THE CONTEXT :

Barely 10% of plastic waste is recycled today. Sorting used plastic is the first essential step in recycling.

Industrial recycling centers use a highly efficient sorting method based on infrared spectrometers that are very fast, but very expensive (+€100k).

In recent years, a number of projects have emerged to democratize plastic waste recovery techniques (eg Precious Plastic, Plastic Odyssey, paillettes-plastique).

Small structures that emerged from these trends use qualitative manual methods, which do not enable all types of plastic to be sorted efficiently. A low-cost sensor would enable these structures - as well as small workshops, fablabs and makers - to better sort plastics, and thus recycle more of them.

Although recently, more affordable spectrometers have appeared, such as the Plastri at €25,000, or the Plastell at €3,500; Today, there are no truly low-cost, open-source sensors for sorting plastic on a small scale...

THE TECHNO :

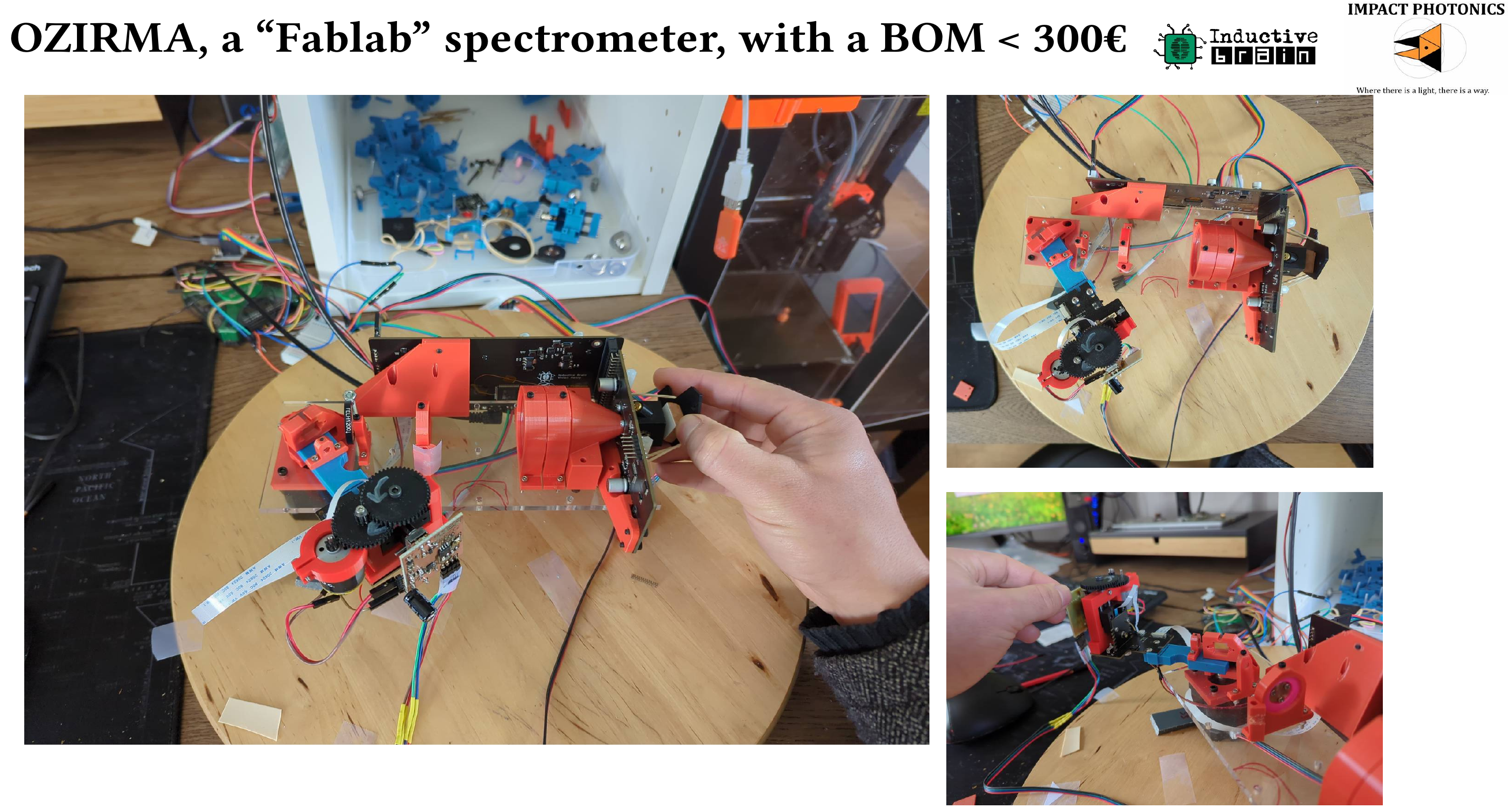

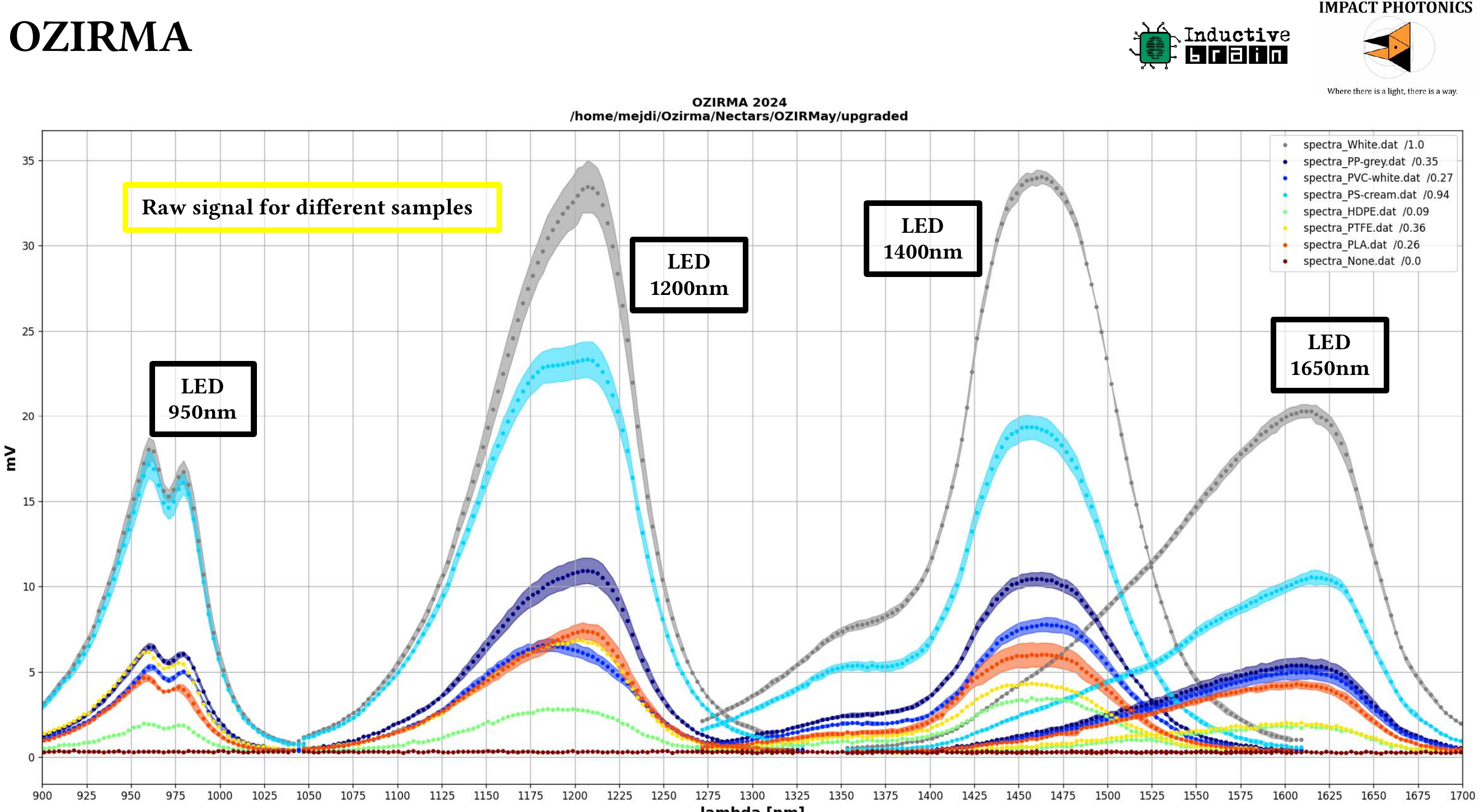

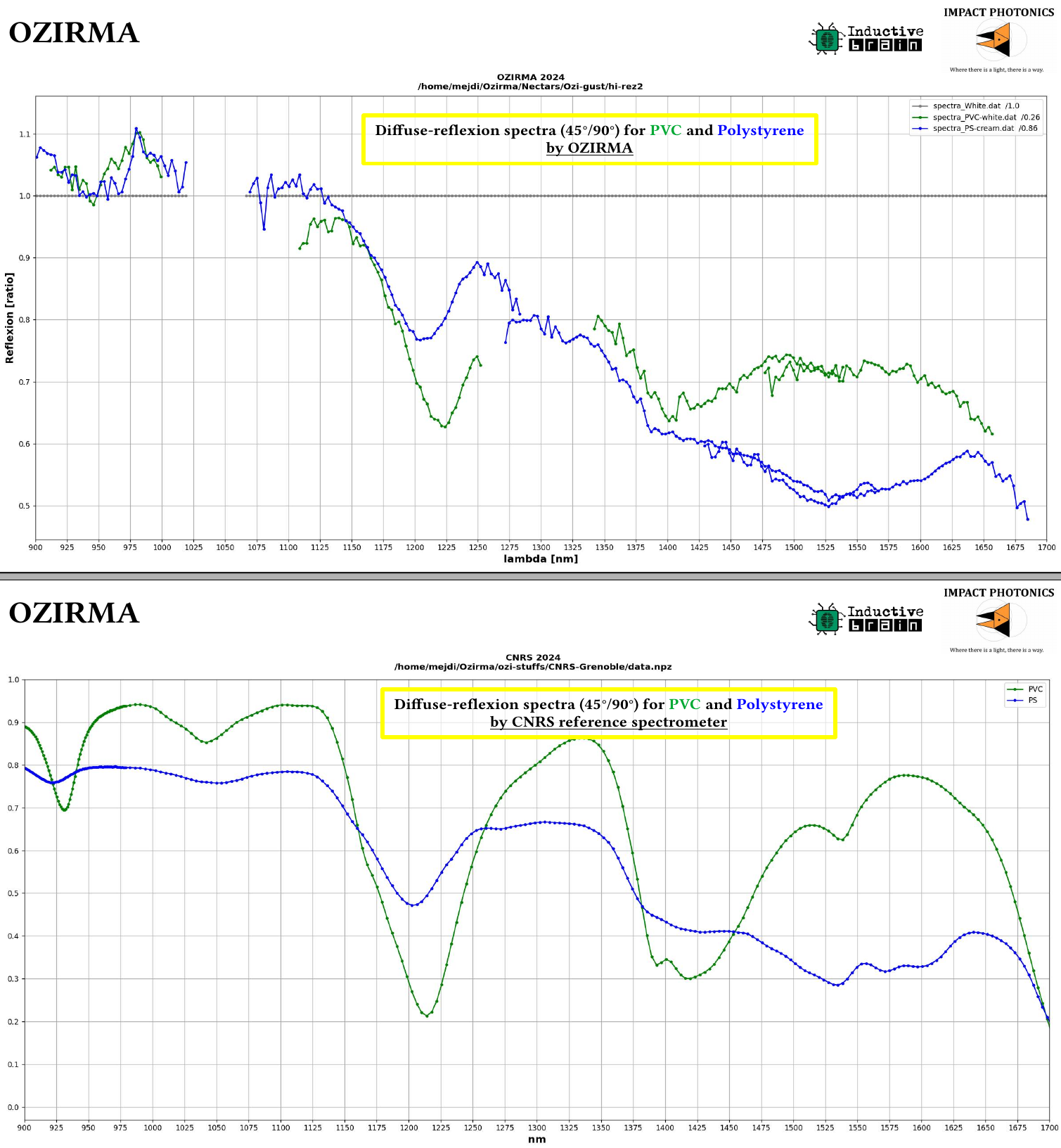

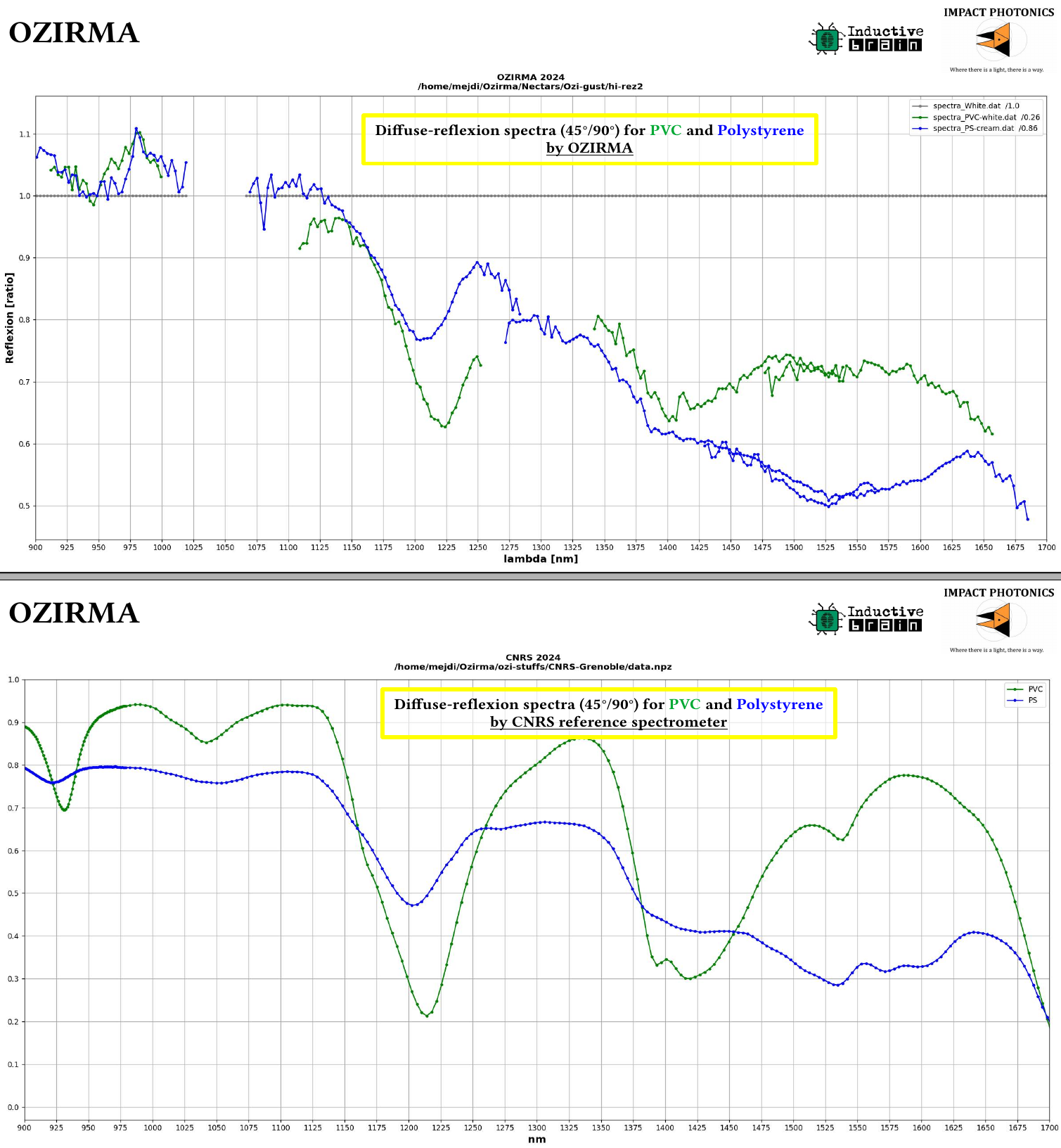

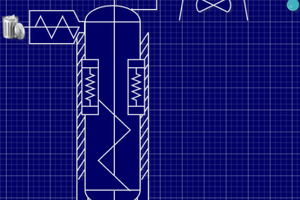

OZIRMA is a small spectrometer that operates in the infrared (900-1700nm). It measures diffuse reflection with a spectral resolution of 15nm. Its light source consists of four infrared LEDs (and a laser, for alignment). Its detector is a photodiode (a single pixel) which scans the spectrum by rotating around the diffraction grating (while compensating for alignment errors).

OZIRMA :

OZIRMA is ultra-low-cost. It requires just €300 of raw materials to be manufactured. The downside of this low cost is speed... OZIRMA is slower than existing solutions. In the context of small recycling workshops, this remains acceptable.

USE : - The plastic sample is placed on OZIRMA. - OZIRMA measures the spectrum of the sample (~30s). - The shape of the spectrum is used to determine the type of plastic, via an algorithm and an open-source database. Eventually, we may also be able to detect other plastic properties such as moisture content or the presence of flame retardants.

What's been done so far

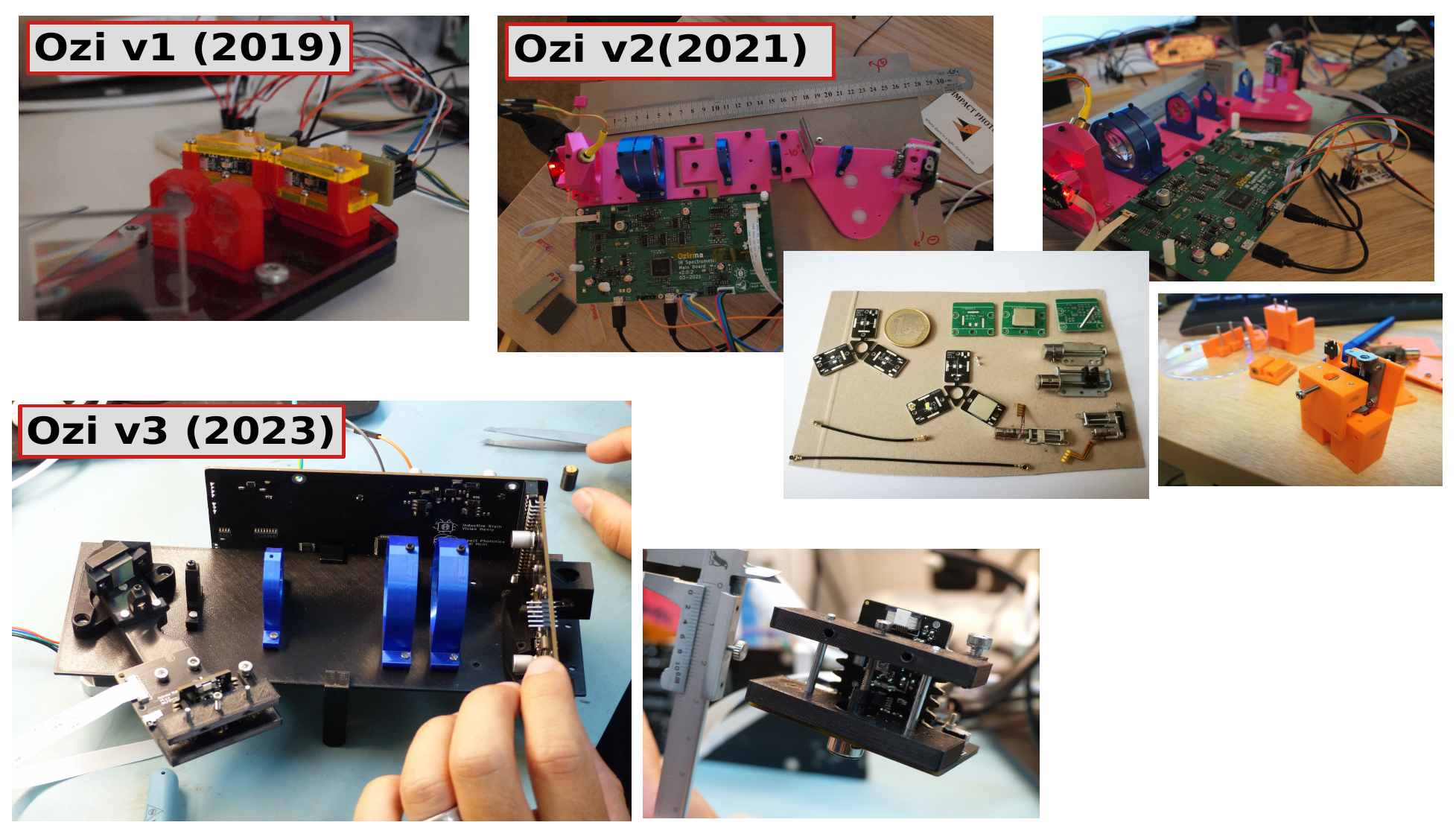

Since 2019, we've been developing OZIRMA on our own time and our own funds. It's a project close to our hearts.

Started a simple idea, it took several modifications and re-designs before OZIRMA v4 (the 4th version) finally worked;

in the sense that it measures spectra similar to those measured on the same samples with a large laboratory spectrometer (thank you, CNRS!).

What's next?

Now that OZIRMA_v4 is up and running, we have a 3-stage plan for building OZIRMA_v5 and validating it in real-life use.

1/ Prototyping OZIRMA_v5 (six months' work for two people)

- Integrate all bug fixes from v4

- Reduce size

- Increase measurement speed (a full scan would now take just 30s)

- Improve mechanical robustness and user interface for field use.

2/ Pre-series (“beta MVP” in start-up language) of six OZIRMA_v5 machines, four of which will be given to partner recycling workshops for evaluation, including the Precious Plastic community and the Paillettes network!

3/ Feedback after 6 months of use: Measurement of spectra of 1000+ known and unknown plastic samples, accessible in open-data. This will enable us to objectively assess OZIRMA's failure and error rates.

We need your help!

To fund our engineering work on this open-source project, we've decided to use crowdfunding.

1st threshold: 5k€ Mejdi and Vivien will produce engineering drawings, specifications and schematics that will form the basis of OZIRMA_v5's design.

2nd threshold: €30k Mejdi and Vivien go into a technical design tunnel (optics, mechanics, electronics and software) to build/test/test OZIRMA_v5.

Vivien Henry

Vivien Henry

Leonardo Zuniga

Leonardo Zuniga

Mathieu Lacage

Mathieu Lacage

Fabian

Fabian

Adam Munich

Adam Munich

I was thinking of building a similar design as a project sometime soon to compliment my UV/VIS spectroscope and wondered if instead of the photodiode rotating around the diffraction grating it could be feasible to rotate just the diffraction grating slightly at a high gear ratio. Maybe this would skew the optical axis too much?