-

Rolling Up My Sleeves

04/02/2021 at 15:25 • 0 commentsI've been enjoying using my TI-58 and TI-59 calculators, and the vastly increased run time before recharging is required. The only drawback is that I have to be very careful when removing or inserting the pack to avoid breaking the fragile retention tab on the FDM 3D printed housing. The reason for this fragility is that the best orientation to print the housing is exactly the wrong orientation to print a robust flexible retention tab.

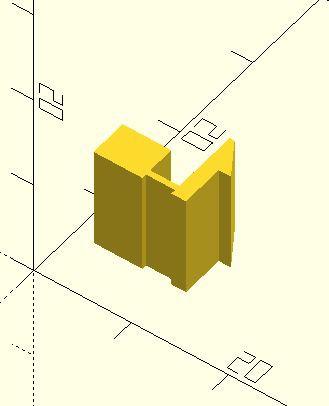

I finally "rolled up my sleeves" and did some more work on this. I started by isolating the latch tab from the housing model and rotating it to the correct printing orientation:

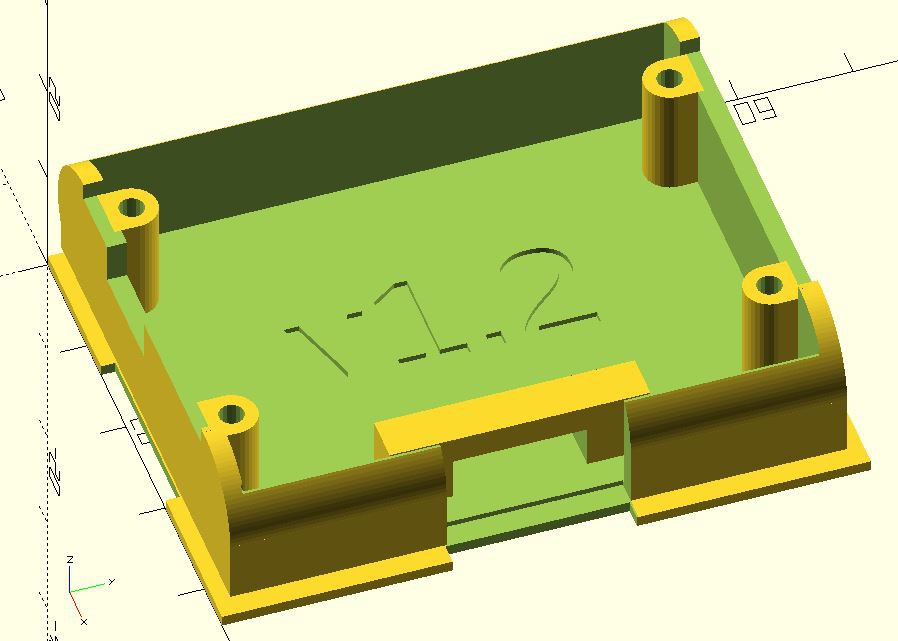

I then printed several of these, with varying beam thicknesses (0.5mm, 0.6mm, 0.7mm, 0.8mm) from PLA+ which results in a bit nicer overall finish. This orientation puts the axis of bending around the Z axis, which is exactly how a FDM item should be oriented to survive bending cycles. The amount of flex of the 0.6mm beam variant seemed pretty good, so the next step was merely to adapt the rest of the holder model to accept the large "stub" of the tab and try it out:

Of course, when slicing this model, supports are required to hold up the 'bridge' of the socket. It actually took a couple of tries to get the socket part to be strong enough and have sufficient clearance to mate with the retention tab piece. After printing, I carefully cleaned the support stuff from the inside of the socket and inserted the tab piece. The results seem to be much more robust and I feel much more confident about the longevity of this holder versus the less complicated all-in-one style.

-

PETG to the Rescue!

02/07/2021 at 19:00 • 0 commentsPrinting the holder from PETG makes a world of difference! This material has a lot more 'give' than PLA and the fragile retention tab really benefits from this. I've even had a few holders fabricated through the Voodoo Manufacturing service and they are even better than what my modest 3D printer can generate - at a very reasonable price (about $6 each holder).

-

'Mechanical Stuff is Hard'

01/31/2021 at 22:30 • 0 commentsStill playing with the holder 3D model. I had to adjust the latch tab (again) a bit, to correctly engage with the inside of the calculator. I still struggle with the fact that I'm printing the holder "wrong". That is, I'm printing the outside surface of the holder as the bottom, and building upwards - this makes perfect sense for everything except the latch. The latch wants to be printed "sideways" so that the FDM lines are running perpendicular to the arc of motion. Unfortunately, on my printer, this would require a lot of support material and probably result in a really ugly holder.

I've tried printing with "soft PLA" (SPLA) and geez is that stuff icky. What a mess! I don't have a heated bed on my printer, so I can't print Nylon or PETG which would probably be much better.

My gut feeling is that, long term, once I've got the geometry of the holder worked out, I'll send off an order to a place that can generate very high quality prints in a nylon-like material and have a dozen or so made (I've got quite a few Ti-58 and TI-59 calculators, and maybe others will want some of these, also).

-

Boards Arrived, More Holder Tweaks

01/22/2021 at 04:30 • 0 commentsThe PCBs arrived today, and the first board went together well. I had neglected to order the correct USB receptacle earlier, so that’s not populated yet. Those will arrive next week, but for now I can charge the battery using my HP pack boards.

I was a bit overzealous on making sure the TI contacts would touch the PCB pads. The PCB was so far into the cavity that the attachment screws and the “charging indicator” LED collided with stuff inside the TI-59 and prevented lid closure. So, I quickly tweaked the holder model by reducing its height by 2mm and printed a new one. Perfect fit in two of my TI-59s and with the holder latched I was rewarded with a running calculator.

Tomorrow I’ll print a couple more and check fitment in a few more calculators. I will also connect an AC adapter and ensure the ideal diode and zener protection is working as expected. If all is well I will upload the revised OpenSCAD holder model (ver 0.6 for those keeping track) and some assembly photos. Final release will have to wait for those pesky USB receptacles to arrive...

-

PCB's ordered!

01/14/2021 at 22:14 • 0 commentsOrder sent off to PCBWay for fabrication, expected before end of January.

1.6mm thick FR4, ENIG surface treatment, black mask, white silkscreen

These boards will be used to check the 0v5 3D printed holder to see if all is well.

-

Mechanical Adjustments

01/13/2021 at 00:57 • 0 commentsI have made some progress on modeling the battery holder, using OpenSCAD tool and a 3D printer to iterate the design a few times. There are a couple of critical dimensions on the BP-1A battery pack, notably the amount of latch tab “engagement” and the depth of the “step” that fits beneath the calculator housing towards the top of the cavity. But, I think I’m there, now I’ll upload the files to GitHub soon.

It seems that PLA is not the best material with which to make living hinge features. It’s quite brittle. The retention tabs have broken off from most of my prototypes. I suspect the best solution is to find someone to print it in ABS - or perhaps send to a service and get even better quality.

I also managed to enlarge the PCB dimensions a bit; now 30x50mm. This should help with the crowding I’m facing in layout, trying to avoid interference between SMD components and the LiPo battery pack.

tomcircuit

tomcircuit