Almost every electronics device uses some kind of a microcontroller nowadays. The thing is, that these chips can be very complicated, and even though you can buy them very inexpensively (like Arduino for example), I've still wanted to take a deeper look into them and understand their inner workings. I soon realised, that I have only a few options to do that:

- Study an existing microcontroller from a datasheet

- Make some kind of a emulator (C / Python)

- Build my own CPU from scratch

You can already guess which path I took.

1. Designing my own CPU:

I discovered Ben Eater's homemade CPU on Youtube and I was so mesmerised and almost immediately got to work. I've improved his design and built myself an 8 bit CPU too. This article is not about that one though. If you want to, you can check out my photos in this Twitter post. I may write another article about that someday.

At this point, I had a pretty good understanding of a really basic CPU, but for some reason, this wasn't enough for me. Shortly after that, I've stumbled across Robert Baruch's Youtube channel and he started working on a 32 bit RISC-V CPU, which also used just a basic logic components. I have done some research about RISC-V and found out, that it is completely open-source and well documented.

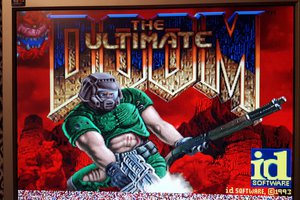

Me being me, I started making my own RISC-V CPU implementation in a program called Logisim-Evolution. Again I set my goal not use ANY microcontrollers or FPGAs in my build - just basic discrete logic components. So, what exactly am I going to build? I needed to NOT set too a high goal for myself, so I would be able to finish this project in *relatively* short time (Is 2yrs short enough? :-) ). The most basic RISC-V CPU, that is supported by compilers, must include the extension "I" (Integer) and it must be at least 32 bit. So now I had all the information I'm going to need, so it was time to start building. Oh, and did I mentioned that I was going to put a VGA output card on as well? (VGA card inspired by Ben Eater; https://eater.net/vga)

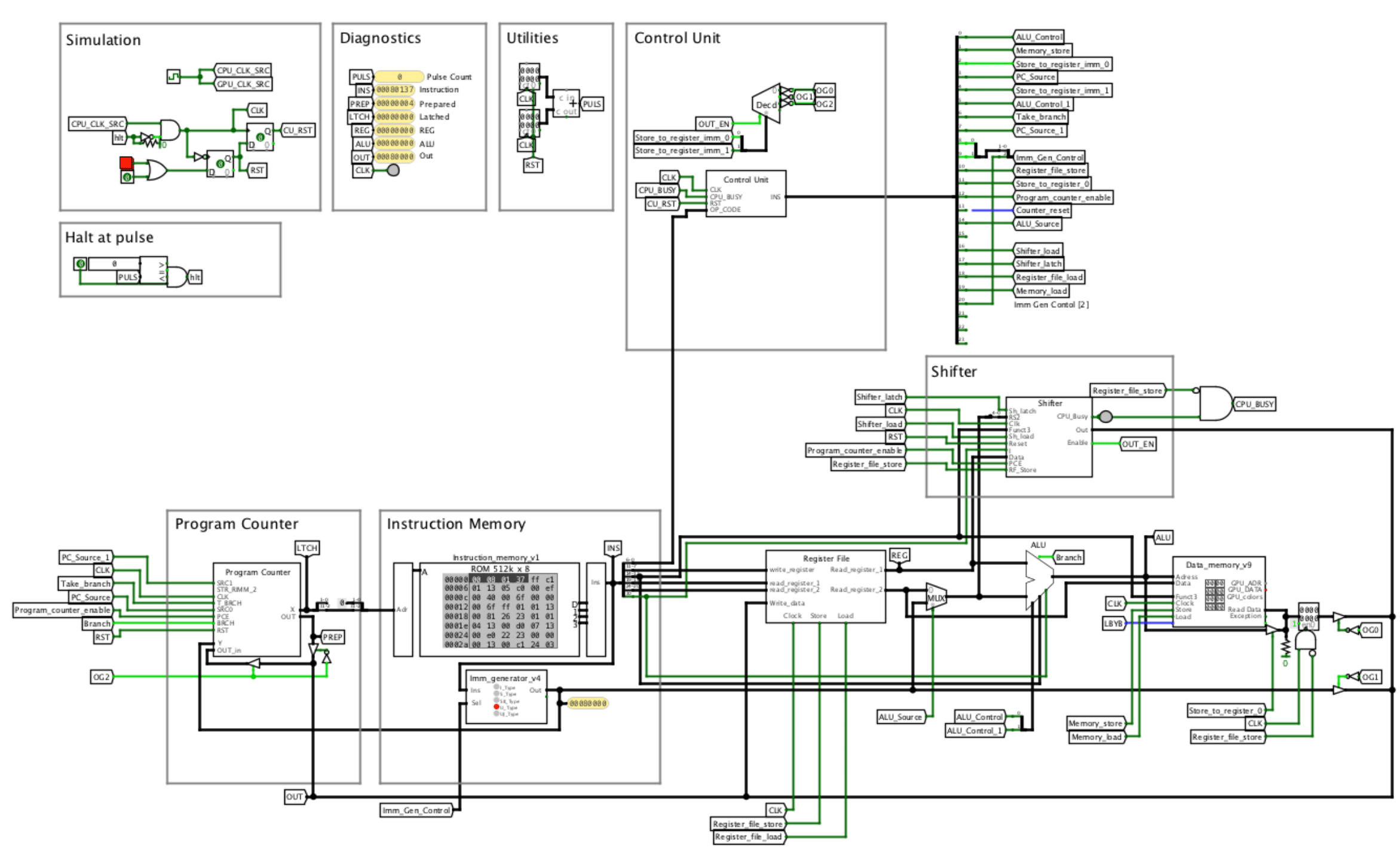

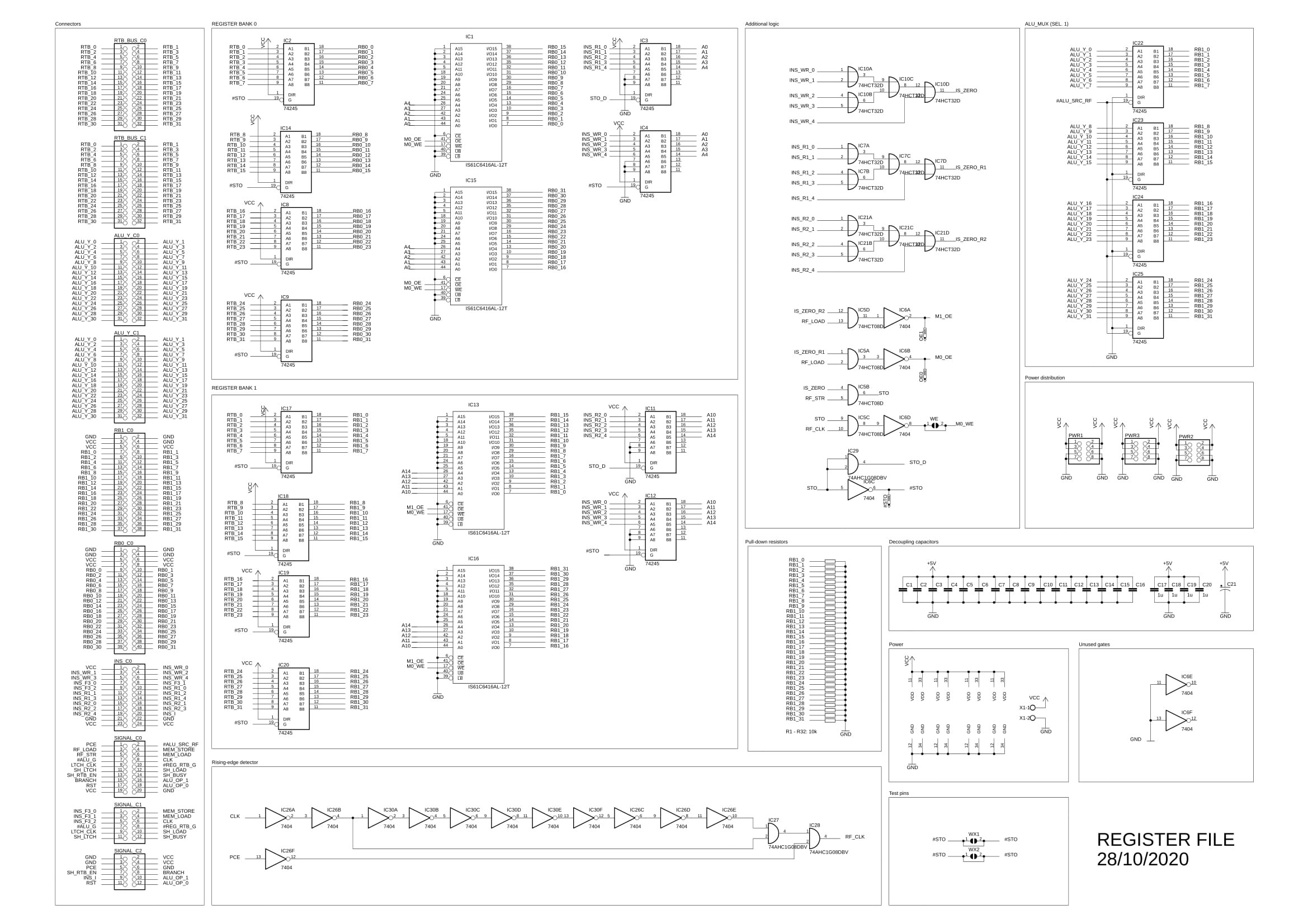

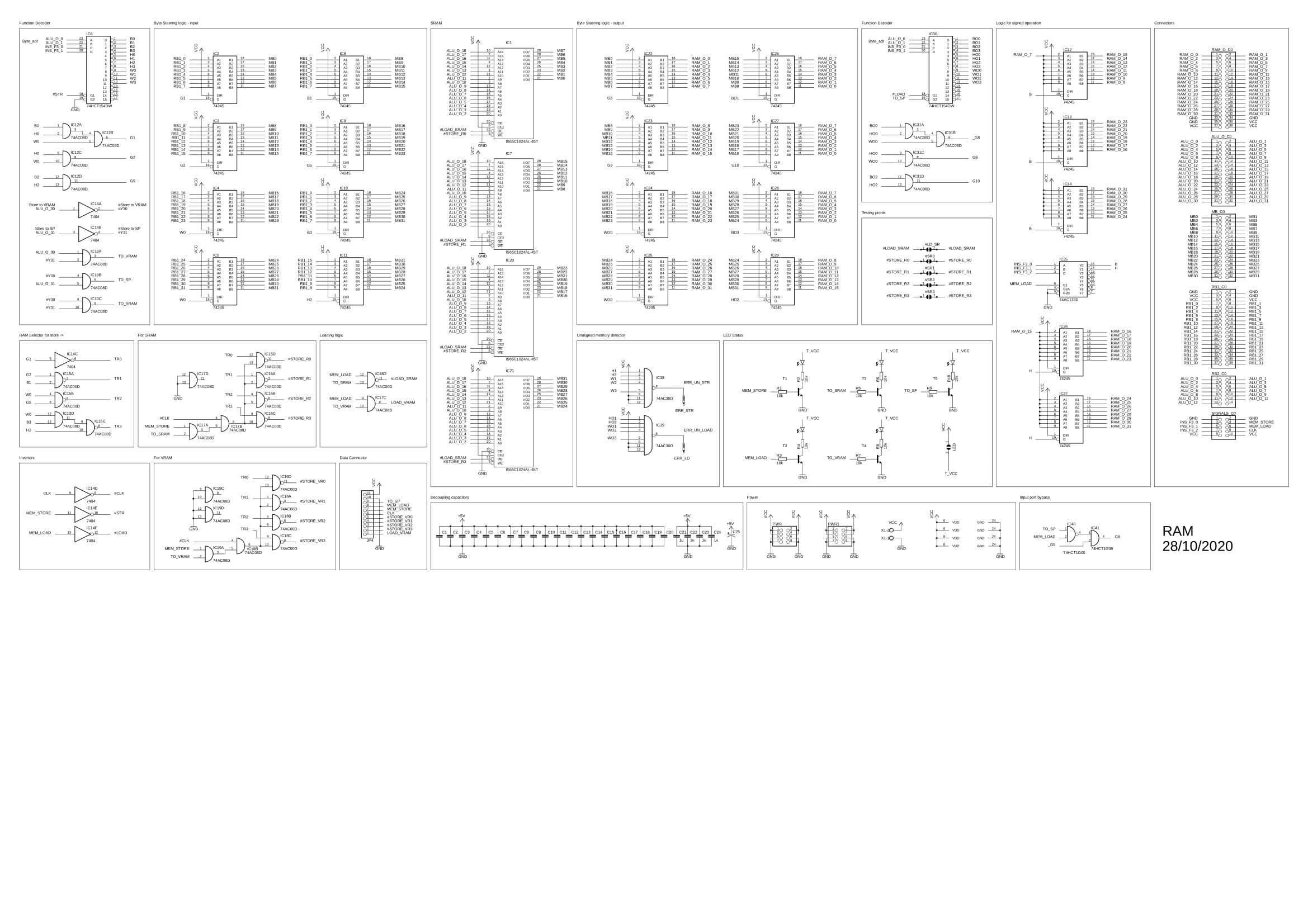

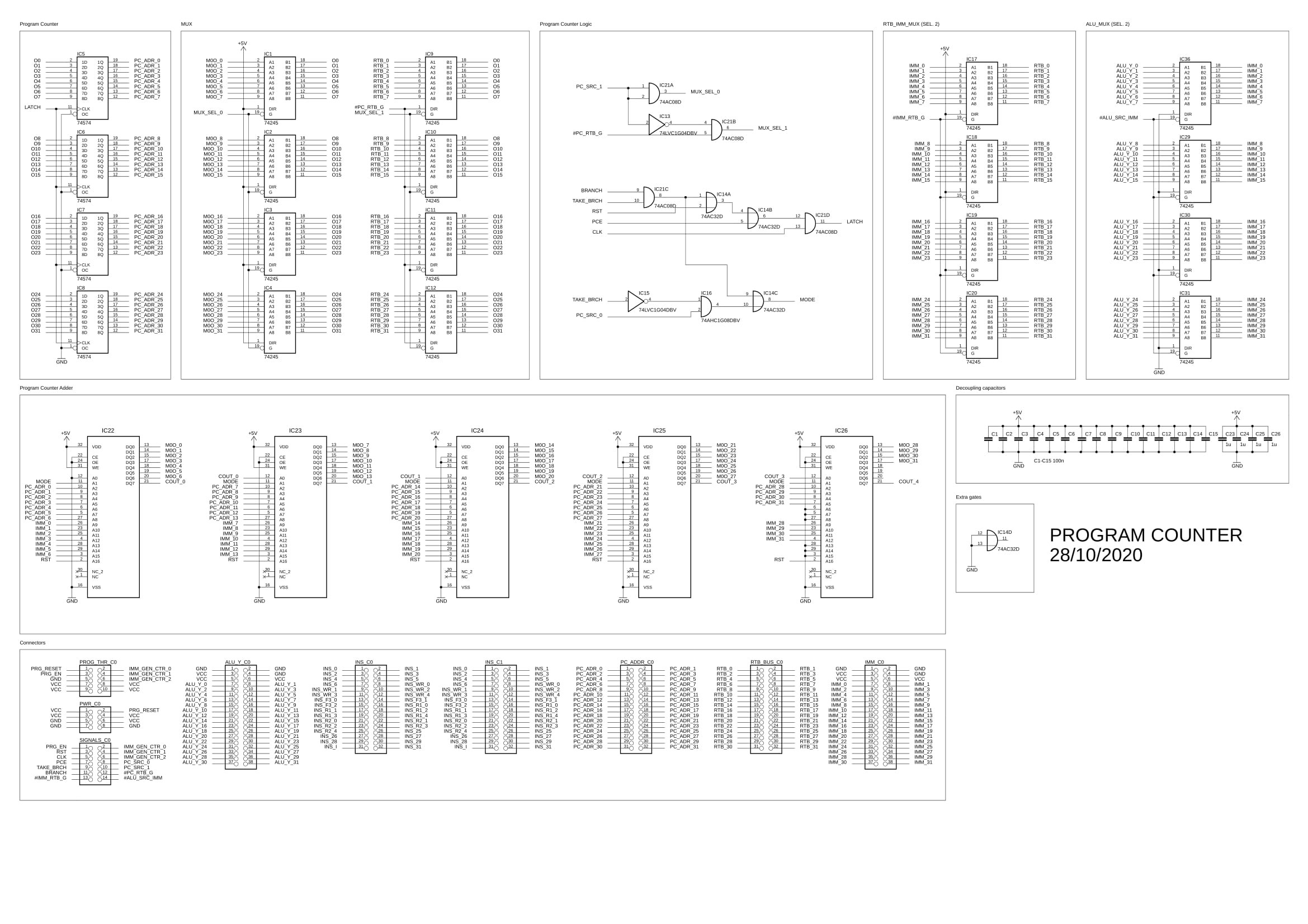

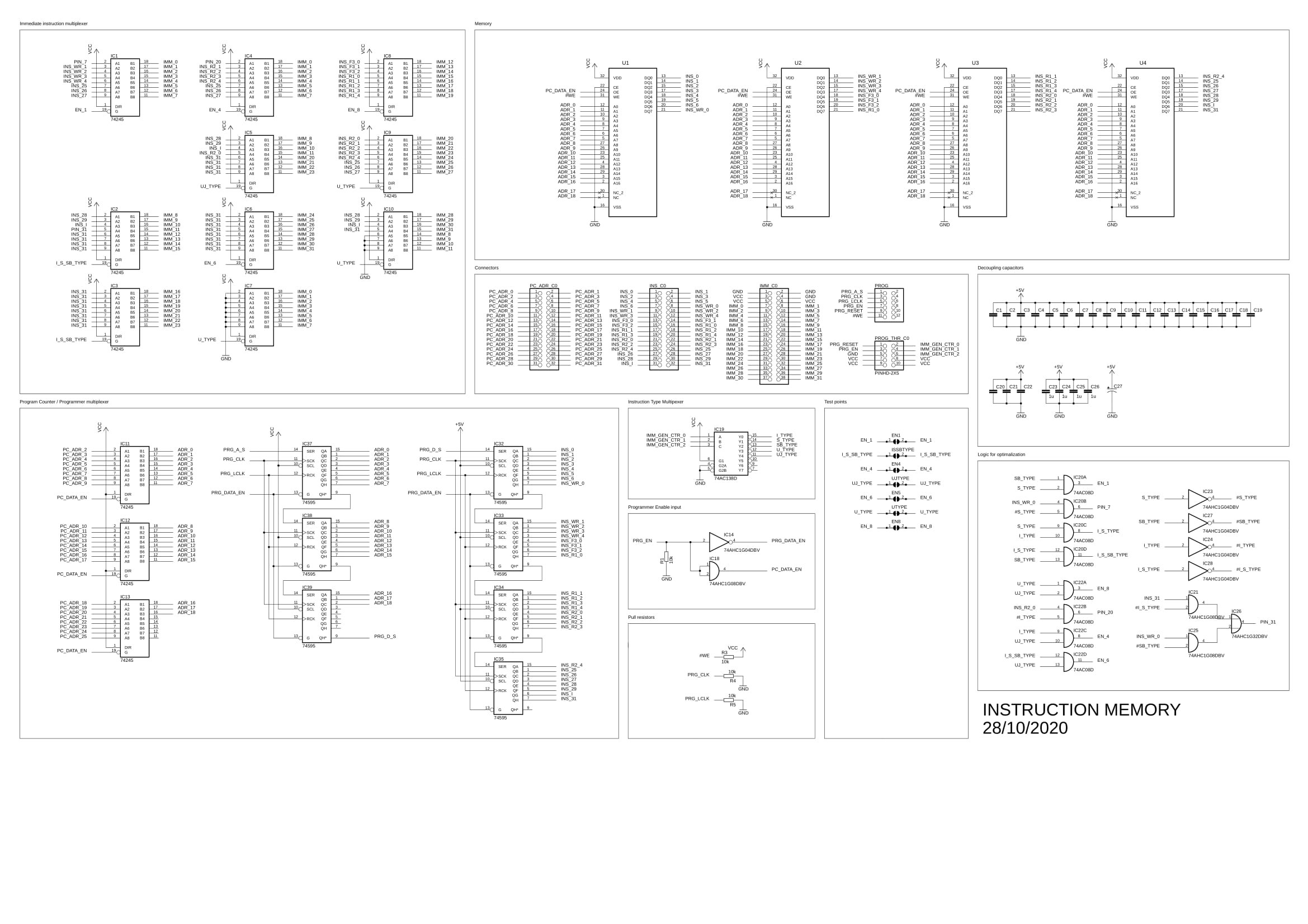

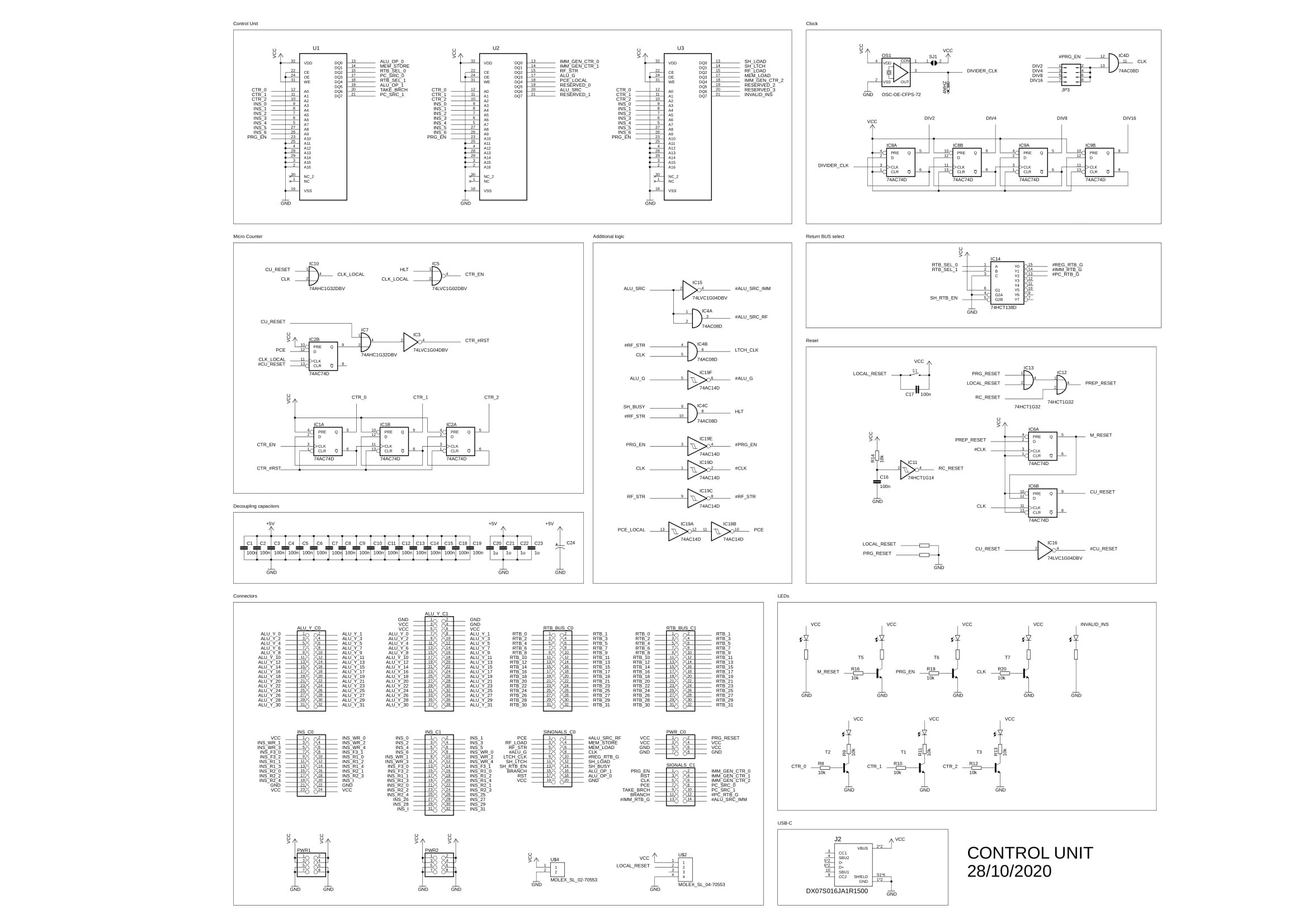

After 6 months of fiddling with Logisim, I had a working "simulation". The next step would be to create schematics for all of the modules, design all PCBs and order them from JLCPCB. But, as this would be my first time ordering PCBs, I didn't want to screw up everything - so I separated the design into modules, and chose few at a time, so as to not overwhelm myself. JLCPCB had a discount for a 2 layer PCB with dimensions < 100mm x 100mm, and I've tried my best to fit into these dimensions to keep the lower cost (and I've managed to fit it in!).

So, now I have a working simulation and my plan is to take few modules at a time, turn them into proper schematics, make a boards and order them. This isn't the best way to do things, but otherwise it would be too much for me. (foreshadowing)

Photo of my Logisim-Evolution simulation

After 2 batches, all that remained were a few modules and one of them is called immediate generator. When I was looking into ways I could turn it from my simulation into proper schematic, I realised that I made a fatal mistake and that I had absolutely no idea how the simulation could have worked. Luckily, the repairs weren't that hard and I was able to easily retrofit one of already made PCBs to completely repair it.

2. Prototype

I knew that this project would be large and I would almost certainly make some mistakes (we are talking about 230+ ICs), so I've decided to start with a prototype, where I have access to all signals and can easily debug the whole thing - I'm not (yet) an electrical engineer and I'm only 19, so this seemed to be a good idea (and it really was).

After I received my PCBs, I've tested each and every one of them by connecting an Arduino to its inputs and simultaneously monitoring its outputs and comparing it to a prediction. Once I've set it up, it was all automatic and to test as much possibilities each...

Read more » filip.szkandera

filip.szkandera

Mad Ned

Mad Ned

Blair Vidakovich

Blair Vidakovich

Samuel A. Falvo II

Samuel A. Falvo II

Matt Stock

Matt Stock

Hi Filipe ! What an impressive work ! The fact that it can not go faster than 500kHz may very well be the carry signal. Looking at your schematic, the carry signal has to pass all 7 flash chips, so the ALU speed is no faster than 7 times the access time of a single flash (probably 55 or 70nS), that would make 385 or 490 nS. Did you consider a carry-lookahead system ?