-

1Unpack Your Kit & Download/Print Assembly Diagram

Your kit has color-coded components and a flyer with the color key. We've given you some extra resistors, capacitors, and LEDs, so you may have left-overs when you're done. Go to the files section of this project and download or print the assembly diagram. You may also want to cross-reference components with the schematic.

You'll note we did not print reference designators on the back. This was purposeful, just to make the kit a little more pesky. But it's good practice - not all circuit boards have enough room to mark reference designators. So think of it as building your surface mount troubleshooting and assembly skills!

Here's how to figure out which components go where:

- Understand your component values. The components are all color-coded. You can match them to the colors on the flyer to figure out their values. Or, if you have a multi-meter with sharp probe tips, you can poke right through the tape and measure resistance and capacitance directly. Also, the resistors actually have their resistance marked on the top if you have magnification or good enough eyes to see it! The leftmost 3 digits are the resistance, and the digit on the right stands for the number of 0s after. It's always in ohms. So "1000" means 100 ohms, "1203" means 120,000 ohms (or 120k ohms).

- Understand your reference designators. We've been SUPER NICE and put the reference designators for the resistors, capacitors, and diodes on the color card flyer. You can also look at the schematic, and match up the values with reference designators.

- Figure out where each component goes. Look at the assembly diagram, which shows you the reference designator for each component's position. Match up the reference designator, value, and position, and start soldering!

-

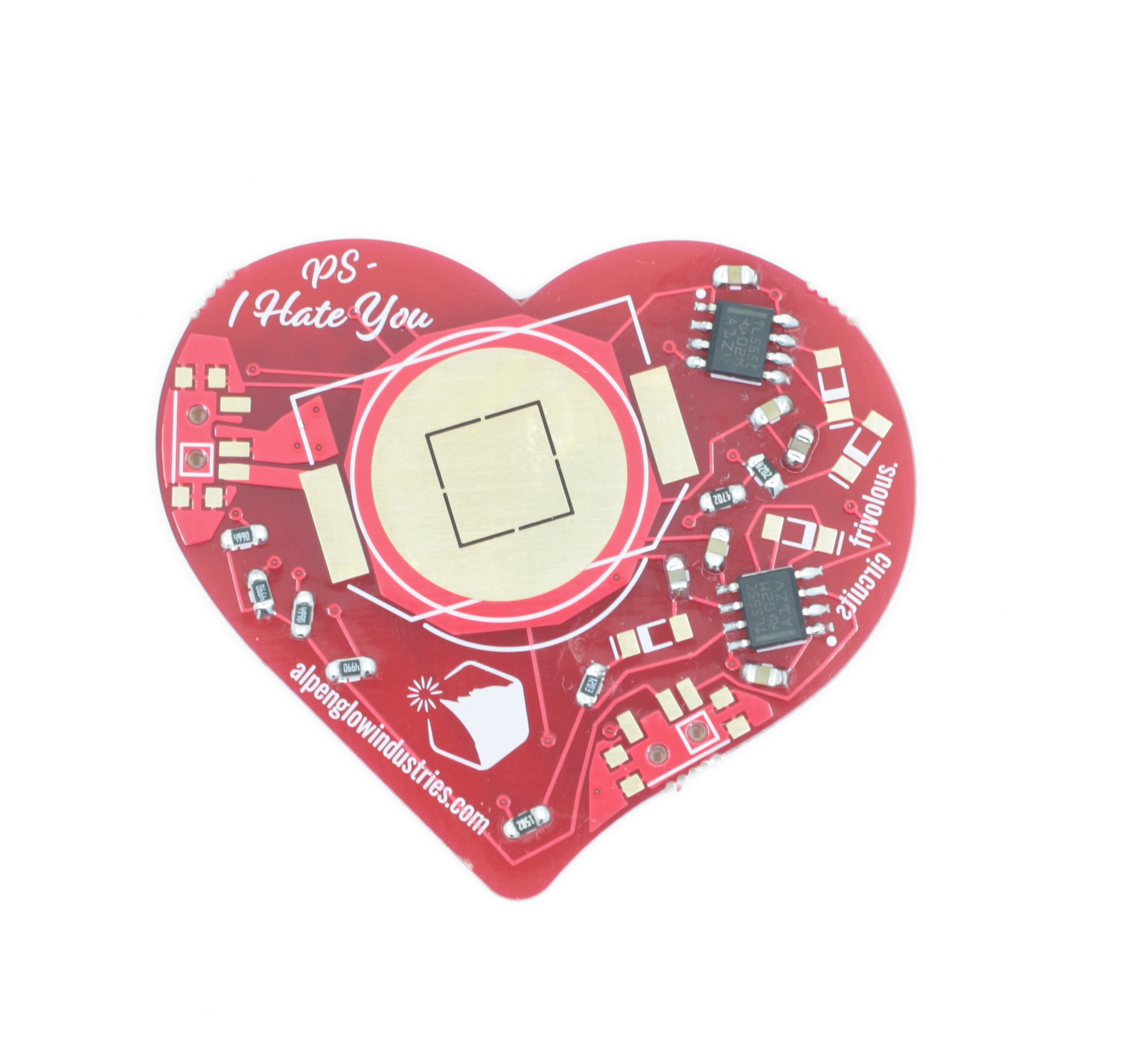

2Start with the 555 timers

Which solder/flux should I use? Lead-based solder will be easier to learn with, but lead-free is totally fine too (and better if kids are handling the solder, and more eco-friendly). We prefer to solder SMT components with water-soluble flux because it's more aggressive and wets out the solder much better, enables you to hit the solder with the iron a few times before it's gone and you get crystallized/cold joints. BUT BE SURE TO CLEAN IT OFF WHEN YOU'RE DONE. Water-soluble flux is more aggressive and can corrode boards if not cleaned off. It is also slightly conductive and will affect the function of your final circuit. Our next favorite is RMA (rosin mildly activated), and our least favorite for SMT work is no-clean. But if that's all you have, it's OK! Don't worry about it, just use it. More important is having a small diameter solder, to more easily control the amount applied. We like using 20 mil (0.5mm) or smaller diamter. We also love using flux pens, it's great for adding just a small bit of flux to a joint to reflow a cold one.

Now solder your 555s!

Note that these are directional! The line on the IC (chip) marks the "top" of the chip, pin 1 will be at the top left. The top of the chip is also noted by a "U" shape on the silkscreen (under the chip in these photos). Also, pin 1 is denoted by a dot.

-

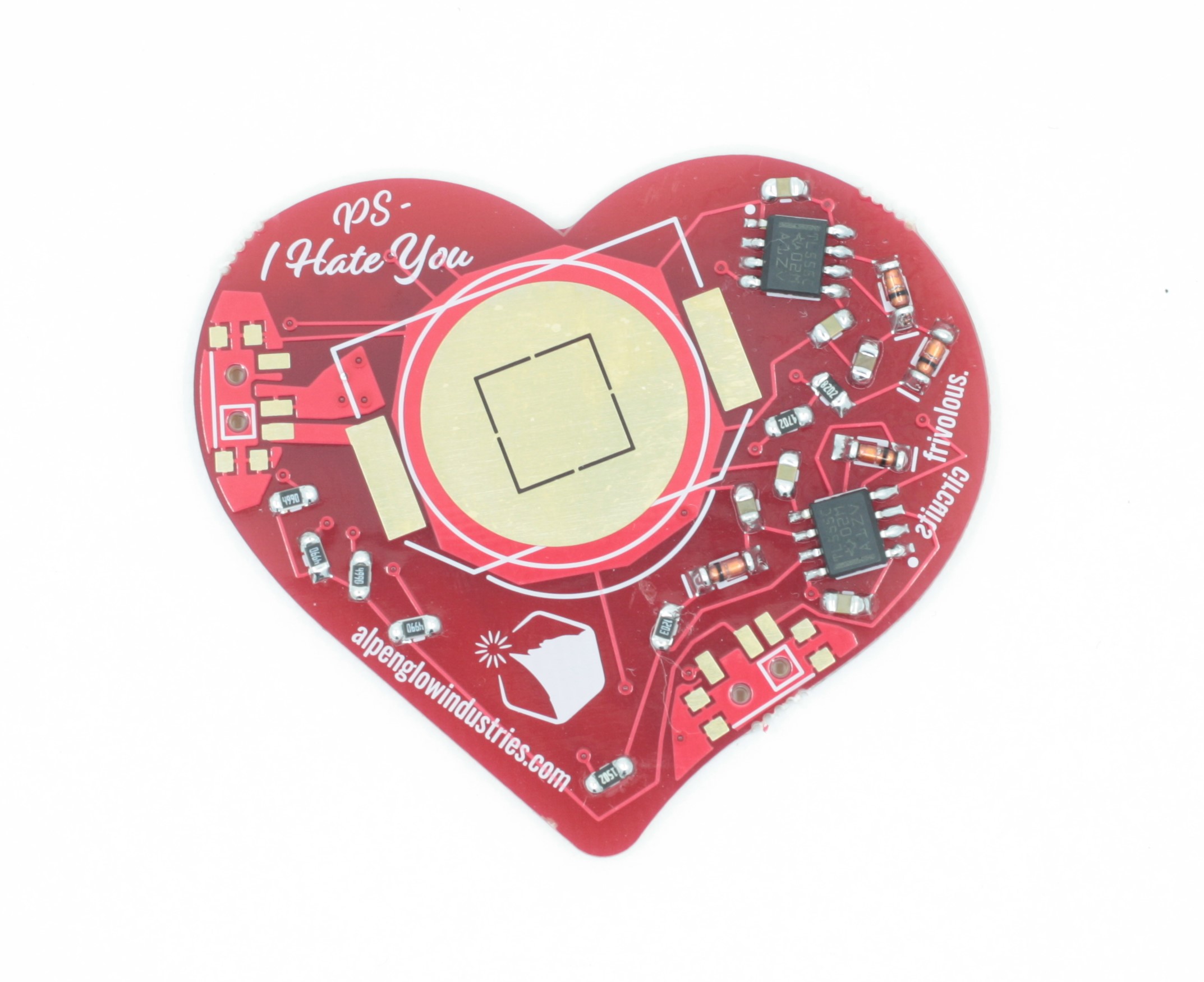

3Next, solder all of the resistors

Be sure to check with the color chart and assembly diagram to figure out which value goes in which position. We recommend keeping your resistors and capacitors in the tape, and only pulling out one value at a time as you're ready to solder it. This keeps them from getitng mixed up on your bench!

If you're soldering two kits at once, use the same technique. Solder all resistors of one value on both boards before going onto solder the next value.

We have given you one extra resistor of each value, in case you accidentally send it flying! The key is to hold your tweezers in a relaxed grip, with just enough force to hold onto the component.

-

4Then, capacitors

Same as above, don't take a component out of the tape until you're ready to solder it! Solder all of each value before proceeding to the next, to minimize the chance of mix-ups.

-

5Solder on all the diodes

Make sure they are facing the right direction! The black lines are the cathodes, they go toward the white lines on the silkscreen. These are a little bit of an old-school glass style called mini-MELFs, they are perfectly cylindrial and like to roll off of your bench. You're welcome!

-

6Switches are next!

We didn't add these to the card because they should be self-explanatory. You can't screw these up.

-

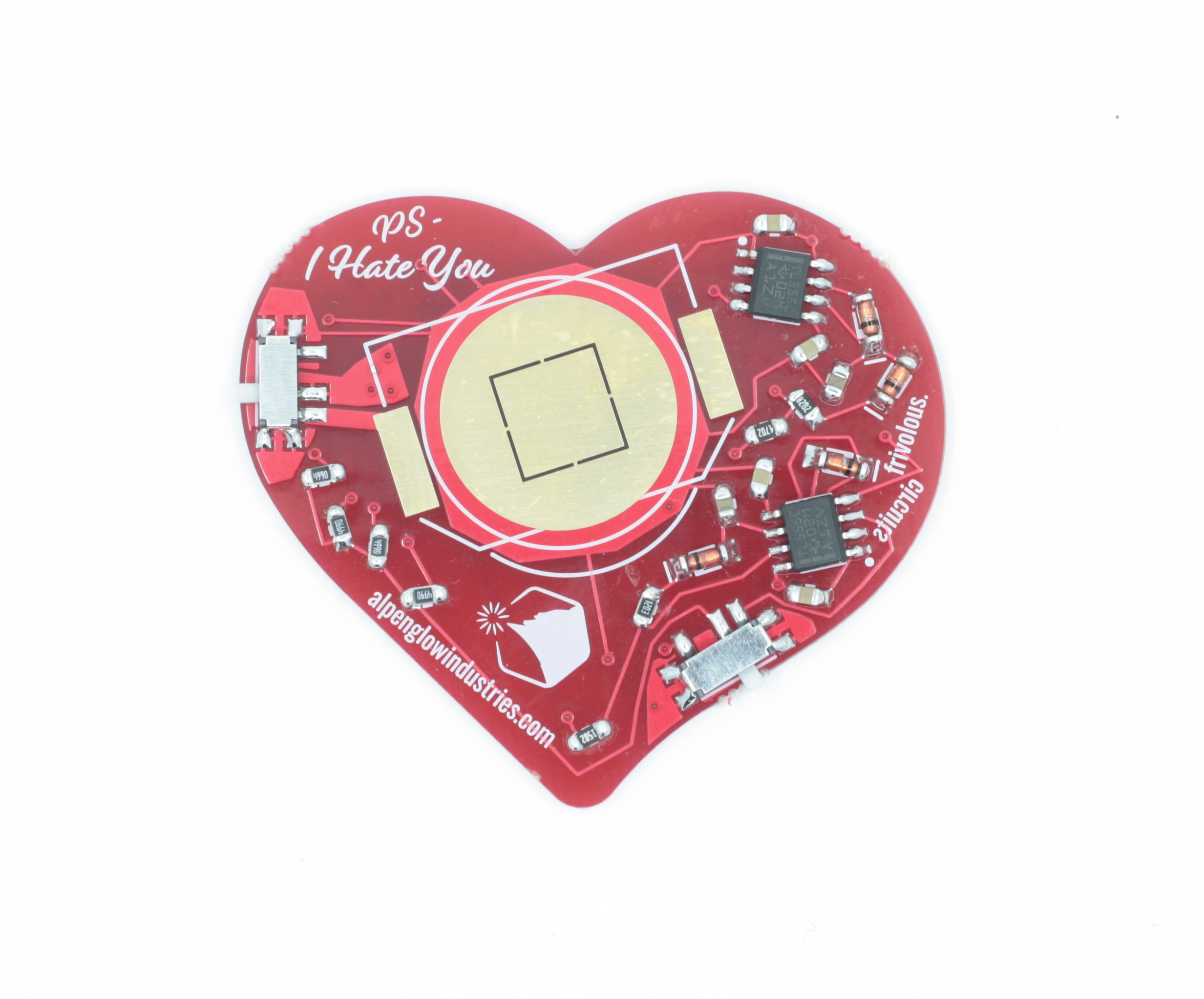

7Now, flip the board over and solder on the 4 LEDs

YES, you are skipping the battery retainer for now!

Make sure the LEDs are facing the right direction! The white lines on the silkscreen should be matched to the veeeeery small dot on one side of the LEDs. You can see this in the photo below. You can also look at the underside of the LED, and note there is something that looks like a line with a dot on one side, which is the very pixelated approximation of an arrow. The "arrow" should point toward the white line. This is probably the trickiest part to get right, but you'll know if you got it when you power it up for the first time!

-

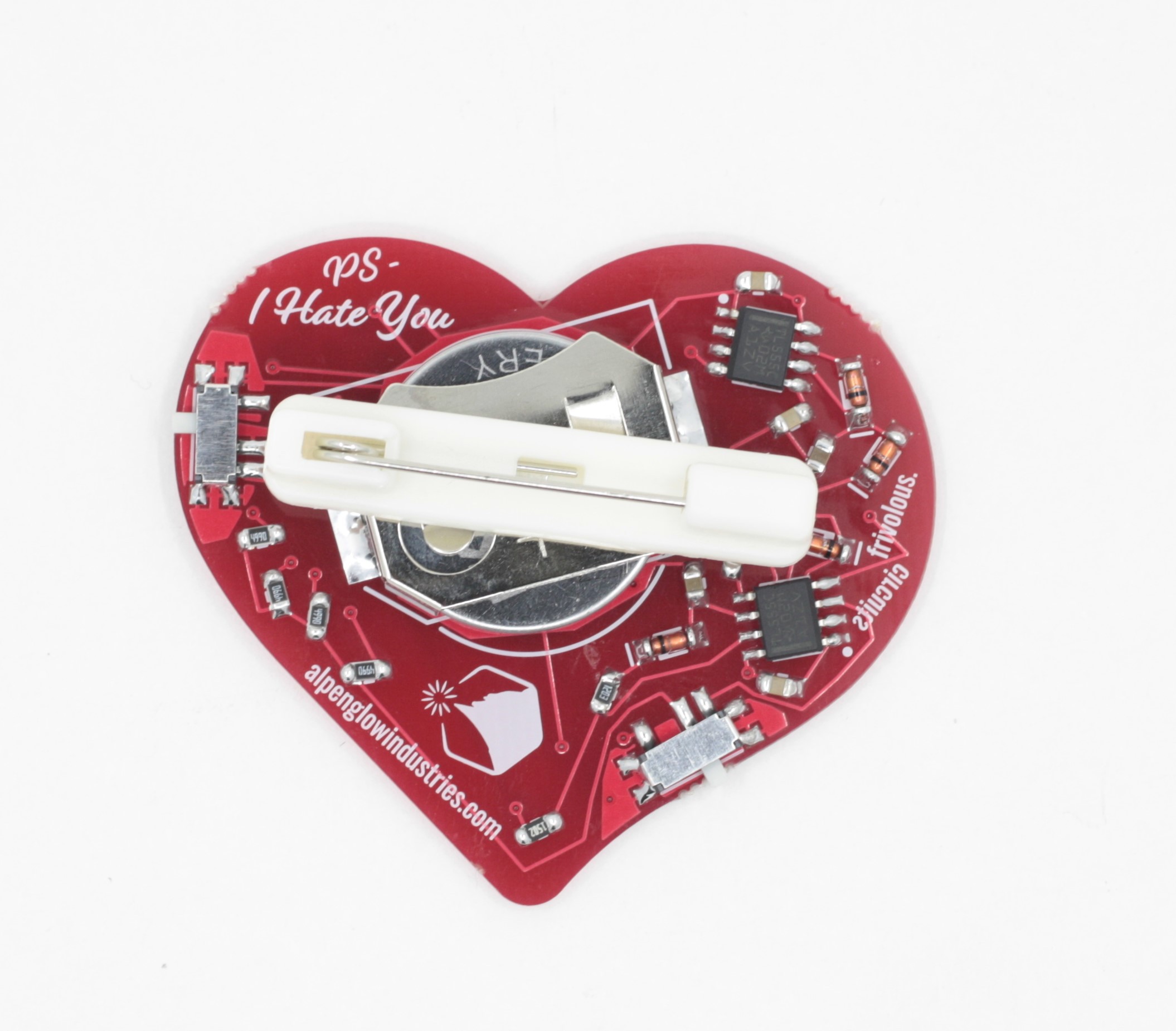

8Flip the board back over and solder the battery holder

Yep, we save this for last so that you had a nice flat surface for the previous step of soldering the LEDs. Make sure the opening faces up (toward PS - I Hate You), otherwise it'll be difficult to get the battery in.

-

9Attach the adhesive pin

If you want to! Otherwise, we also include a magnet if you want to magnet it to something. It's a great workbench or refrigerator decoration, just sayin'.

-

10Clean off the flux!

This step can be important for this board. Especially if you've used a water-soluble flux, the residue can actually conduct enough to alter the blinking circuit! Crazy, huh? This has actually caused issues with production electronics, so now you know a true pro tip. Clean off your flux, even if it's rosin. No-clean might be OK, depending. For water soluble flux, use warm water. For rosin or no-clean, use 90% or higher isospropyl alcohol. In either case, it's also nice to blow off your board with canned air, to get any residual water or alcohol out from under components.

PS - I Hate You

A love letter to all our fellow circuit board artists who hate it when components aren't perfectly aligned at 45 and 90 degrees.

Alpenglow Industries

Alpenglow Industries

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.