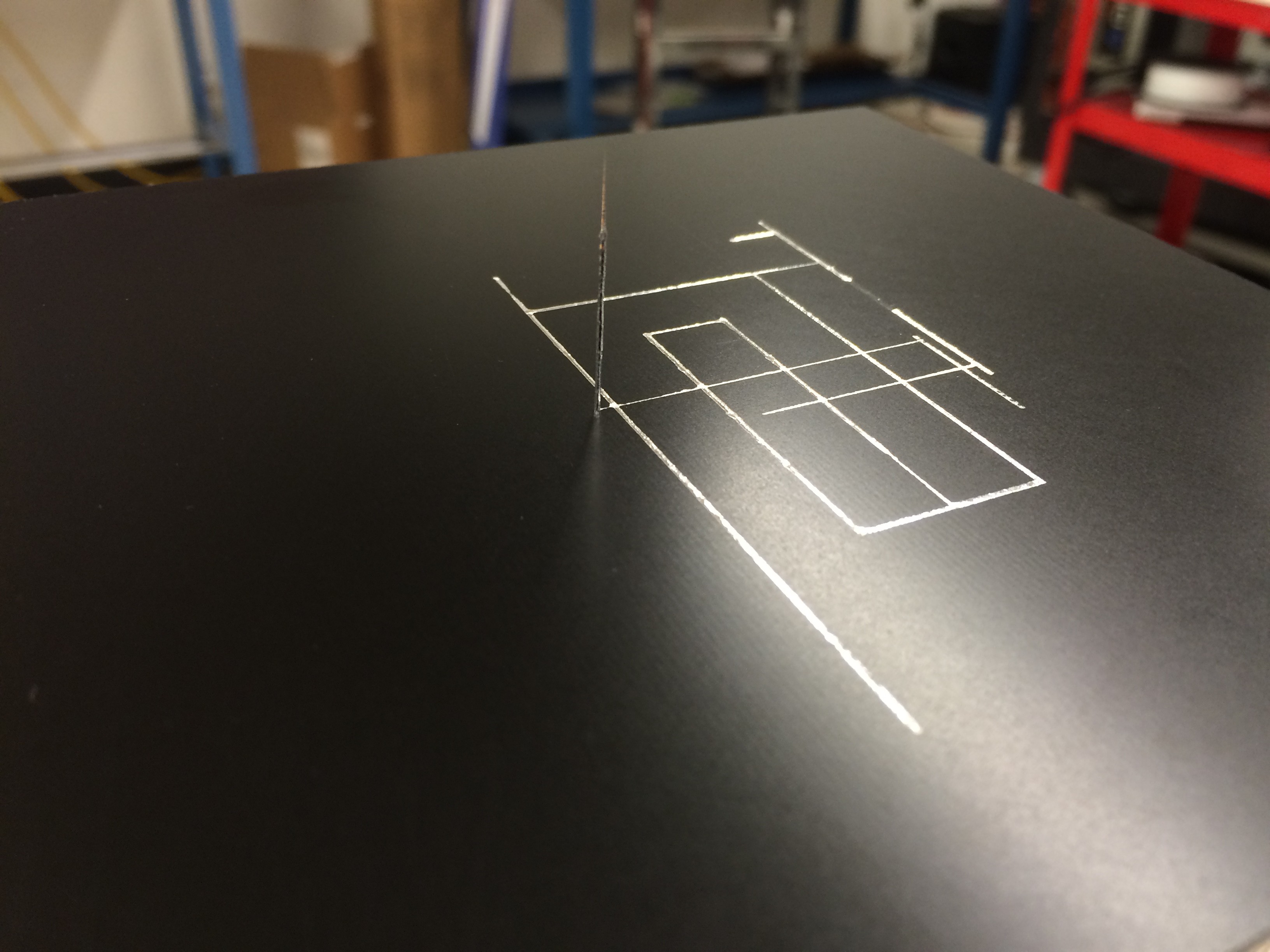

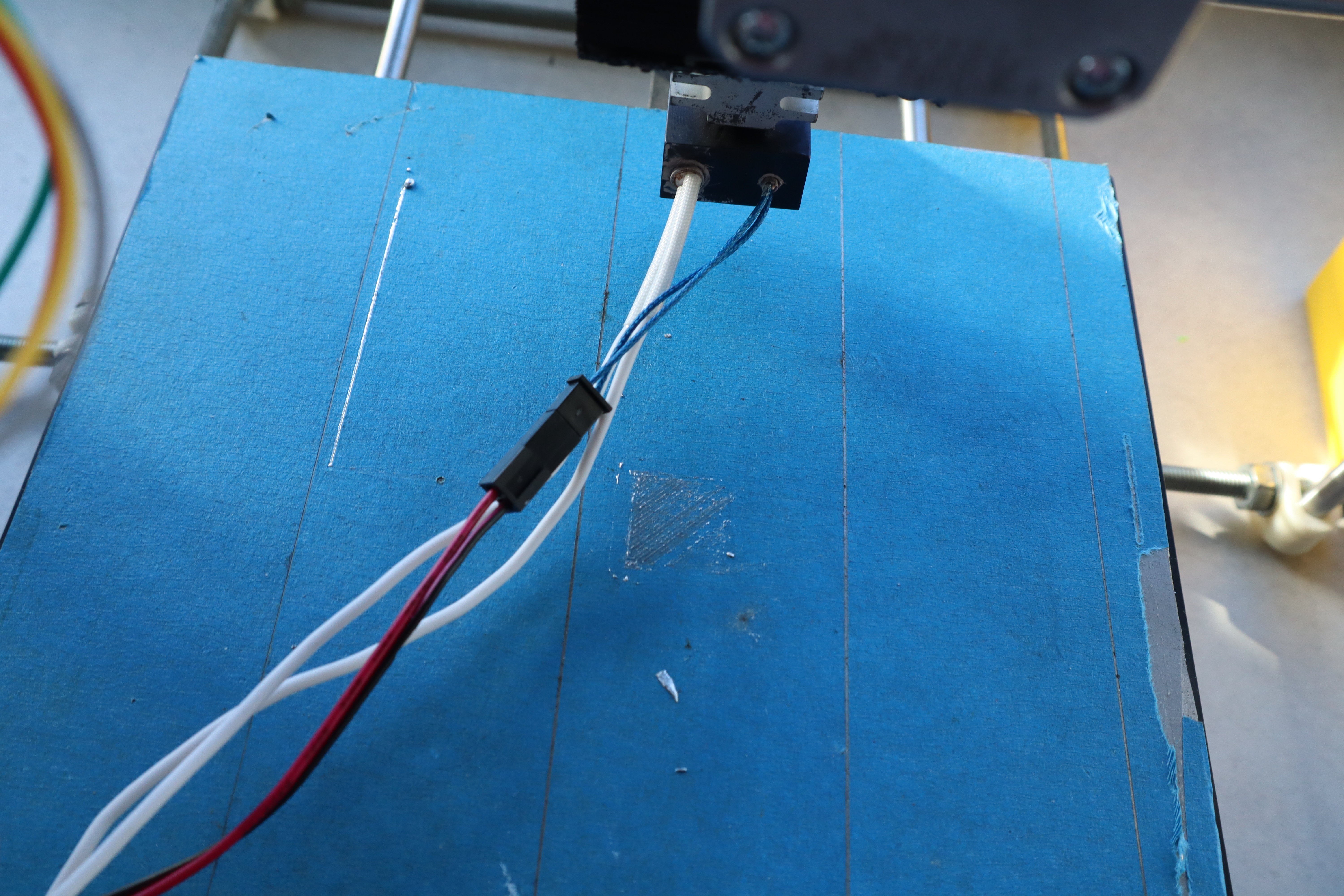

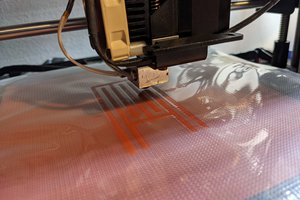

This technology can be used to print conducting traces and antennas like this:

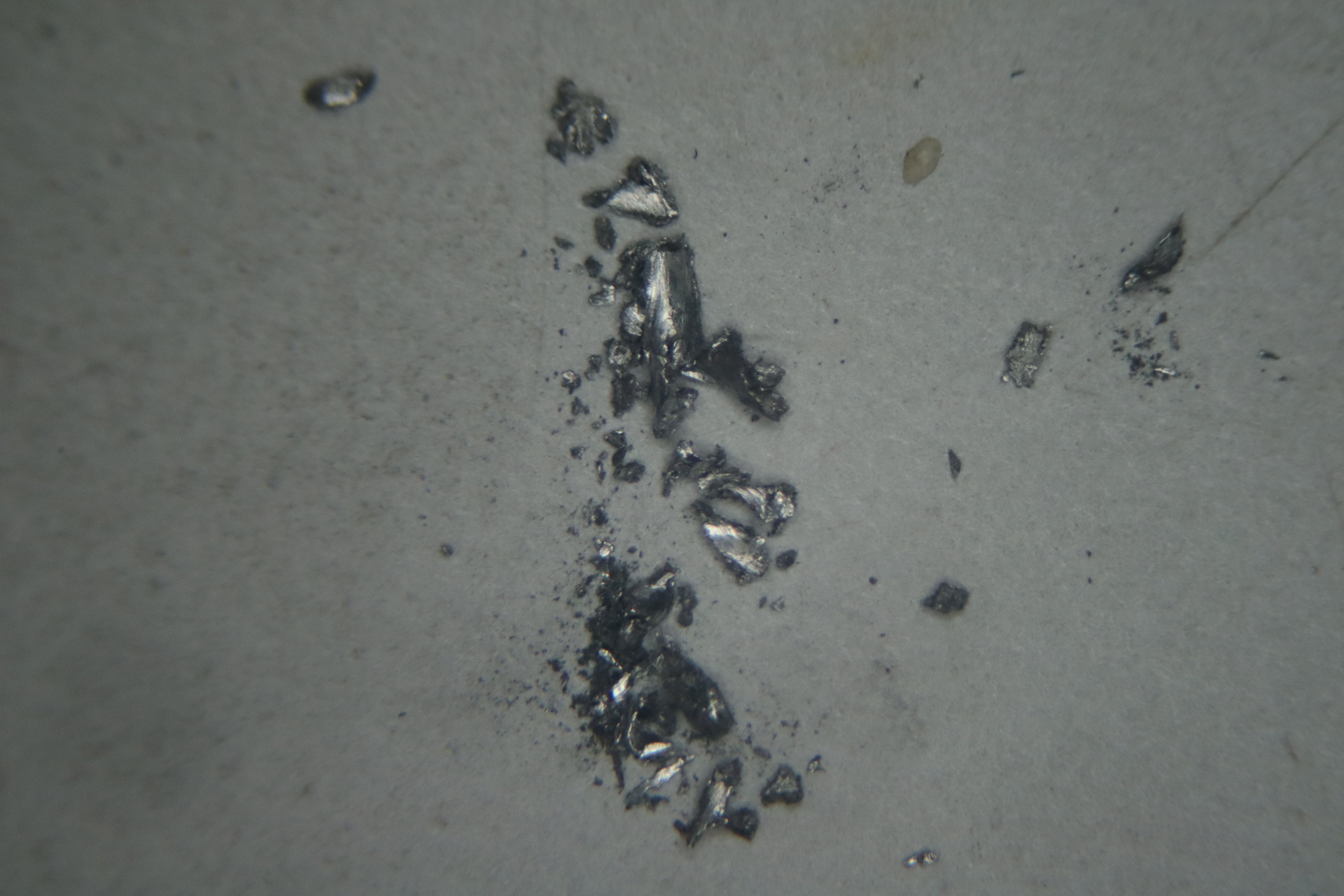

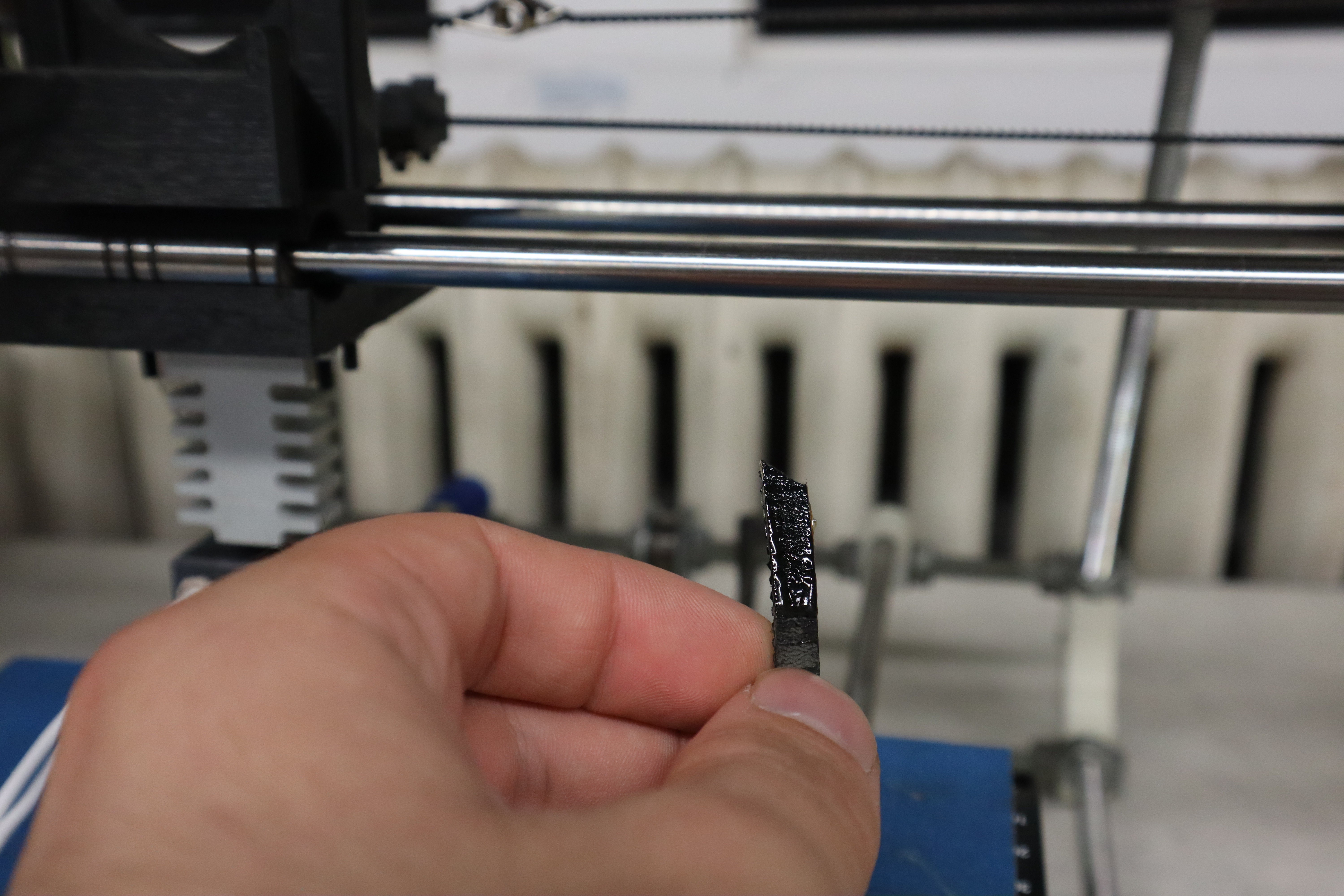

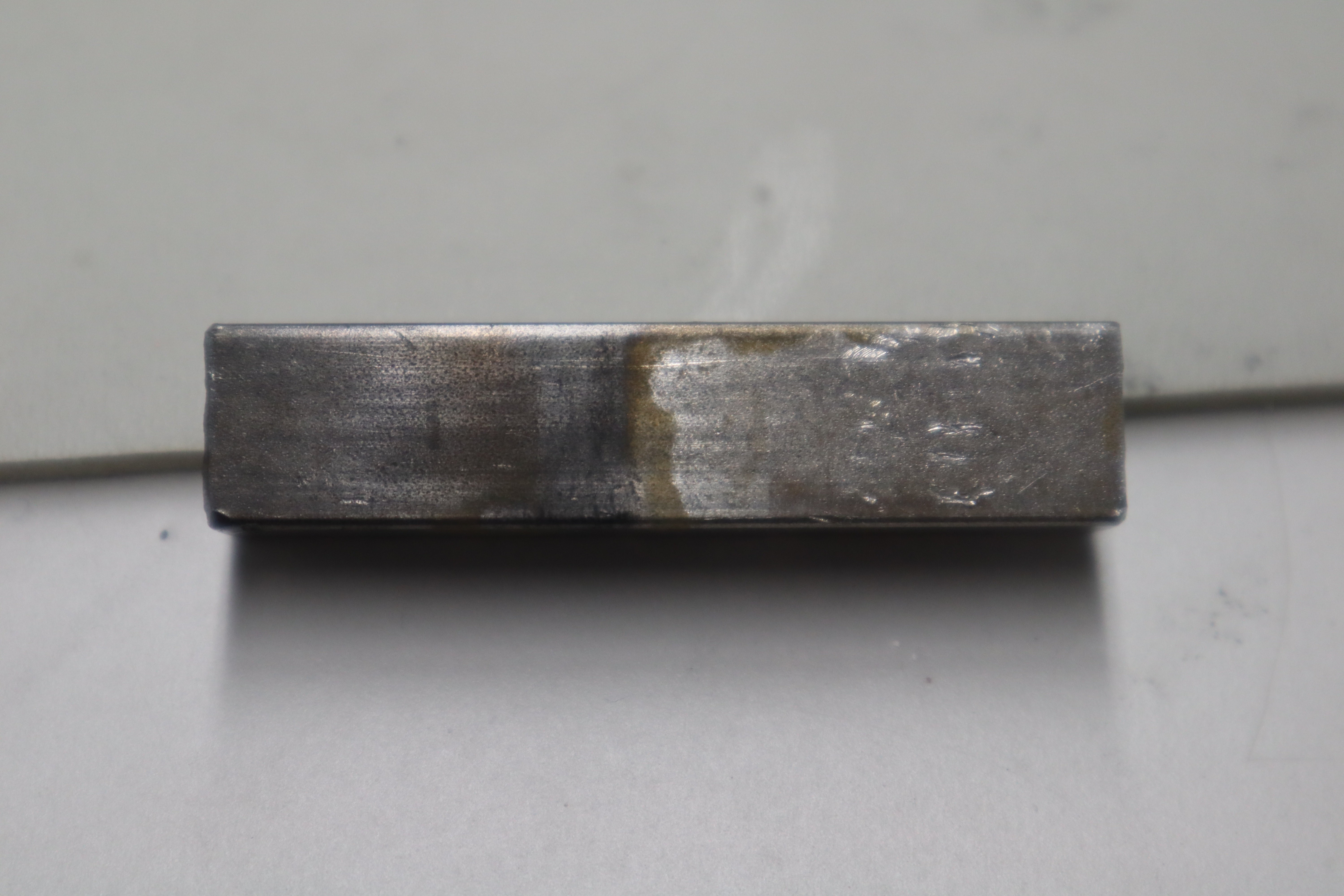

Which was done on an earlier prototype of this technology. Since the tin-zinc alloy melts at 240C it is compatible with PETG printing and as long as your PETG doesn't offgas water vapor (dry it well before use), the mechanical interface should be strong between the materials. Solid metal parts can also be printed with this machine, which do not require any difficult post-processing steps like sintering.

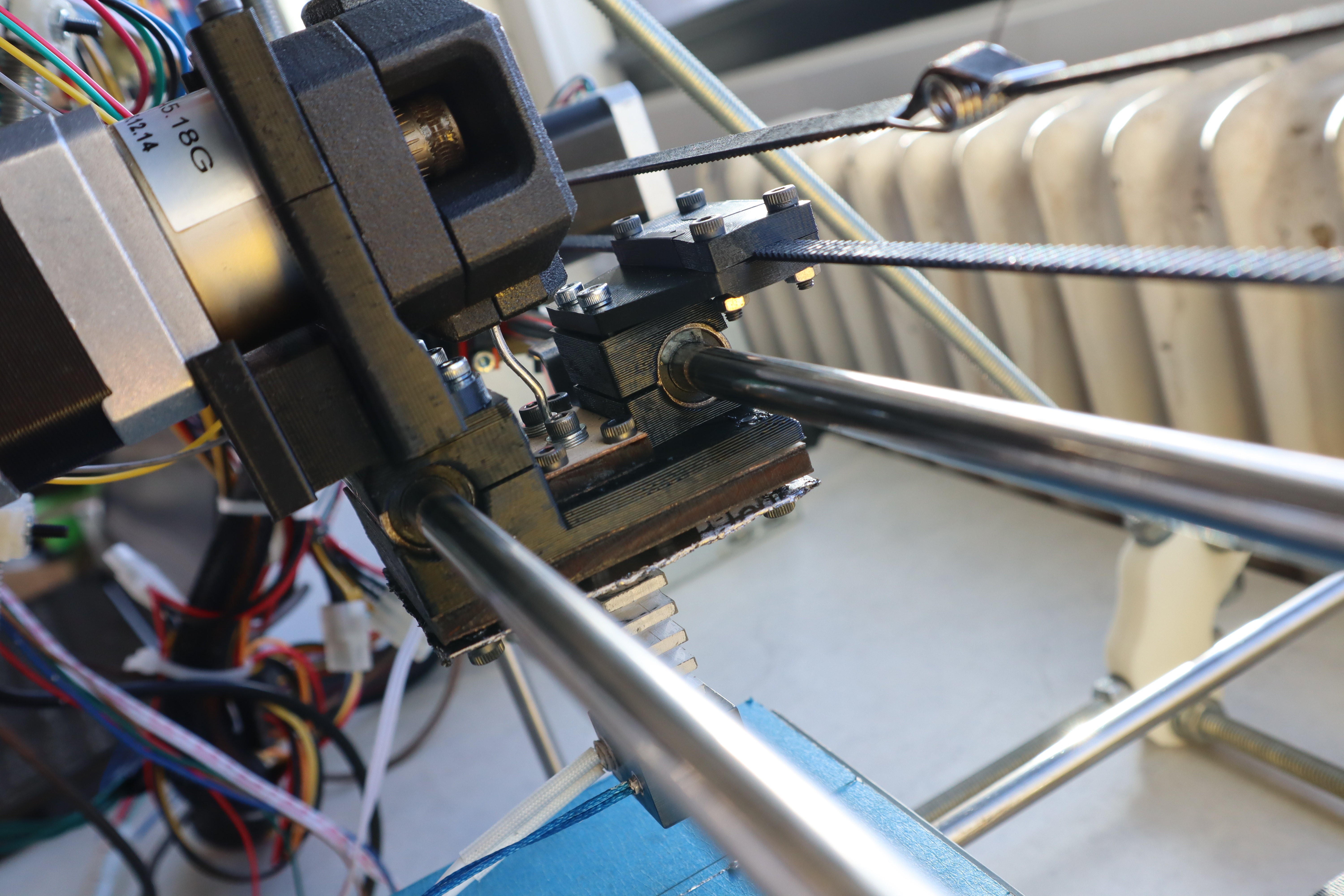

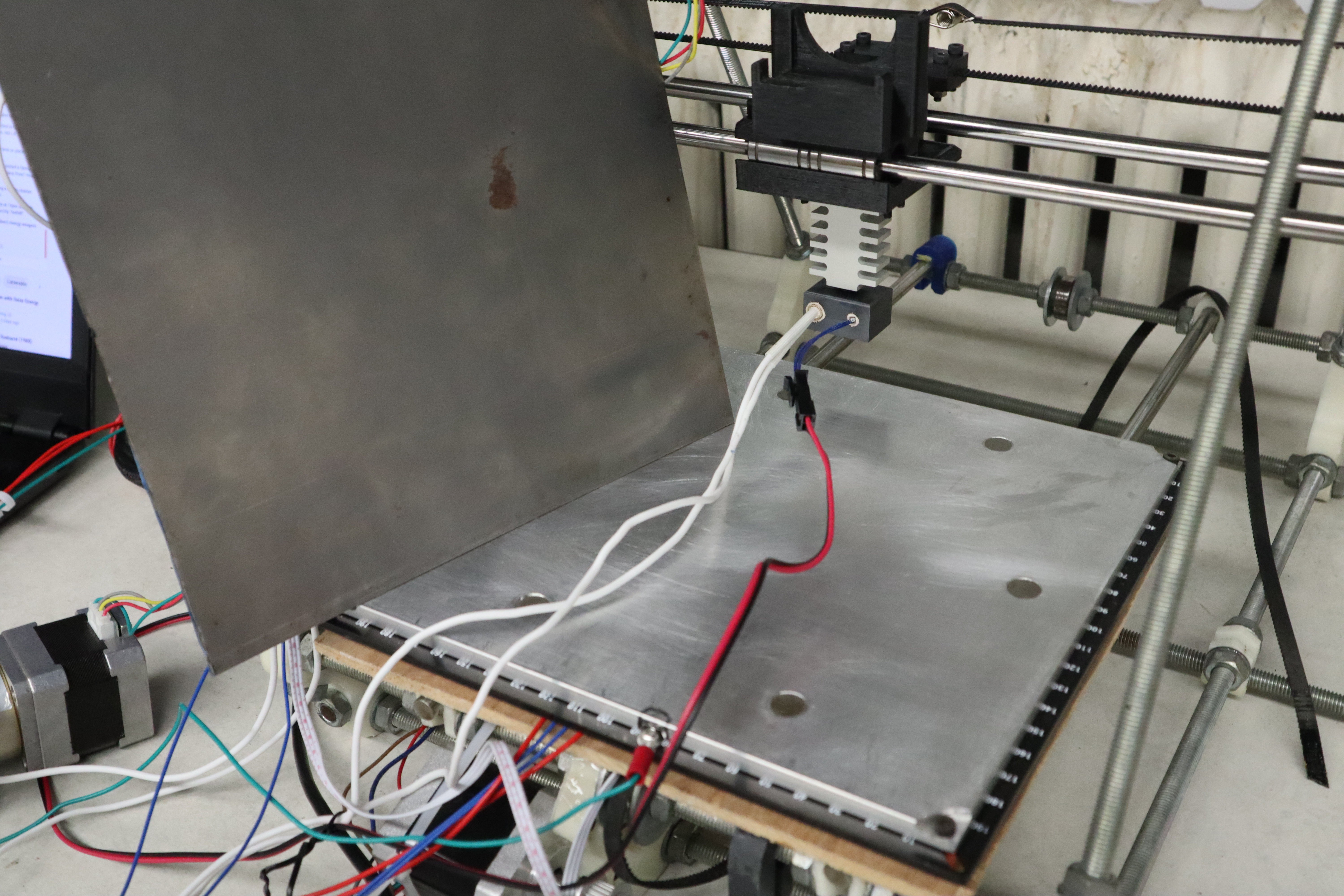

System features:

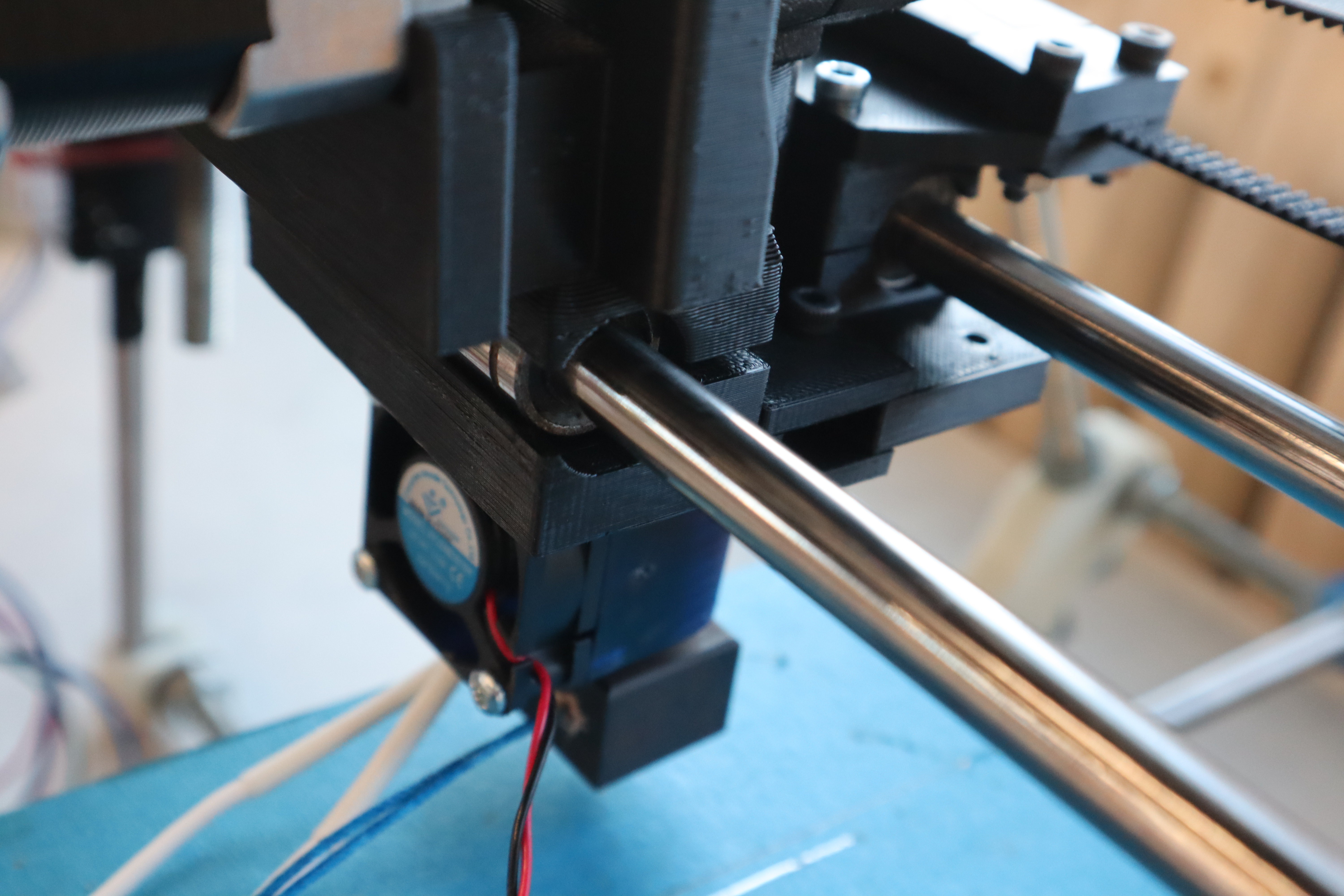

- Print bed which can go up to 200C (E3D's high temperature heat bed works fine for this)

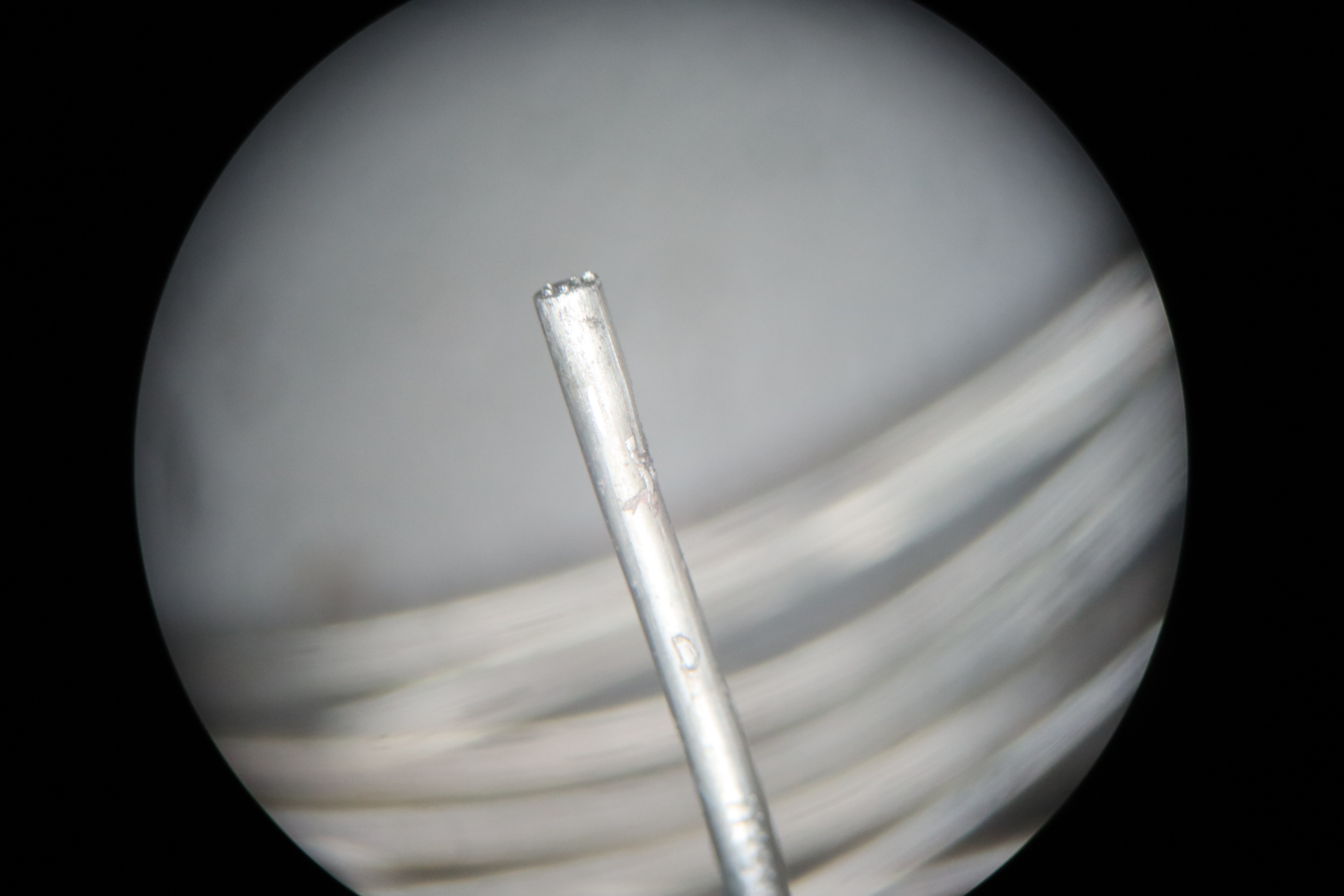

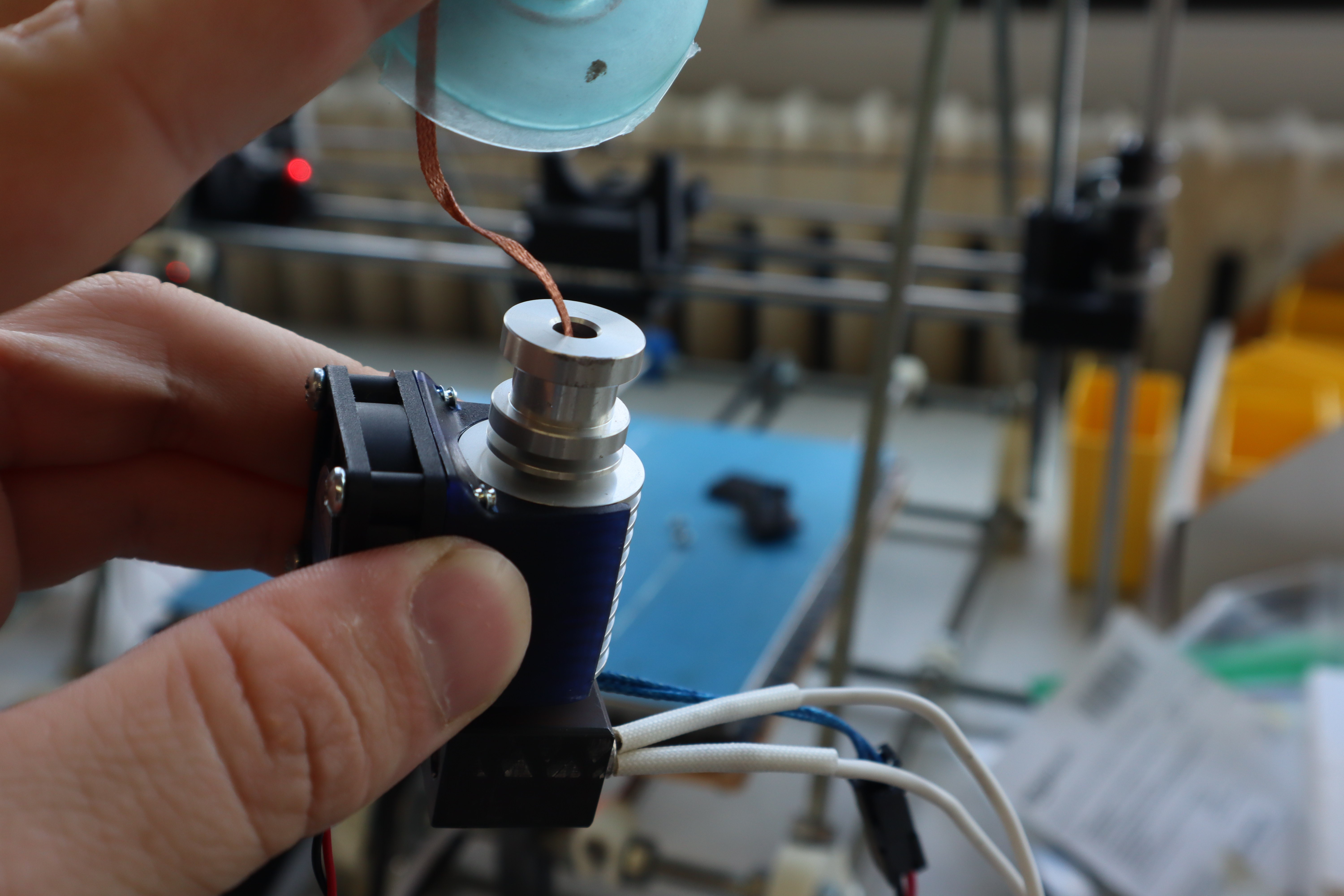

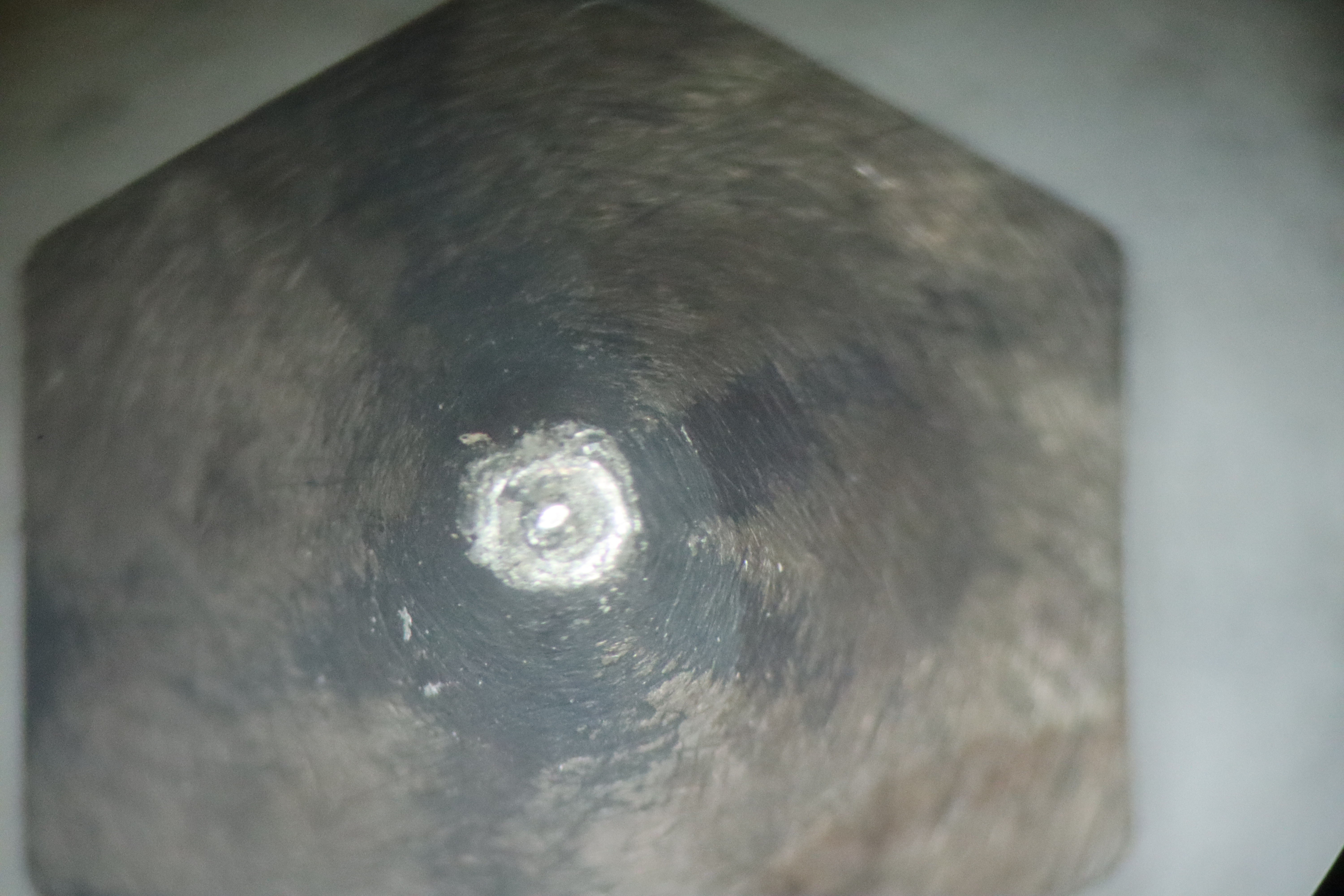

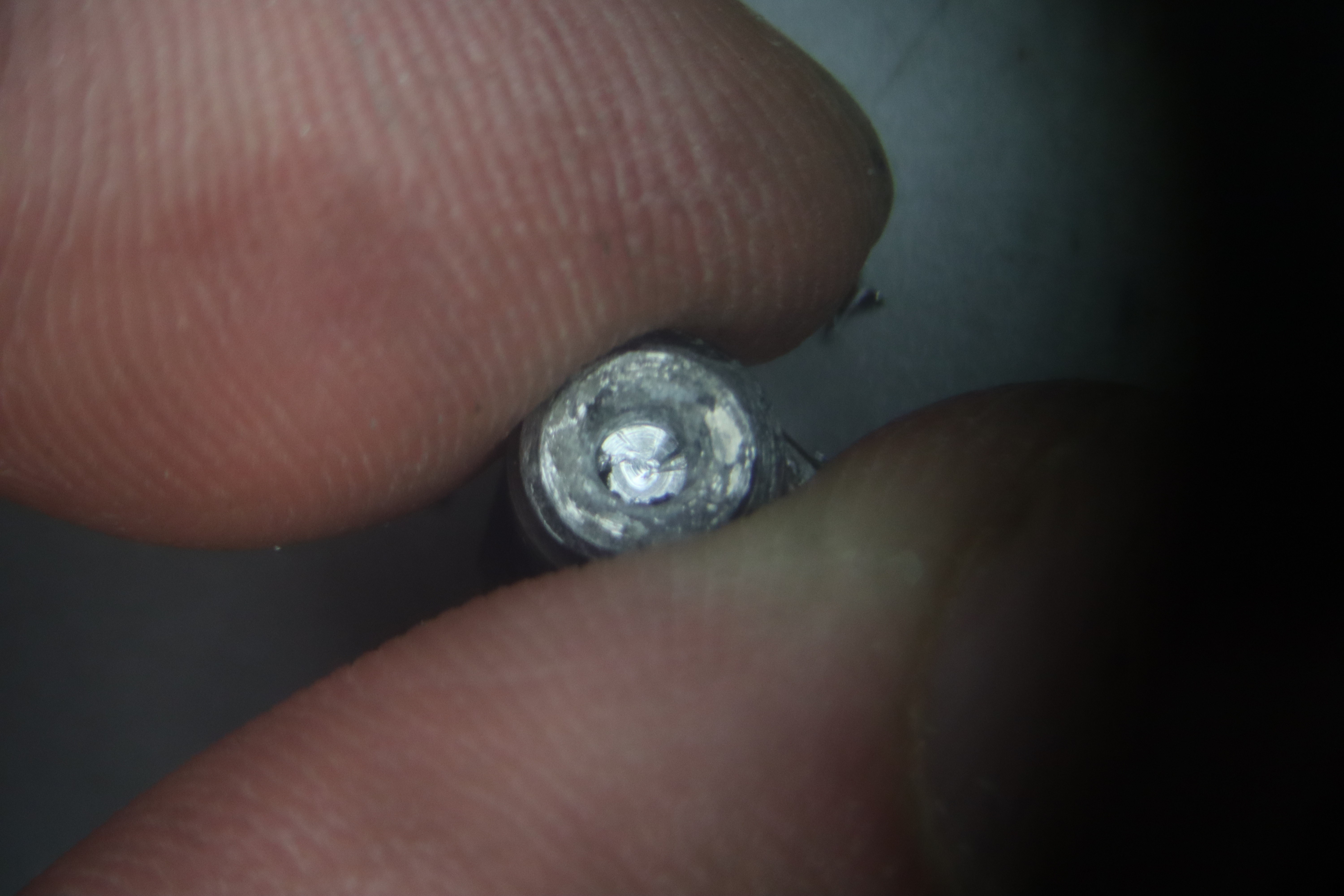

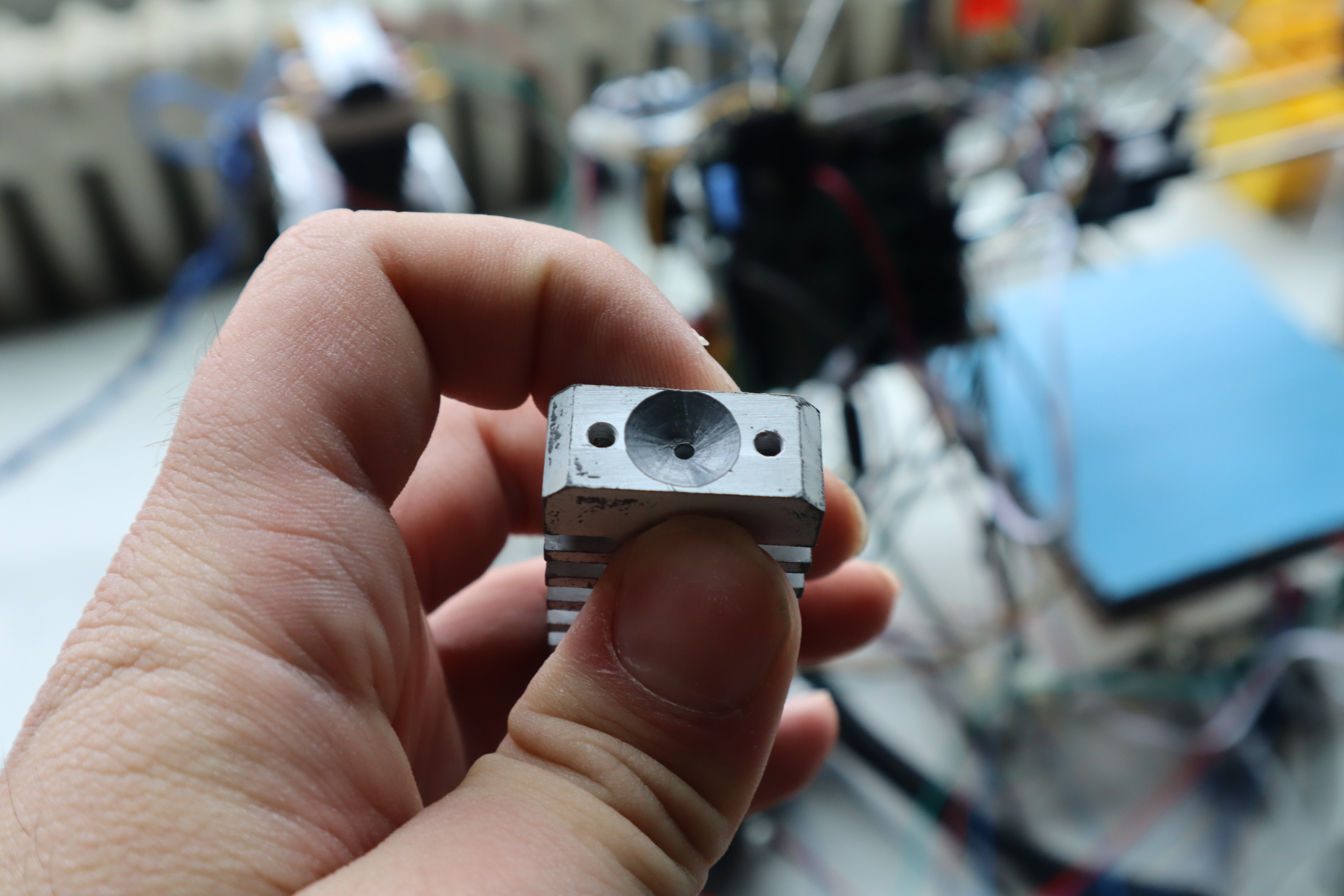

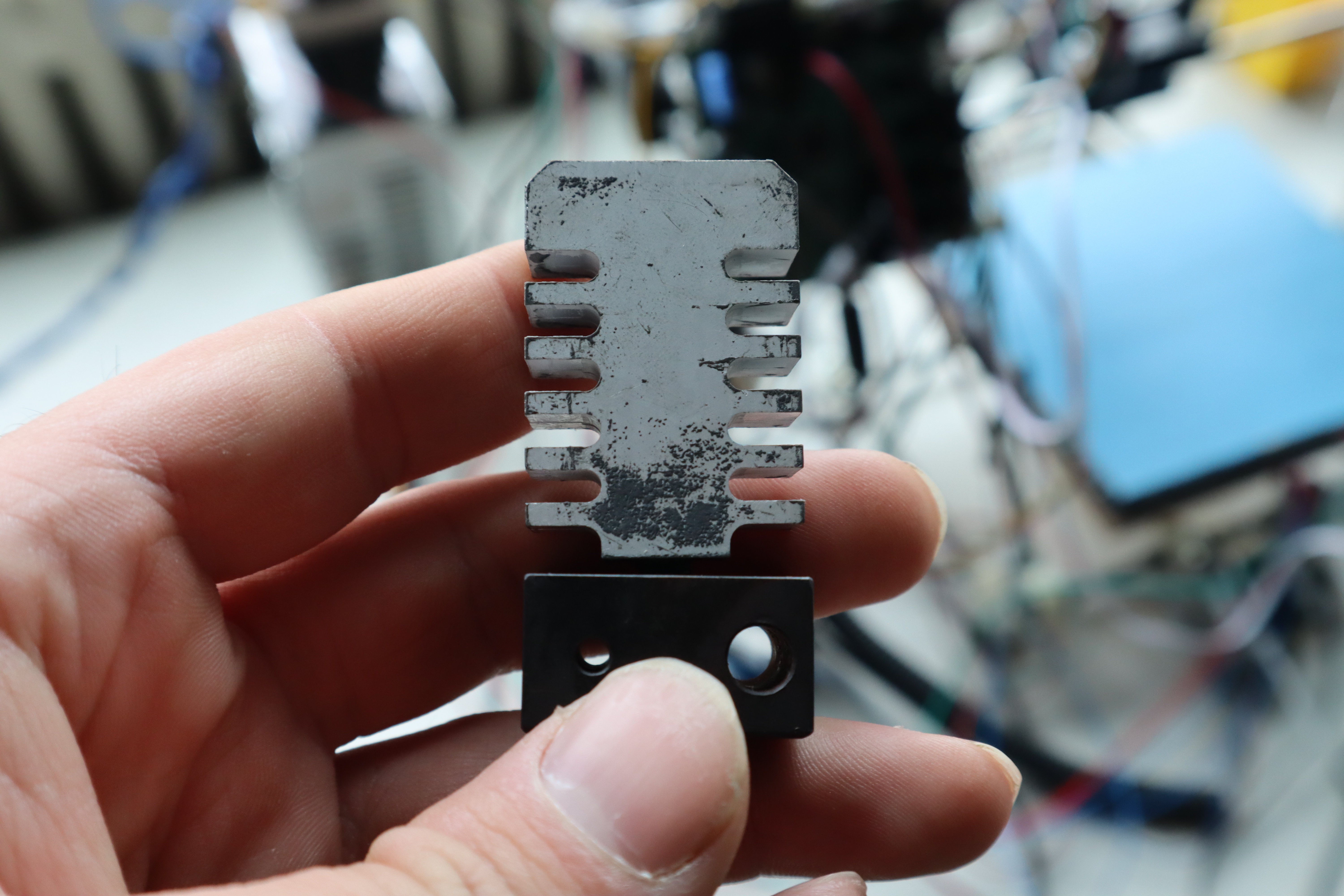

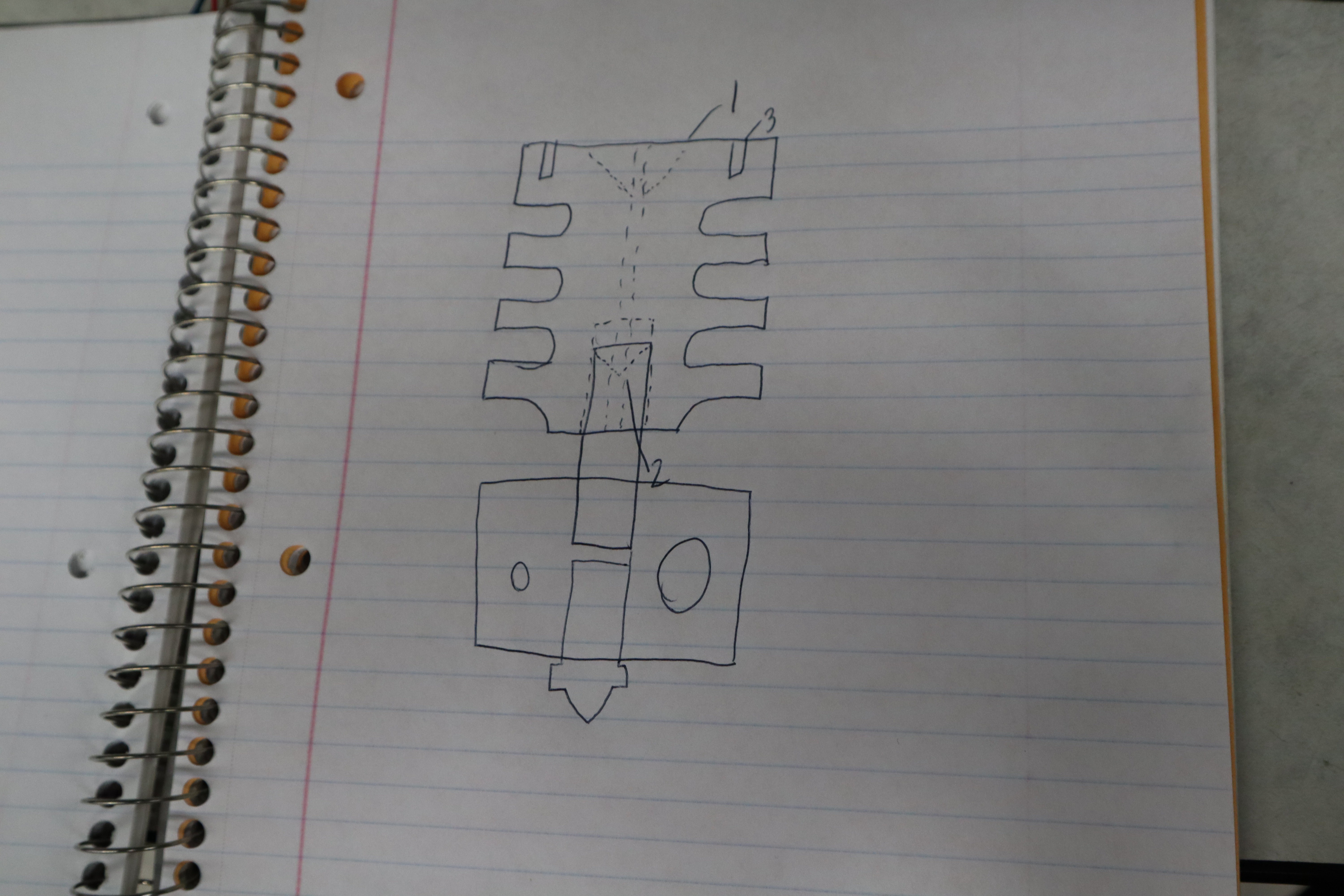

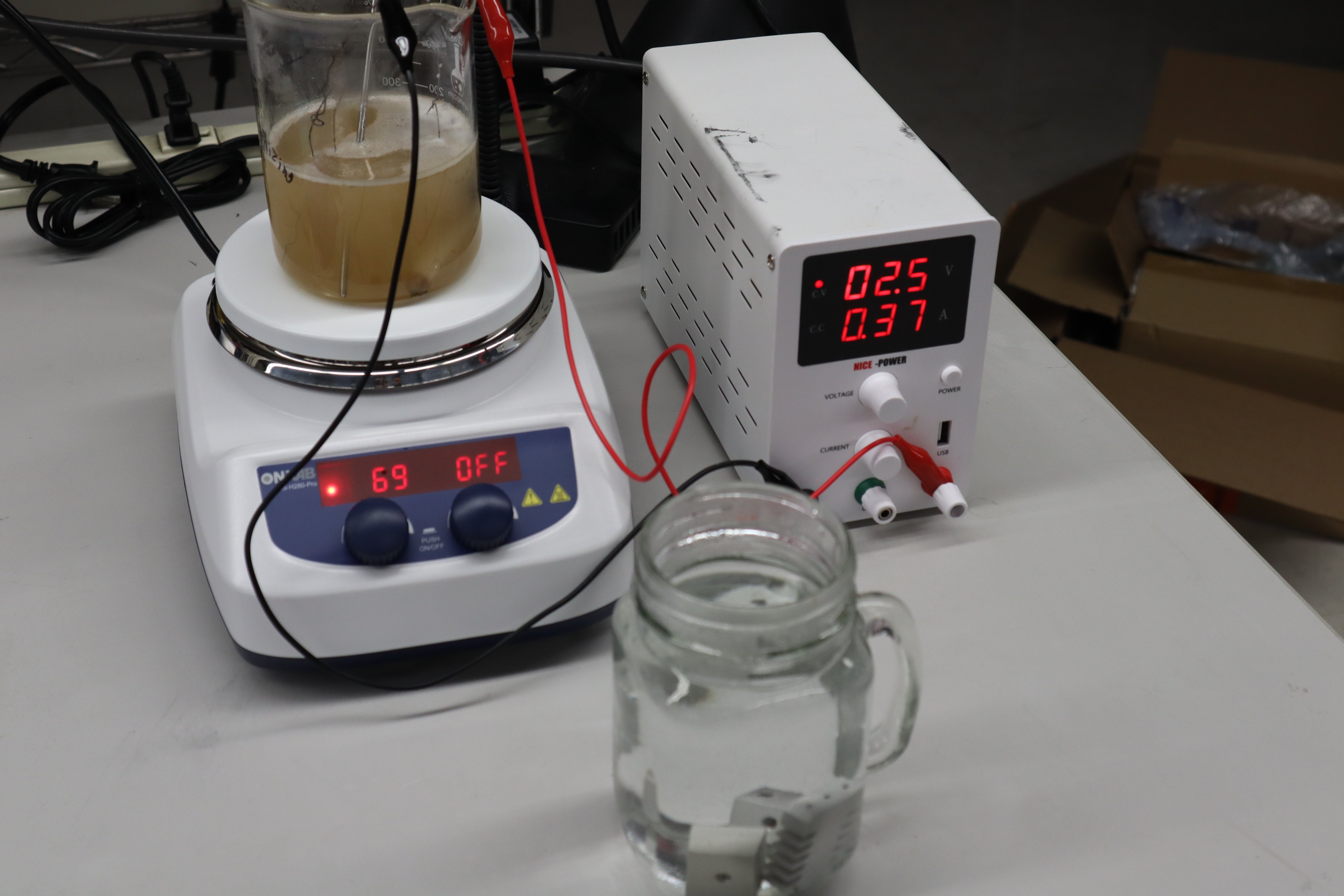

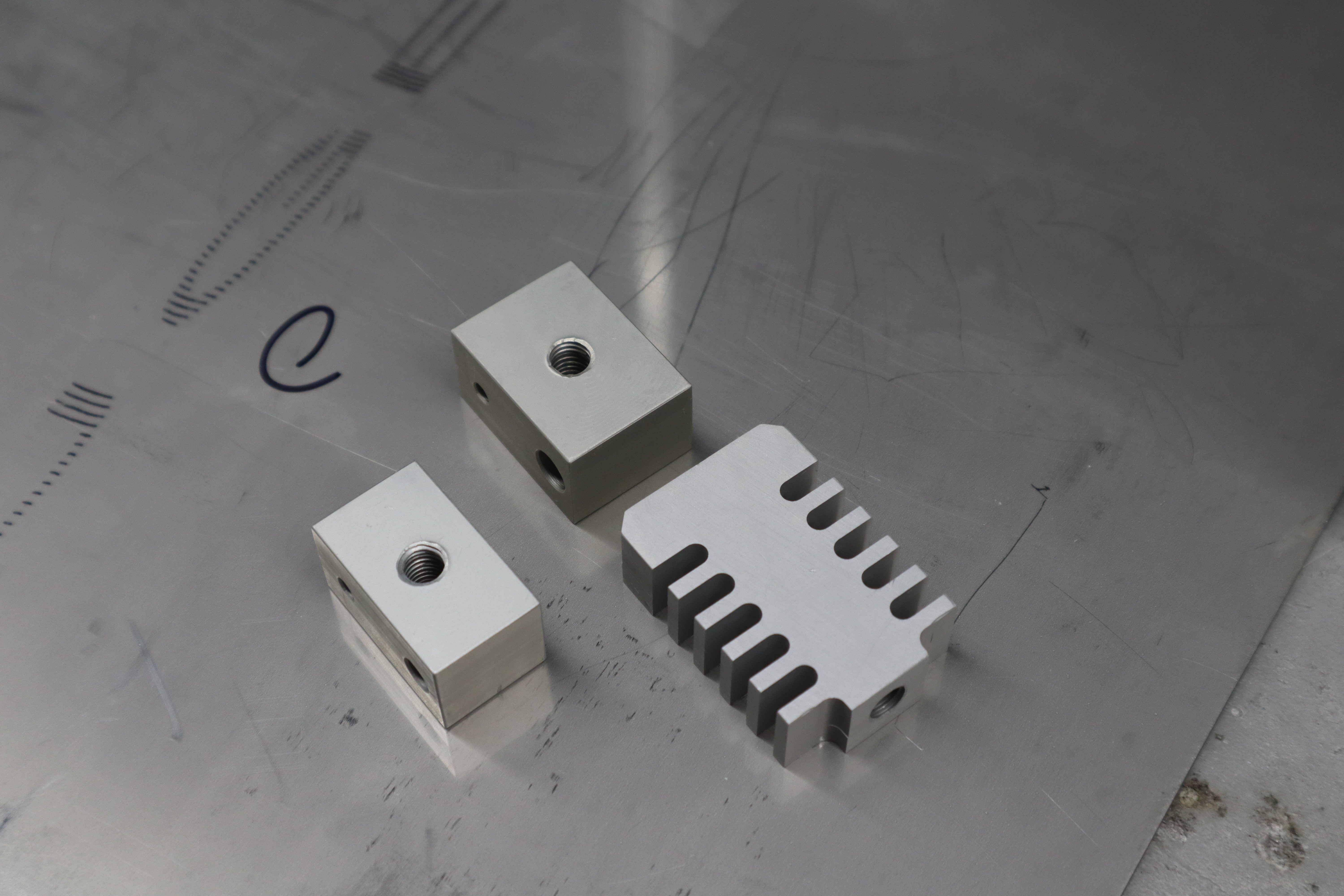

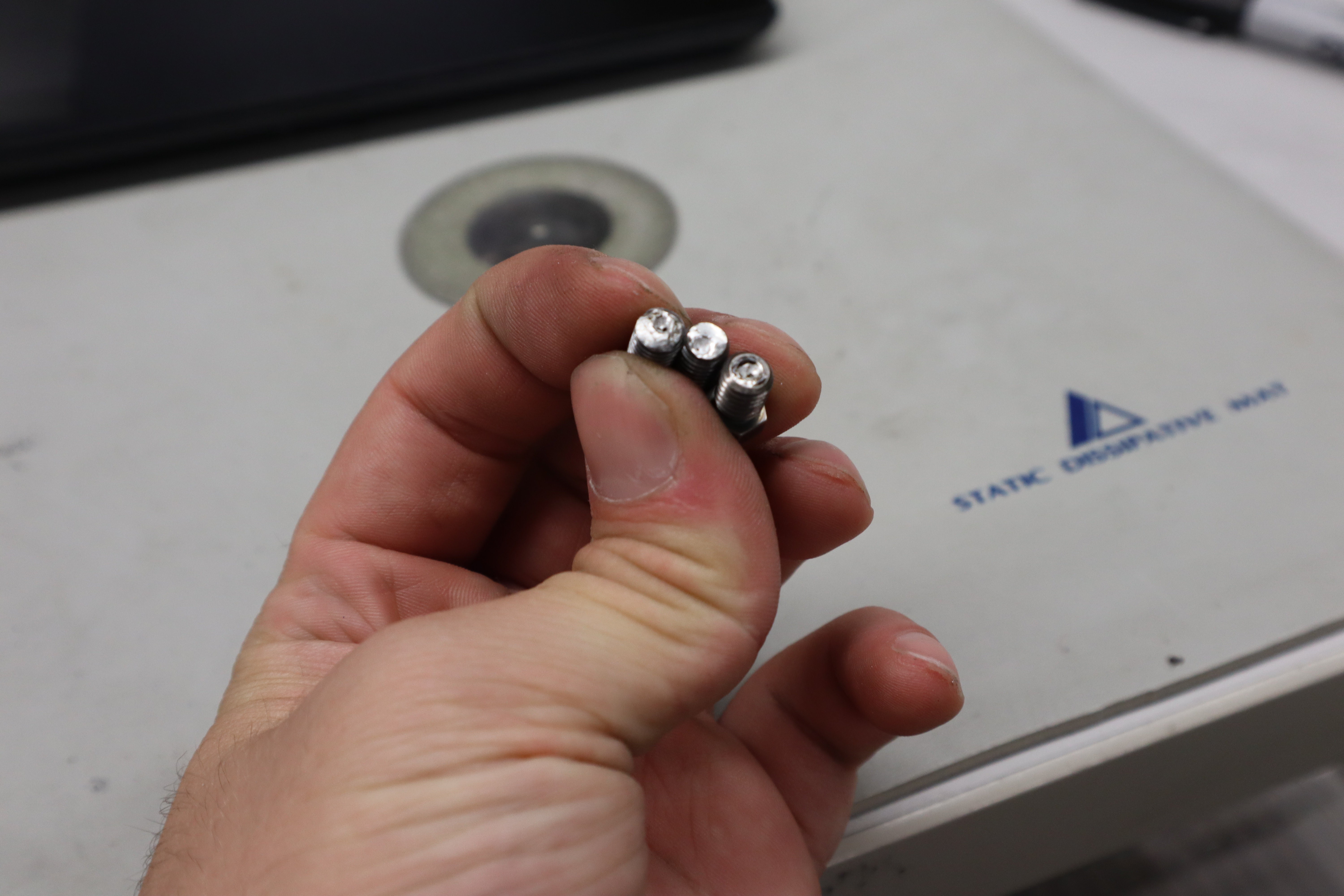

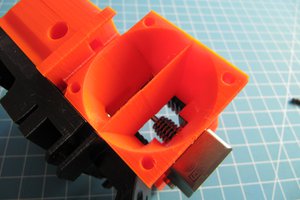

- Wettability-patterned hotend components

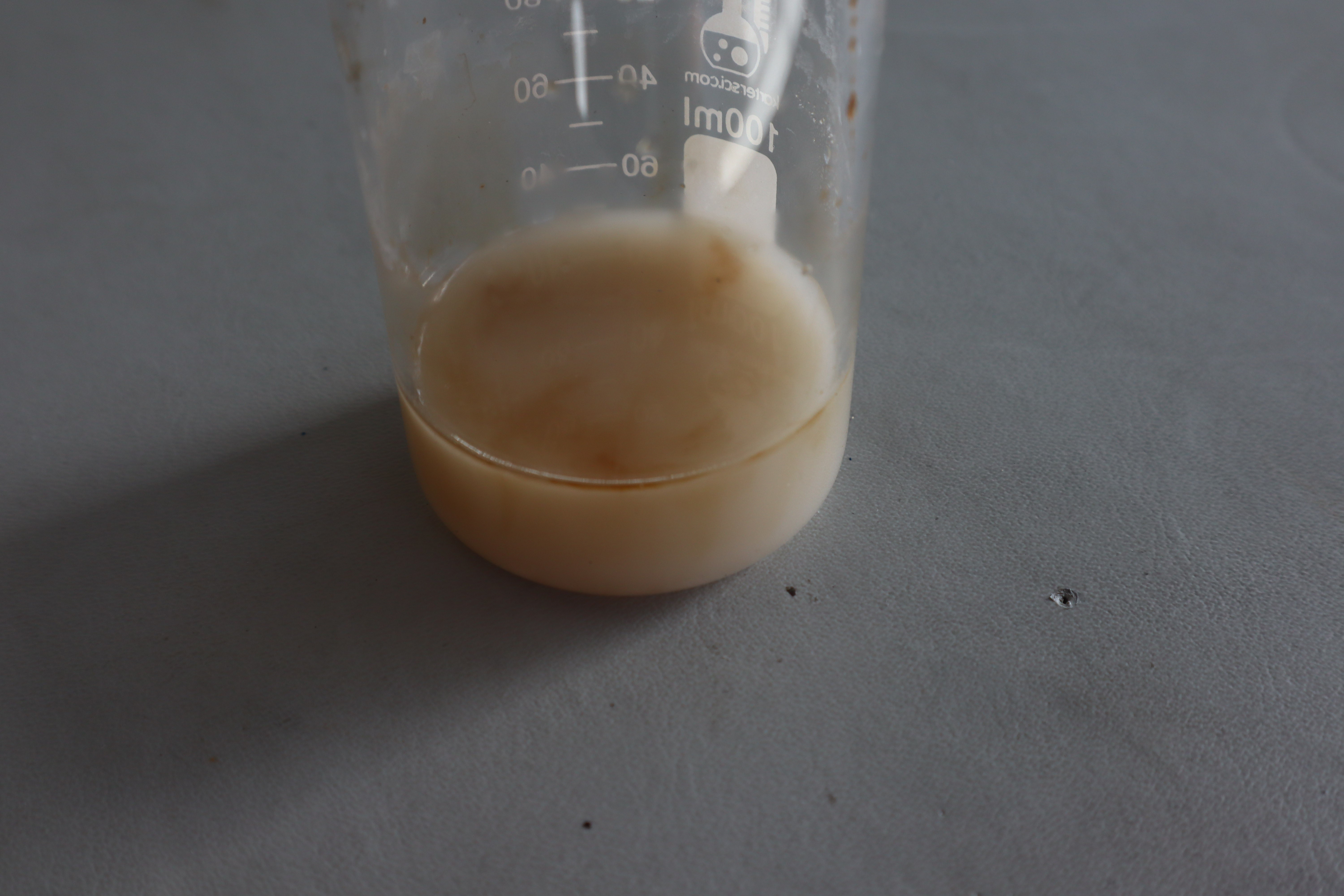

- Optimized printing materials

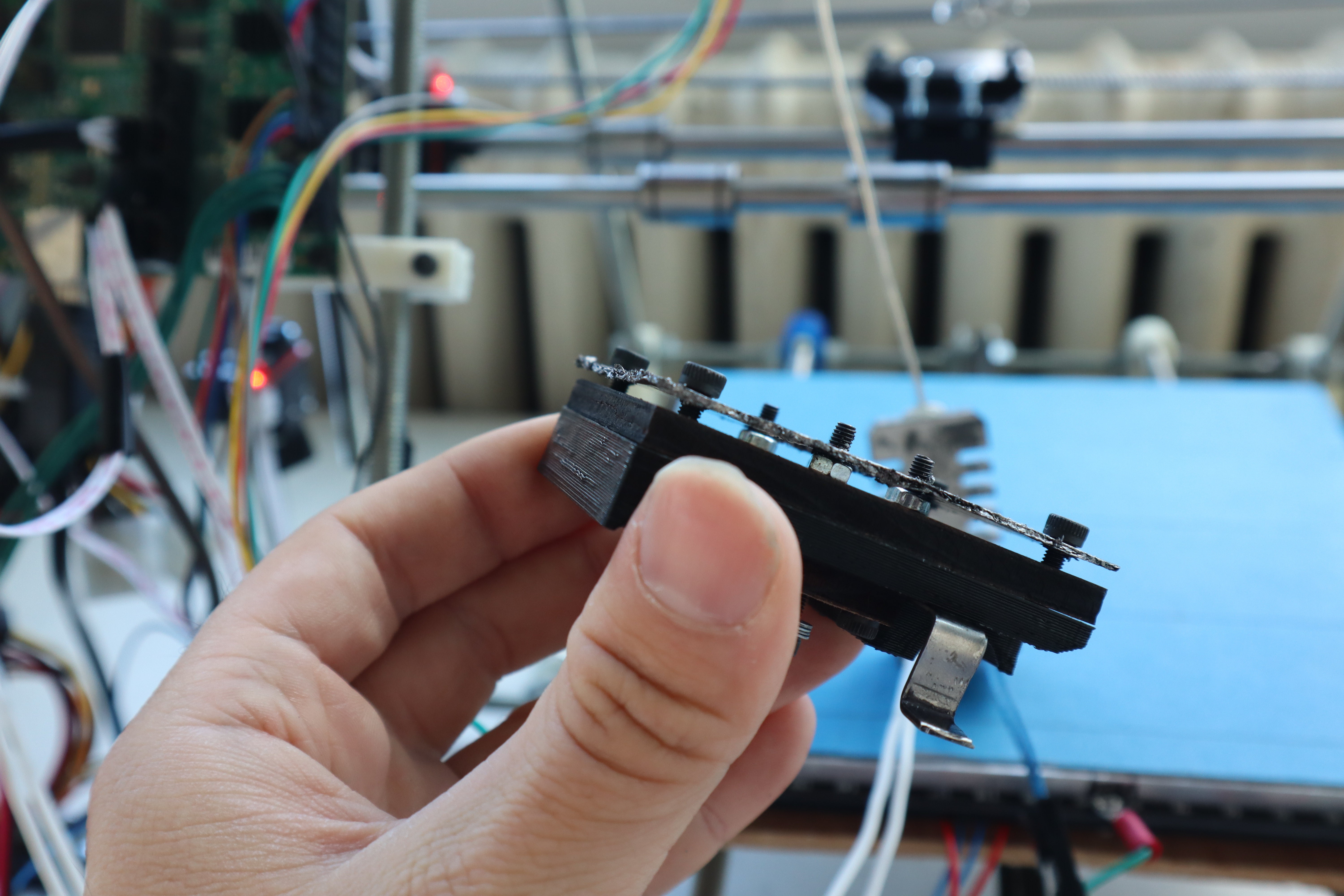

- liquid glass gasketing and liberal use of X-Pando to seal the liquid metal during extrusion

- brush to guide metal onto substrate

You can find the Github page here.

The license for this project is Apache-2.0, and there is a provisional patent for an industrial version of the technology which can print aluminum, copper, and steel alloys, but anything that doesn't glow red hot and that a hobbyist would feel safe about using at home is fair game and open-source.

Michael Perrone

Michael Perrone

TheGrim

TheGrim

Cadmium

Cadmium

Thane Hunt

Thane Hunt

Ahron Wayne

Ahron Wayne

Thanks for sharing it. As we were thing to print the logo of https://mostvaluednoob.com/enlisted-system-requirements/ on metal. But were unable the whole process. Got the complete knowledge from here now it will be easy for us. You have share a really impressive and read worthy topic.