-

Liquid level sensing concept

05/12/2021 at 06:45 • 0 commentsMore details coming soon, here are some images

![]()

-

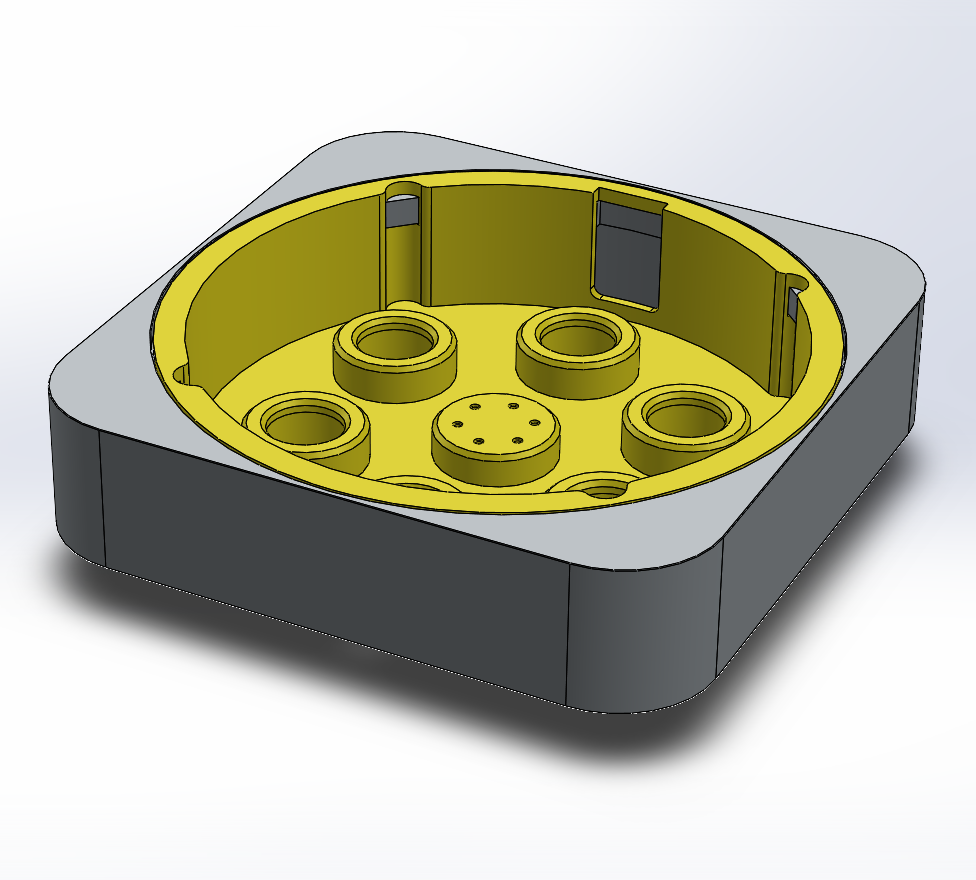

New design and some parts

04/27/2021 at 12:59 • 0 comments![]()

-

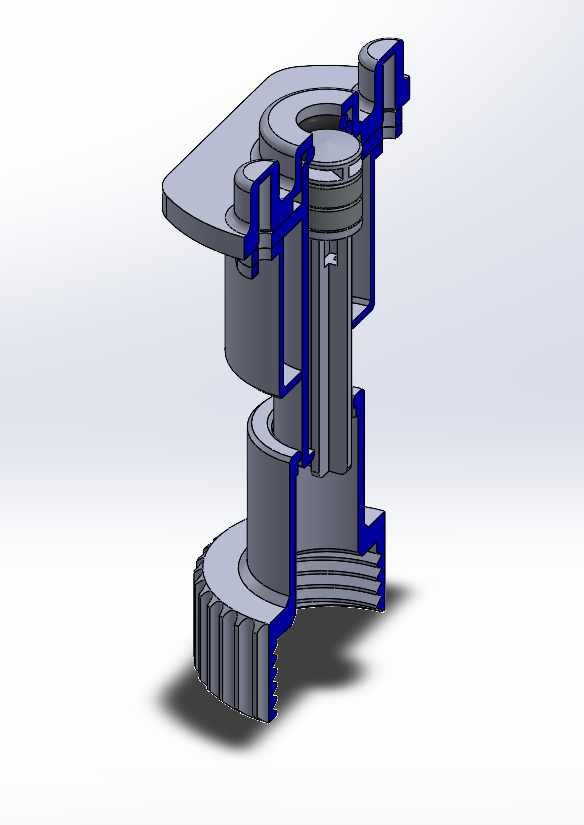

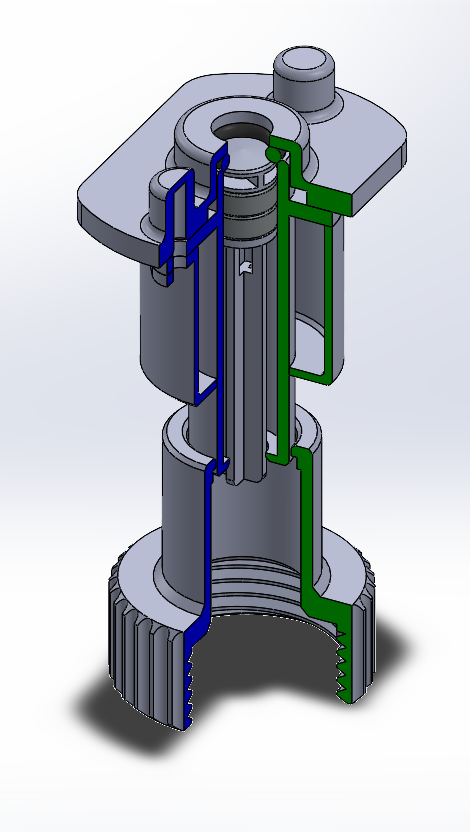

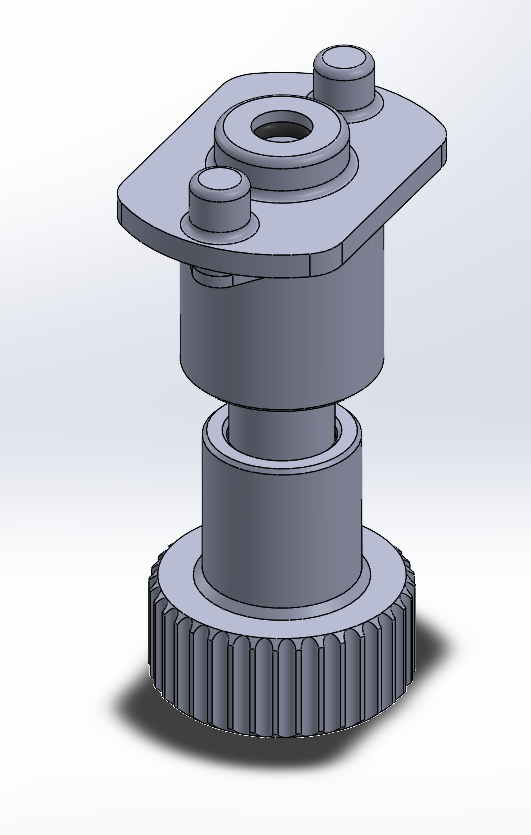

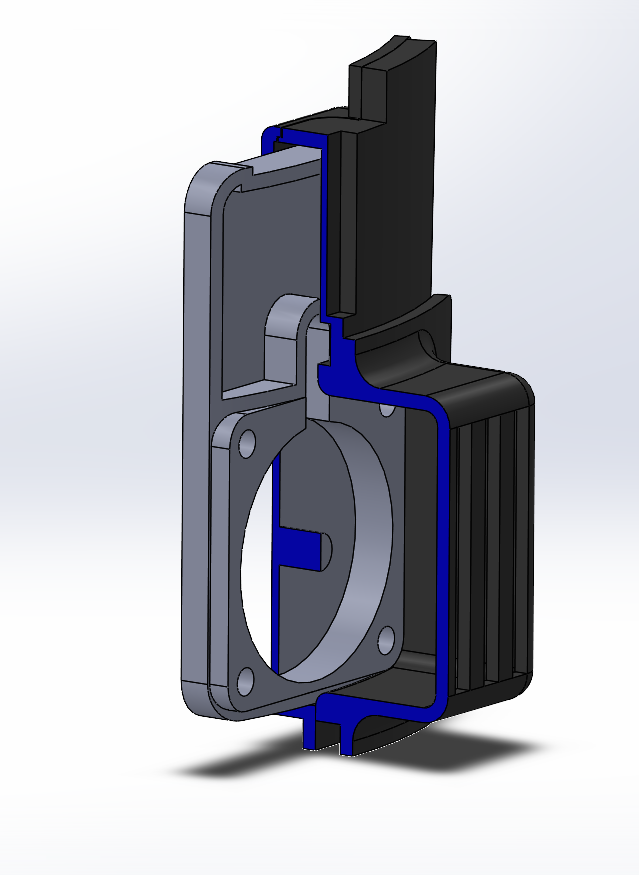

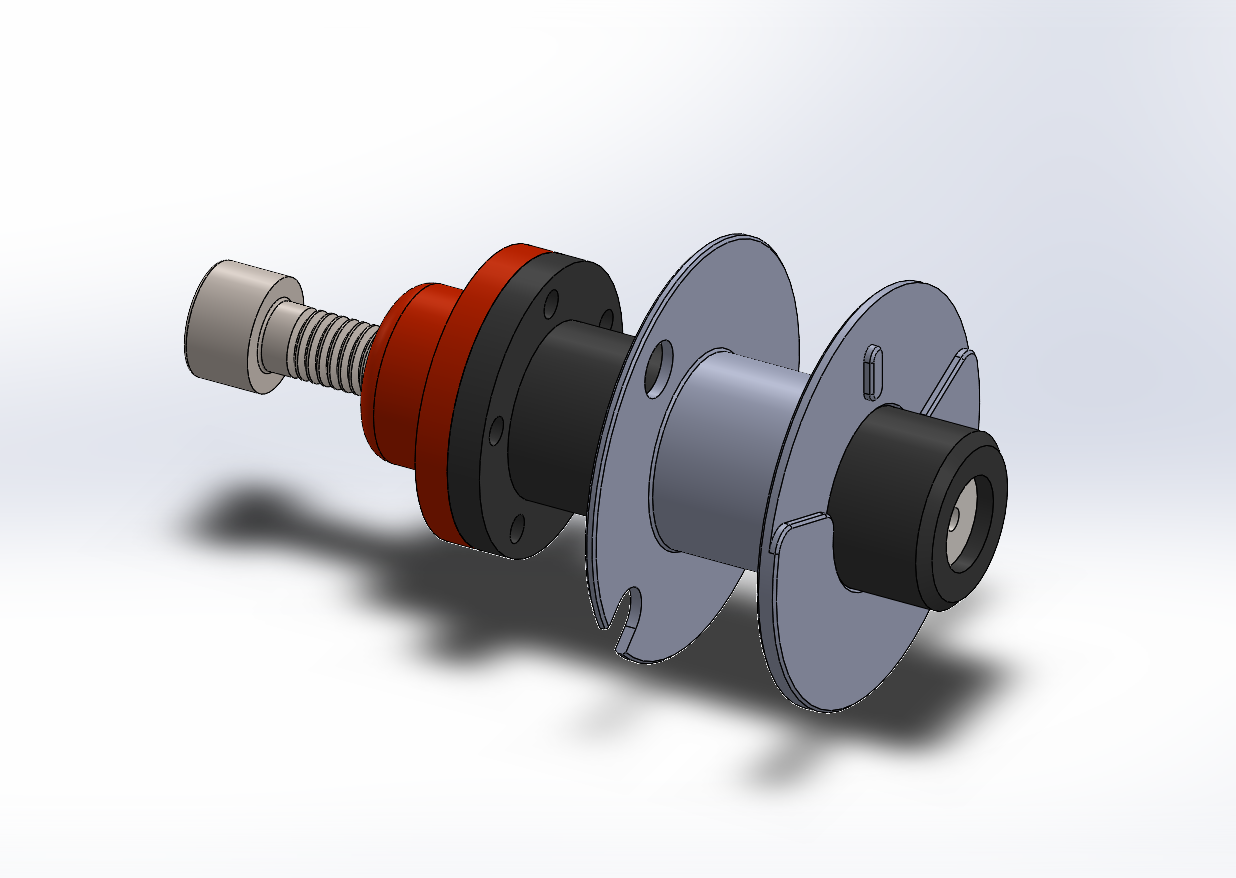

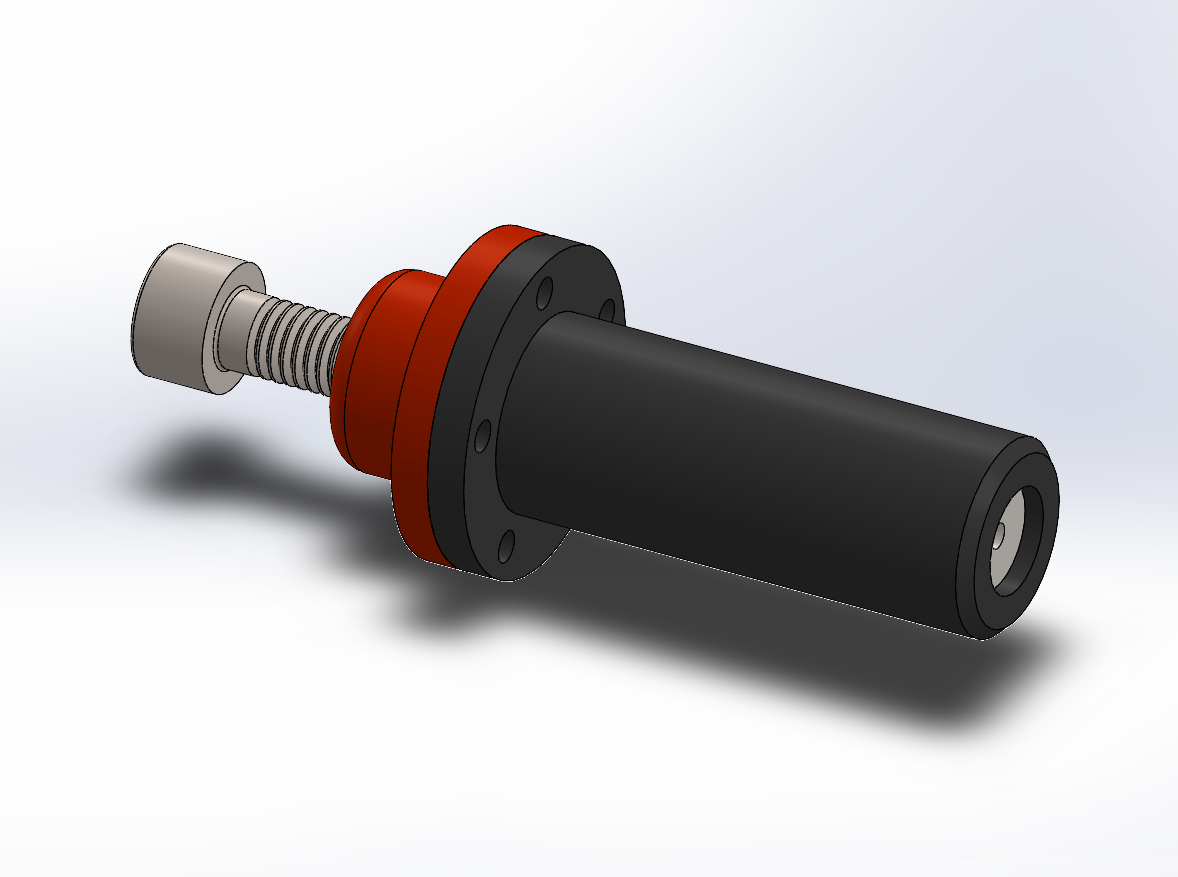

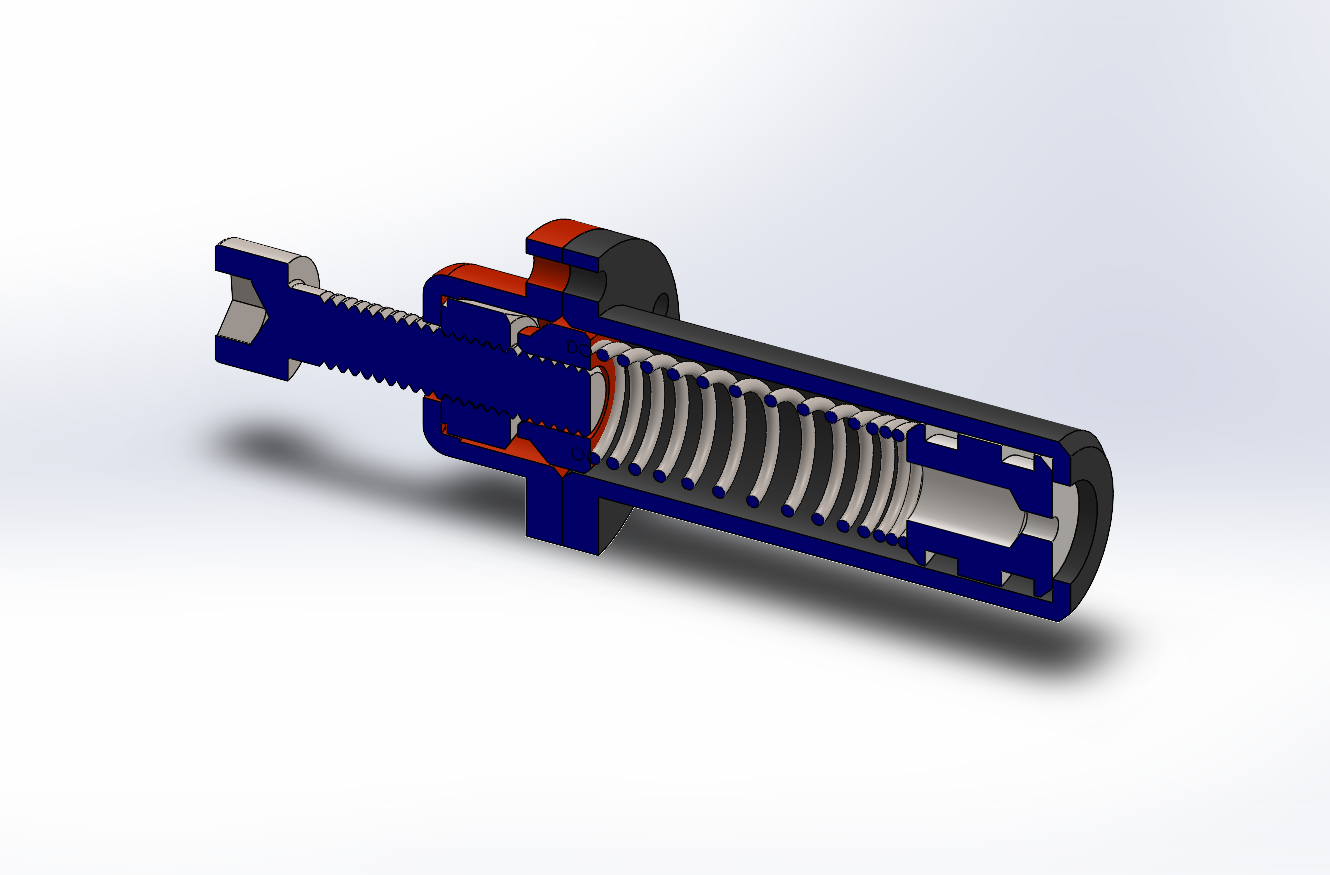

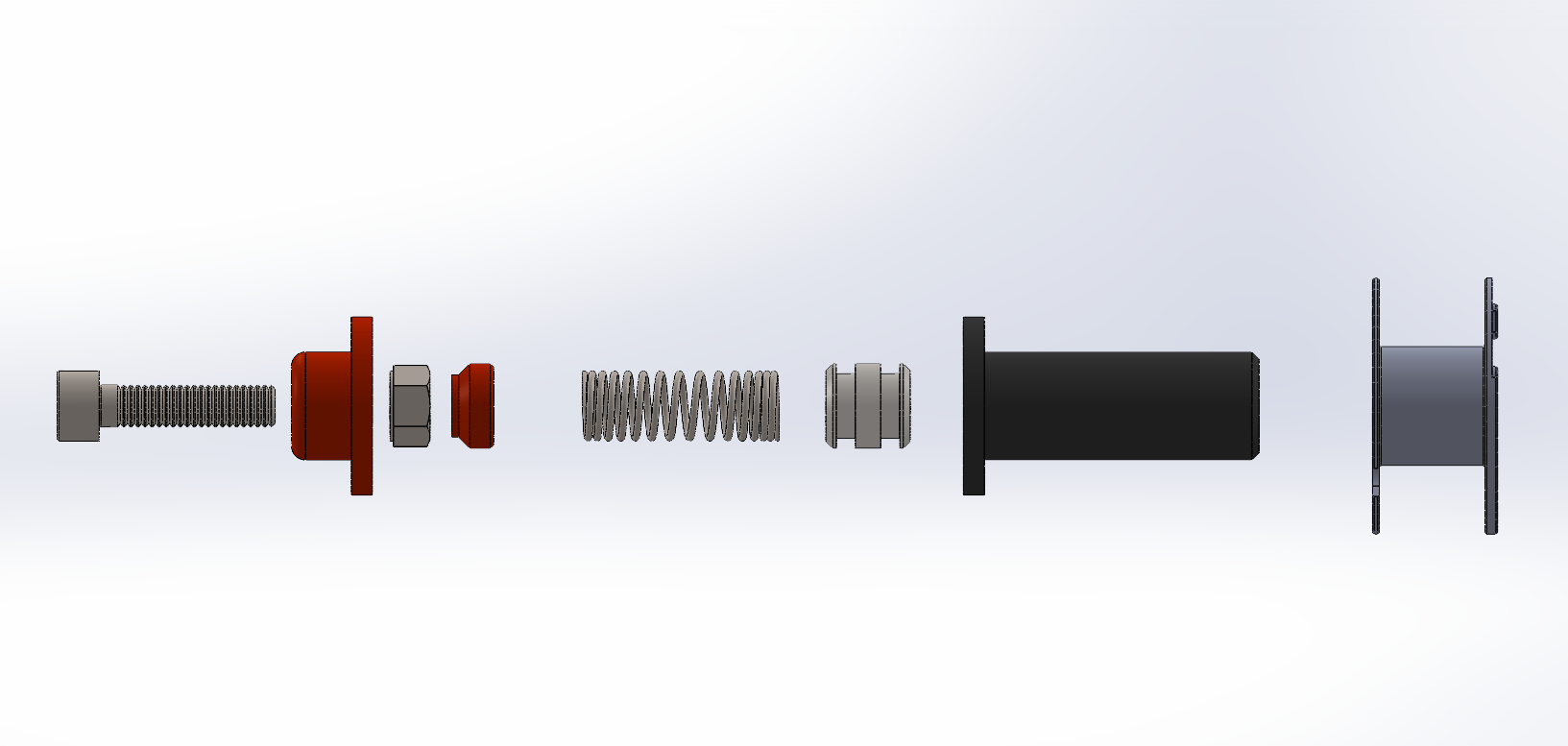

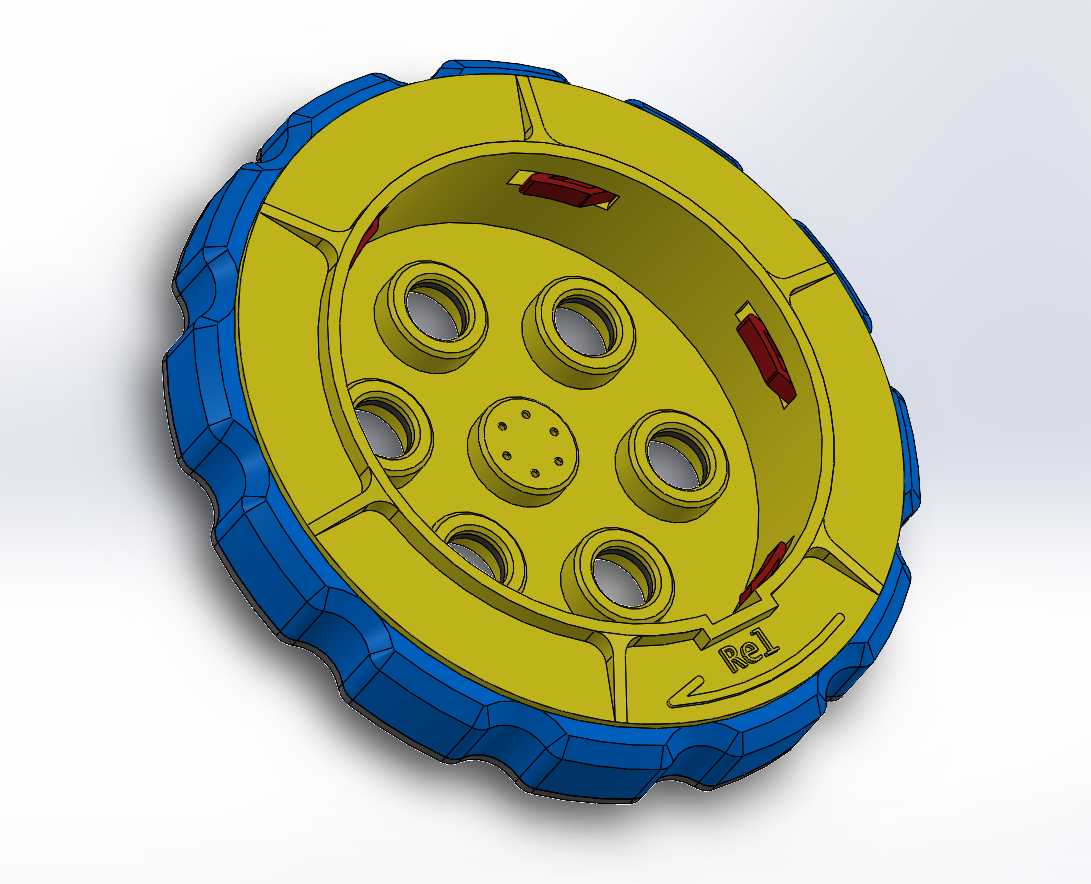

New valve concept [Code name uterus]

04/17/2021 at 10:19 • 0 commentsTesting of the first iteration of the valve design is over. It does not work as expected, downsides are:

- Tight tolerances on the parts

- Additional metal treatment like hard chroming or chemical nickel plating

- High current solenoid coil

- Low wear resistance

- Large part count

Old design

![]()

![]()

![]()

So, here is the new valve concept, we started from the beginning, and the first thing that we did was to separate valve from the lower body of the plant pod. New design has lower part count, improved resistance to wear, no tight tolerance parts, it can be 3D printed, and it uses plastic plunger with ring magnets.

New design

![]()

![]()

![]()

![]()

-

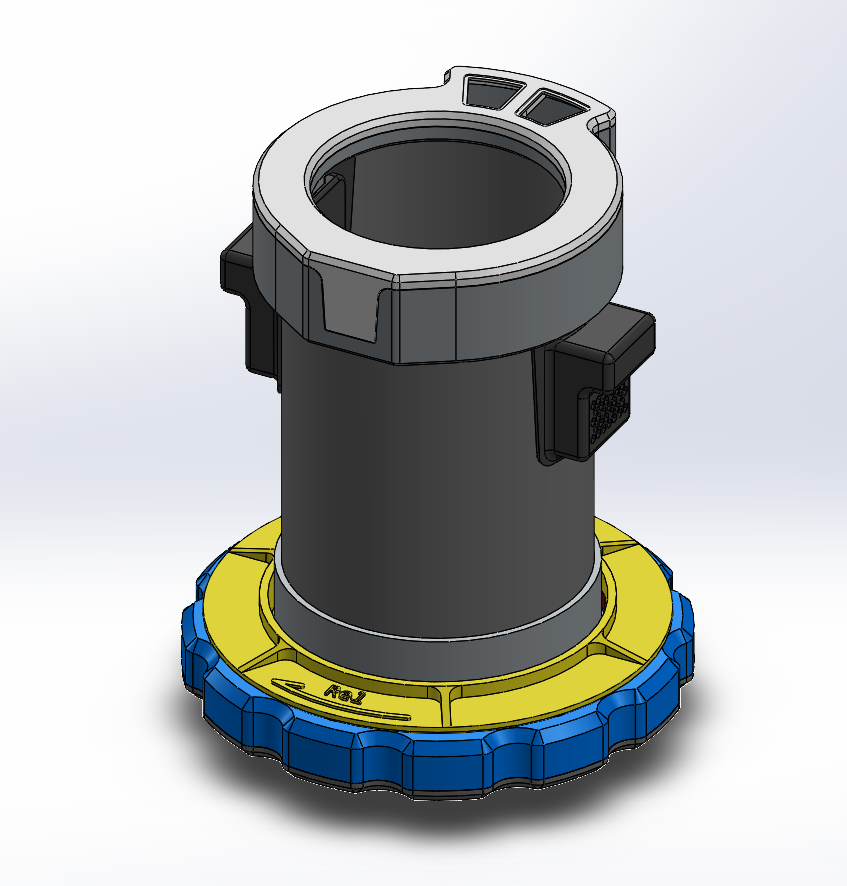

Mr. Potato meats the toilet seat

04/09/2021 at 08:26 • 0 commentsAs the title says, current design looks like a Mr. Potato wearing toilet seat as a hat, so we decided to change it. This is the new concept design of the Plant pod. We will post more details soon.

![]()

![]()

-

Parts!

04/08/2021 at 14:36 • 0 commentsHere are some parts

![]()

![]()

![]()

-

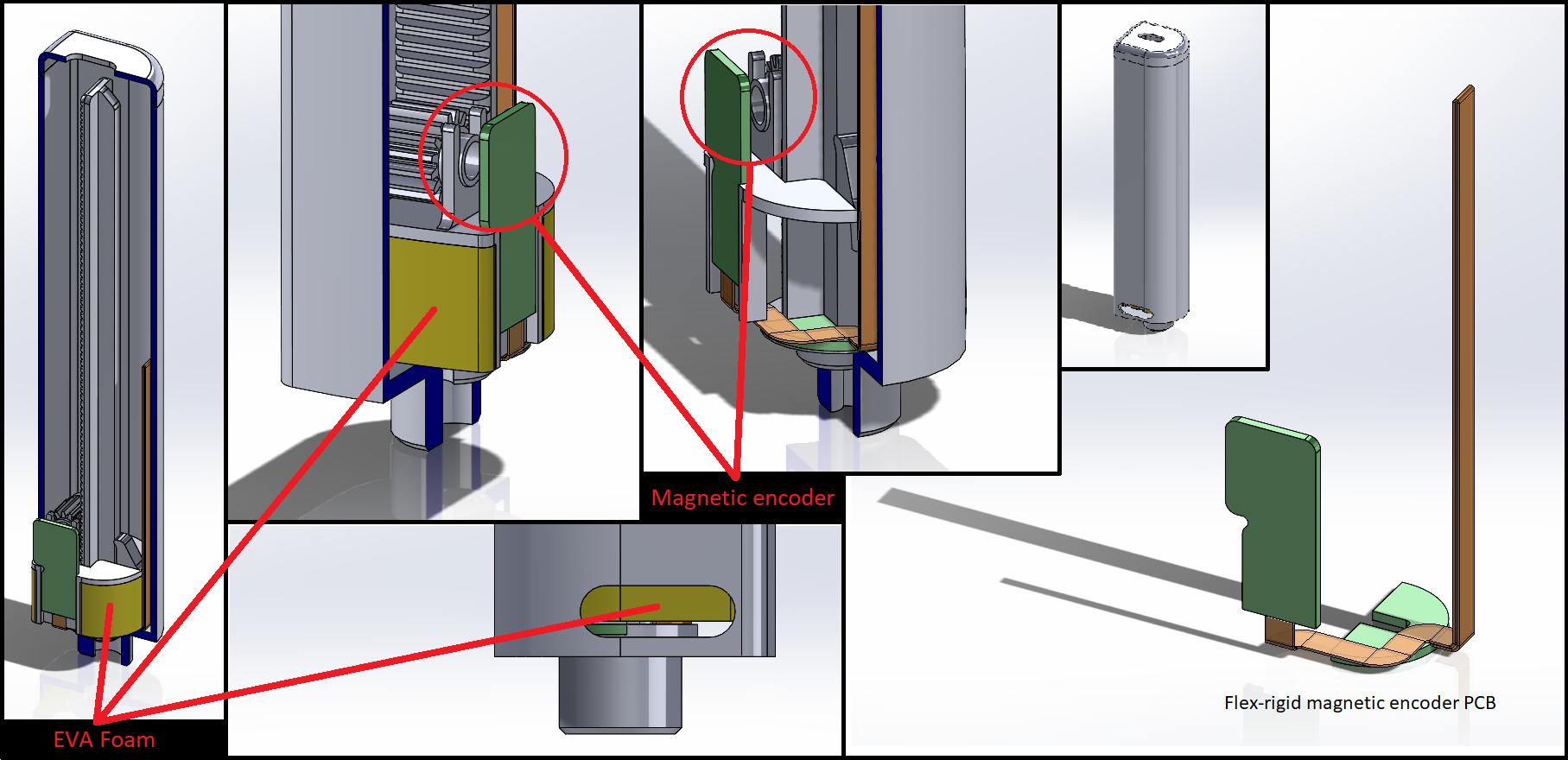

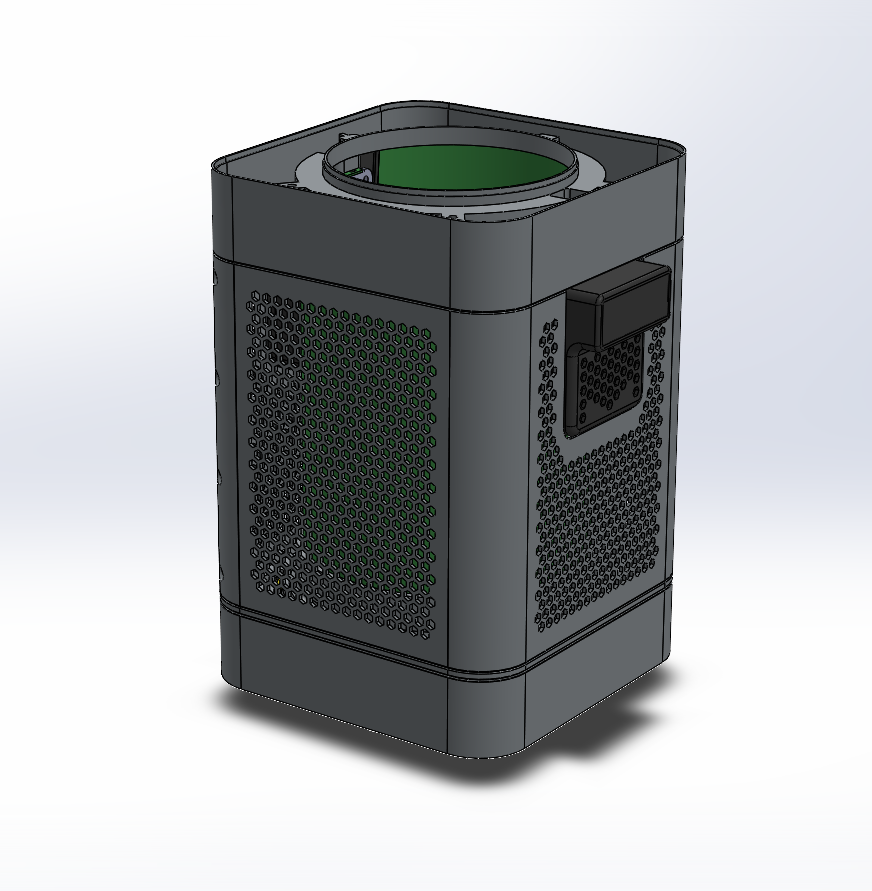

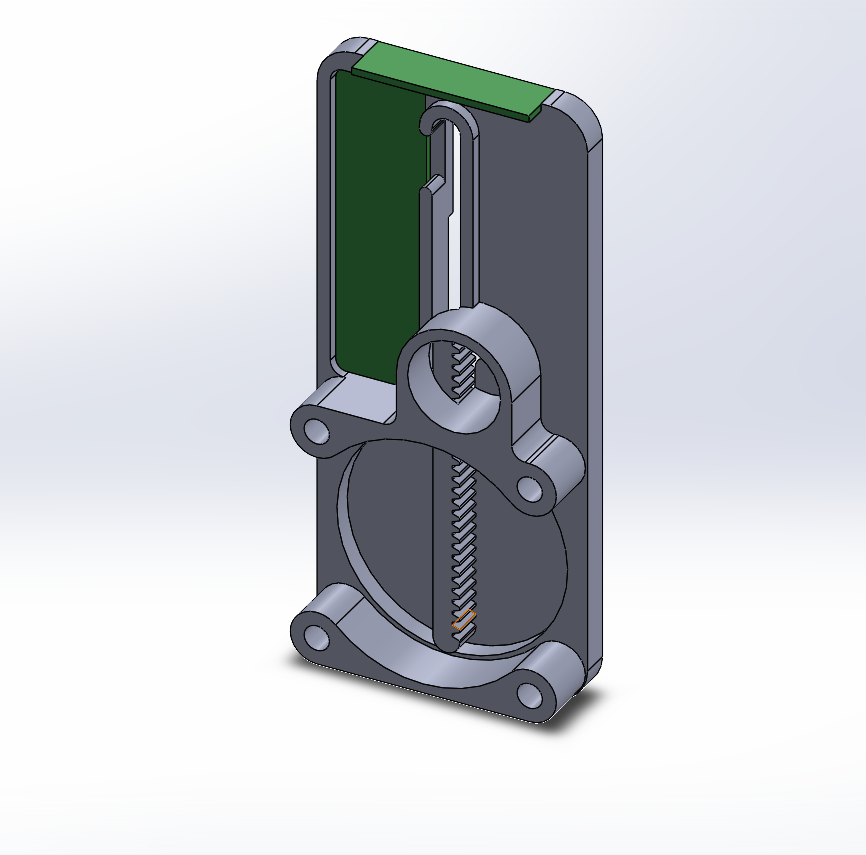

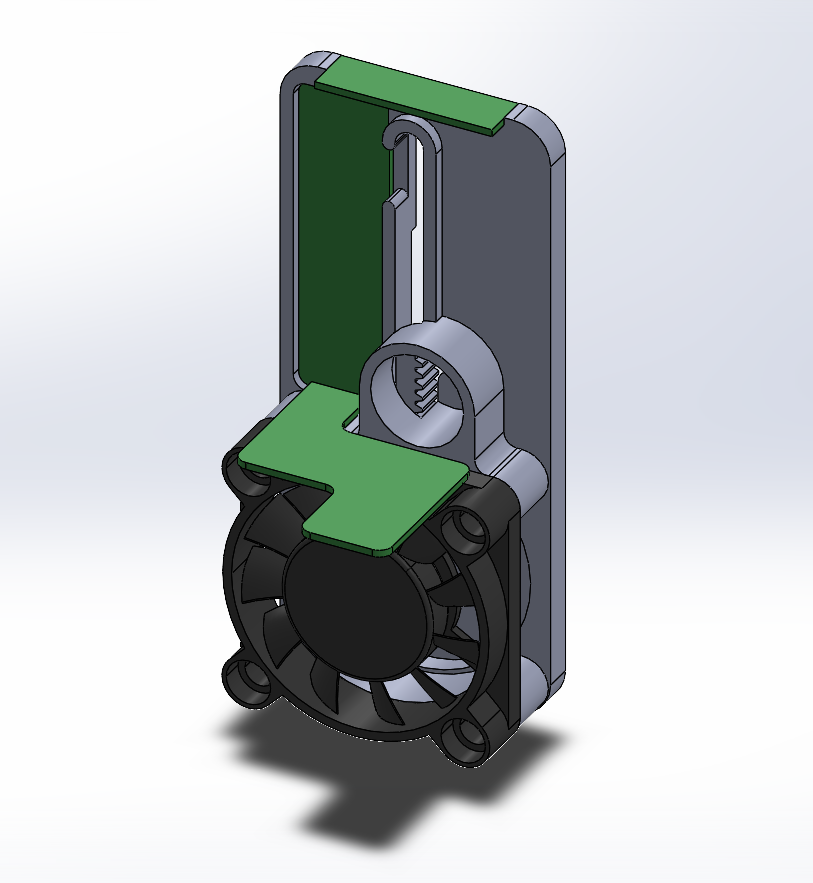

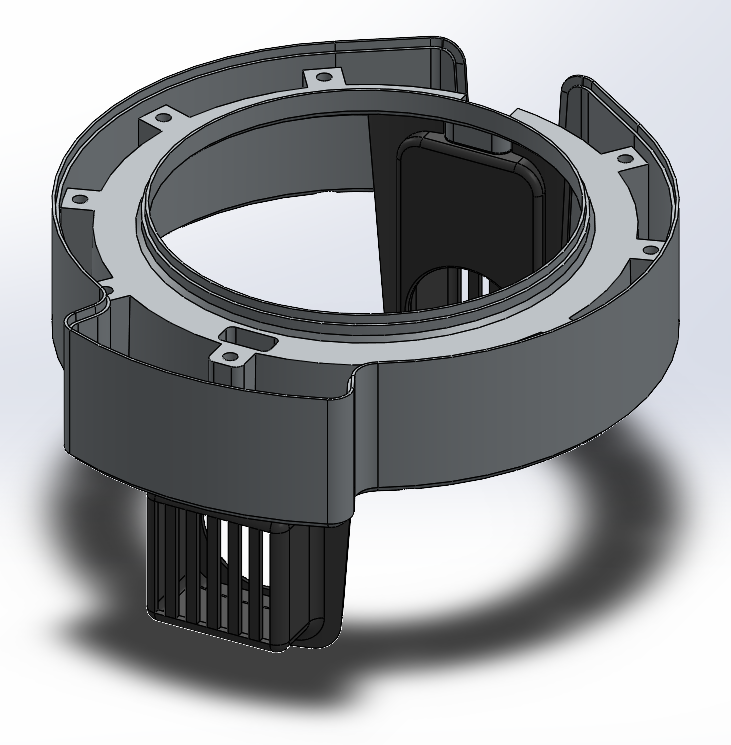

Air IO valve

03/27/2021 at 11:18 • 0 commentsThis is the current stage of the air IO valve component, here are some images:

![]()

![]()

![]()

![]()

Working part of the air IO valve assembly consists of 3010 (30mmx30mmx10mm) fan, small motor with planetary gearbox, that drives the rack of the valve disc, hall effect sensor, that in combination with the magnetic disk on the end of the motor shaft creates an encoder, used to position valve disk, and small limit switch in the top of the rack sliding slot (To be able to determine valves disk top position). Air IO valves are connected to the top part of the plant pod using pogo pins, and uses I2C protocol to communicate with the rest of the system. These valves are optional, and device can be used with or without them, or in some other configuration (Ono valve, one heater etc.)

-

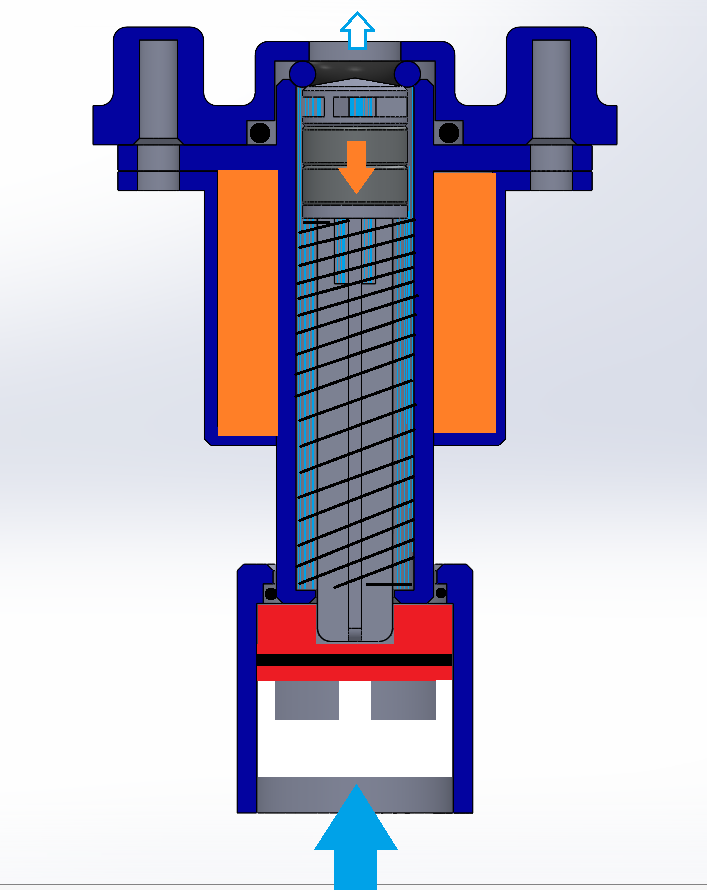

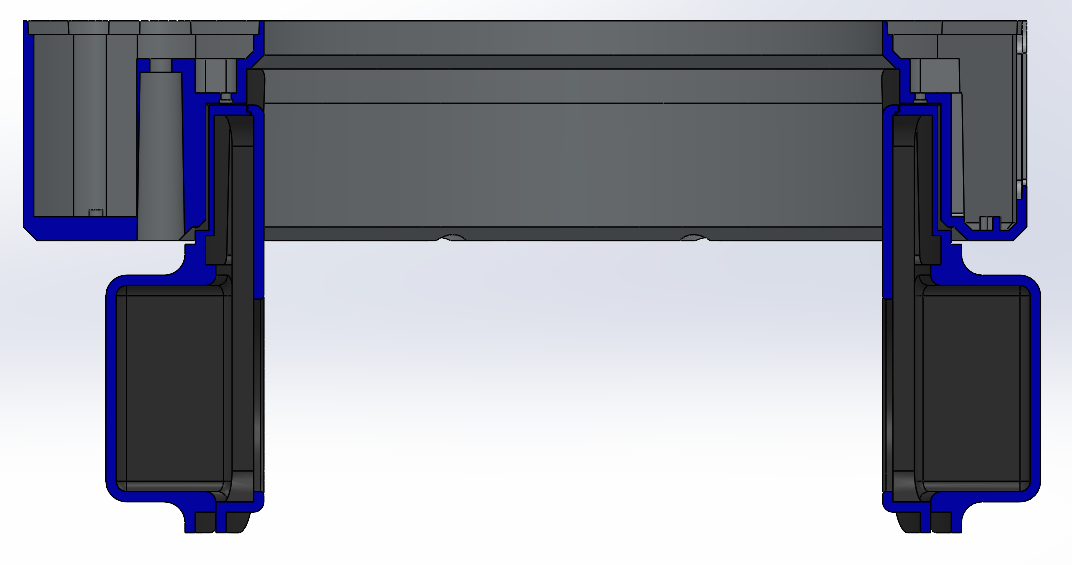

Air inlet/outlet valve concept (VOTE)

03/20/2021 at 14:13 • 2 commentsHere are some of the air inlet/outlet design concepts, help us to choose wisely...

1. Vader

![]()

2. Eve

![]()

3. Bee hive

![]() ---------- more ----------

---------- more ----------More images and details

![]()

This is a cross section of the modular air IO valve, with 30x10 mm PWM fan (Not shown in the rendering).

The idea is that these air IO valves can be added, removed or combined in any desired way depending on the plant itself. By utilizing this kind of design, we open more possibilities for further development of the Plant pod device, like external air supply, etc. Air IOs are connected to the top of the device using pogo pins, like this:

![]()

![]()

Vote for the design You like the most, and help us decide ;)

-

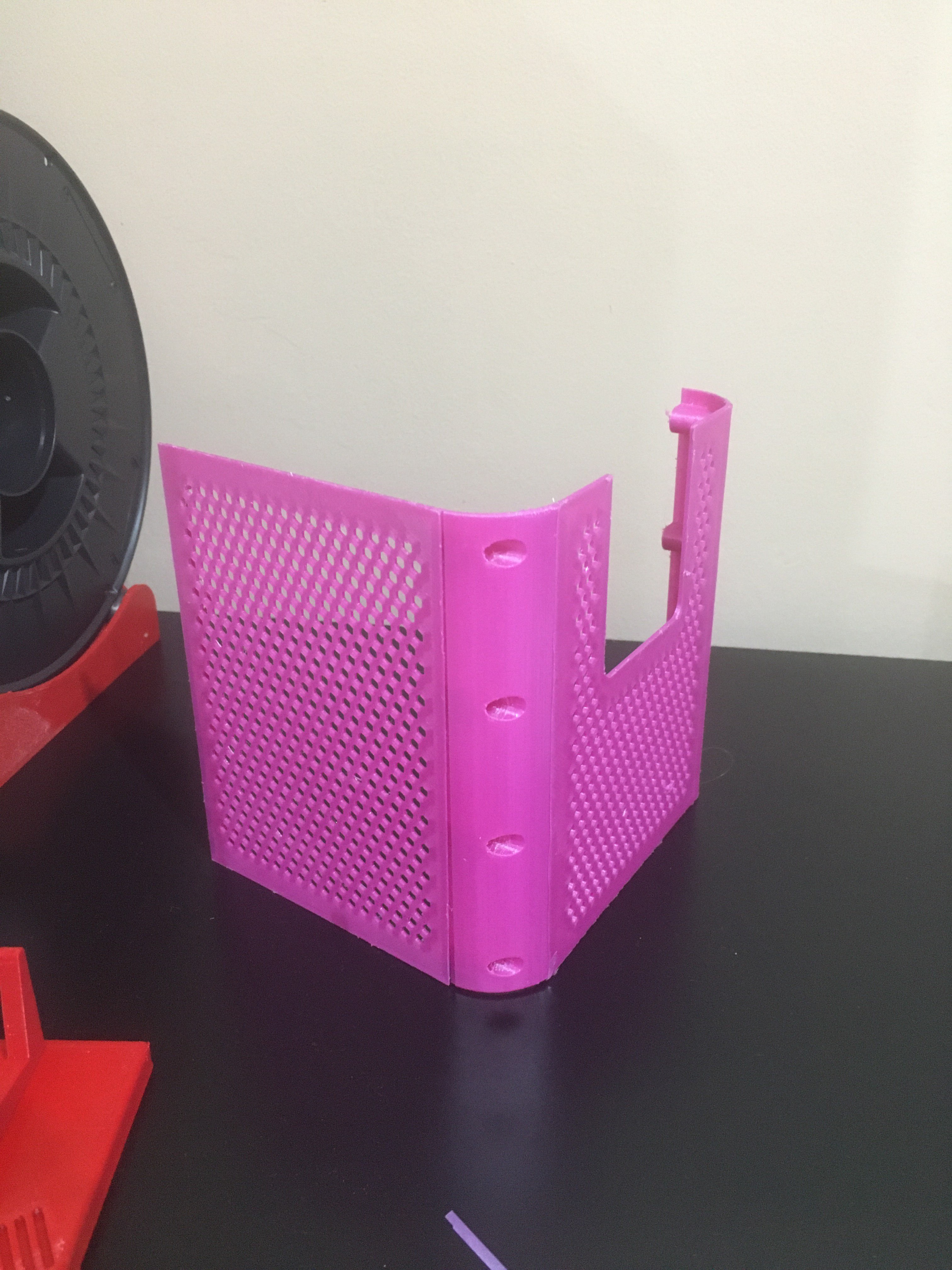

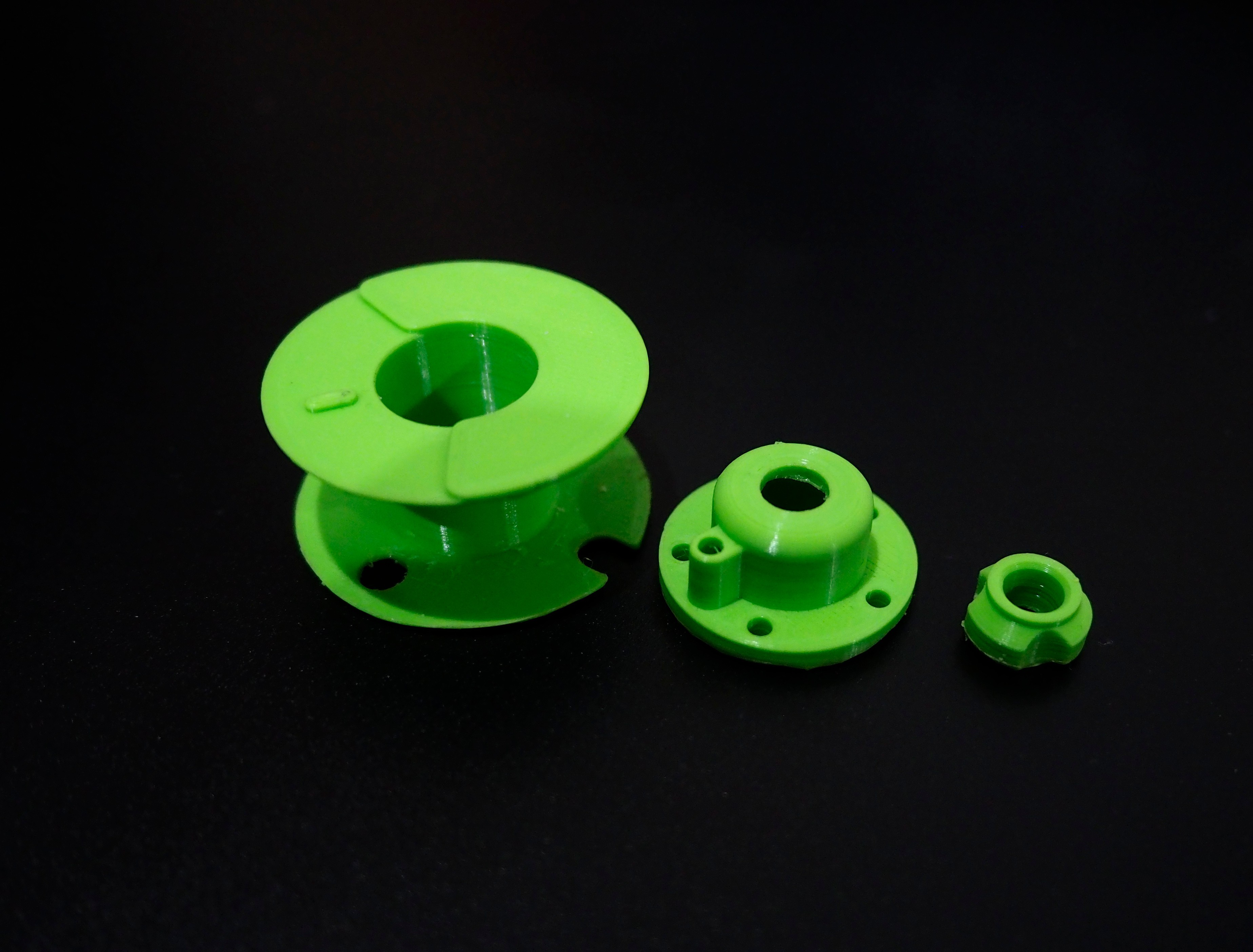

First 3D printed parts for Solenoid Pump

03/18/2021 at 16:42 • 0 commentsWe have started with first 3D prints for prototype of our Solenoid Pump. Currently in this stage of build we are using PLA filament because print time is a lot shorter, so we can save some time till we have completely functional prototype of pump. In future we will probably use PET-G filament since it's more resistant to higher temperature and mechanical stress.

![]()

-

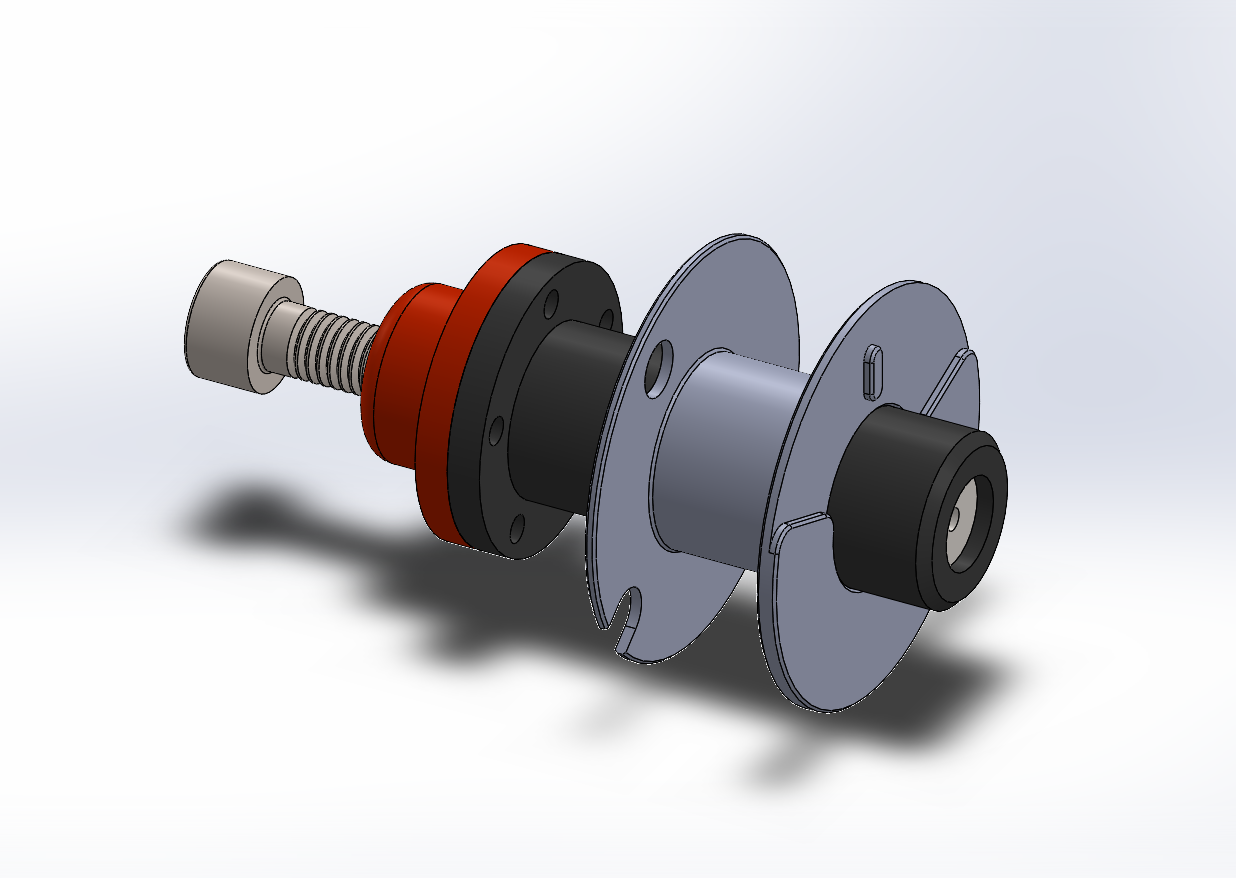

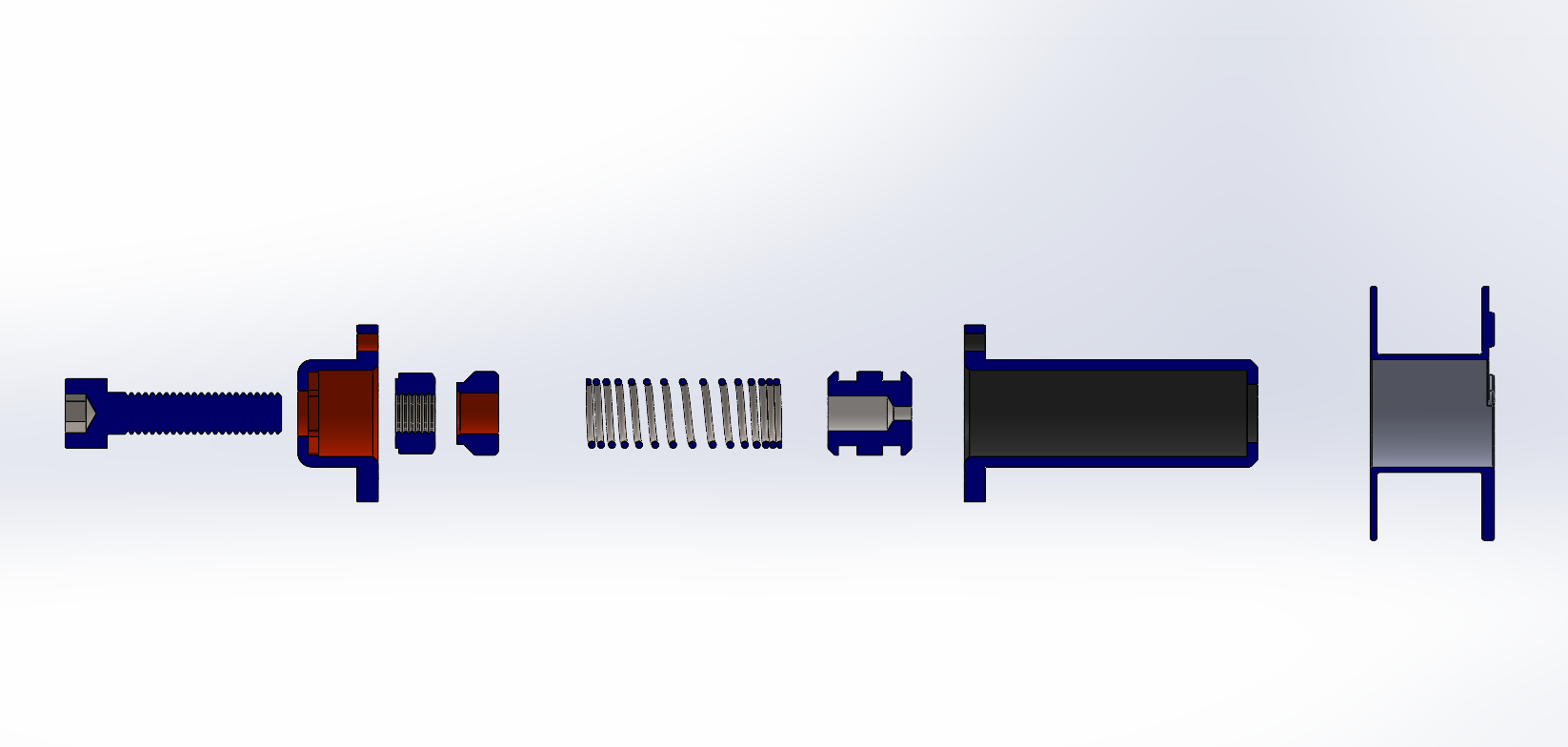

Solenoid pump POC

03/14/2021 at 13:26 • 0 commentsOne of the critical components of the Plant pod device design is integrated solenoid pump. Before starting manufacturing of any of the base components, we need to be sure that this pump design will work correctly. This is a proof of concept and test rig at the same time. We need a tool to test different spring and coil combinations. Pump's main body and piston will be machined parts, due to the tight tolerances, rest of the system will be 3D printed parts, and some "of the shelf" hardware, like nuts, bolts, springs etc. Here are some images.

![]()

![]()

![]()

![]()

![]()

-

Quick release

03/12/2021 at 12:19 • 0 comments![]()

Nikola Secerovski

Nikola Secerovski