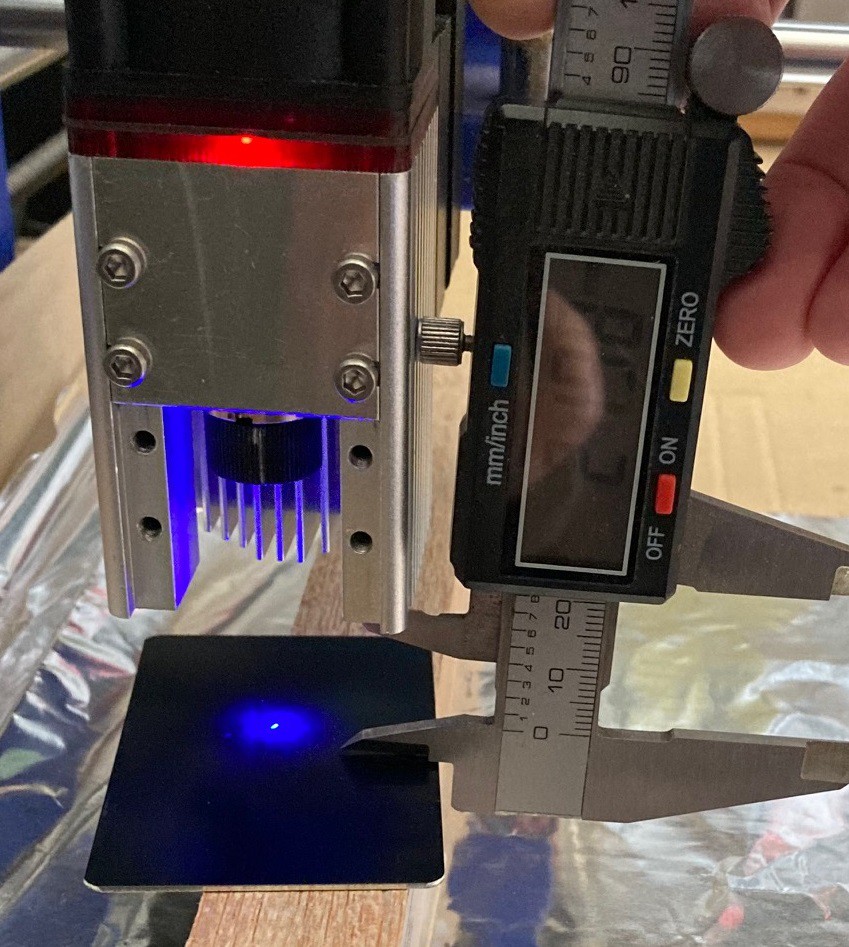

So a few posts ago I messed around with making the focus much higher. This is more in line with the current recomendations from NEJE and it allows me to have more clearance when trying to use my laser with the rotary axis. Using a 6mm focus height brings the laser housing very close to the jaws of my rotary chuck.

However going to this higher focus height caused interference with my old air assist nozzle. The bottom of the nozzle was being hit by the laser and it caused some melting of the nozzle as well as a loss of power from a reduced focus spot size. This lead me to redesign my air assist nozzle.

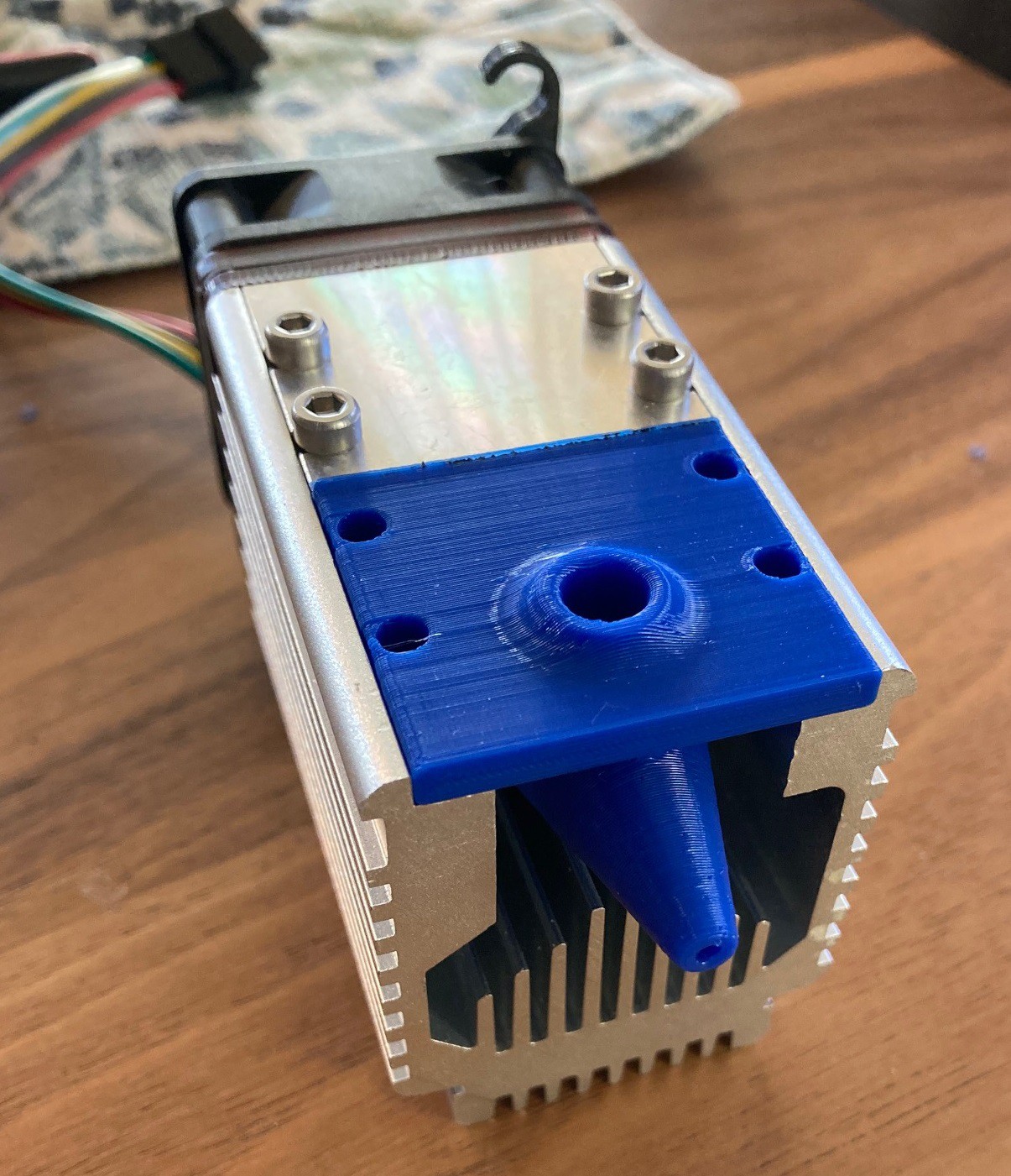

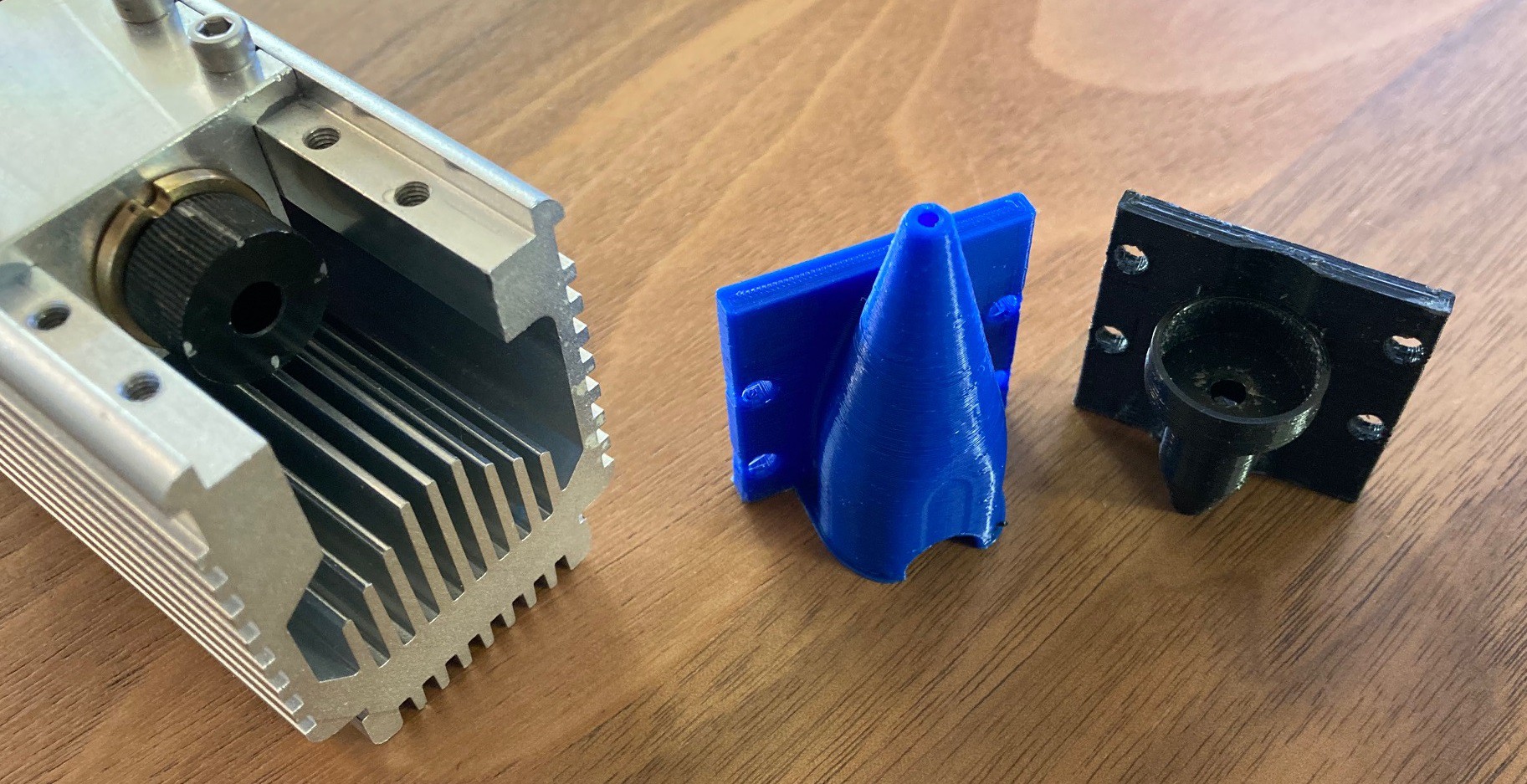

My old nozzle was designed to be printed tip down with no supports. It worked ok, although there was some issues with elephants foot on the nozzle opening. The new nozzle carefully extends the part that covers the lens all the way to the top so it can be printed upside down without any supports.

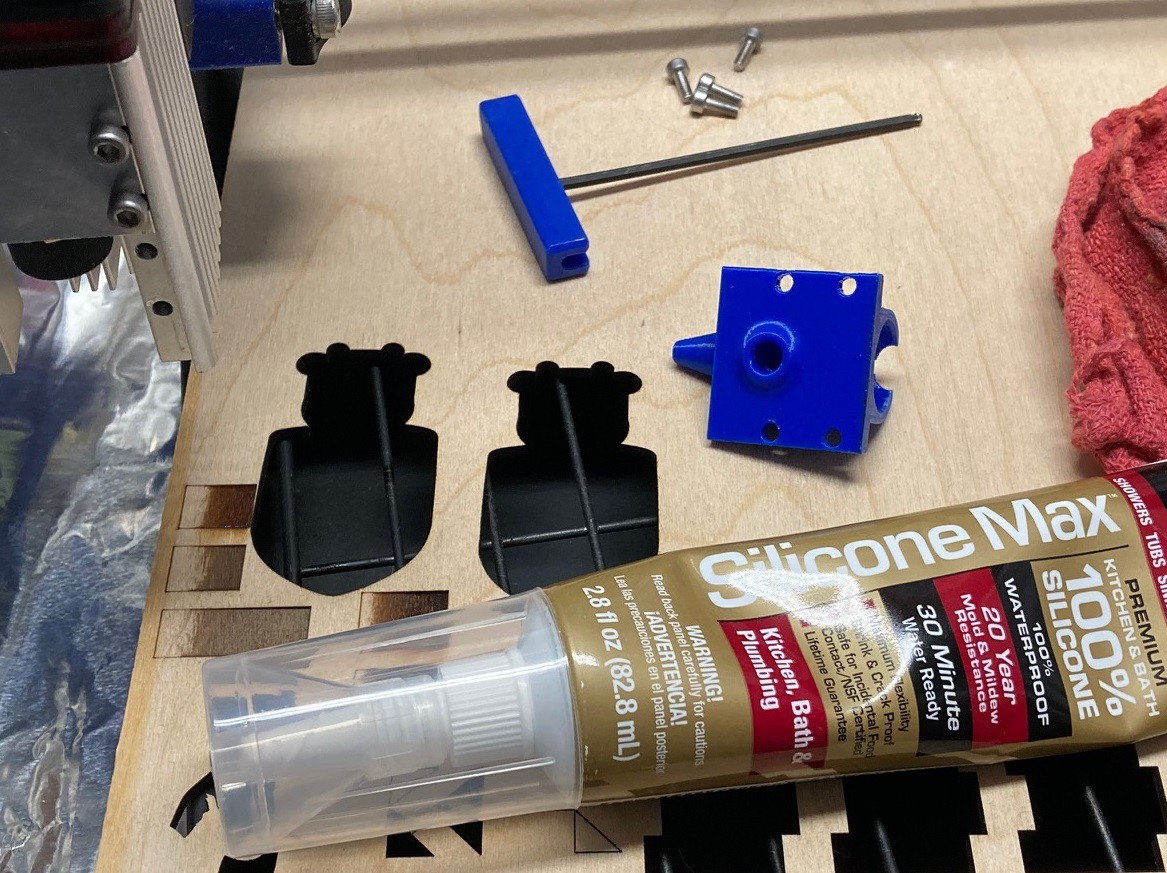

Since I changed how the nozzle was printed, I went ahead and made a new nozzle hole size test. This time I made it as a single monolithic piece that goes from 1.5 mm to 3.5 mm diameter holes. Again after lots of back and forth testing the 2mm sized hole appears to be optimal both with my aquarium fish pump and with 15 psi from my pancake compressor.

I designed this to have a 22 mm focus height from the base of the housing to the top of the work surface. The nozzle itself is 12 mm tall leaving 10 mm from the tip of the nozzle to the top of the cutting surface. This is roughly in line with what NEJE recommends.

The nozzle has a close interference fit with the end of the lens. However there is enough of a gap that a significant amount of air flows around the lens.

To work around this I applied a small amount of silicon all around the inside of the nozzle with my finger, then pressed the nozzle on over the lens and let it dry overnight. This has formed a solid coupling and since there is no lip inside the housing the extra silicon did not get forced back inside the lens opening, a problem I had with my last nozzle.

I have uploaded all my laser related models to Thingiverse if you want to grab any of them. This includes the air assist nozzle and a housing for the NEJE display/controller board.

---

Here are focus dimensions taken from various NEJE images posted to there website for several different laser modules. You can see that even there own numbers are not very consistent. That is why I picked an average value of 22 mm focal height from the base of the housing.

n30820

- 12(32) mm focus to top of lens

- 15(35) mm to base of wood

- 8 mm max cut

- 5 mm below top of material

- 2(27) mm to top of material

N40630

- 17(37) mm focus from base of laser

- 20(40) mm to base of wood

- 8 mm max cut

- 5 mm below top of material

- 12(32) mm to top of material

A40630

- 17(37) mm focus from base of laser

- 25(45) mm to base of wood

- 18 mm max cut

- 10 mm below top of material

- 7(27) mm to top of material

A40640

- 22(42) mm focus from base of laser

- 30(50) mm to base of wood

- 18 mm max cut

- 10 mm below top of material

- 12(32) mm to top of material

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.