I uploaded all versions of my project (see them on https://github.com/Sergio0o0o0o/Over_engineered_analog-digital_photo_frame) because I would like to explain you the entire process from the idea itselfs.

short video to explain the project's action

NOTES:

- None of this version are yet optimized for 3D printing (or any crating process), I will do that after we solve the problems that we are able to see in the 3D model.

- Every version has a list of problems that I noticed, but the last option is always "..." to encourage you to find more, thank you for your collaboration.

- Write me if you think you can help me or even just to ask questions about it. I will appreciate it.

V1

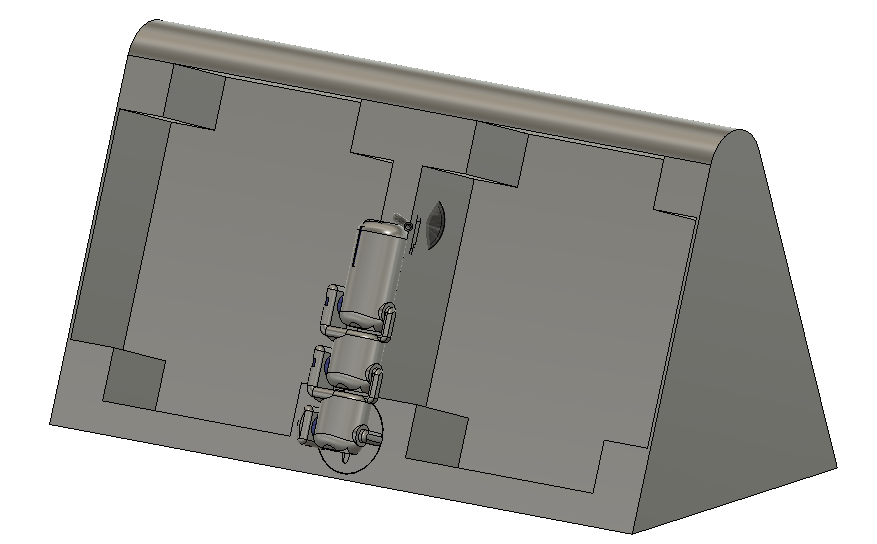

I thought that using two different frames was easier, so I decided that the frame had to be equipped with a small robot arm (with 9g servo motors) and a suction cup. The arm is long enough to reach the middle line of the picture box, take one photo with the suction cup (and a small 9g motor with a syringe to create vacuum) and position the photo in the other side of the frame. In this way all the photos are shown and (theoretically) it should work.

Problems:

- very big;

- the photos in the middle of the column are shown more frequently than the ones at the beginning and at the end;

- too many motors [6] (many things can go wrong, I would like to keep is simple, and it would be too noisy);

- ...

V2

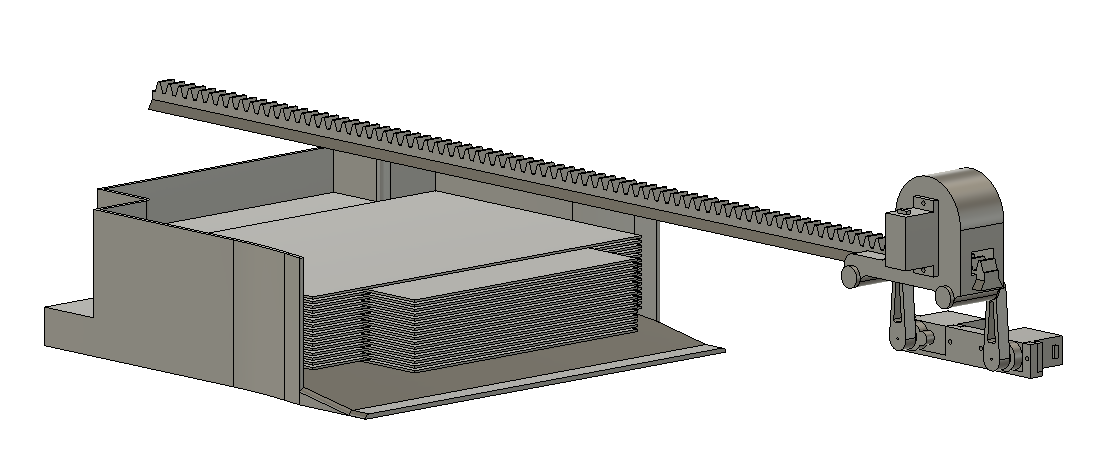

The idea was to create something able to take the first photo and place it under the column of photos. In this way each photo will be shown just once every cycle, solving the 1st problem of the previous version. I thought about using a long linear actuator with a rubber piece at the end that could drag the first photo down the pile. A small ramp (in the frame) could leave the space for the entrance of the photo under the pile and the arm could push the photo. In this way only 2 motor were used, solving the 3rd problem.

Problems:

- very big;

- how should the design be completed?;

- will it work in a nearly vertical position?;

- ...

V3

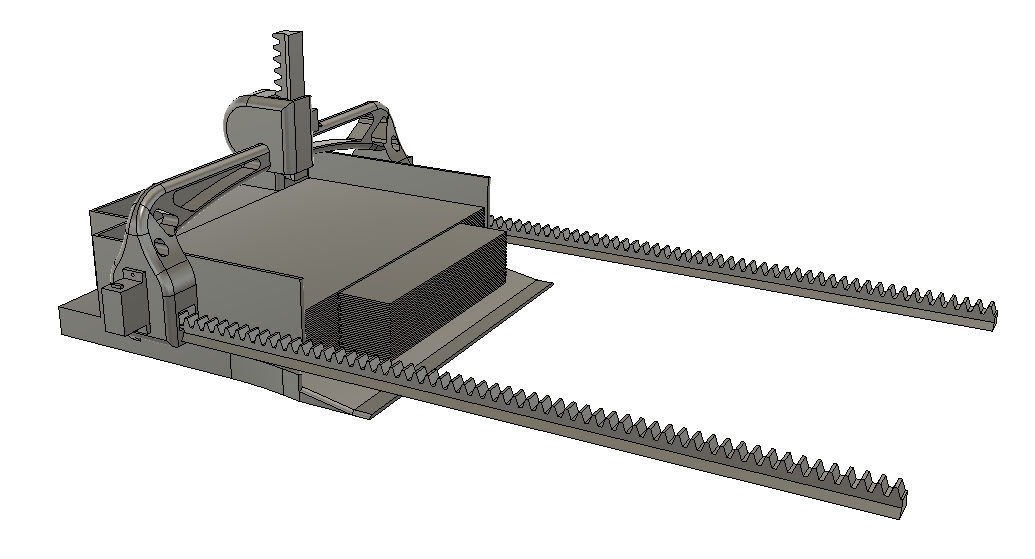

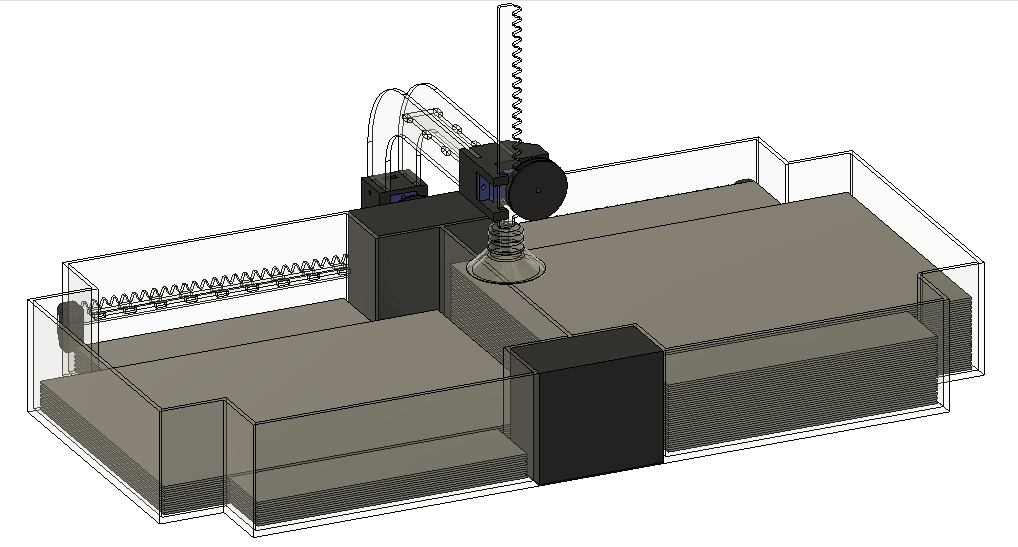

3rd and 4th problems pushed me to think about a new version, without wasting more time. I thought about adding a moving-bridge style actuator, to take the photo from the top of the pile (with vacuum gripper) and put it where the linear actuated arm (as in V2) will be able to push it under the pile.

Problems:

- very big;

- too many motors [6] (many things can go wrong, I would like to keep is simple, and it would be too noisy);

- ...

V4

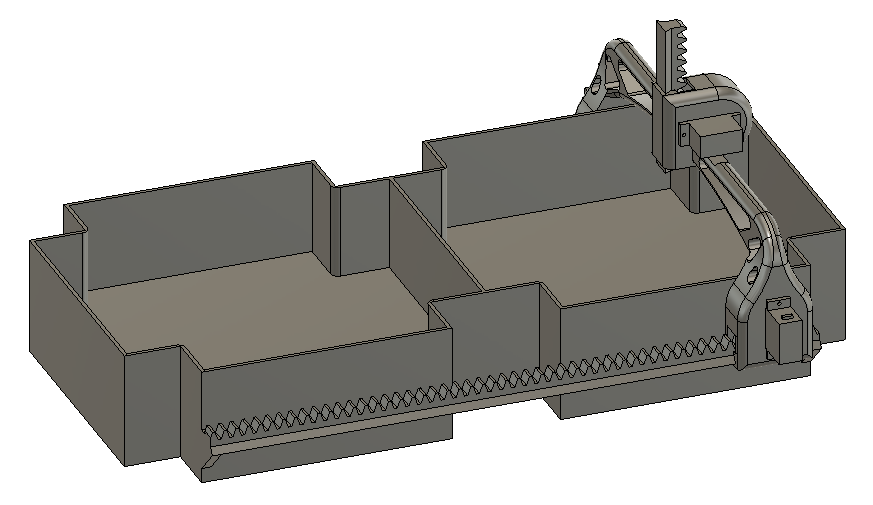

the V3 pushed me to think again about the V1, a moving-bridge stile actuator could solve the 3rd problem (the worst). So I decided to give it a possibility.

Short video to explain the project's action:

Problems:

- very big;

- the photos in the middle of the column are shown more frequently than the ones at the beginning and at the end;

- ...

V5

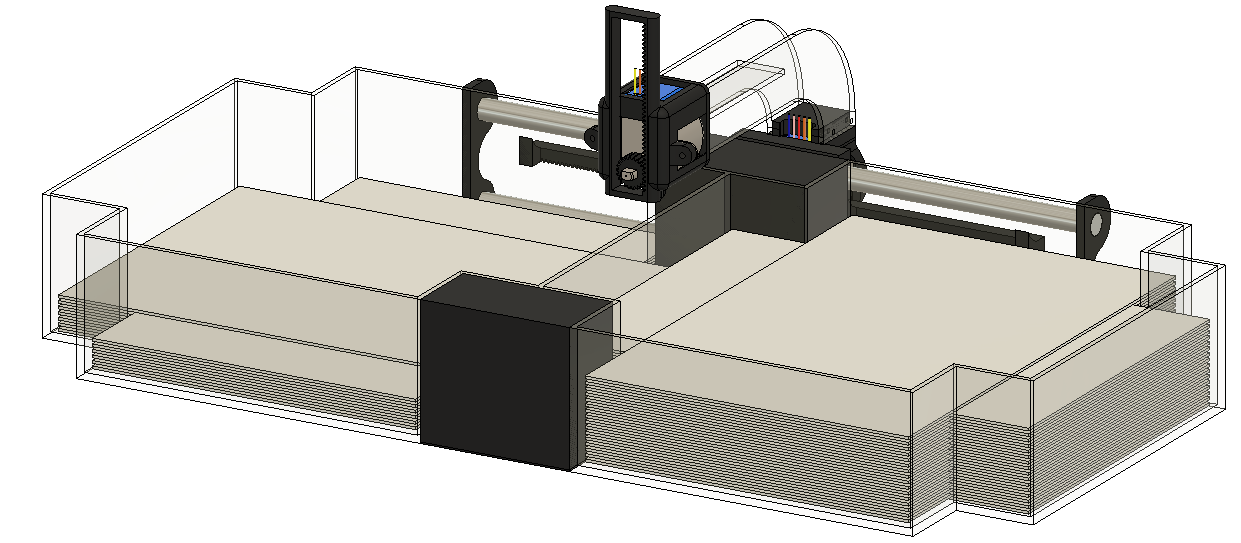

I think that using 2 mm plexiglass as the main material may "solve" the 1st problem of all designs: transparent material might make the project look smaller than it really is. As suggested from you, I've also added a "single sided bridge" instead of the big one of the previous design. I really like this idea, but I'm not sure about the strength of my design. Two boxed (probably made out of plastic, to hide cables and electronics) were added.

This is a '3D models web viewer' to visualize the project from any device, to really understand how things are supposed to be: link.

Short video to explain the project's action:

Problems:

- the photos in the middle of the column are shown more frequently than the ones at the beginning and at the end;

- strong enough?;

- ...

V6

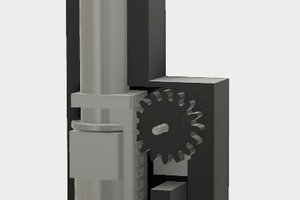

The strength problem was solved: I added 3D printed linear bearings and 8mm metal rod to slide on. I also decided to change the motors: 28BYJ-48 stepper motor are still cheap, but more quiet and precise than 9g servo. I also added a 503012 hall effect sensor and a magnet, to have an absolute position of the actuators. I'm really satisfied by this design, but I still...

Read more » Sergio Gugliandolo

Sergio Gugliandolo

Giovanni Leal

Giovanni Leal

ben.brochtrup

ben.brochtrup

too complicated, rotor table is better