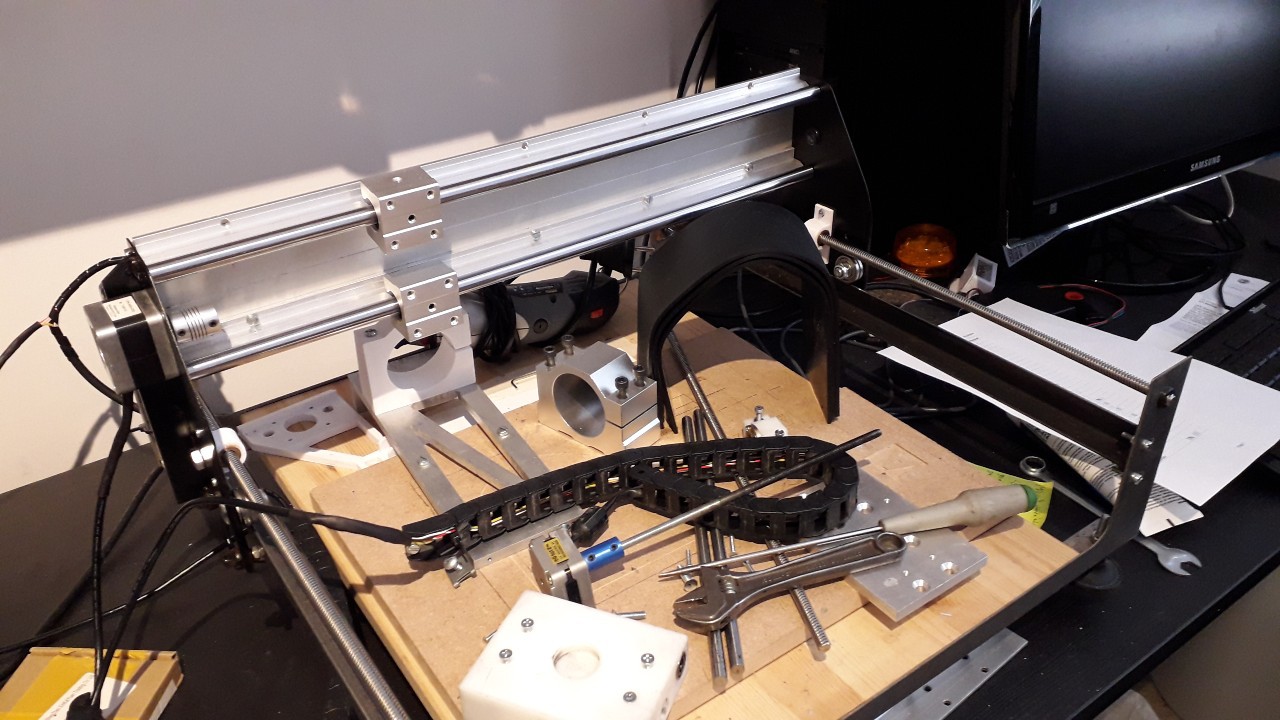

Yup, theres a long way to go until I can make injection molded parts. To be able to produce reusable molds, I needed to stiffen up the old CNC that I built many years ago to be able to handle aluminum.

I've just finished all the rewiring, with a new USB controller since the old one (parallell-port) didnt work with my "new" computer.

At the moment I'm changing the old Y-axis that was made with metal rods I got from an old printer, into a lot more rigid linear rails. This will take the tolerance down from 3mm to 0.5mm. When milling plastics and wood that worked fine, but aluminum is a whole other ballpark.

To get it down to 0.1mm I will also replace the nuts for the threaded rods to anti-backlash versions. Also a new router spindle is on its way from china, to replace the noisy and cheap dremel-style machine. Then we're good to go...

Daniel Nikolajsen

Daniel Nikolajsen

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.