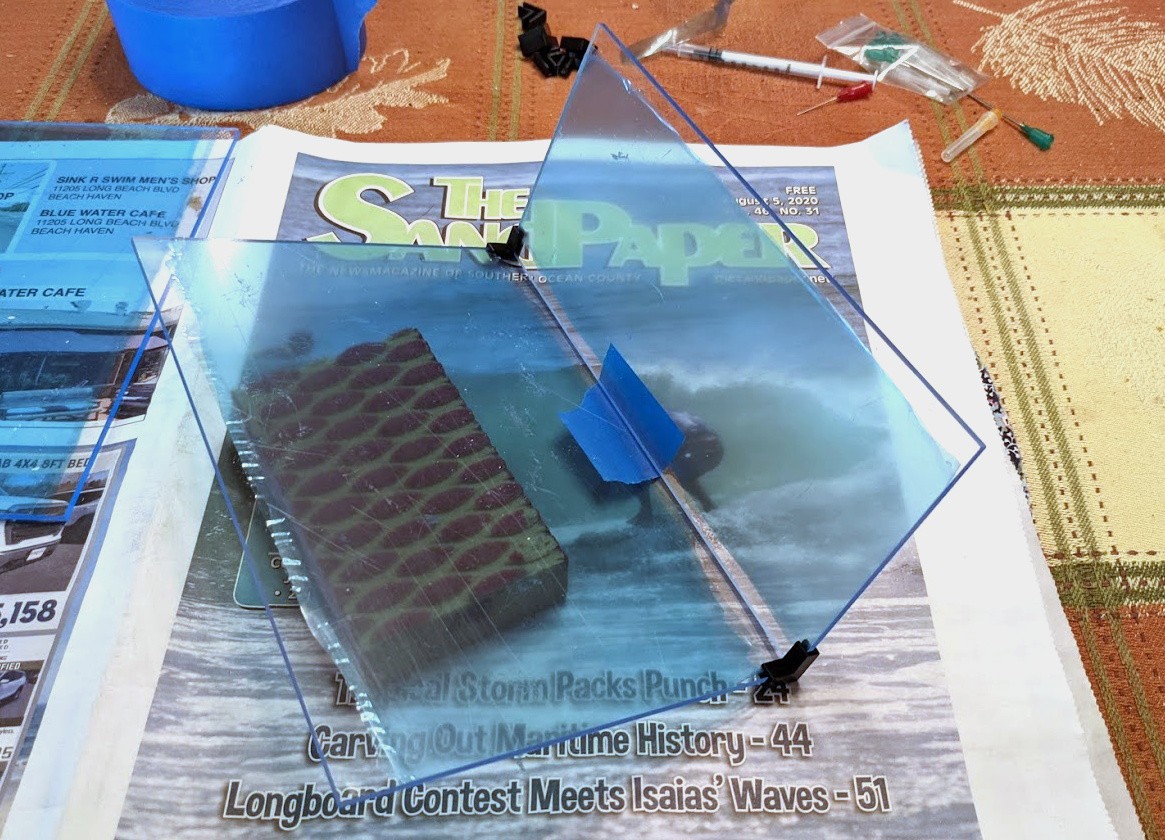

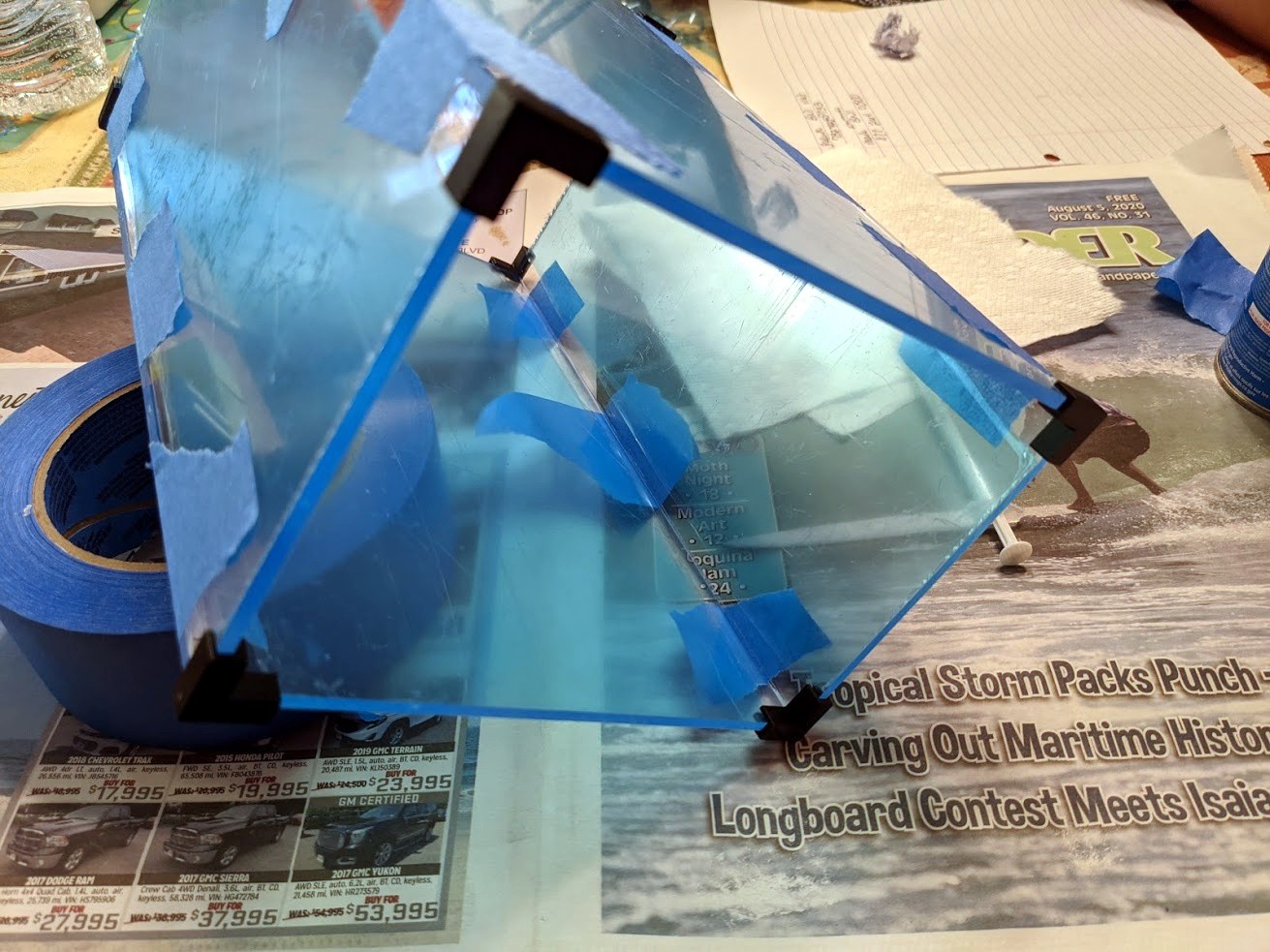

Each box is made up of four pieces of 3 mm acrylic sheet, bonded together with Weld-On 4. The side panels are 150 x 220 mm, and the front/rear panels are 100 x 220 mm. As I don't have access to a laser/CNC currently, I ordered them custom cut from TAP Plastics.

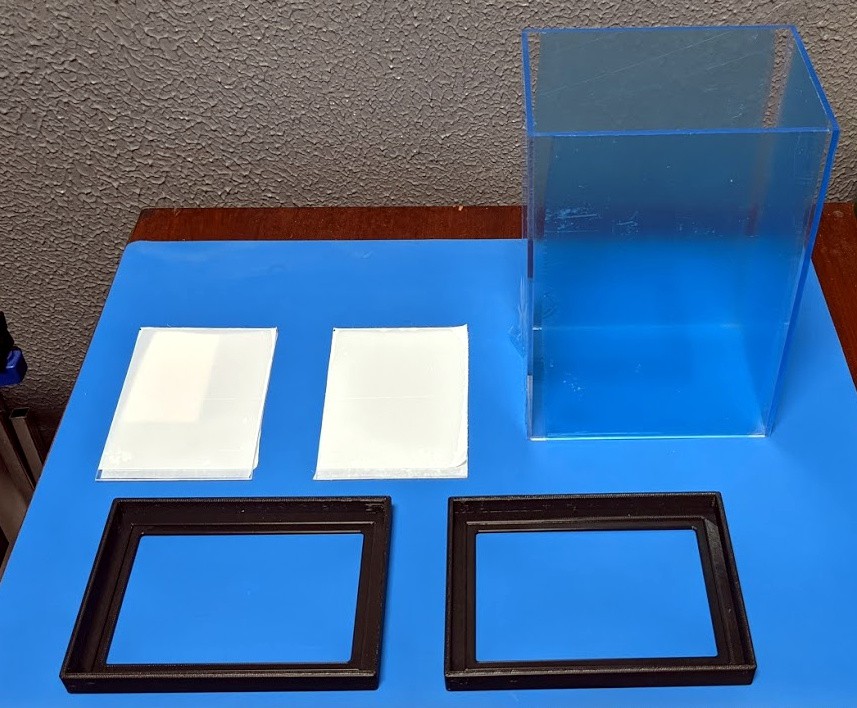

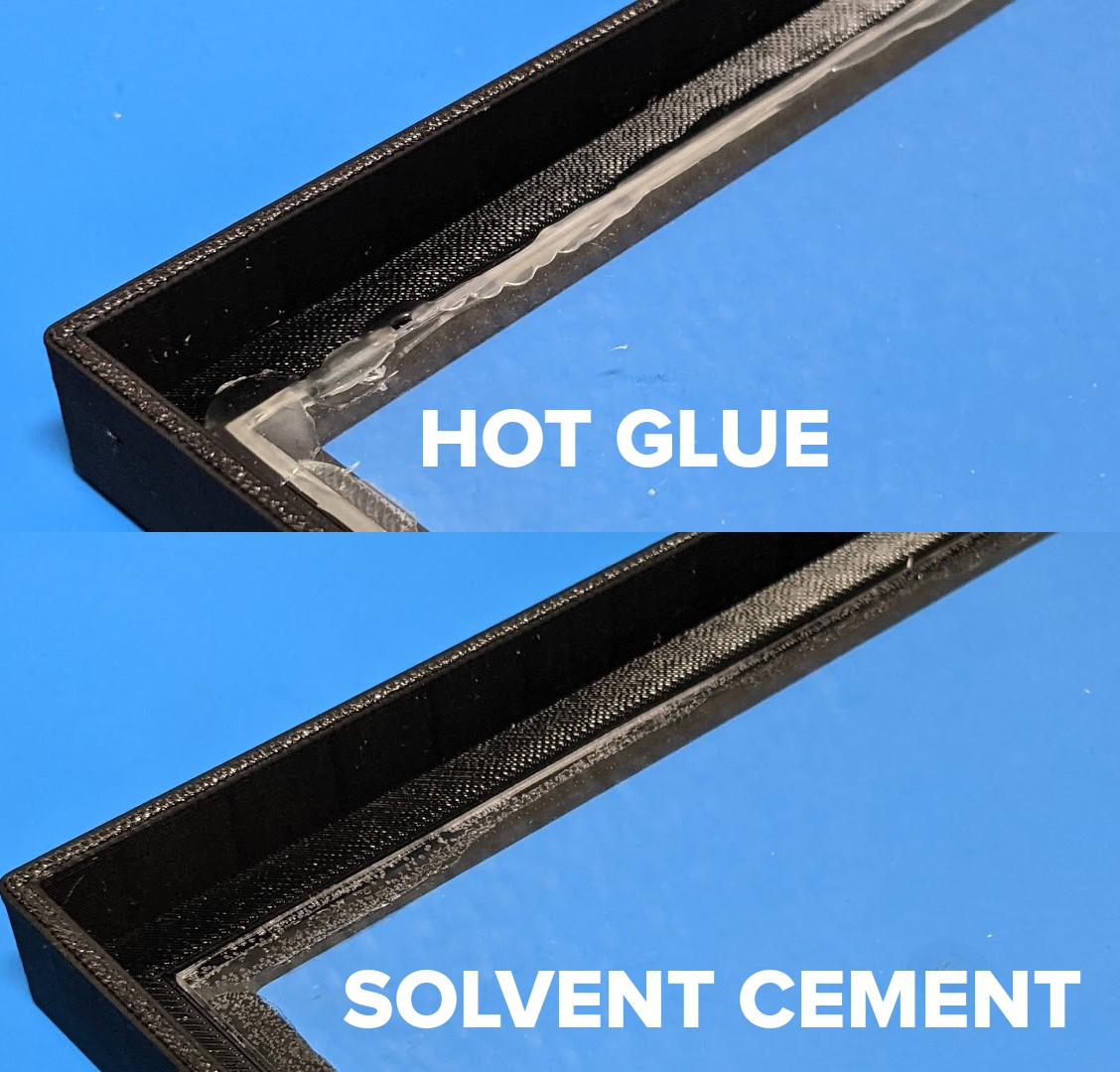

The end caps are 3D printed in PETG to resist warping. Both end caps are identical, and are designed to be tight enough that the top can be held on with friction, and a bead of hot glue keeps the bottom one affixed. To reduce printing time, I put a window in the end cap that gets filled with another piece of acrylic. This saved an hour of print time for each cap (or 12 hours over total project), but in the end the added assembly time and effort to fit the hand-cut acrylic windows meant it may not have been worth it.

Tom Nardi

Tom Nardi