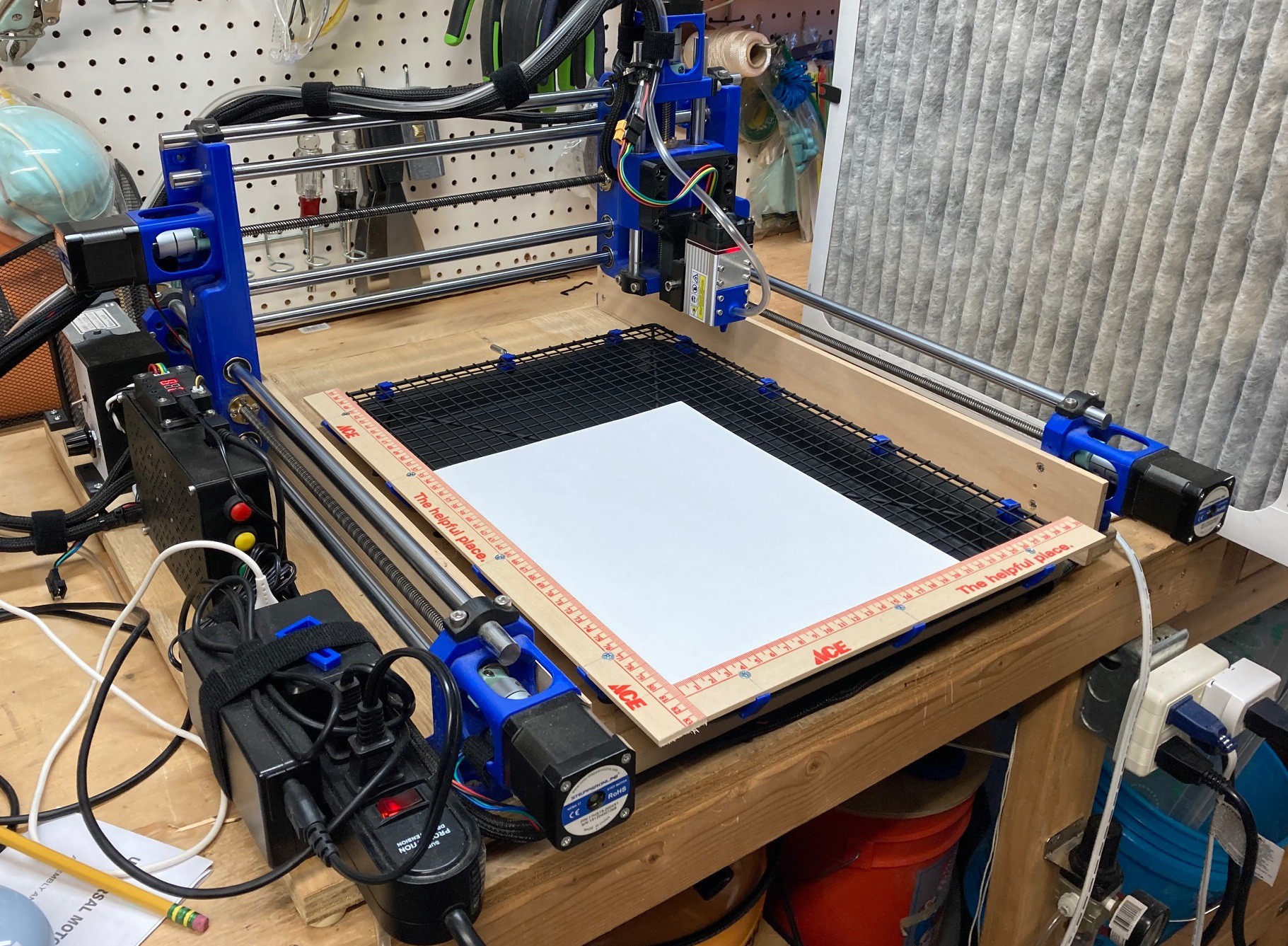

My spoiler board has an edge installed on it, and I was able to push the laser bed up square to that. I added a pin in the spoiler board at the far end as well to help located the bed in the Y direction.

In the end I have a working bed size of 430x300 mm, with a perfectly square reference edge and only a mm of deviation across the whole bed.

in the end I probably put $20 into this, and ended up with a bed that is nearly as good as anything out there.

You can find the stl files over at Thingiverse, and I wrote this up as its own project here.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.