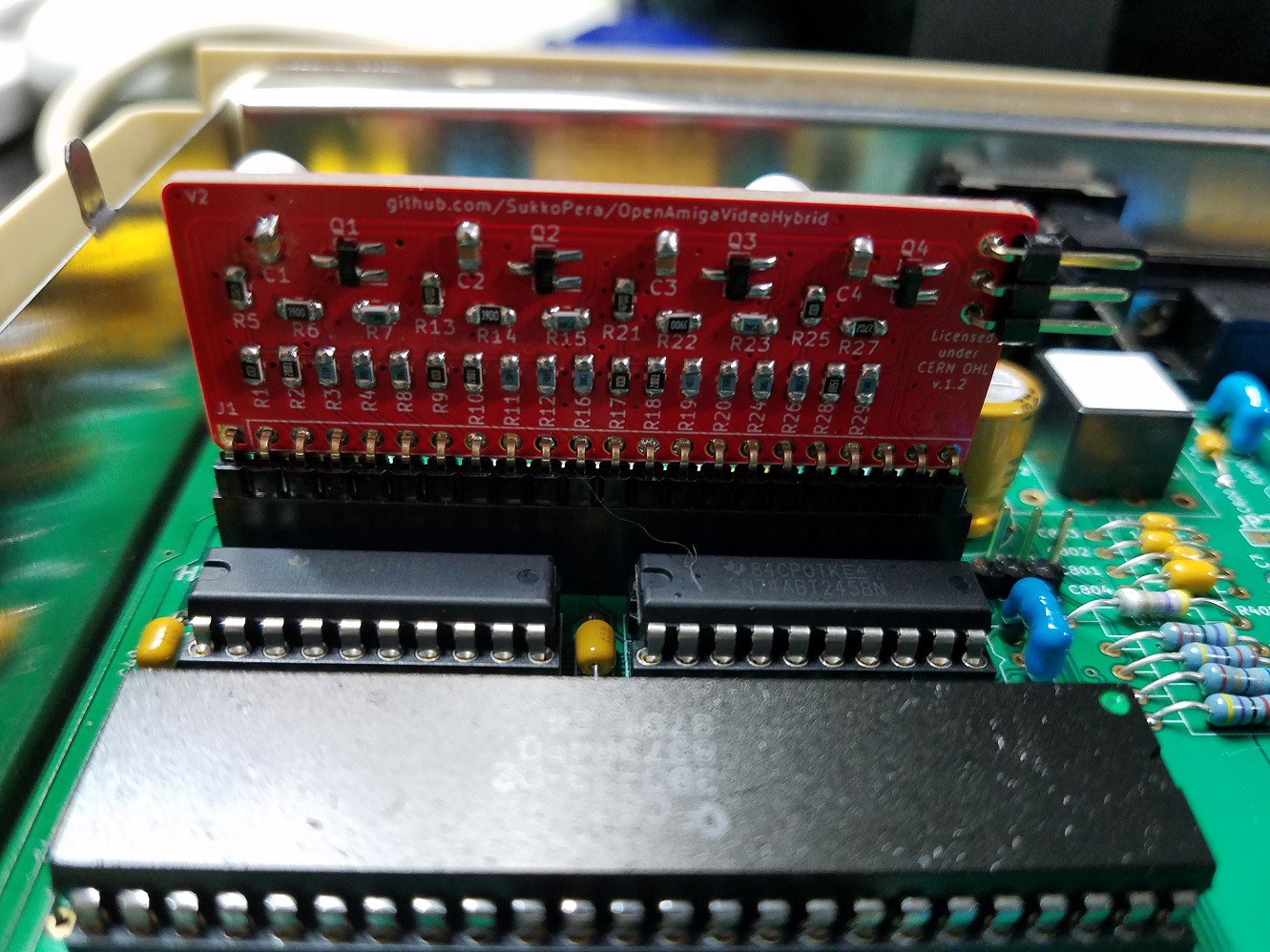

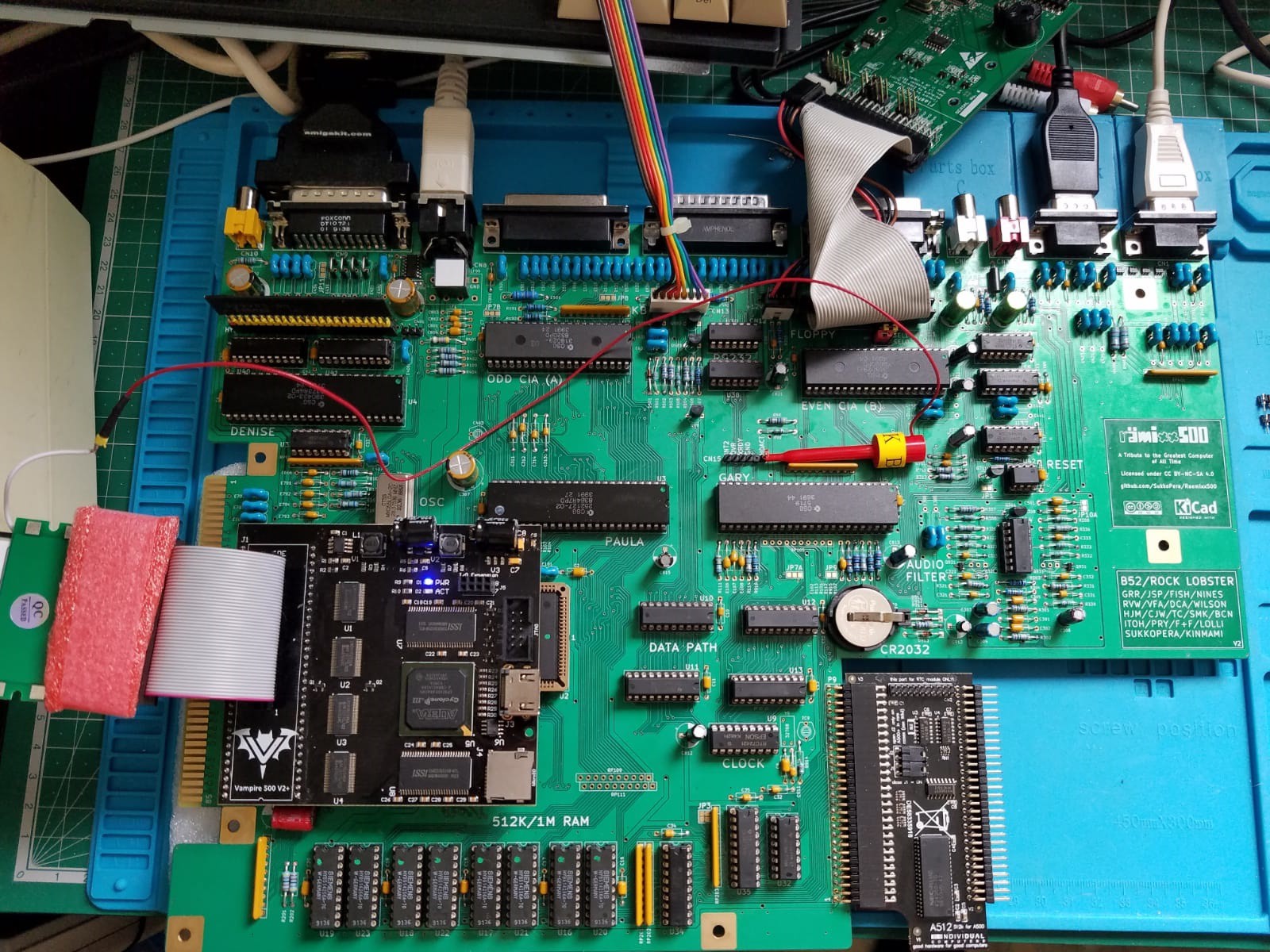

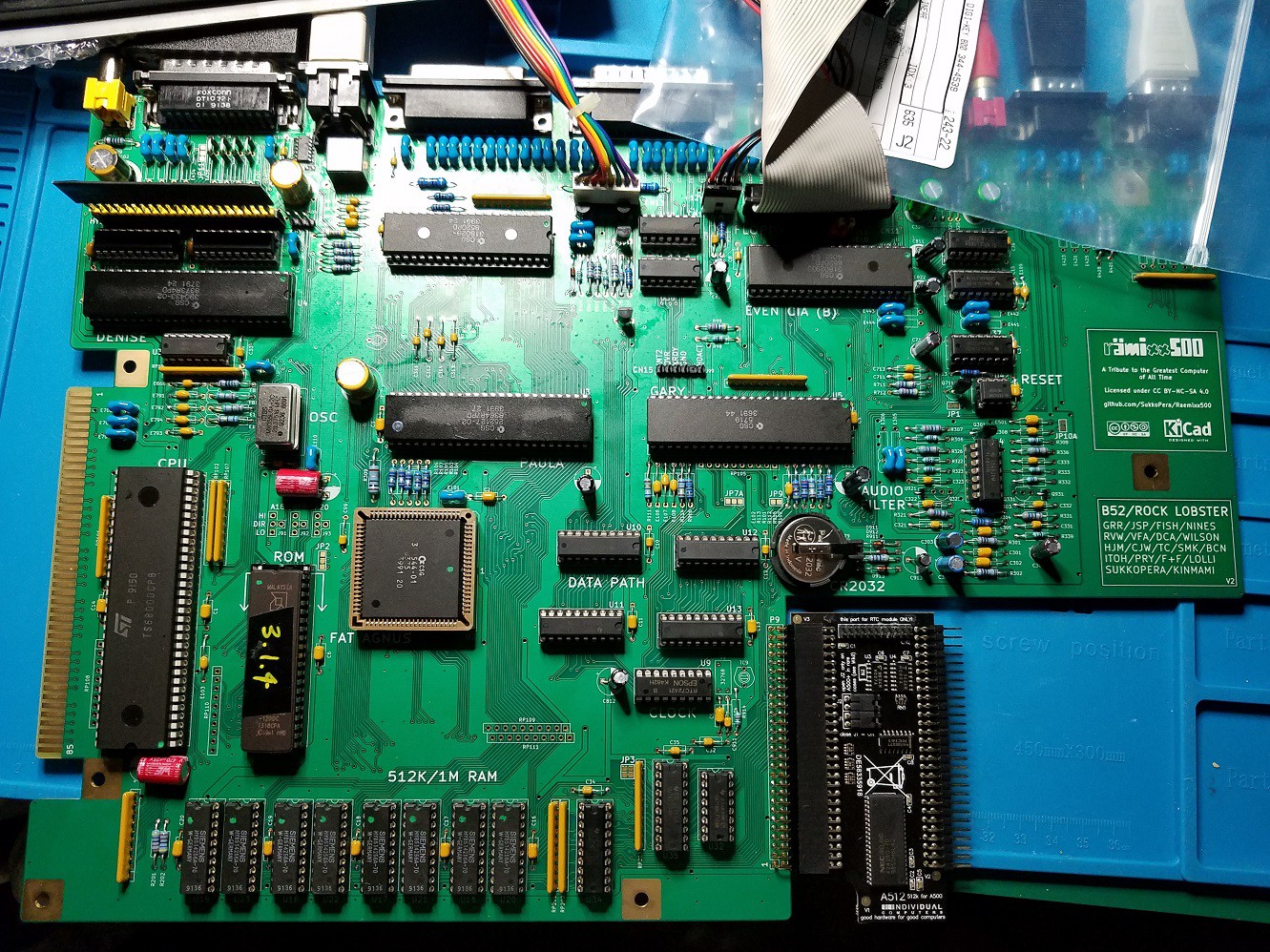

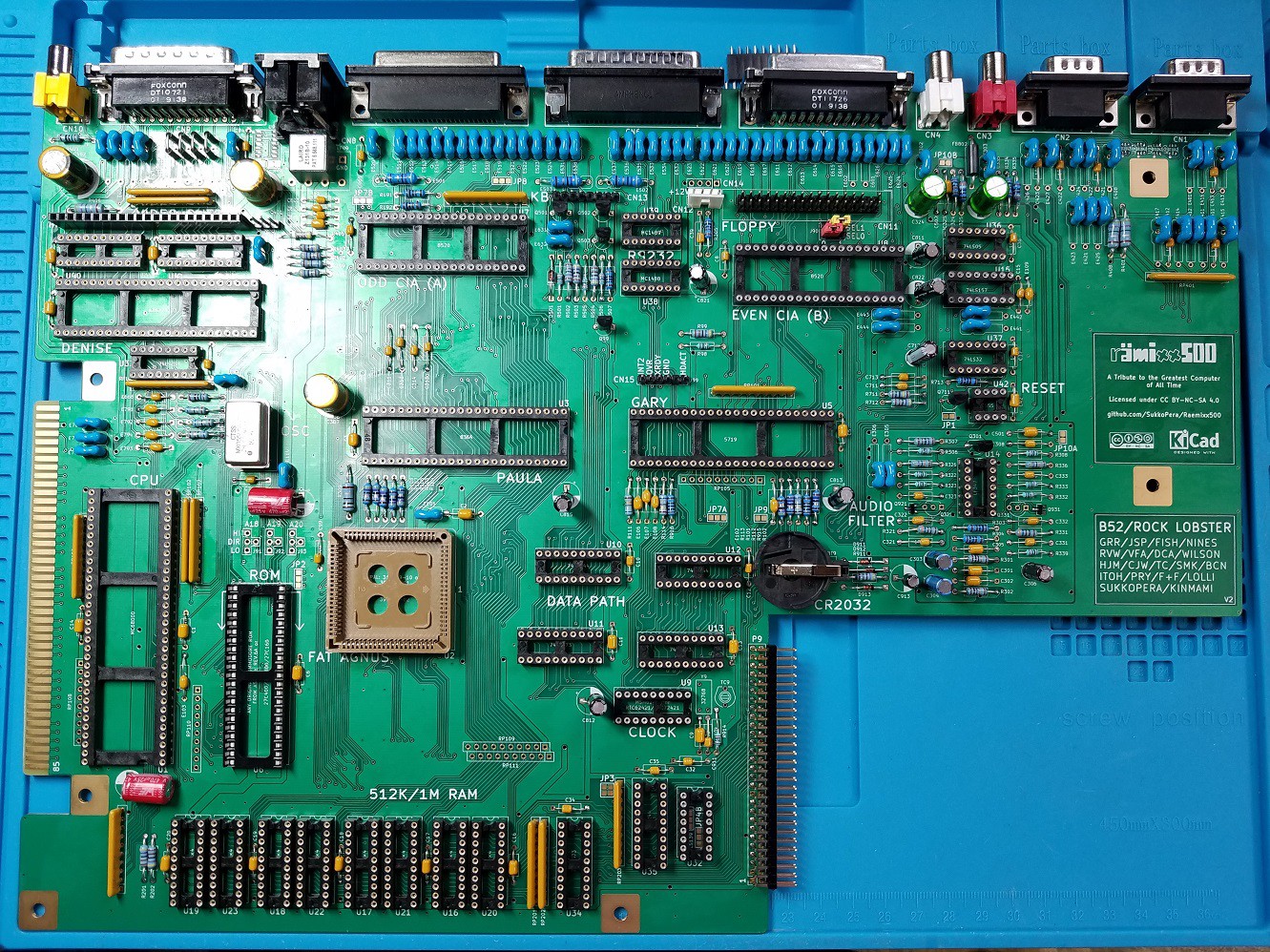

There are other projects like this one out there, but none of them is Open Source and none of them comes with both schematics and board. This is a big advantage, since anyone can modify the board and make new improved versions.

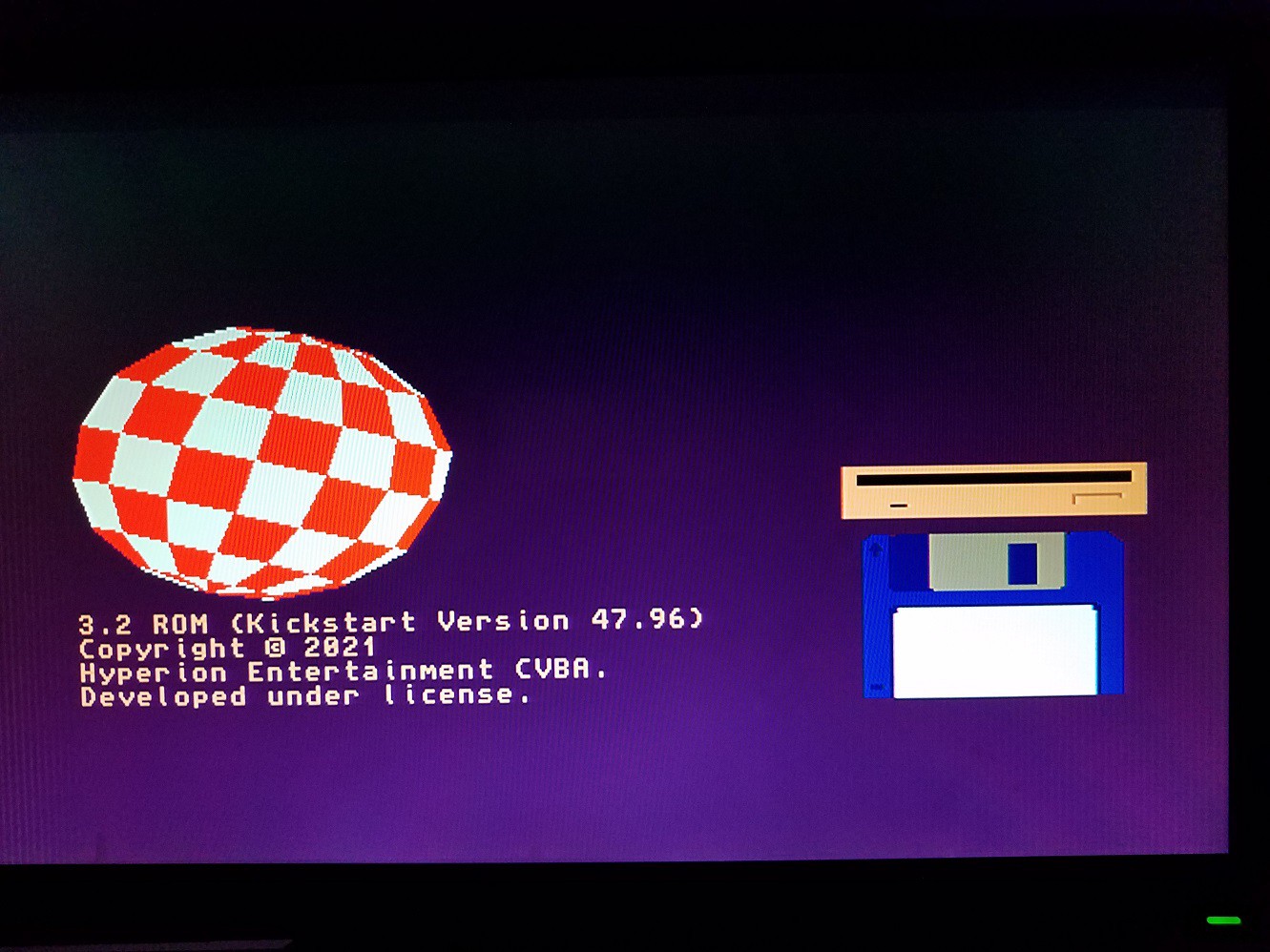

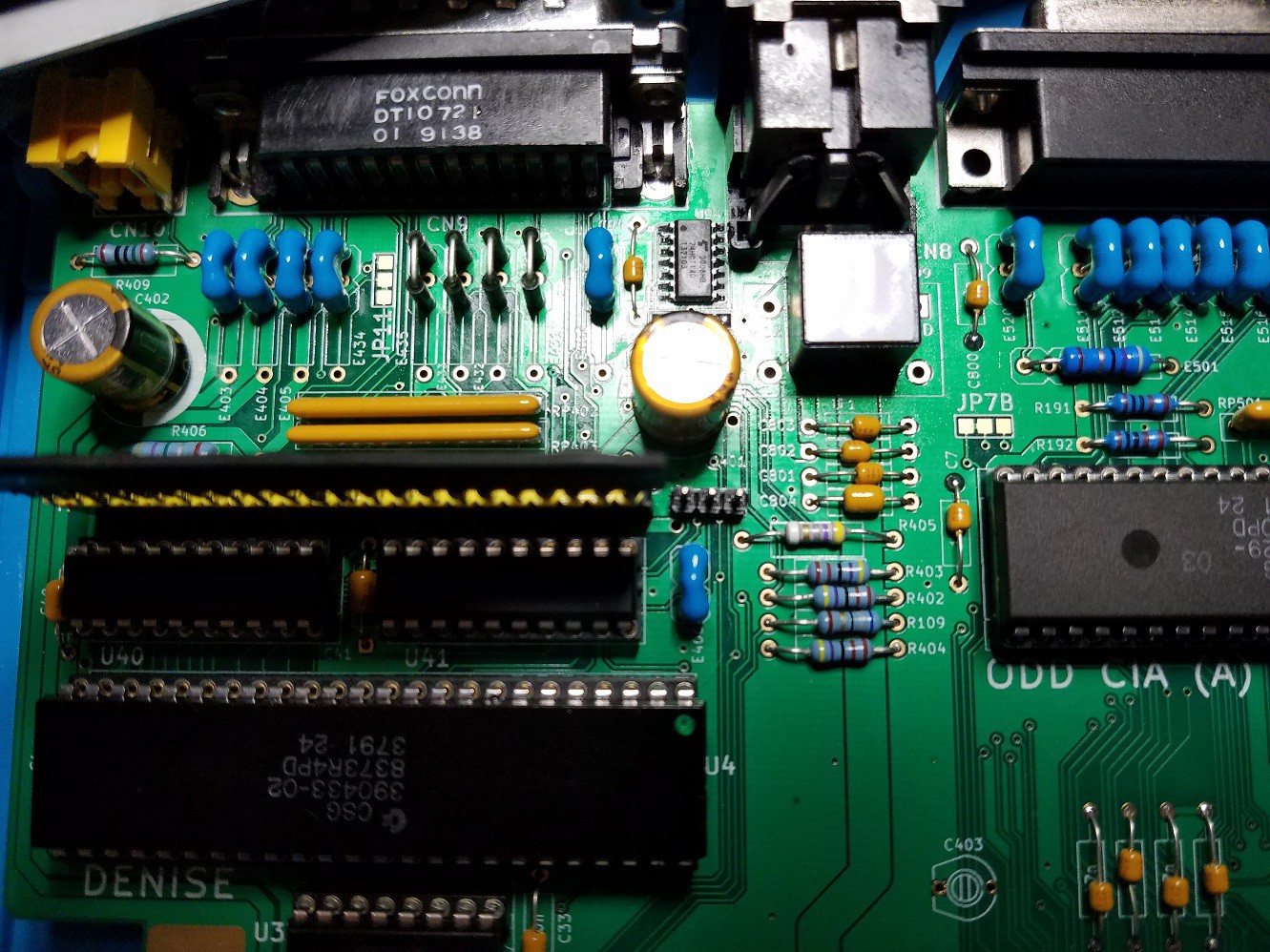

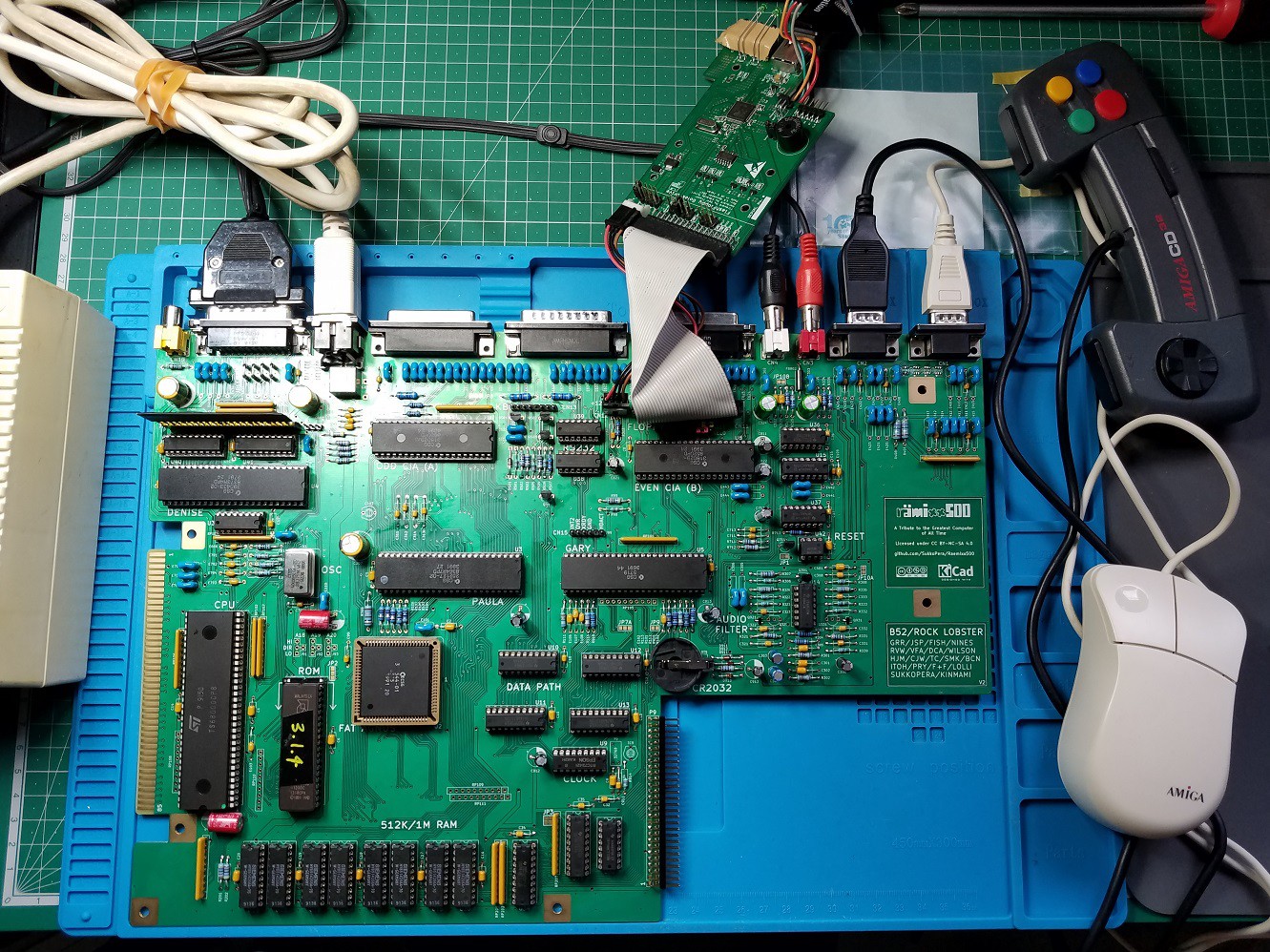

Rämixx500 - Amiga 500+ Mainboard

Open Hardware Remake of this Commodore Masterpiece

SukkoPera

SukkoPera

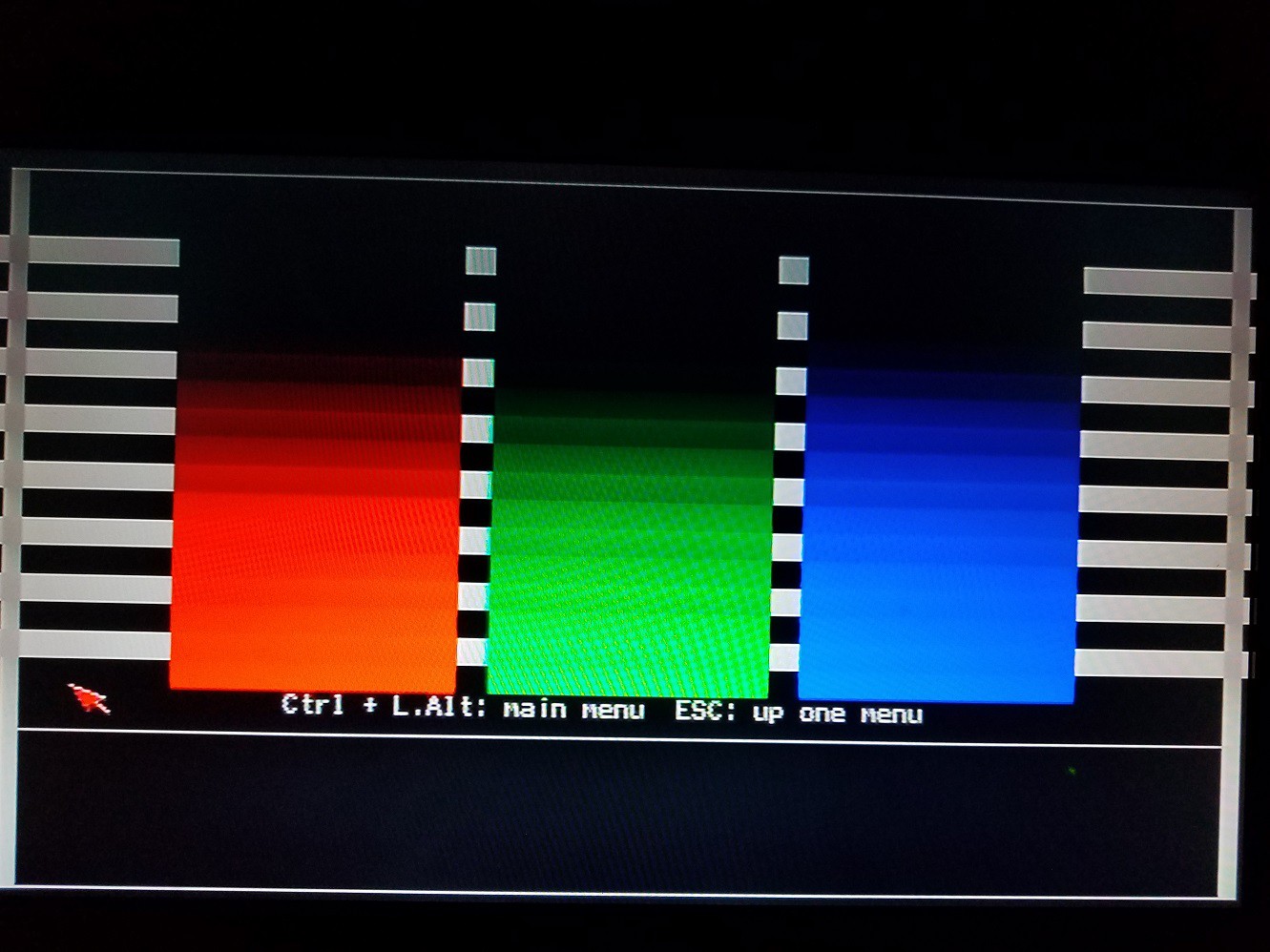

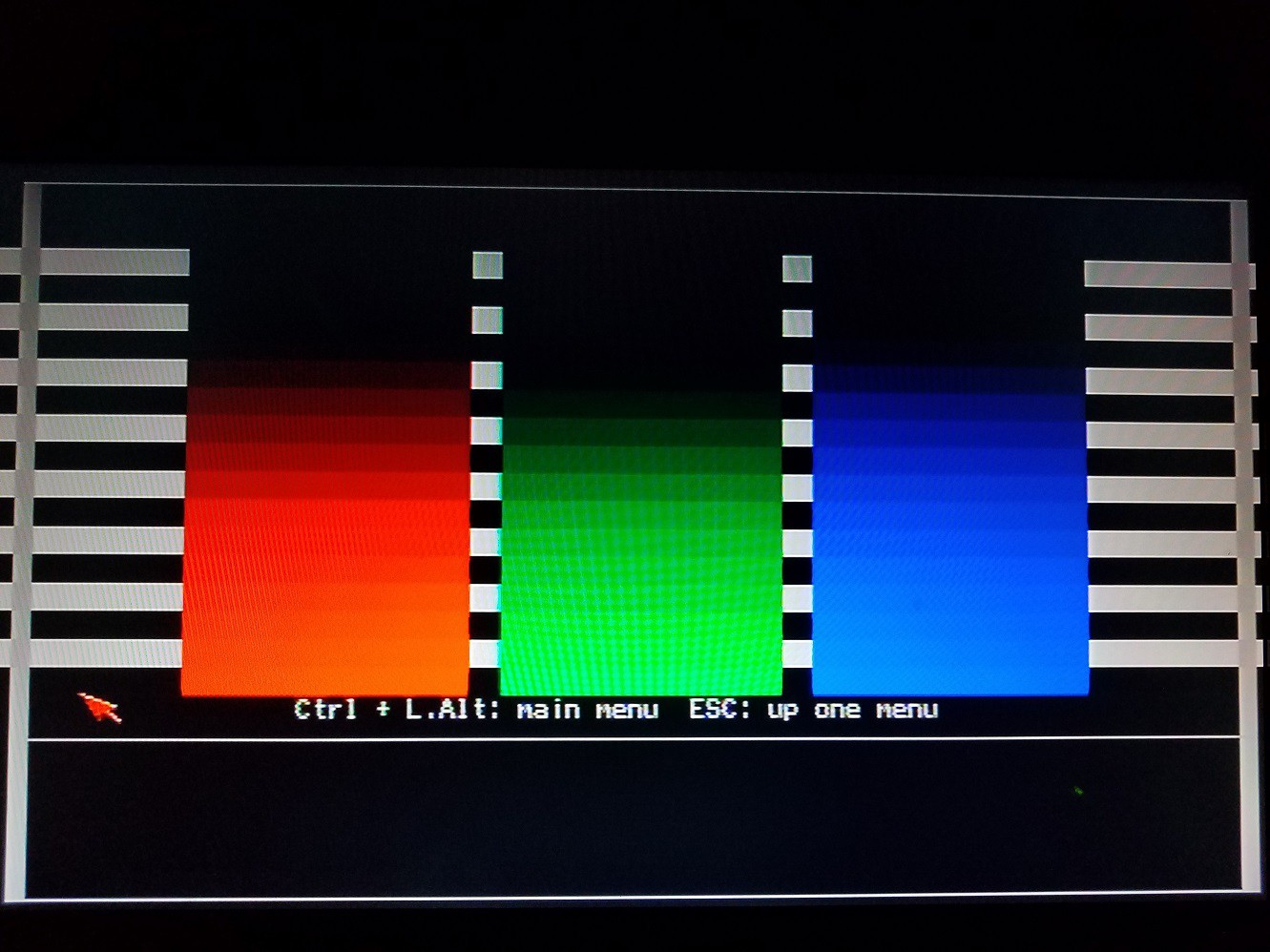

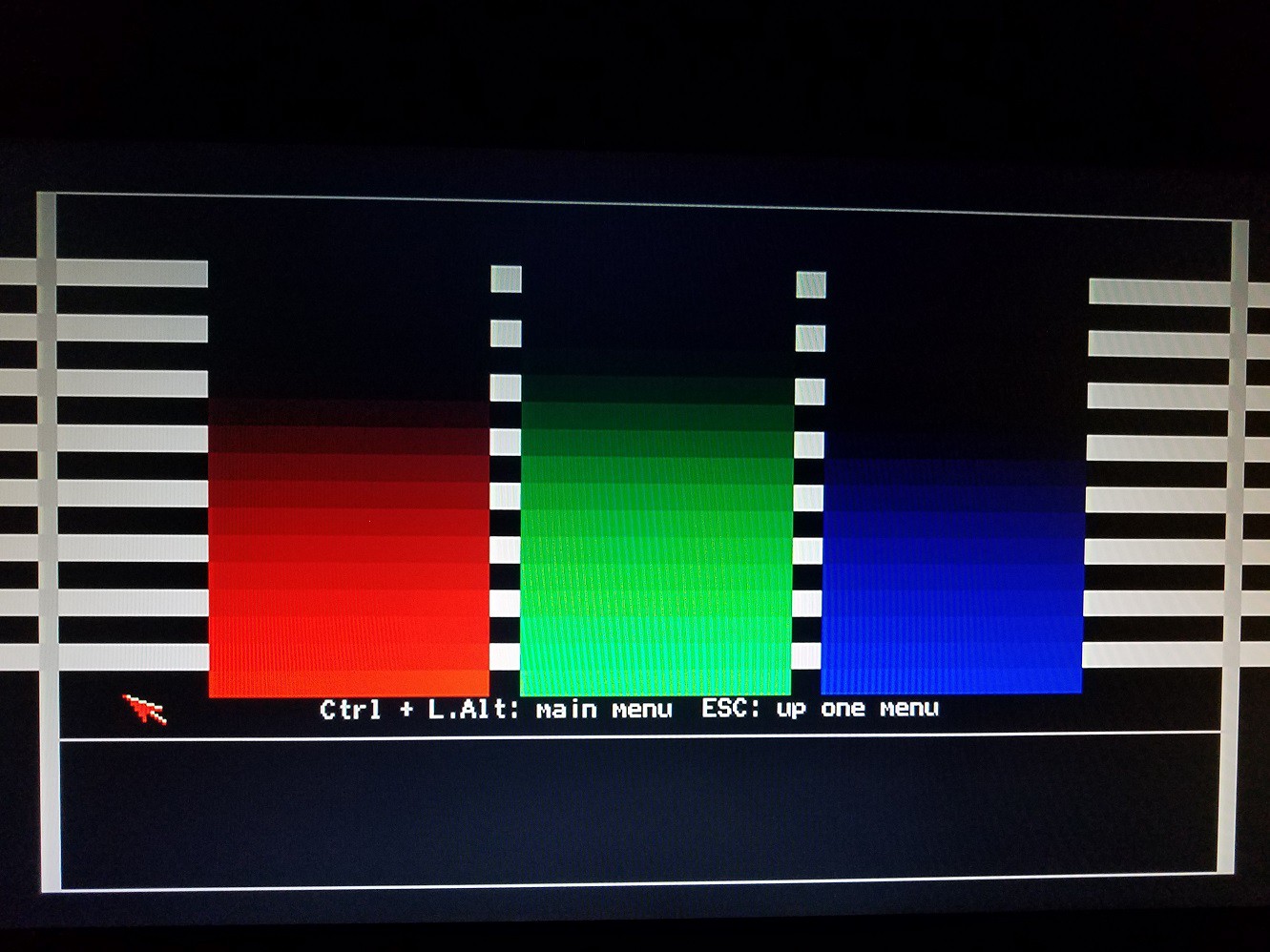

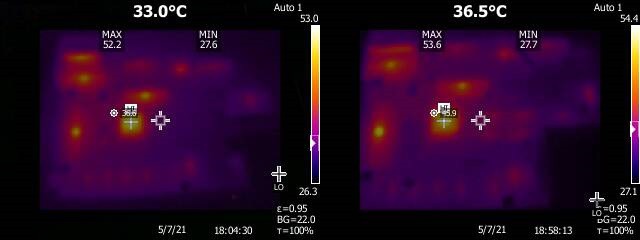

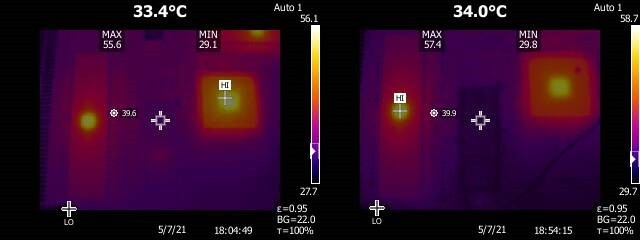

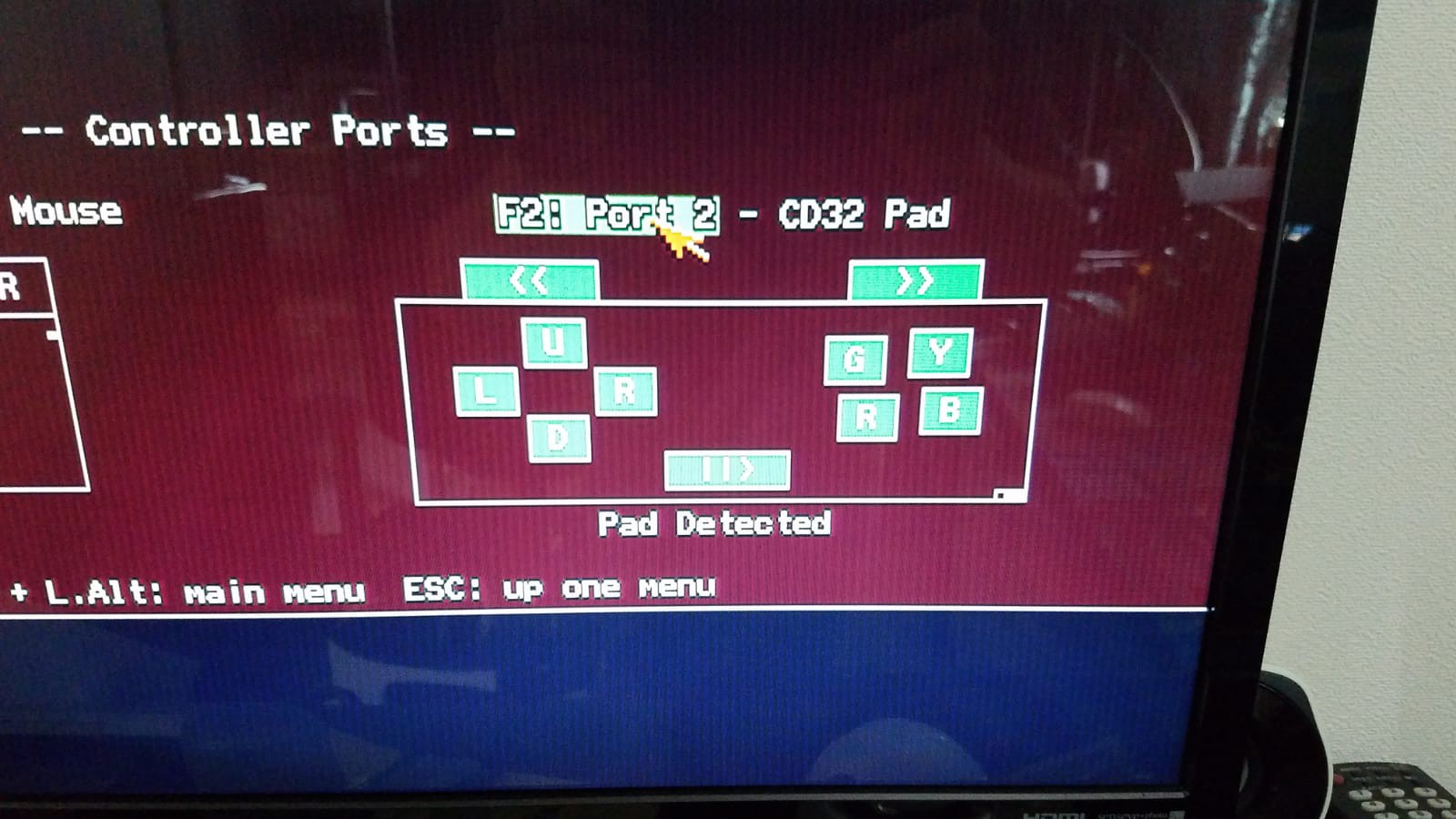

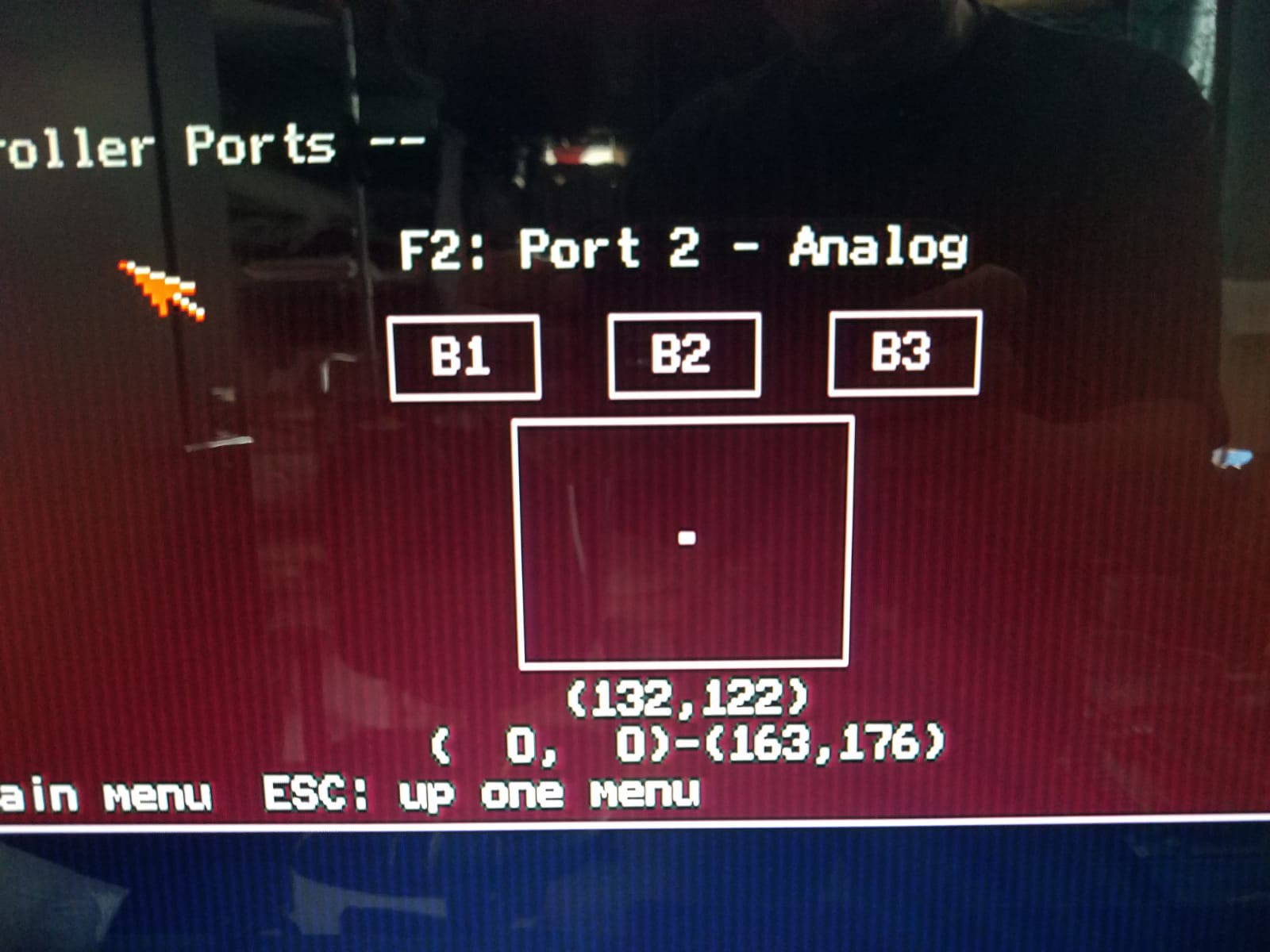

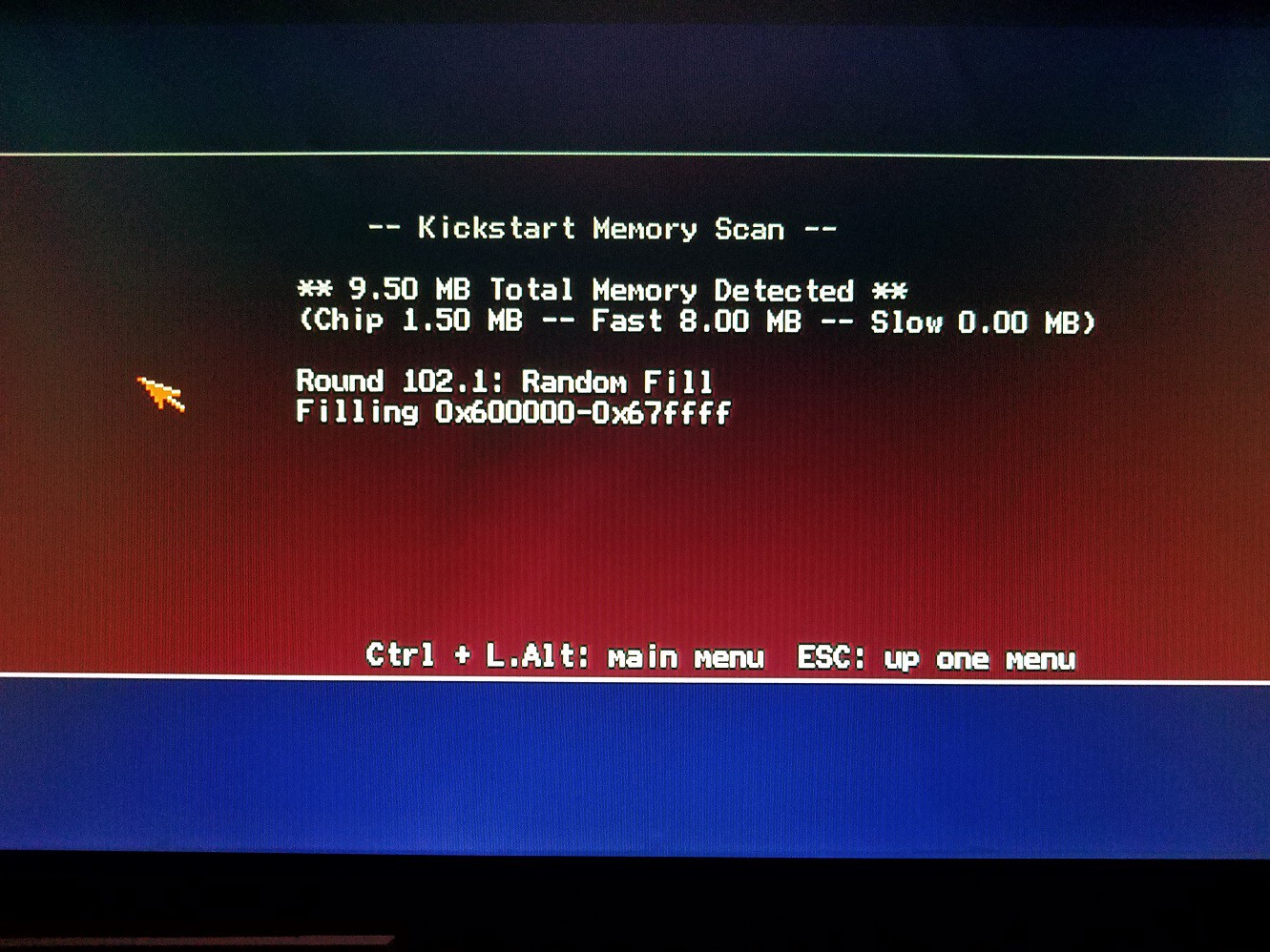

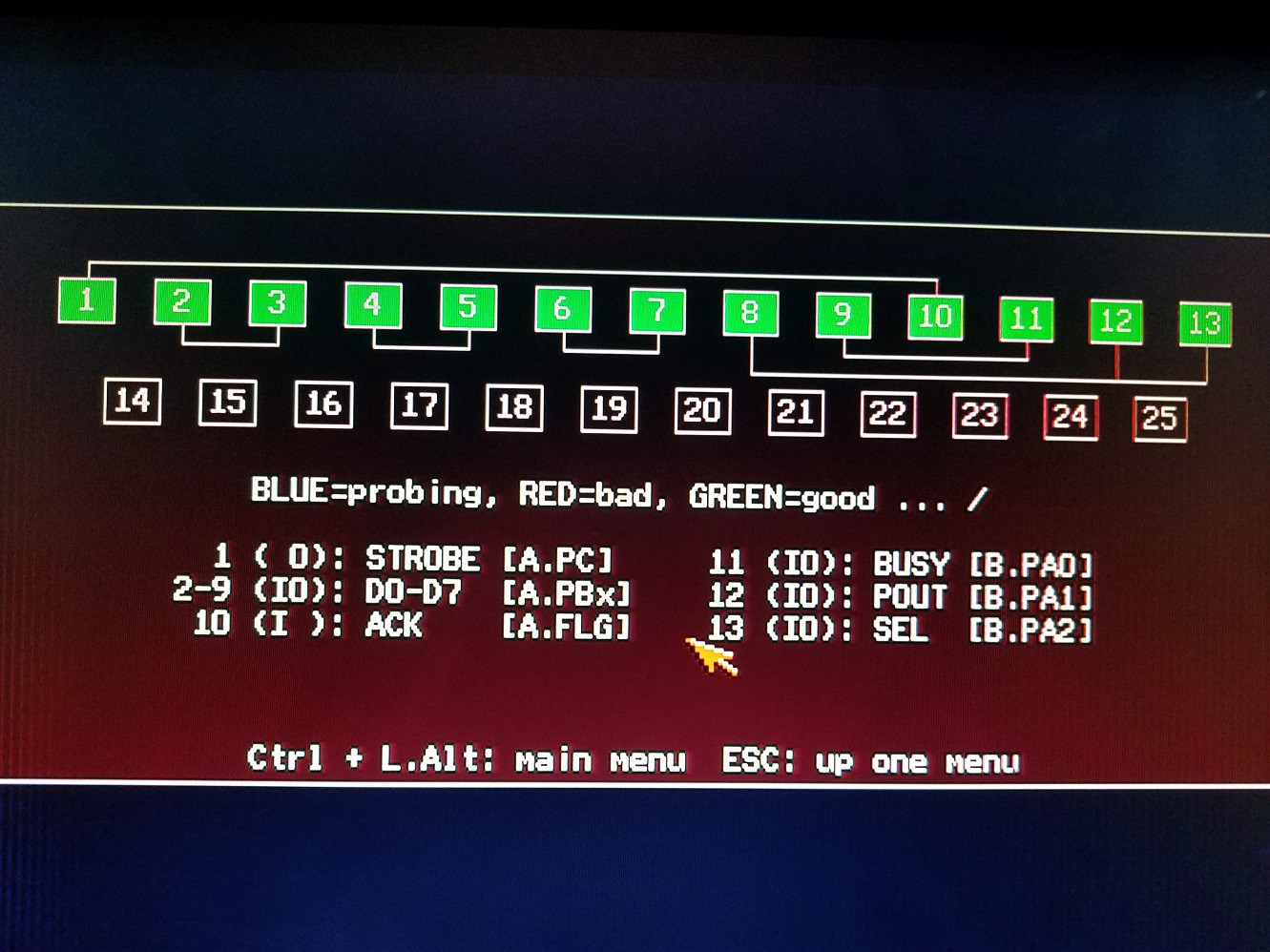

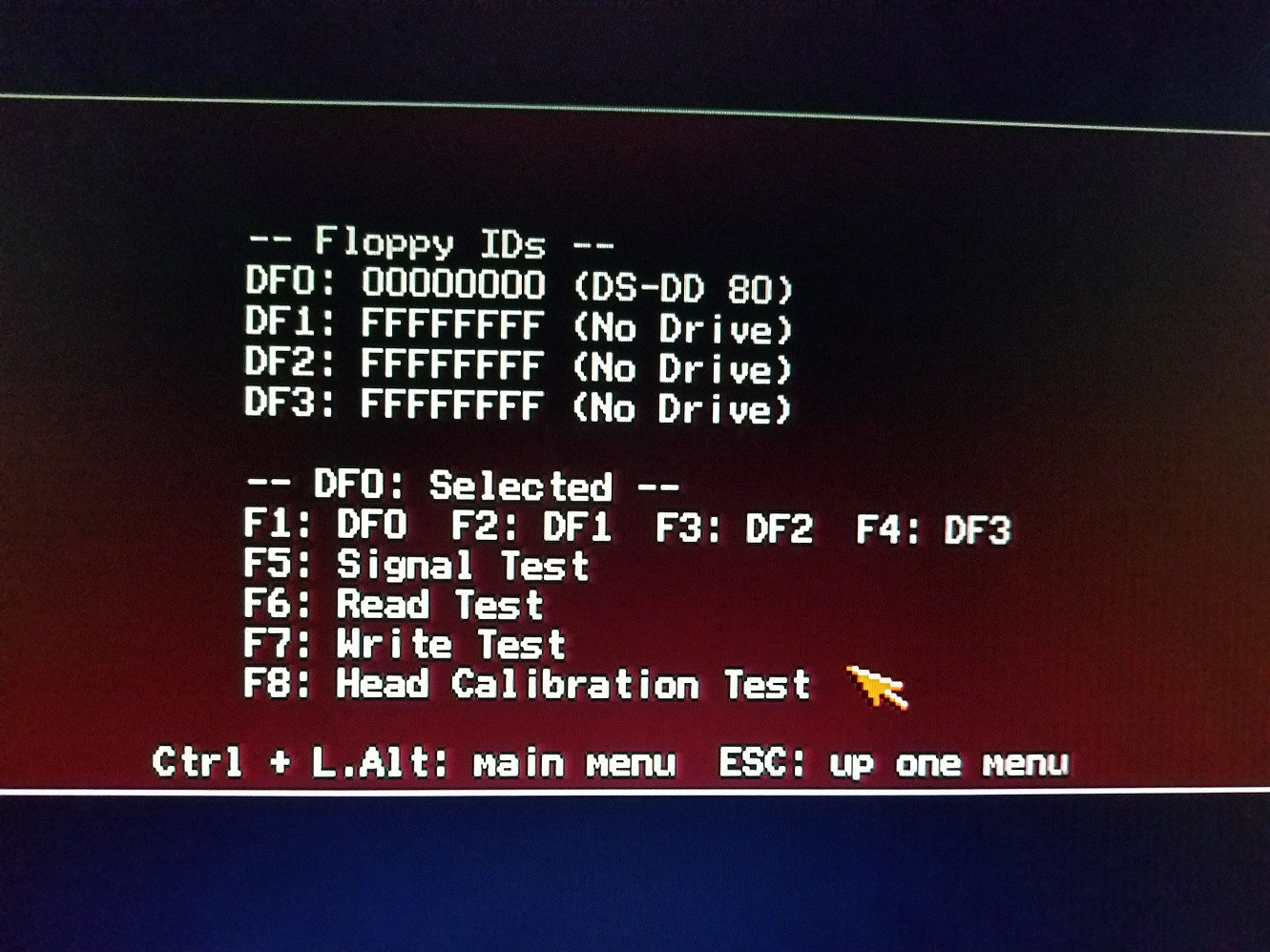

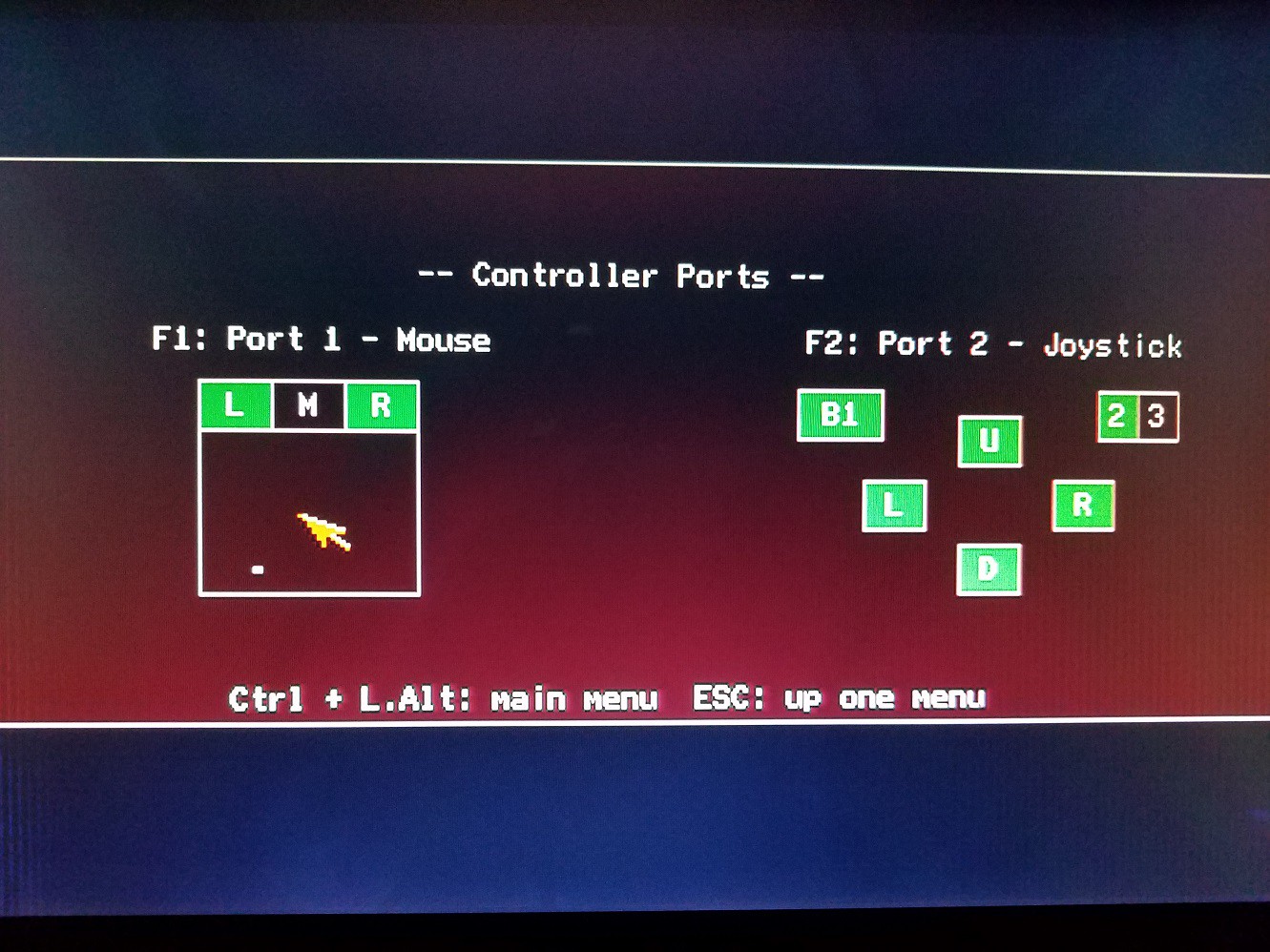

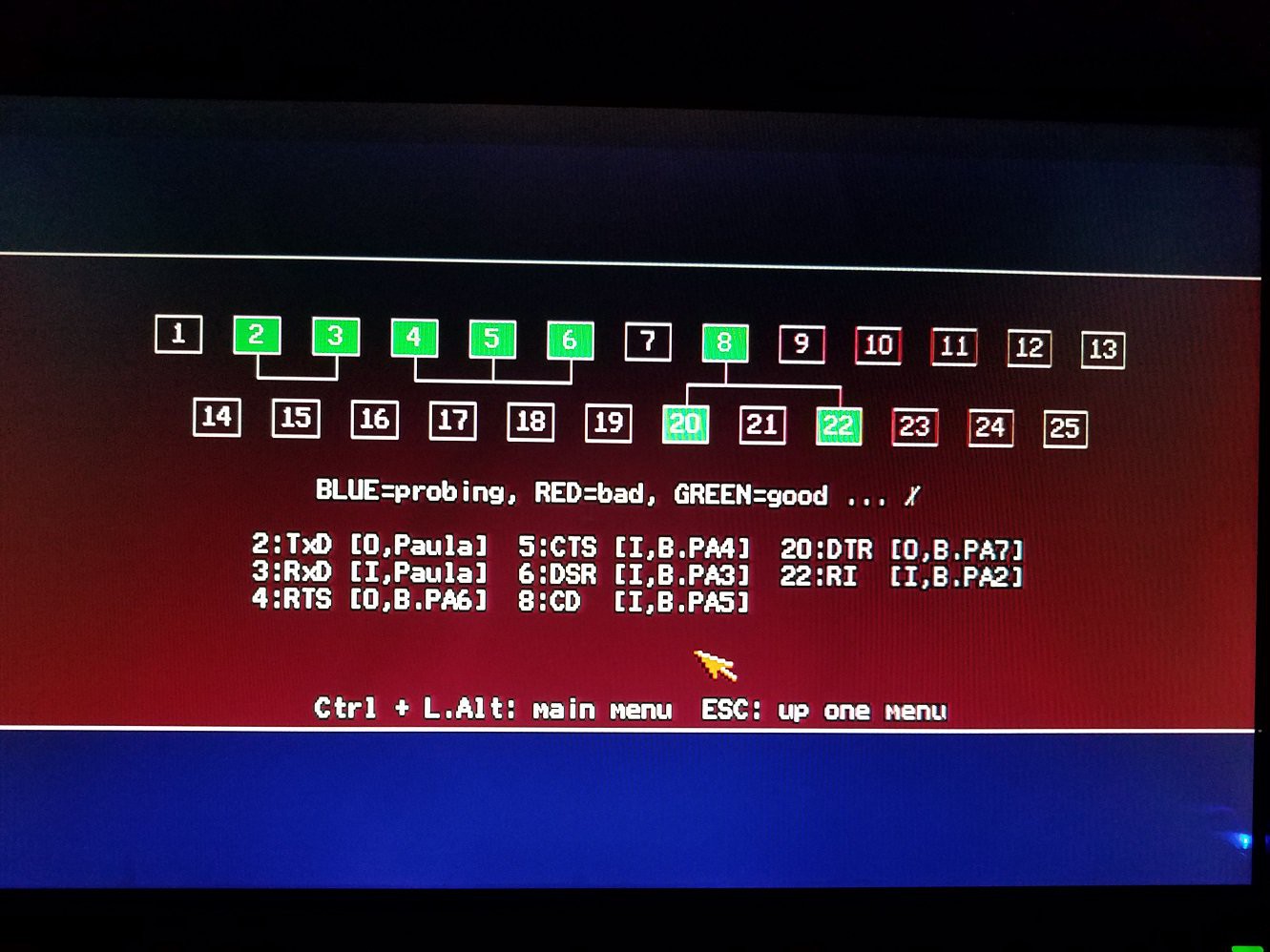

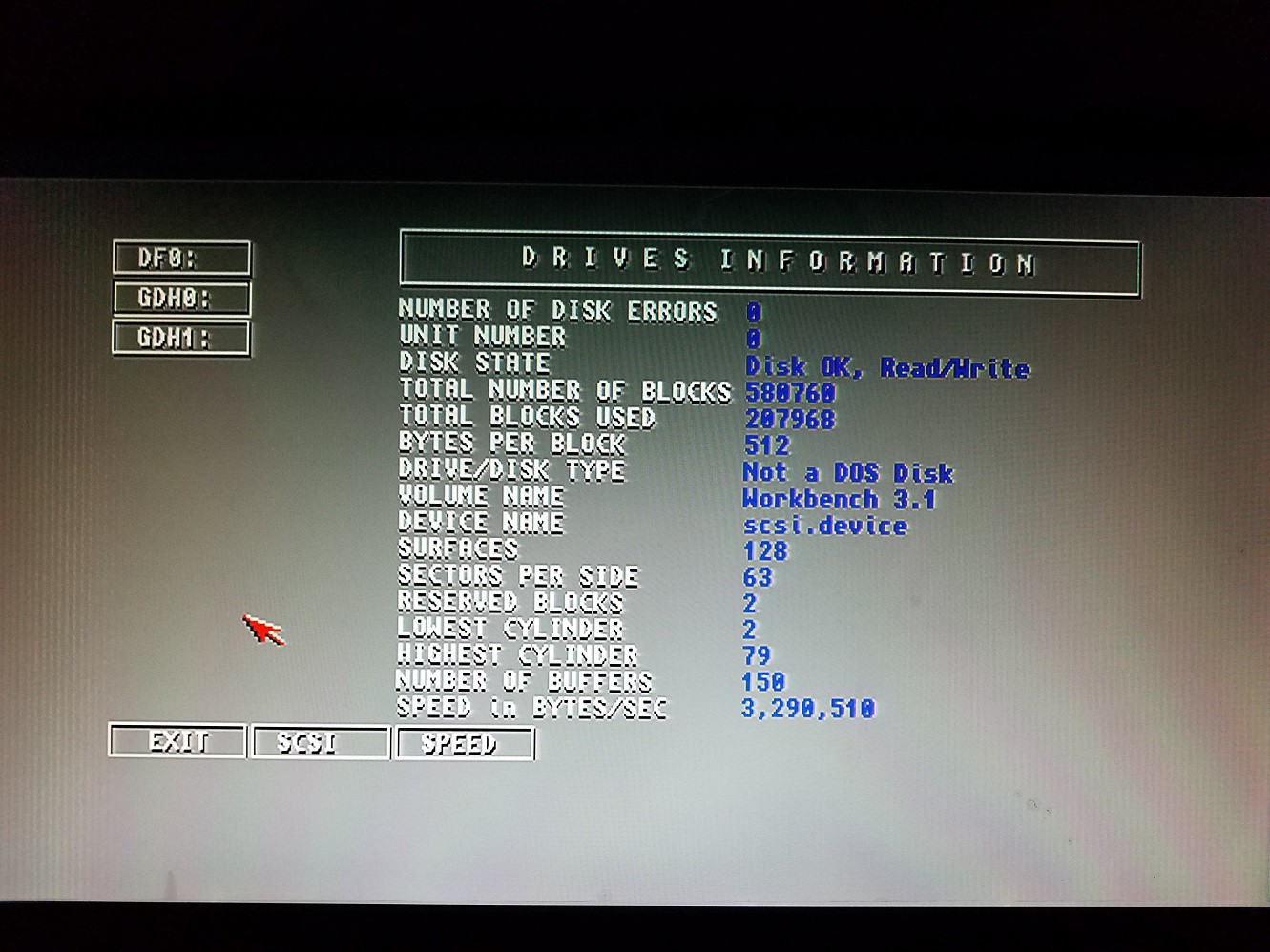

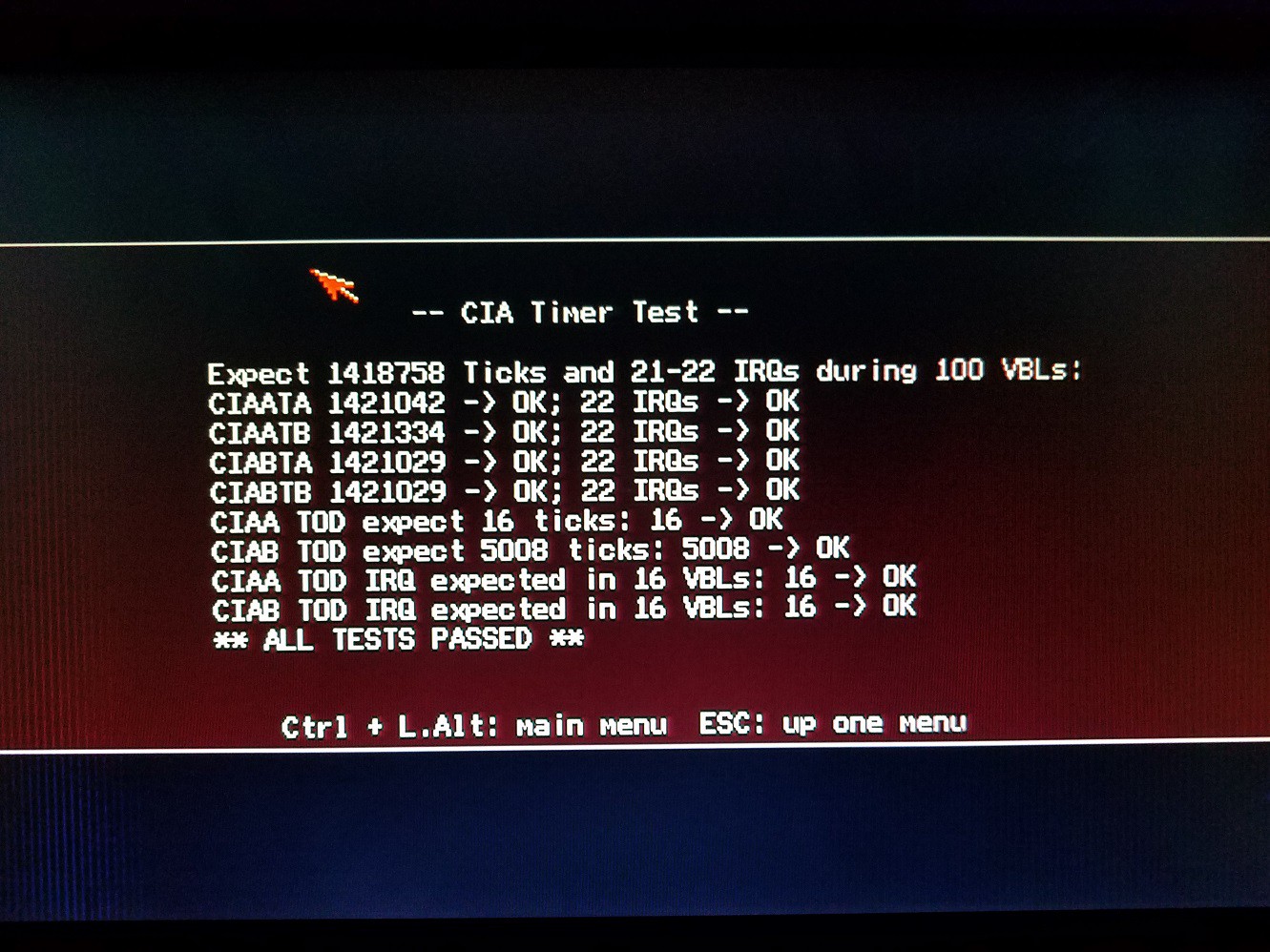

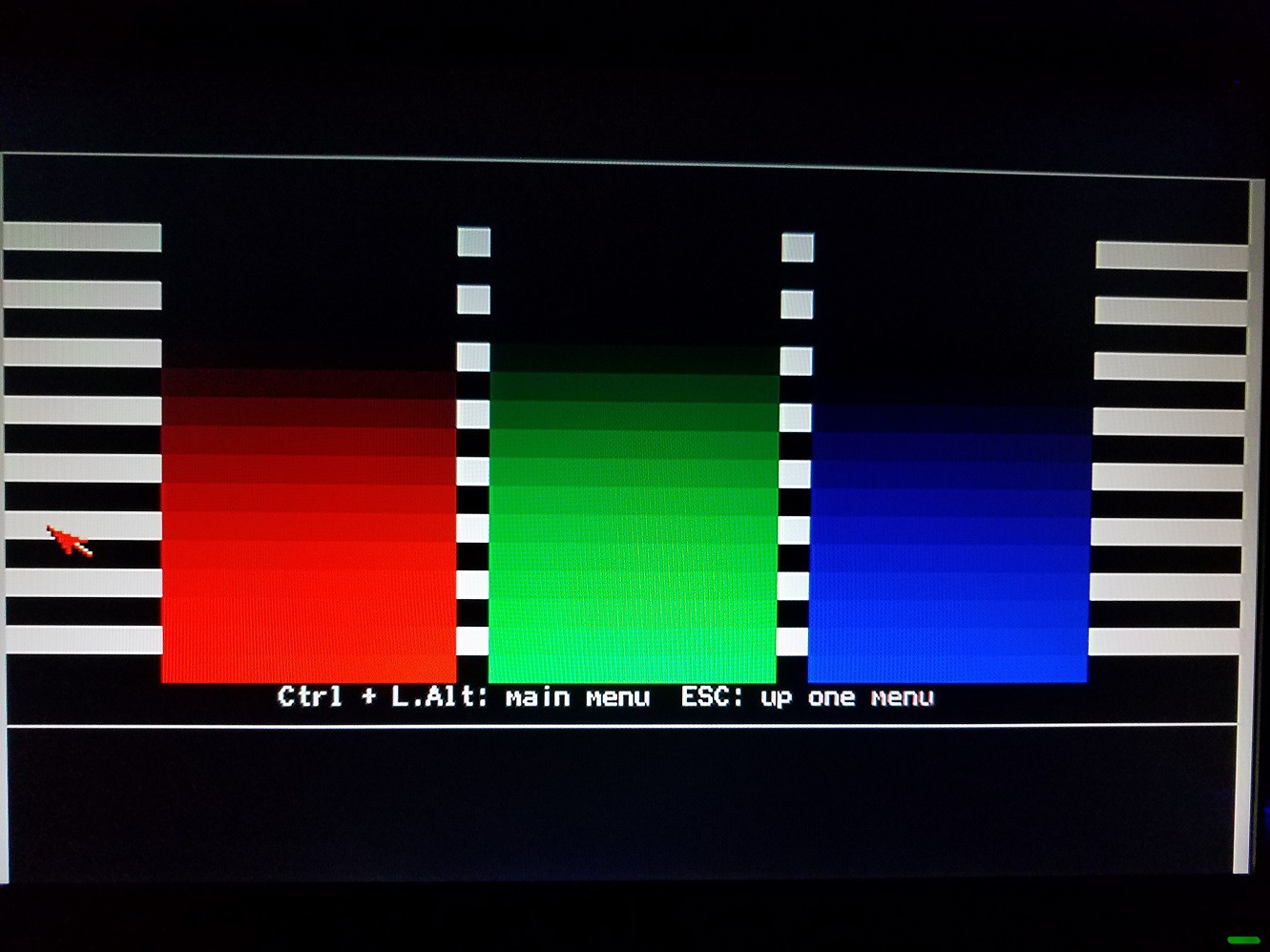

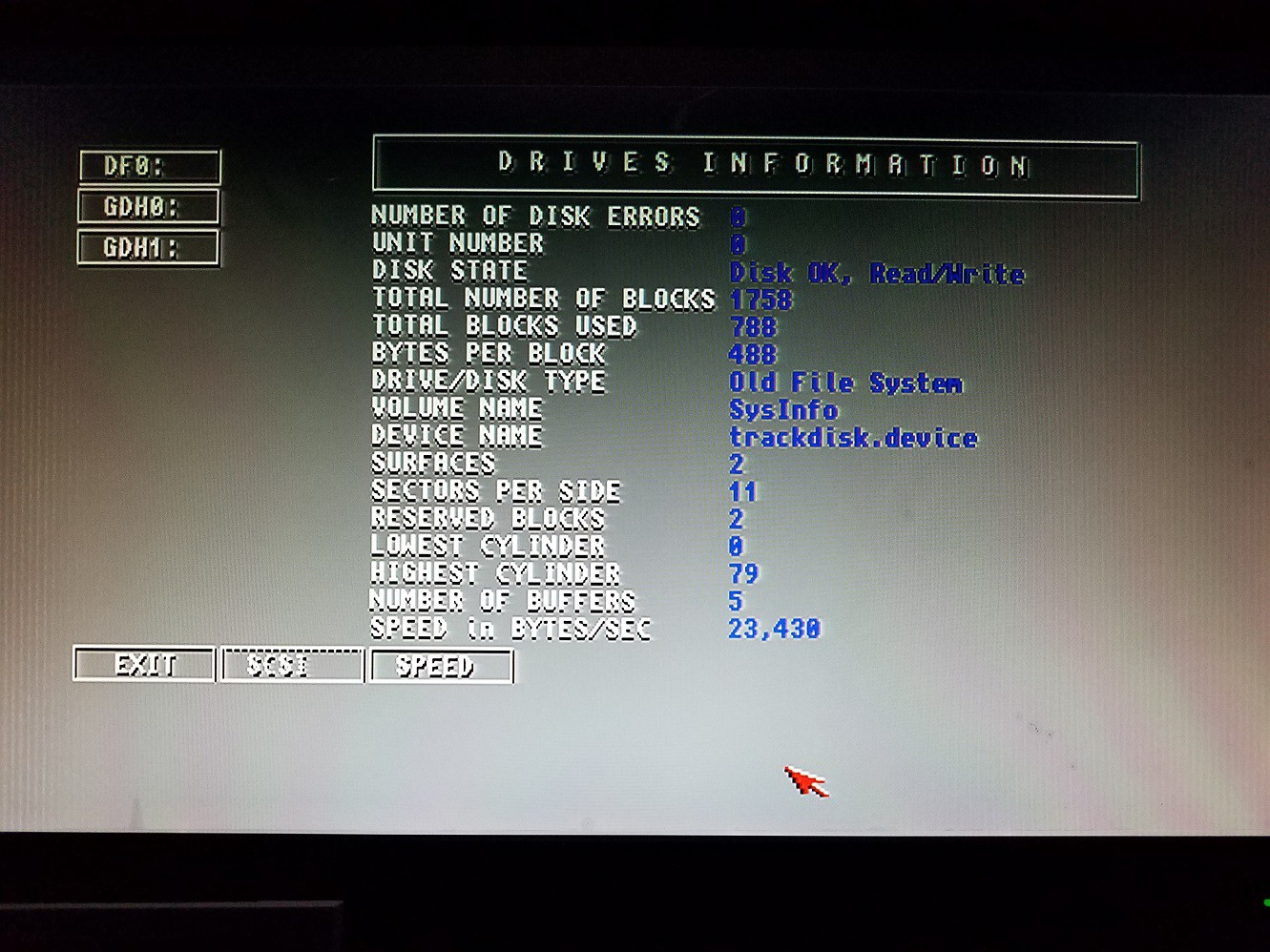

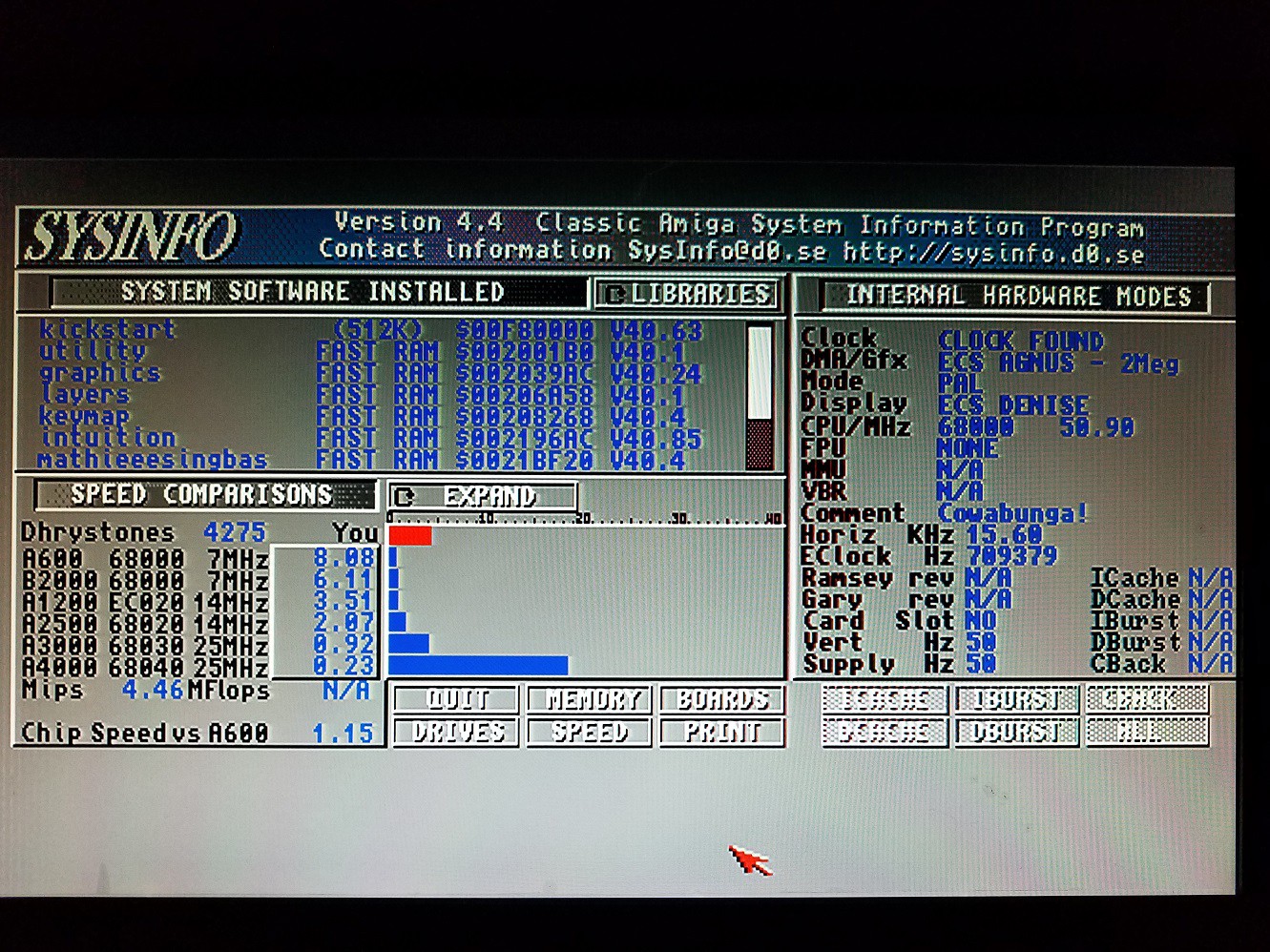

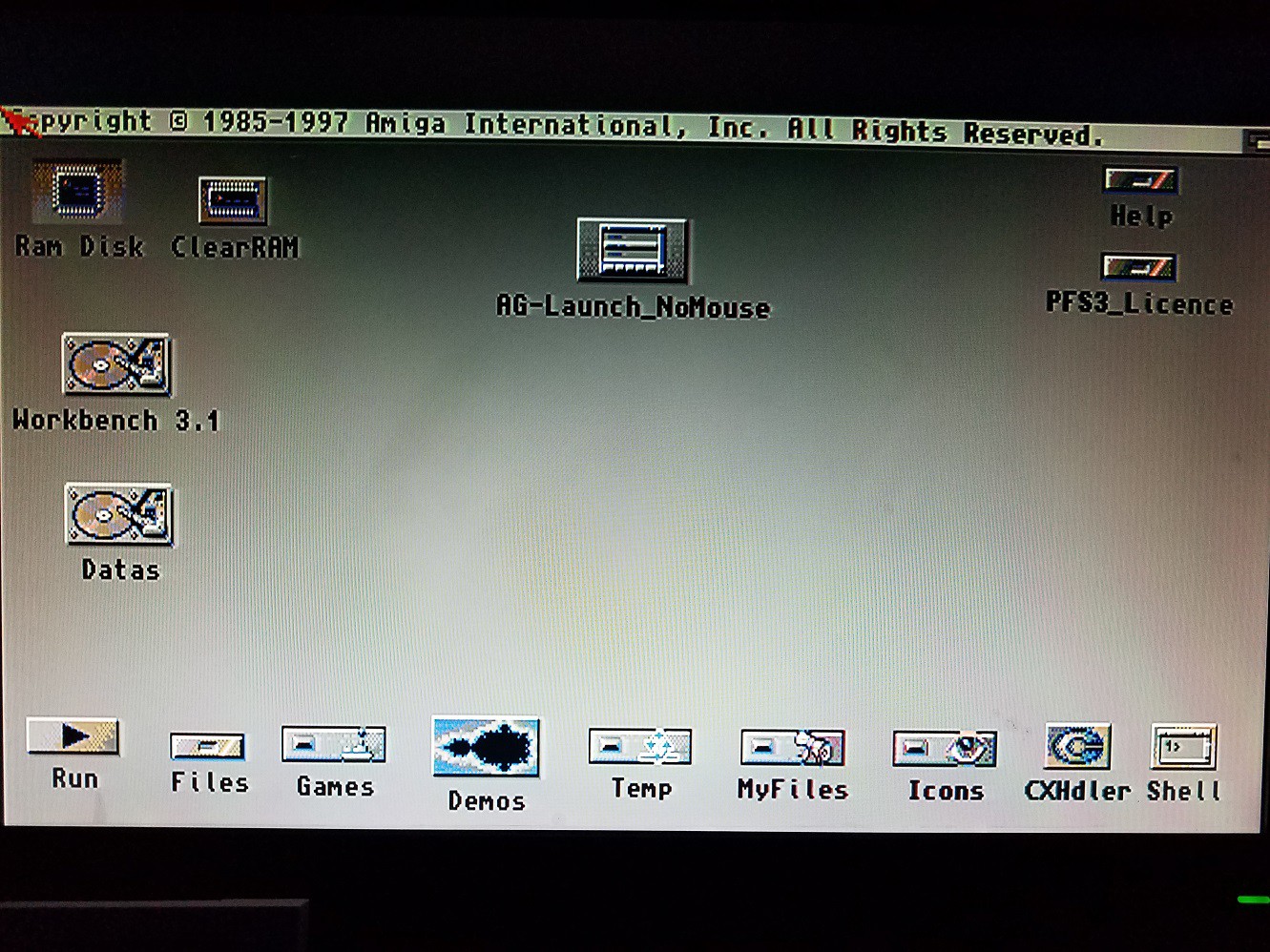

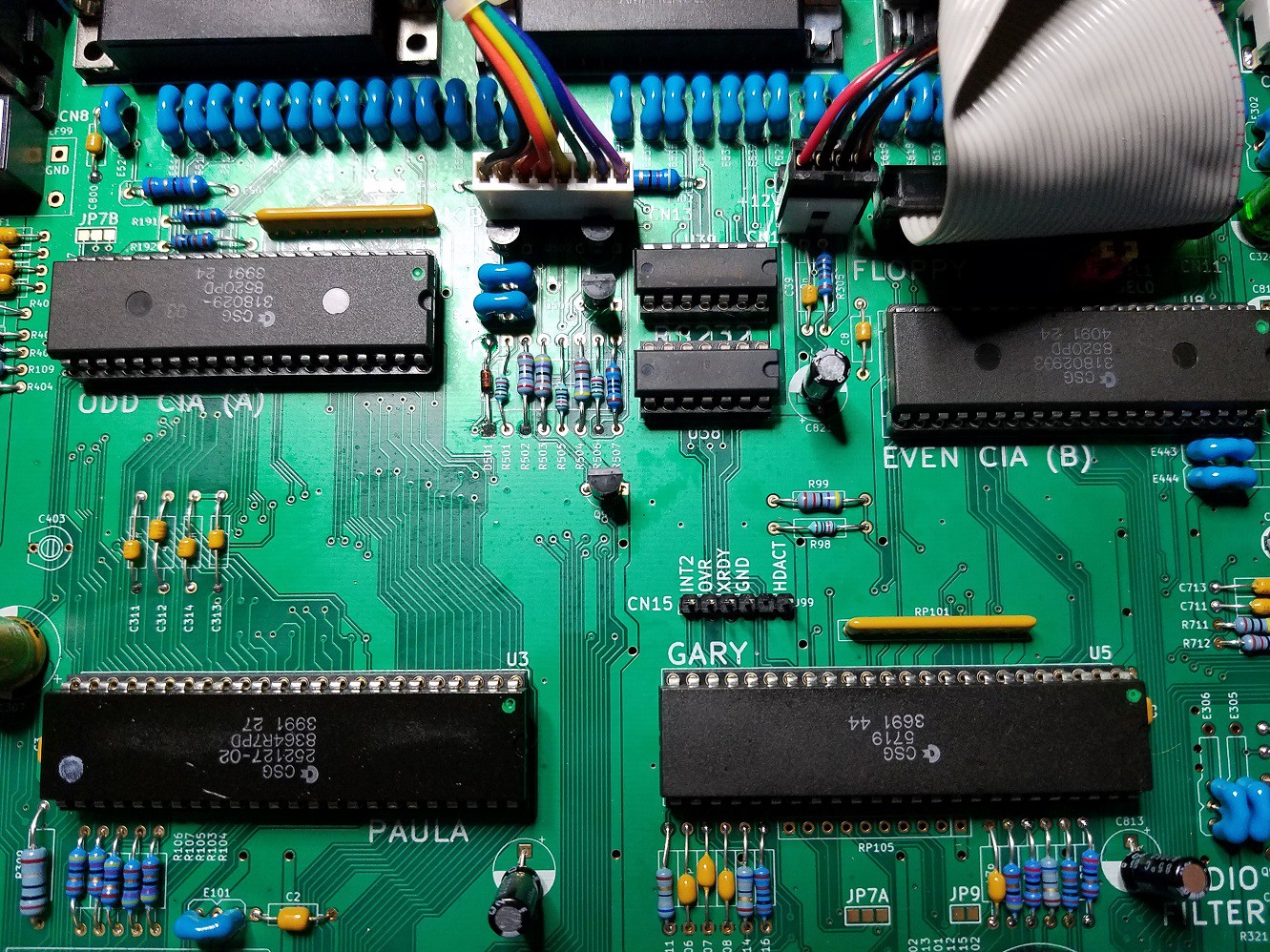

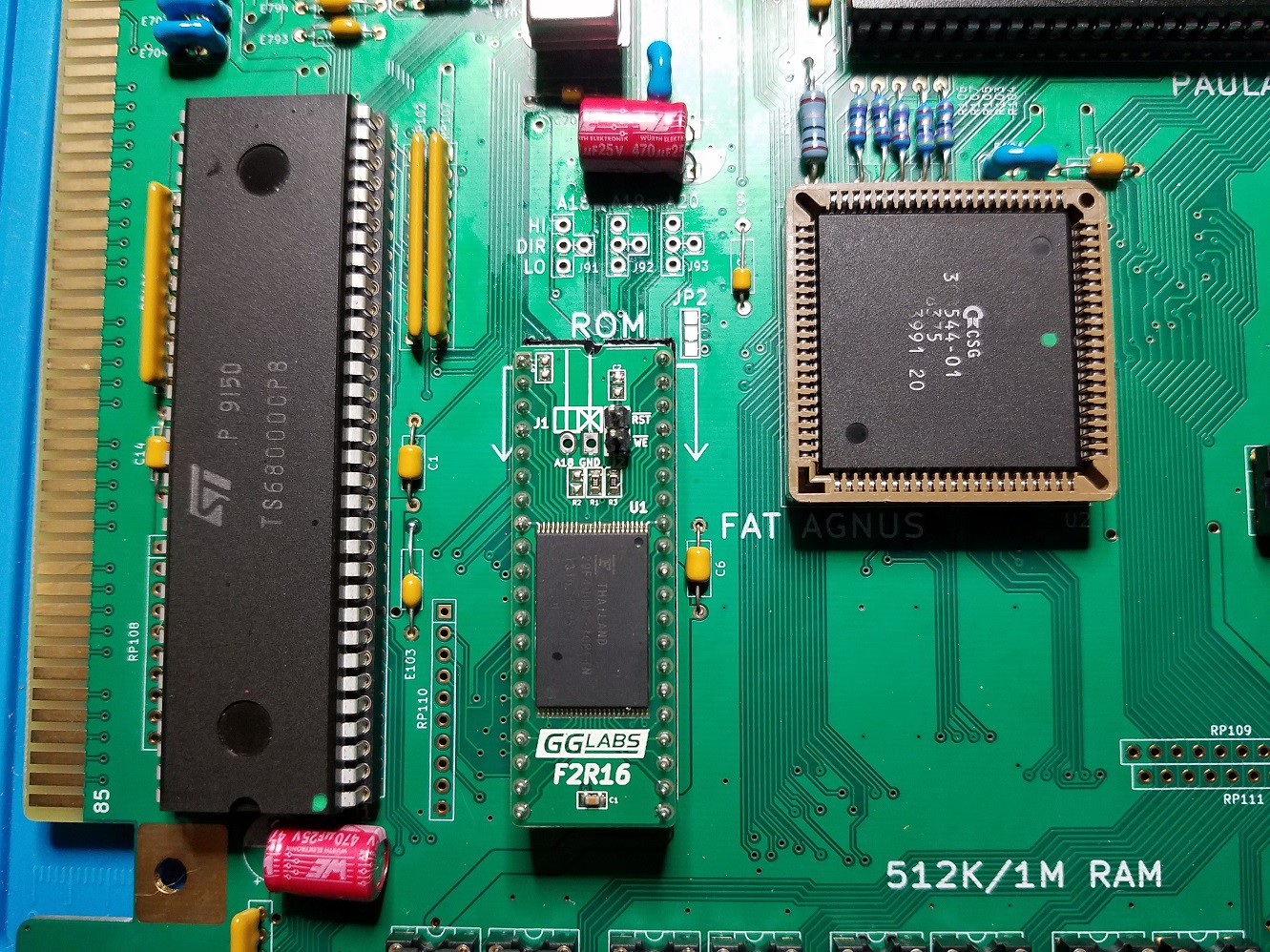

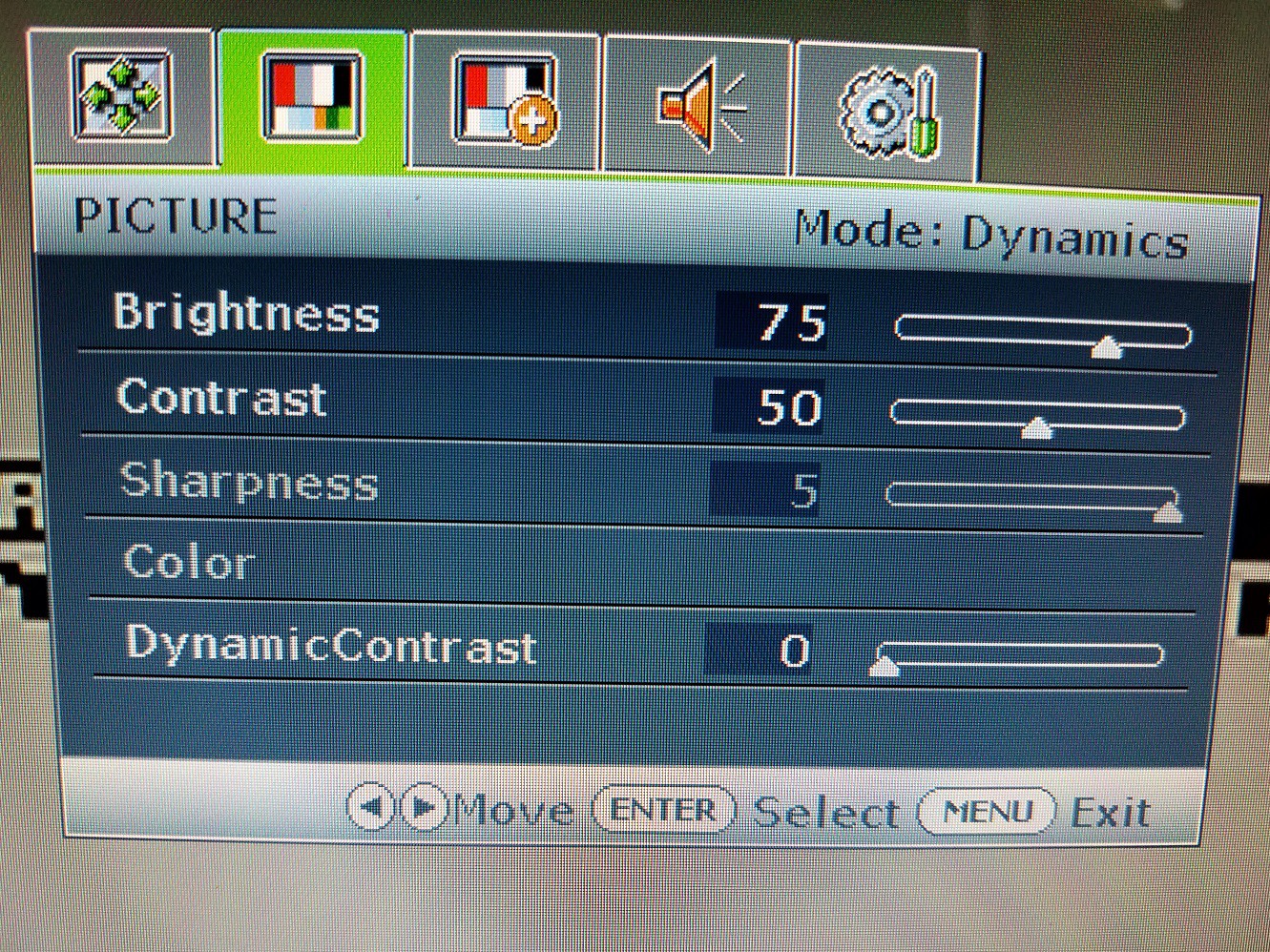

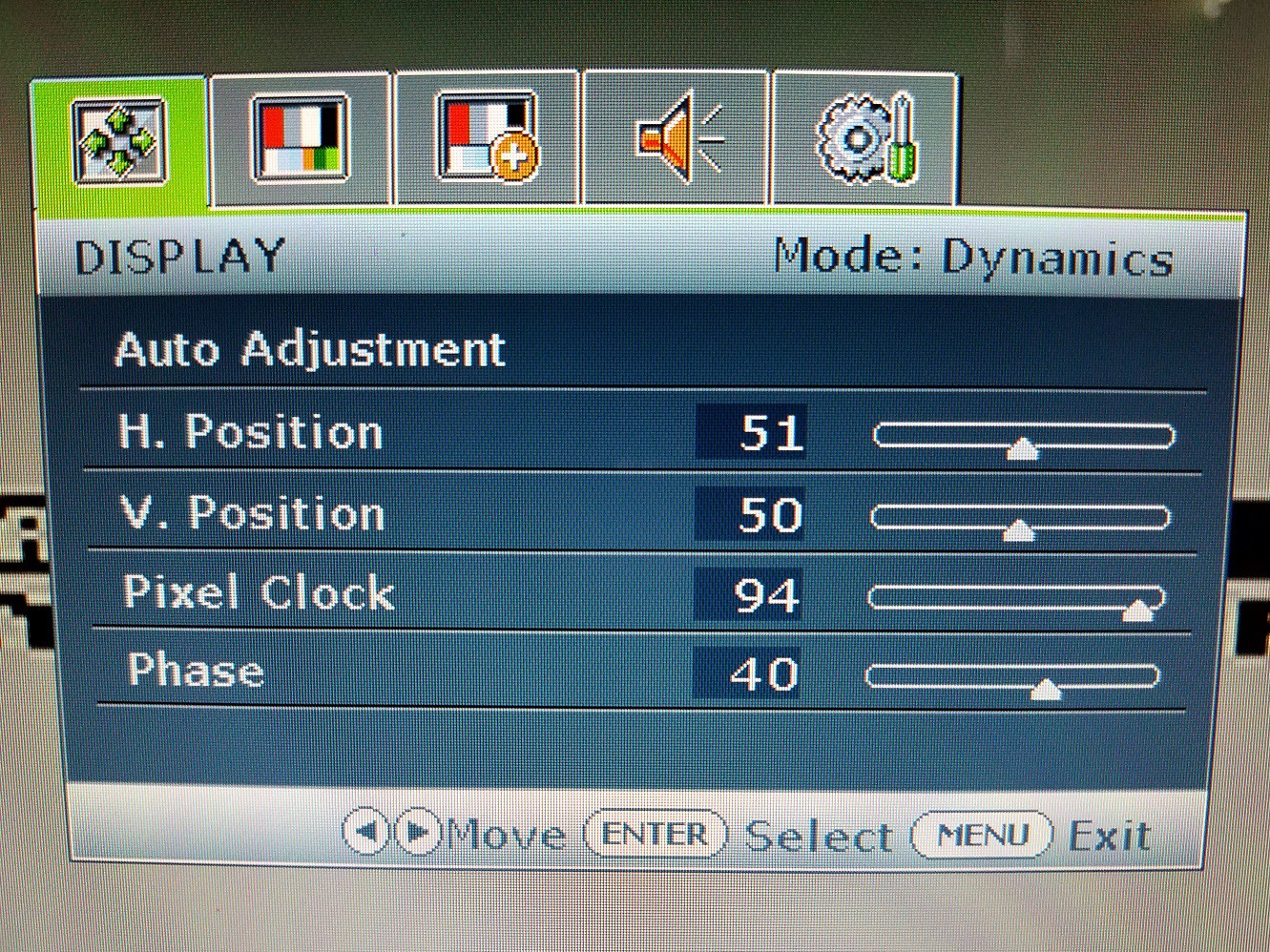

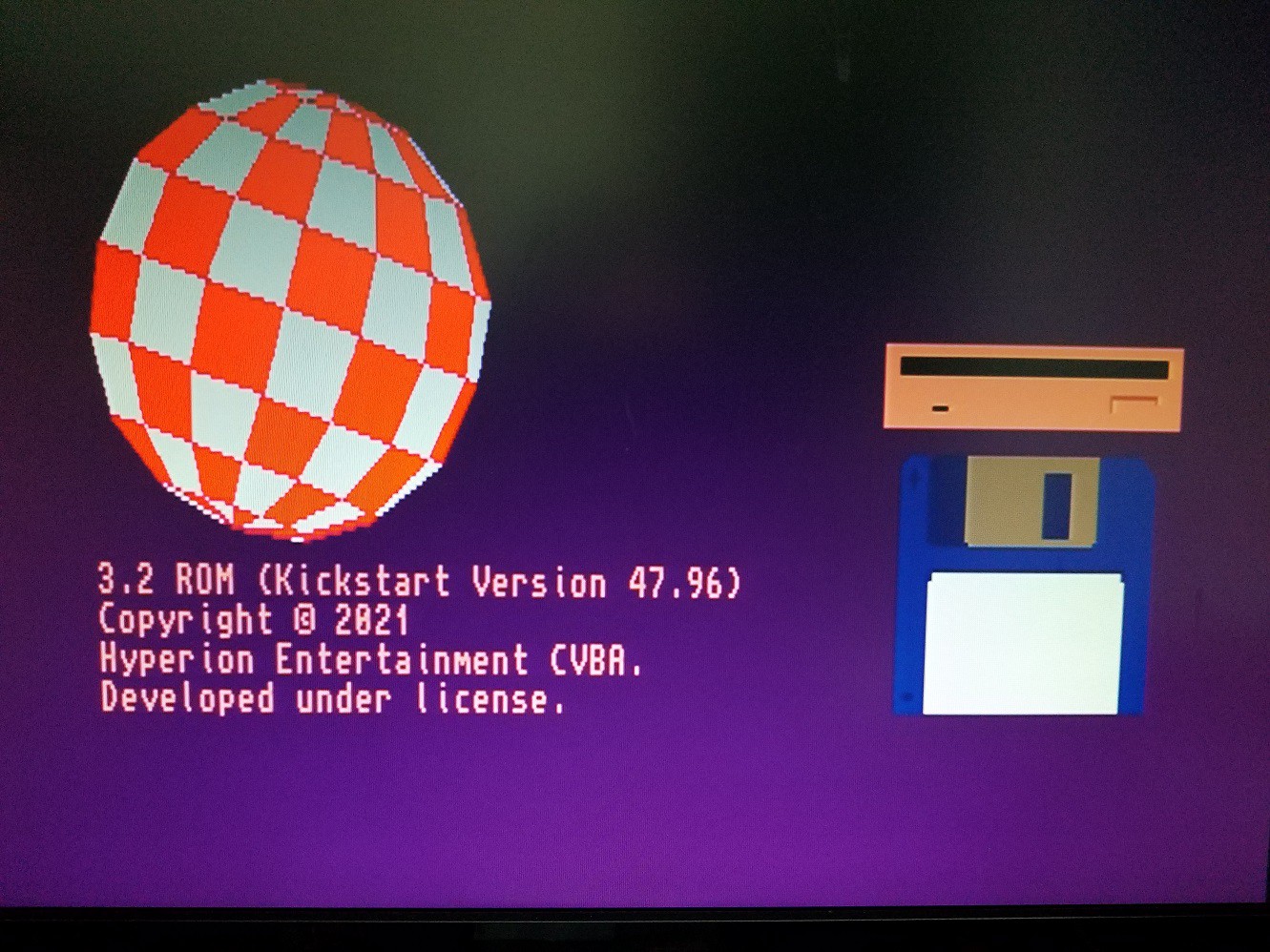

Just been building up a V2 board - finally after waiting months for components. Got a bit of an issue with it though. Anyone had any success or pointers before I get elbow deep in looking for errors