-

Finalizing the first batch

03/27/2022 at 08:28 • 2 commentsFinally Im getting close to finishing the first batch of Satrans. Hopefully I can sell the first ones in the week to come.

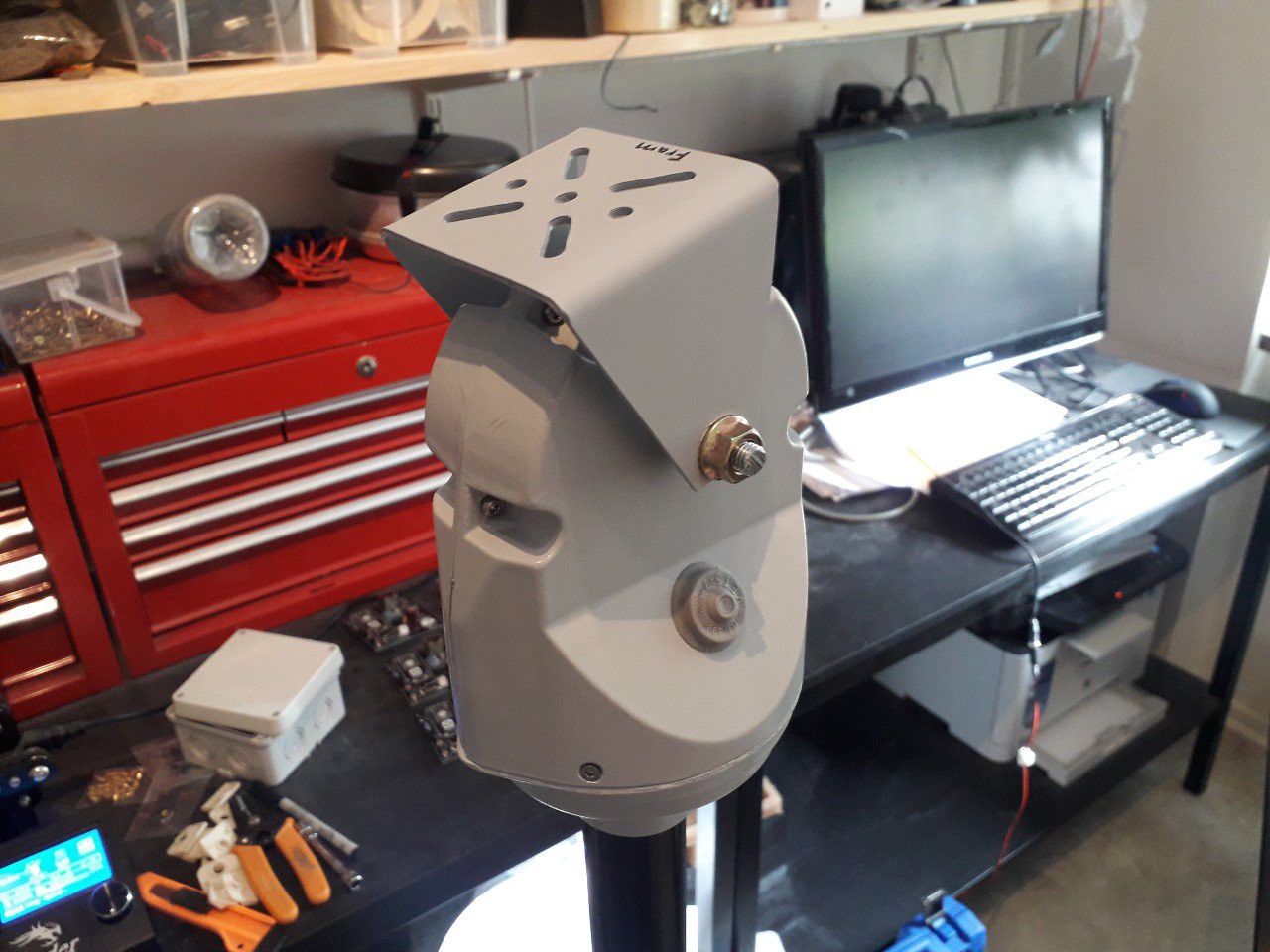

![]()

The new default paint job is grey like this prototype. But I will make them in other colors later, like black or olive green for those hiding out in the bush instead of mounting it on their rooftop, or just wants that extra "cool factor".

The rubber gasket on the side is for those who wants the antenna coax cable to run inside the mount pipe instead of hanging loose on the outside. Neat and tidy, just like IKEA.

Visit www.satran.io and signup for the newsletter to make sure you get notified as soon as they hit the shelves.

-

I never get board

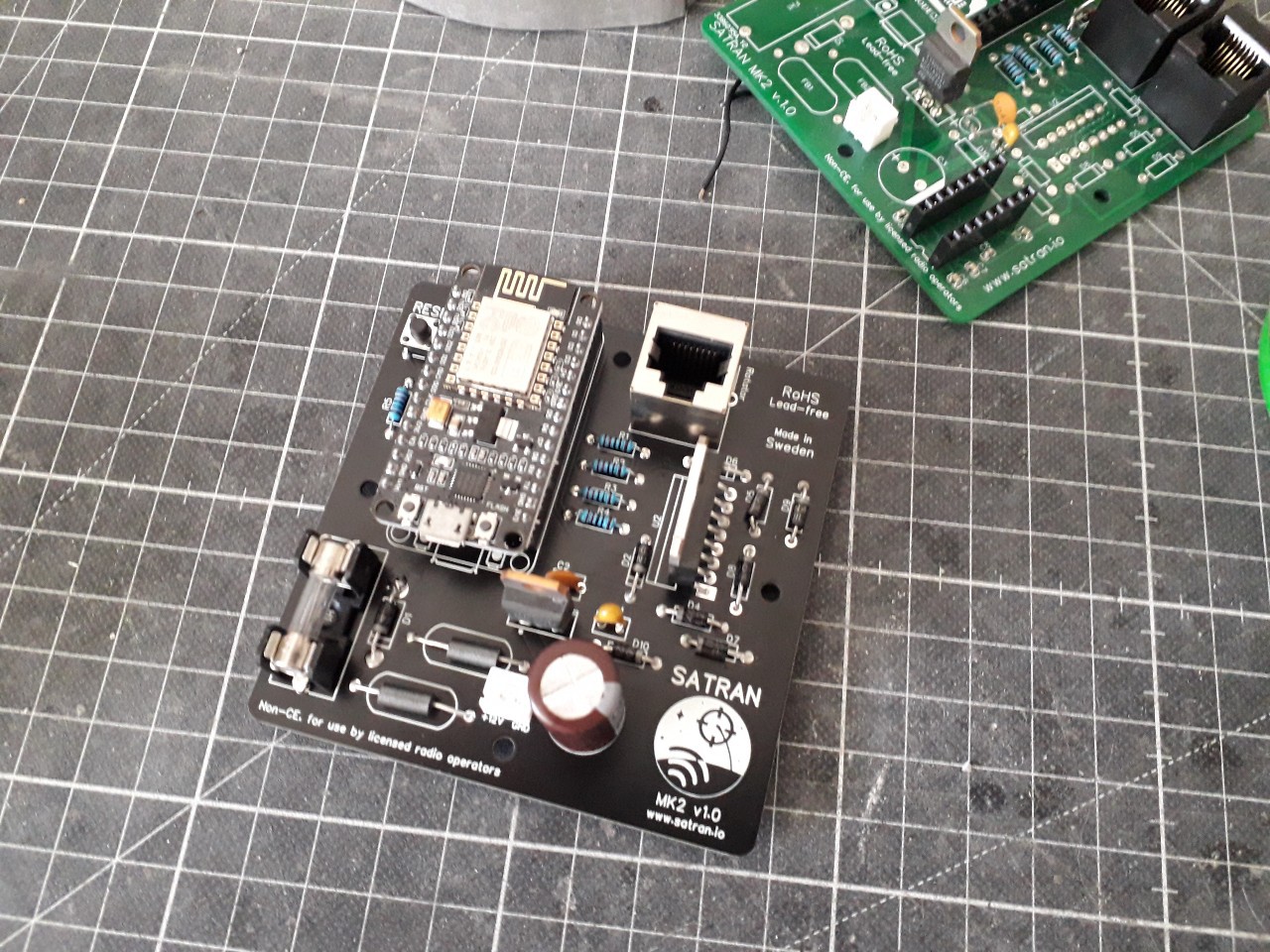

03/04/2022 at 08:07 • 0 commentsBut now I do! Yesterday the PCBs finally arrived after a long wait, and I hastily soldered together the very first one (the green one is the old prototype). Fingers crossed that it will work and that I didnt mess something up when I made last-minute design tweaks, but at least they look awesome with the logo and all.

![]()

-

One down, 999 to go

03/03/2022 at 10:18 • 0 commentsYesterday I managed to make the very first sand cast sides for the rotator. Its enough to put together the very first all-metal prototype, but hundreds more are to come.

![]()

The sides have very fine details and thin sections that are almost impossible to sand cast. Bigger companies use die casting for such things, but for that you'll need insanely expensive molds. But with lots of practice, a good alloy and "jävlar anamma" (meaning grit) as we call it in sweden, anything is possible.

-

Bootstrapping 101

02/24/2022 at 08:37 • 3 commentsIm turning every penny as I am getting closer to finishing the first batch of Satran antenna rotators "MK2". Product development is insanely expensive and time consuming. At least when you wont compromise on quality or cant pay someone else to do the work for you. But nothing will stop this great project.

![]()

The first batch is only 10 pieces, but it will bring in enough capital to pay for necessary equipment and components to scale up further. RnD on a budget means I need to learn and master almost every step possible myself. Quite a big challenge, but I probably have learnt more in the last year than in the previous ten. It all seems overwhelming right now, but will make a big difference in the future.

I expect the first kits to be ready for sale within a few weeks. Fingers crossed.

-

The last challenge

02/15/2022 at 07:57 • 1 commentMost of the components for the first batch is now in stock, but one big challenge remains before production can start for real. Aluminum casting.

This is a true handiwork that requires good equipment, basic understanding and a lot of practice. But oh my is it rewarding when you pull it off.

![]()

The sides for the housing are the most intricate and hardest to make. The first try was not a complete failure, but I need some more practice and tweaks to get the perfect finish and for the mold to fill up completely.

![]()

-

It's closer than you think

02/04/2022 at 09:36 • 0 commentsA big update for the blog today. The prototype has secretly been up and running for a while to try out different scenarios and to develop the code. It's already much better than the previous "MK1" rotator in many aspects.

![]()

The fact that the MK2 uses positioning sensors instead of end limit switches, gives you an instant reading of where it is pointing and the chances of it dropping the count is basically zero.

Also the code has been completely rewritten so that both the motors can turn simultaneously. On the old version the azimuth turned first, and then the elevation. Hence the new rotator is much faster, and thanks to PWM ("pulse width modulation") it also chooses different speeds depending on how far it is supposed to turn.

And the color! Instead of black like the old ones, the new Satrans will be painted grey. A brighter color will blend in better with the sky when mounted on a rooftop, and it doesn't get as hot when the sun is out. But if you prefer it black, green or perhaps bright orange I would be open to customize orders.

At the moment I am developing the firmware so it can respond to hamlib/rotctl-commands so you can control it with Gpredict or other similiar software for PC or linux. It will still only offer wireless ethernet control in the basic version, but later I might develop control units with a wired ethernet shield or perhaps even serial communication.

![]()

Prototype for the new controller and the very first cast aluminum pipe before it has gotten sand-blasted, machined and painted.

-

Big progress

01/14/2022 at 17:14 • 0 commentsThats right, I am doing really big progress on the project. The very first prototype is actually up and running in my office, but it needs a lot of programming before it can actually track satellites. As soon as I get time I will make a new youtube-video explaining all the big updates compared to the first Satran MK1 az/el rotator.

![]()

Today I went to the old farm house where I have my metal shop, and besides perfecting my aluminum casting skills, I built a simple sand blasting cabinet from an old shipping crate I found in the barn. Keeping busy =)

![]()

-

Circuit design, check!

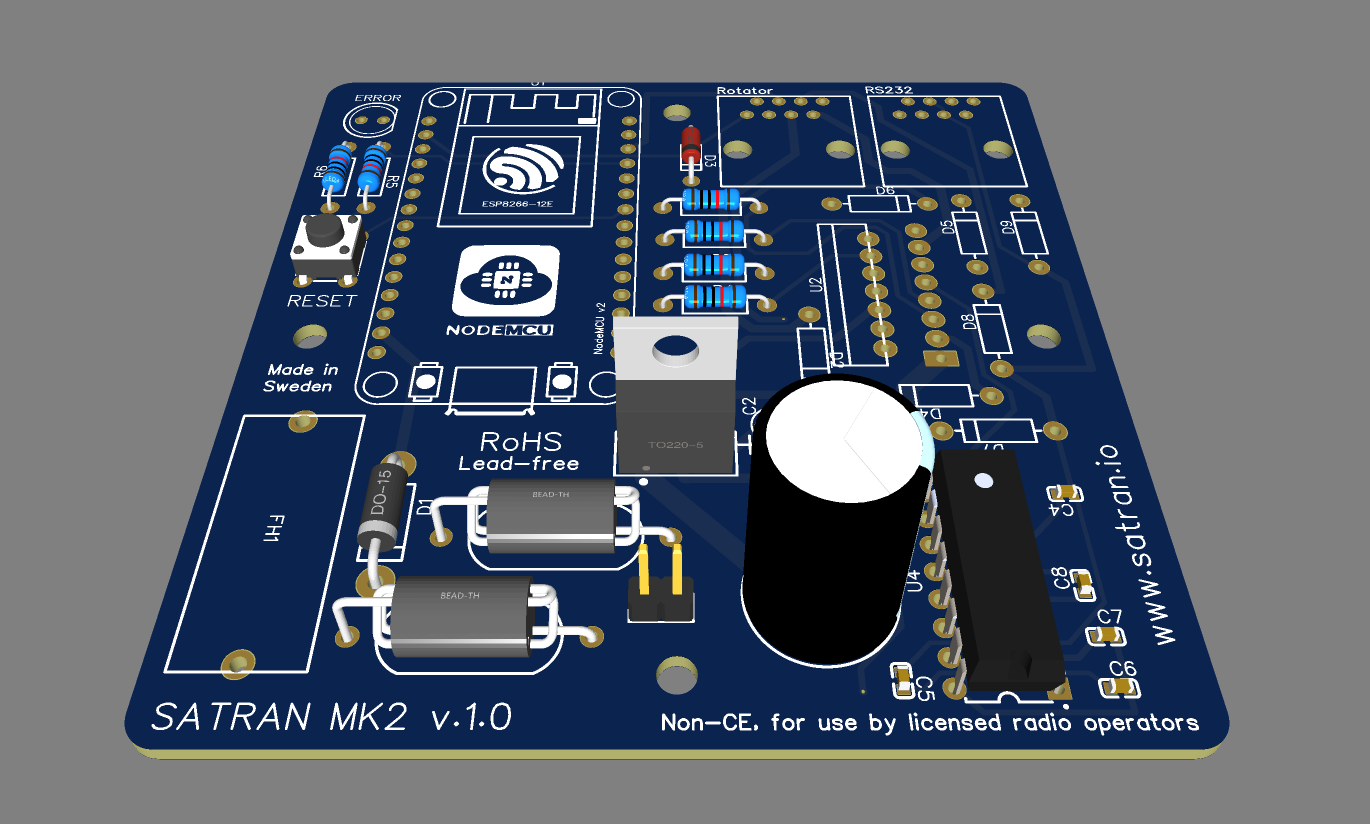

01/06/2022 at 10:18 • 0 commentsYesterday I finished up the new circuit design and ordered some prototype boards. They should arrive within a week and then I can wire up the very first MK2 rotator.

![]()

There will most certainly be some more adjustments to the electronics design and some extra filters to make it handle whatever EMI that might occur. But since all needs to fit on a 80x80mm board you need to be quite nifty. Also I prefer to use through-hole components instead of SMD for their durability and solderability.

As you might have noticed, the board will have two RJ45 connectors. One for the rotator, and the other one for RS232 serial interfacing. I have my concerns on RJ45 and a short TP-cable being able to handle the motors and sensors without glitching, but I like to experiment. The control board will be housed in its own water tight housing, on a meters length away from the rotator and its high-powered antenna(s).

To the left on the board there is a fuse holder, which I am not quite sure about if it's needed? It takes up a lot of space on the board, so I might replace it with a RC-filter that put a limit on the current while also removing HF-noise.

I will also do some experiments and see if it would be possible to run it over serial/USB which is preferred by some, plus there are already a lot of documentation out there on Satnogs, Gpredict etc with serial comms.

-

Gear up! Prototype soon to be finished

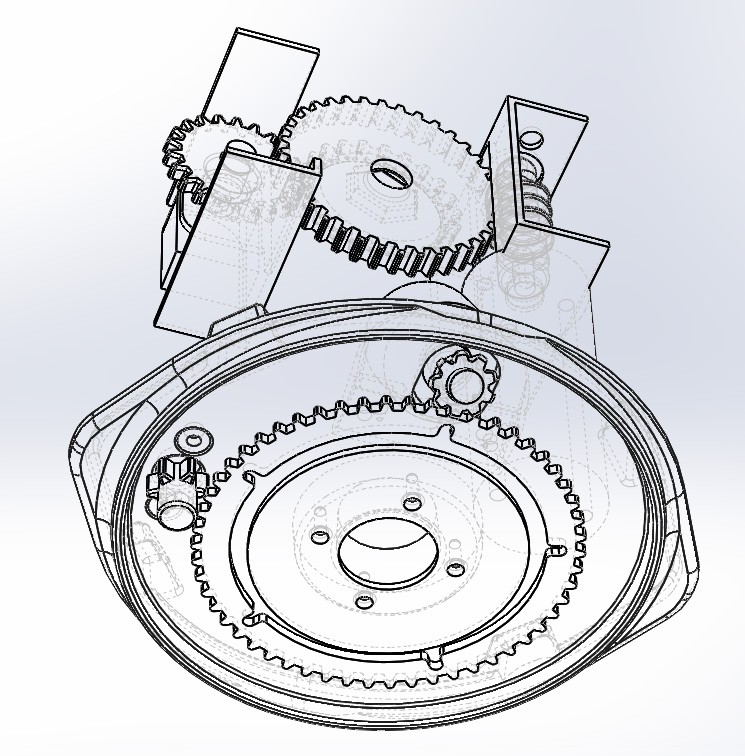

01/02/2022 at 08:58 • 0 commentsThere has been a lot of activity lately, and now the new MK2 prototype is coming along nicely and should be finished sometime next week.

The new design uses linear potentiometers as position encoders instead of limit switches, which means a lot of extra gears are needed. That takes a lot of time to design, but it's well worth it as you can see...

![]()

-

Casting aluminum, so much fun!

12/19/2021 at 17:24 • 0 commentsWhen I started building the furnace and all the tools needed for the craft of casting, I was skeptical that it would turn out any good. The videos I have seen of green sand molds made it look quite hard and prone to errors. But even with my simple homemade cat-litter green sand it worked like a charm!

![]()

There is definitely some skills involved, but with not too much exercise I am sure I will learn to make really intricate parts for the Satran antenna rotator.

![]()

The prototype foundry is very simple, and uses charcoal briquettes and a small 12v radial fan that pumps fresh oxygen into the fire. The crucible was made of an old christmas tree stand by some welding. It turned red hot and I was worried the bottom would give up, but it worked perfectly. As soon it got hot enough the aluminum melted in seconds, very satisfying.

![]()

![]()

![]()

As you can see the part was quite detailed (its approx 6cm in diameter and 2-4mm thick. You can even see some of the layer lines from the 3D-printed original part. The feeder/riser-holes unfortunately weren't perfectly designed so there was a huge air bubble in the middle of the finished part. But next time I will take more care to create a much better mold, and perhaps buy or make some oil-based casting sand. Also with some grinding, sand blasting and powder coating it's gonna look great and last for years.

SATRAN - Satellite Tracking Antenna

Wifi-controlled, azimuth/elevation antenna rotator.

Daniel Nikolajsen

Daniel Nikolajsen