-

Talking to plants in Telegram!

07/14/2021 at 17:22 • 0 commentsuPlant gave us the opportunity to master technologies that we have not used before. This new technology was a Telegram chat bot running on ESP32.

We chose Telegram messenger because we wanted to communicate with plants not in a separate app, but as a chat in the same place as with relatives / friends / colleagues - we use Telegram a lot, for most of our messaging needs and also to read channels and news. The example bot is often used to retrieve data or control electronics. Our goal was communication with plants.

Writing a bot is no less difficult than writing firmware (technically speaking it is a frimware as well since it runs on a MCU), so the process is not fast. At the moment, we have made it possible to connect several uPlants and can receive data on their condition (soil moisture, air temperature).

Next, we plan to be able to choose the "character" of the plant and based on this, the plant will be able to communicate with you the way you imagine it.

For now, plants already can respond to questions with several dozens of synthesized phrases - and of course stickers!

-

uPlant v3 is here - all green PCBs and 3D printed case

07/13/2021 at 15:07 • 0 commentsAfter getting good readings from the 2nd PCB version, we decided to make a third iteration that would solve all its problems at once!

The list of changes is quite significant:

1. Power source. While LiPo batteries are good and more eco-friendly than disposable ones, they complicate production and shipping. We decided that if one battery can last for 2 years, then a disposable one wouldn’t be such a bad choice - and so we changed it to CR2032.

2. Connectivity. IR LED proved to be unreliable and inconvenient - so we switched to BLE, and it looks like the only way to keep the cost low with it is to use nRF52 chip - namely, nRF52810, so that it would also handle all calculations (thus replacing atmega328). In order to keep power consumption even lower, it works as a non-connectable device, only advertising data once in a while.

3. We reduced the size of the upper part of the board as much as possible - basically it’s the size of the battery plus a small PCB antenna (34*30.2 mm).

4. We made the probe thinner and more rounded at the lower edge to reduce risk of damage to the plant’s roots when uPlant is inserted into the soil. They're now 6 mm wide and 1.2 mm thick (same thickness as the main PCB).5. We made probes removable and of several lengths for different sizes of pots (so far we have made two lengths to test them - 60 mm and 120 mm).

Here’s some fre$h green v3 PCBs - we got them just a few days ago, and made some green 3D-printed cases to match the look:

![]()

![]()

-

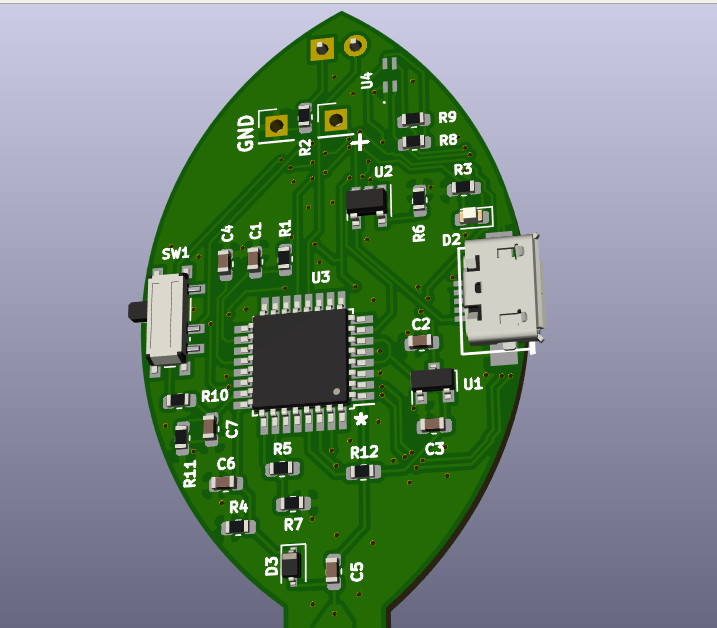

uPlant v2 - capacitive sensing!

07/11/2021 at 21:56 • 0 commentsWithout thinking twice, we decided to change the design of the board. First, instead of two probes with galvanic measuring we used one with capacitive measuring. Then we made the top in the form of a leaf. And finally, we switched to the green color of the PCB - quite an obvious decision that yet took us some time!

Components remained mostly the same - design based around atmega328 with LiPo rechargeable battery, and IR LED for sending out measured data. Our motivation was to keep it extremely cheap in production - although when implemented, it became evident that IR data link is not really convenient for this purpose.

The photos show that uPlant is now indistinguishable from a plant!

![]()

-

Let's start!

01/15/2021 at 18:22 • 0 commentsWe came up with a simple and rather generic PCB design, produced a prototype set - and assembled one to test the whole concept. We never dealt with this kind of sensors before, so most likely we'll change a lot as we go - possibly the whole approach - but the first step was made.

Unfortunately we didn't have soldering paste at hand, so had to put solder on each pad, then cover them with flux again, and then place components - even without paste, hotplate is still more convenient than soldering them one by one.

Anyway, here is a video of the process:

uPlant soil sensor

open source soil moisture, temperature and light sensor with Telegram bot

Ultimate Robotics

Ultimate Robotics