So the peristaltic pump runs 90% of the time, unlike the 3D printed pump which ran 10% of the time. The reason is it's so slow it turns off as soon as the water level is high, rather than overshooting like the 3D printed pump. There could be a way to delay the on event, based on prior knowledge of the mist consumption & tank size.

Also noticed the mist smells like sawdust if it's off for several weeks. The odor goes away after a few minutes, but reminds lions of hikers who died from algae poisoning. There's no visible algae in the tank & nano misters have been sold for years. It could also be the smell of forest fires getting enhanced by the water droplets.

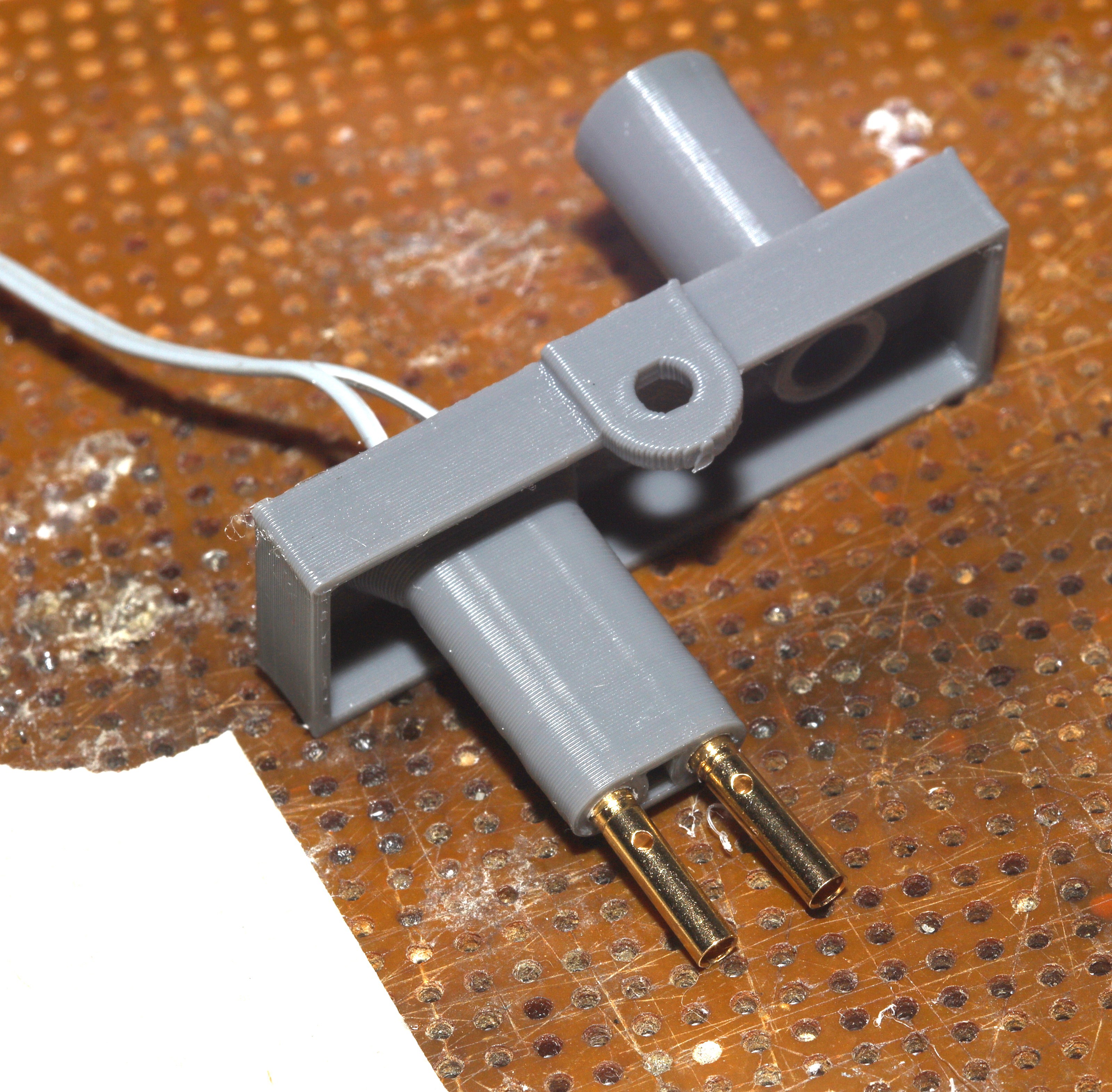

The water level sensor started failing a lot more with the peristaltic pump. The leading theory is it had more deposits because the water never fully covered it. The overshooting pump might have rinsed off deposits. There were no visible deposits on it, but a new water level sensor was created anyway. This one uses fully gold plated, 2mm bullet connectors. They should be easier to clean, at least.

Resistance sensors are always going to be problematic. The next idea was a bulky floating sensor with optical interrupter & a lot more wires. The tank is too small to generate enough buoyancy to flip a switch. A simpler sensor would be a floating magnet with hall effect sensor, but magnets don't float.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.