There was this idea of letting the vapor escape instead of condense, but it still failed on. It leaned towards splashing getting water on the standoffs.

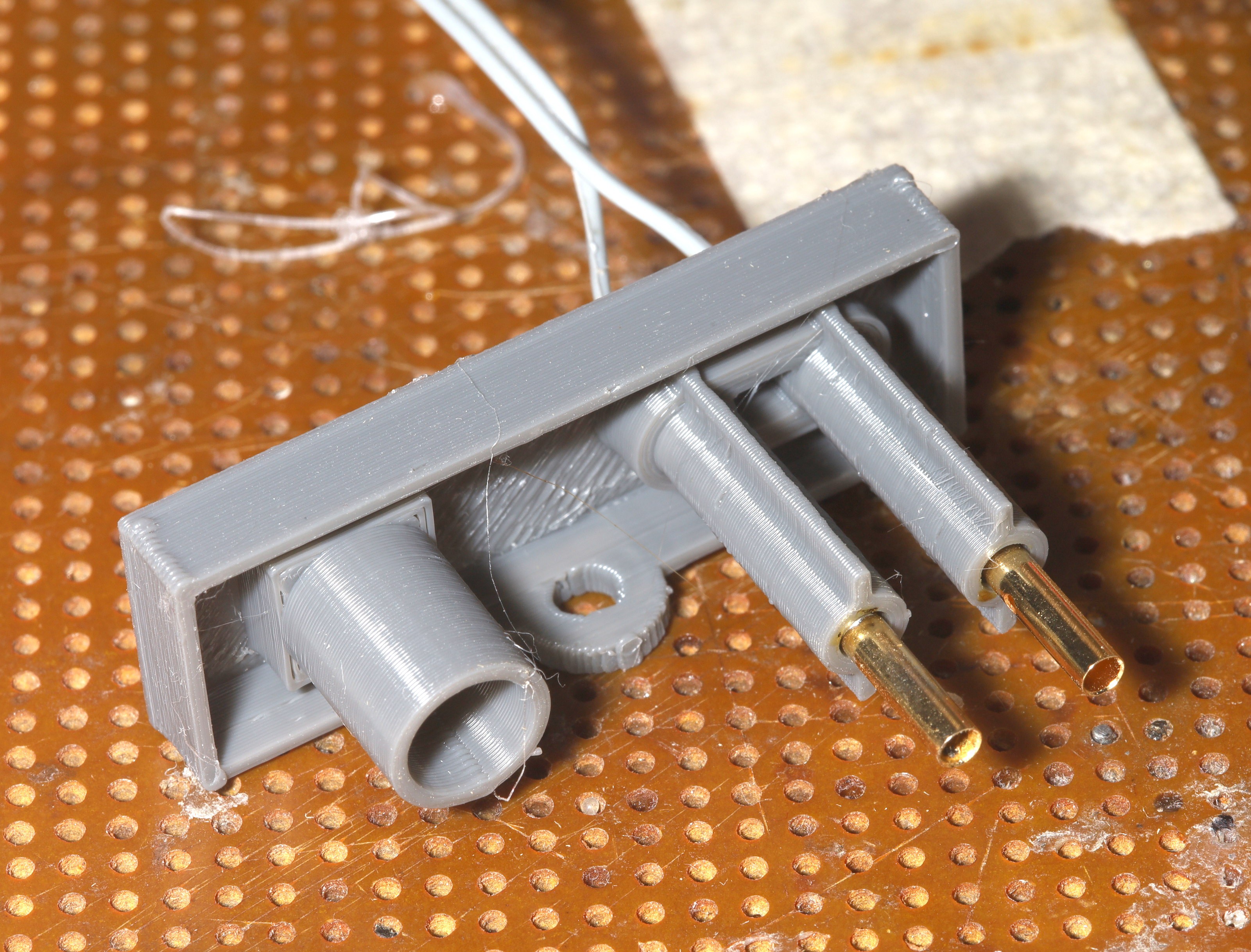

Then this idea came along. This showed the spacing might be 2-3mm away from enough to overcome surface tension. It would require tweeking the ADC threshold. It is a fiddly value. There's mounting the electrodes sideways & opposing. The idea with vertical electrodes is the ADC value rises as the water level rises. Horizontal electrodes would give a single ADC value for all water levels.

Another sensor was made with 2mm wider spacing, but by then temperatures fell below what was causing the problems.

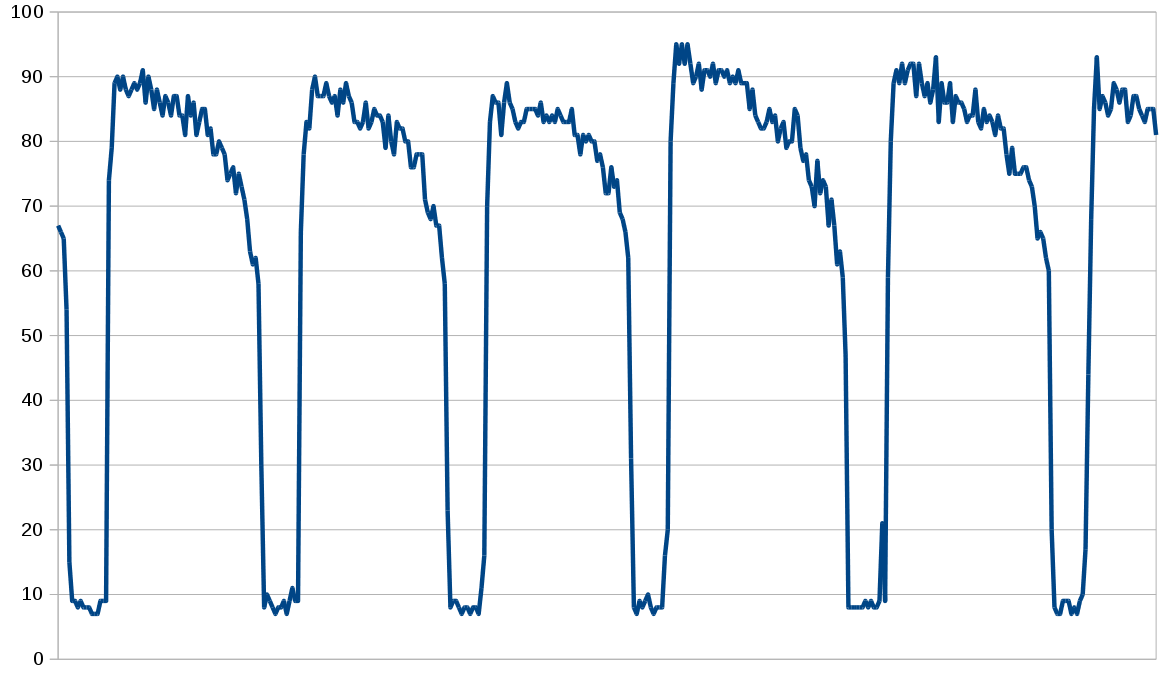

For future lion, we have the typical life of the sensor flipping high when the tank fills, slowly dropping as the tank empties, flipping low when the sensor dries out. The spacing didn't impact the readings.

It was noted that an electrode was eroding, so it was swapped out. Gold plating only buys time. This led to suspicions the sensor might fail off one day.

The decision was finally made to make the pump timeout after 90 seconds, to avoid emptying the 5 gallon tank on the floor. It typically takes 40 seconds to fill the tube & transducers.

The new sensor is a lower profile.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.