The cheap pumps on the internet have sketchy reliability & are not self priming. They need animal power to get started, which makes topping off a tank a pain.

The home made pumps are not waterproof enough to last very long. Any submerged bearings or brushes would die quickly & contaminate the fluid with oil. All motors end up rusting & dying, including the commercial pumps.

The ideal pump would be a peristalsis pump. The complete pump is over $25 https://www.adafruit.com/product/1150. The flexible, high endurance tube alone is a more tame $3.50. https://www.adafruit.com/product/3659.

What lions needed was a submersible pump which would last a long time in pulsed mode.

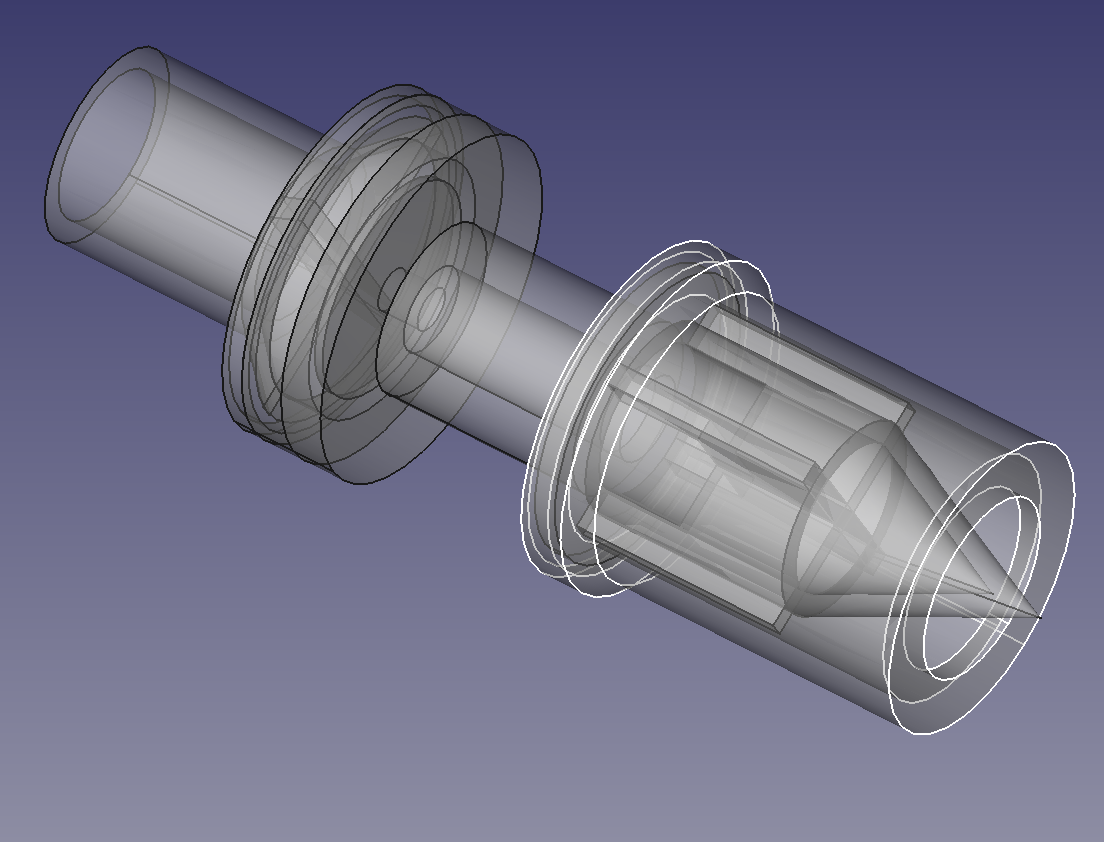

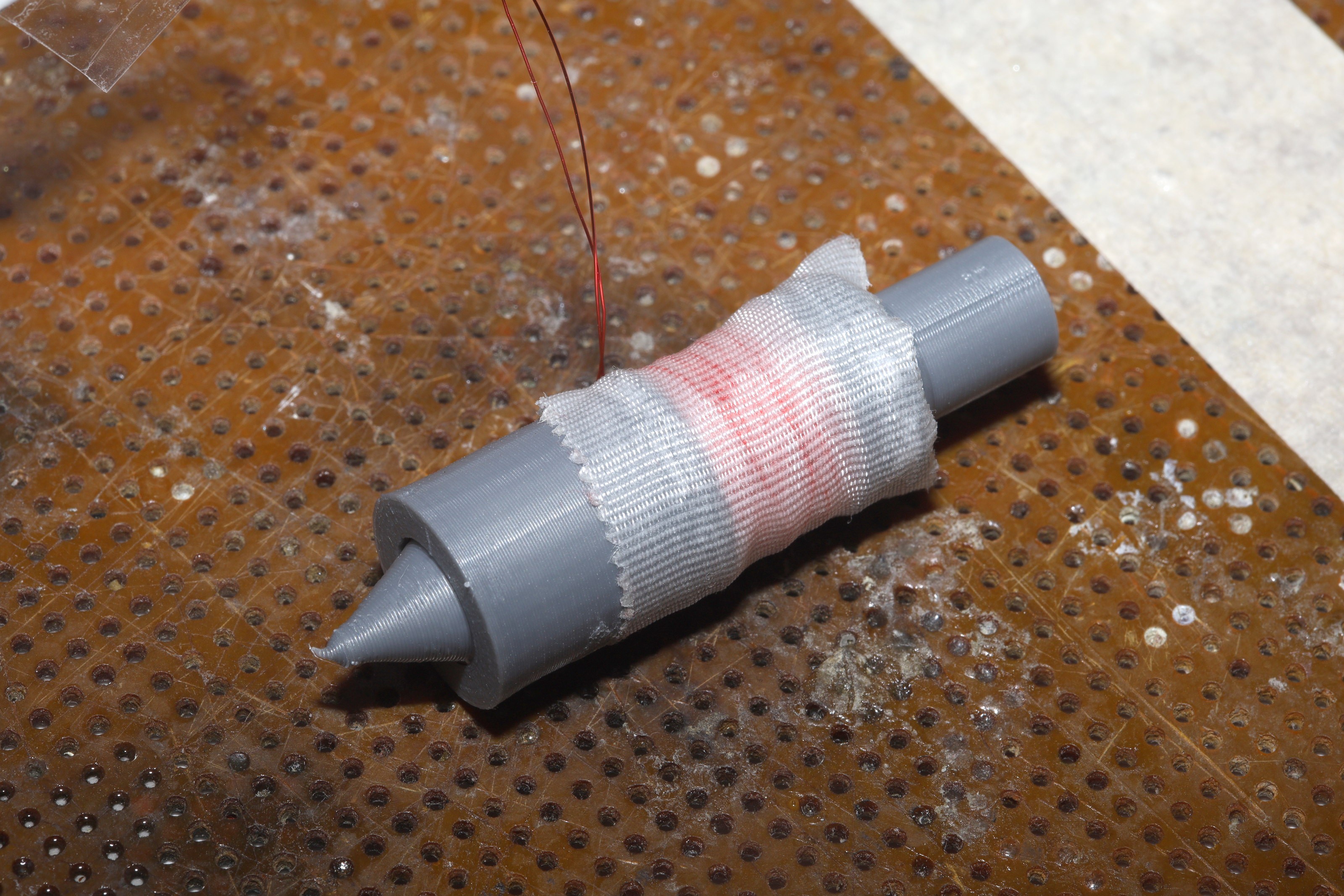

The lion kingdom went all the way to designing a simple reciprocating thing with a custom check valve & a solenoid driving a plunger.

The idea was the plunger would have enough drag to develop pressure without a seal. This was a failure. The valve couldn't keep the water out & a plunger without any seal couldn't develop any pressure. It might be more practical if the plunger was in a rail gun which accelerated it to high velocity & the valve had a spring loaded diaphragm.

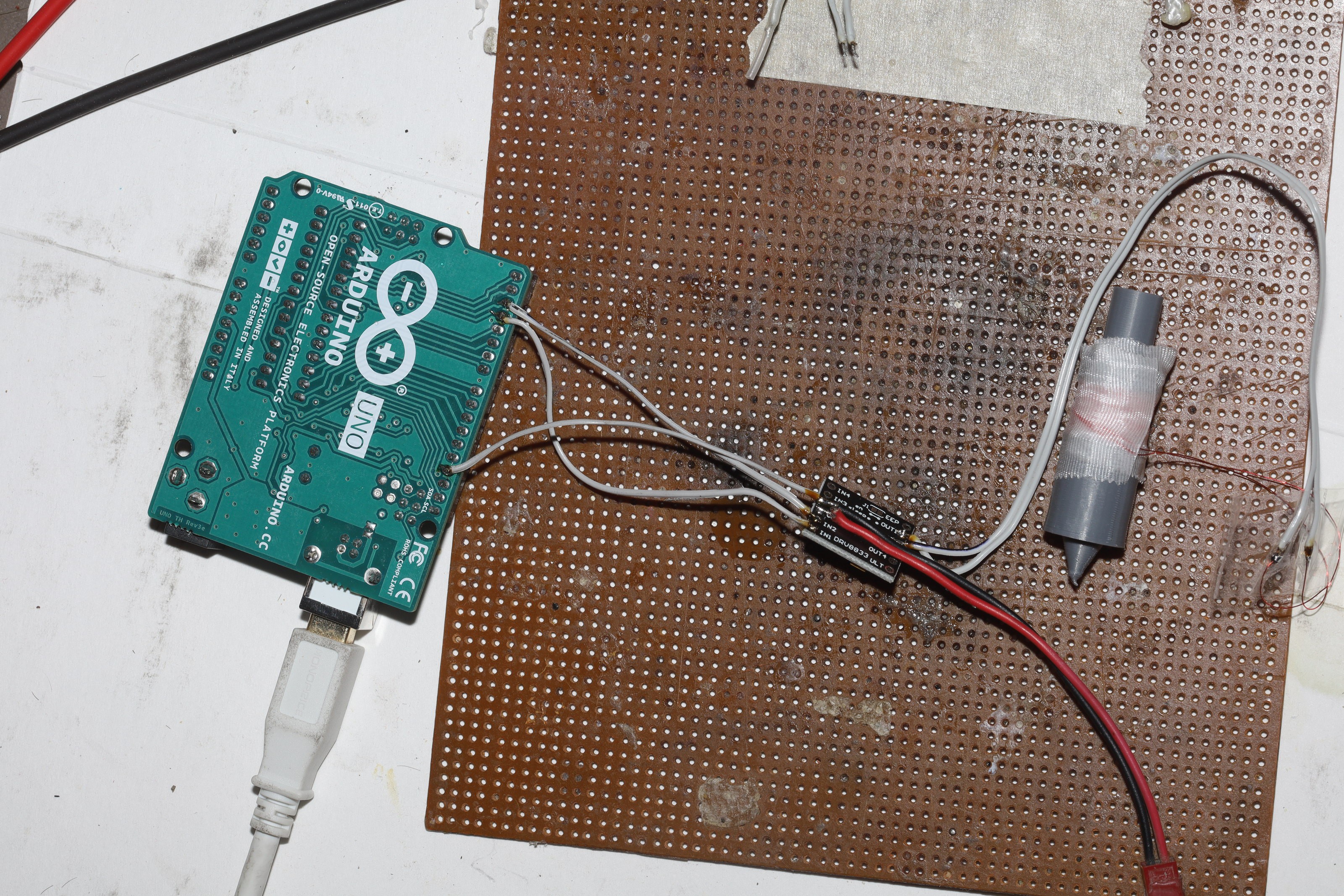

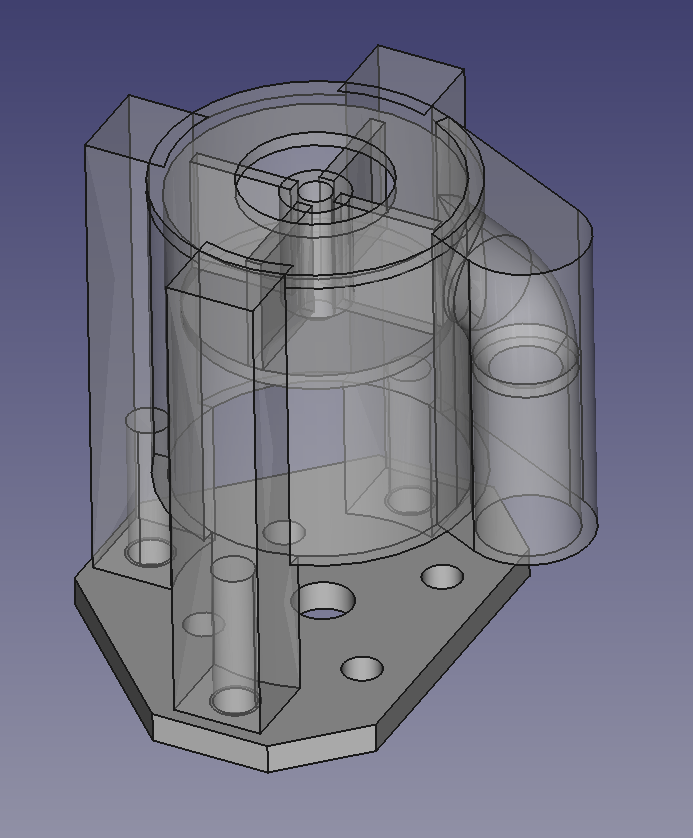

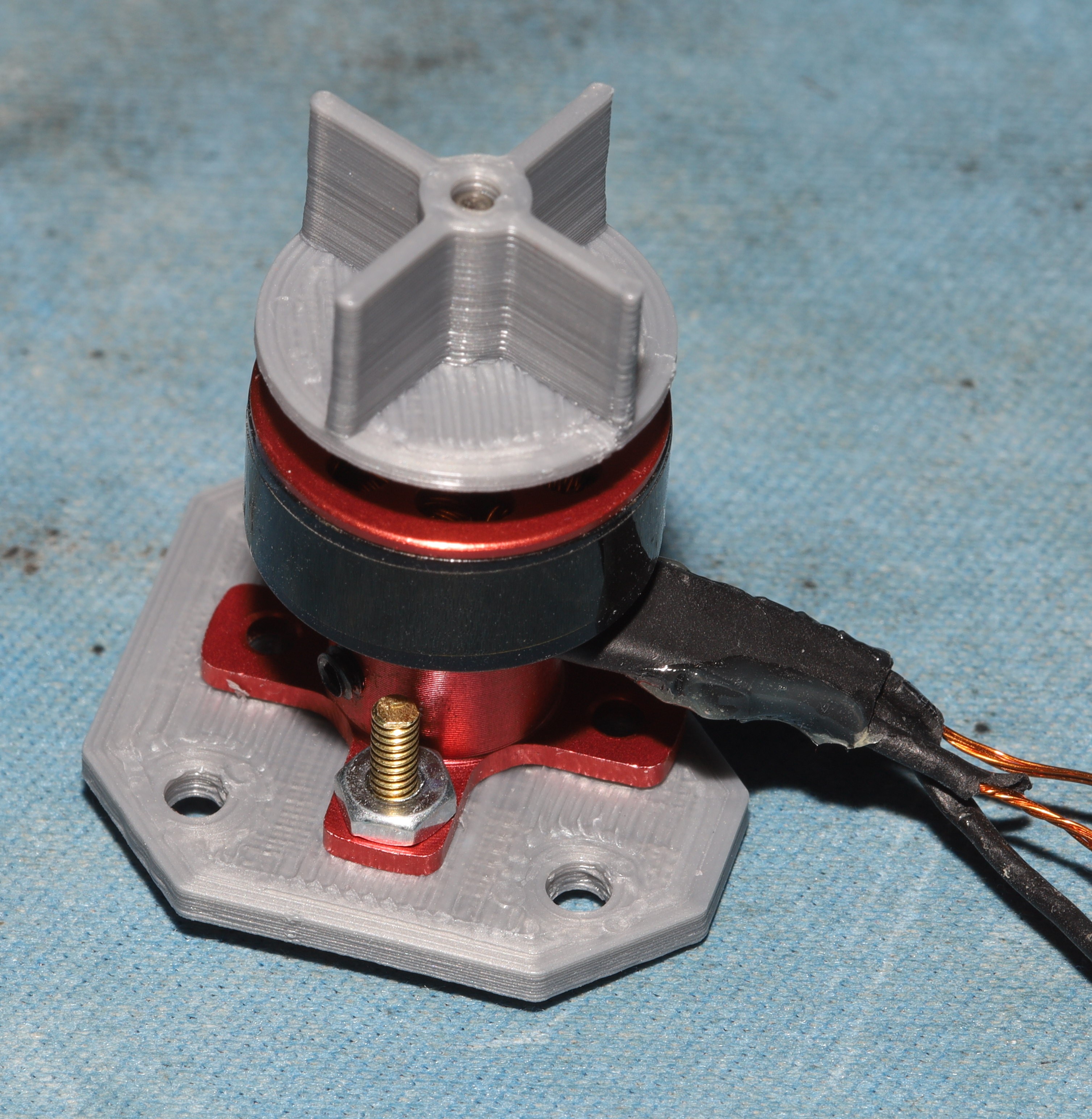

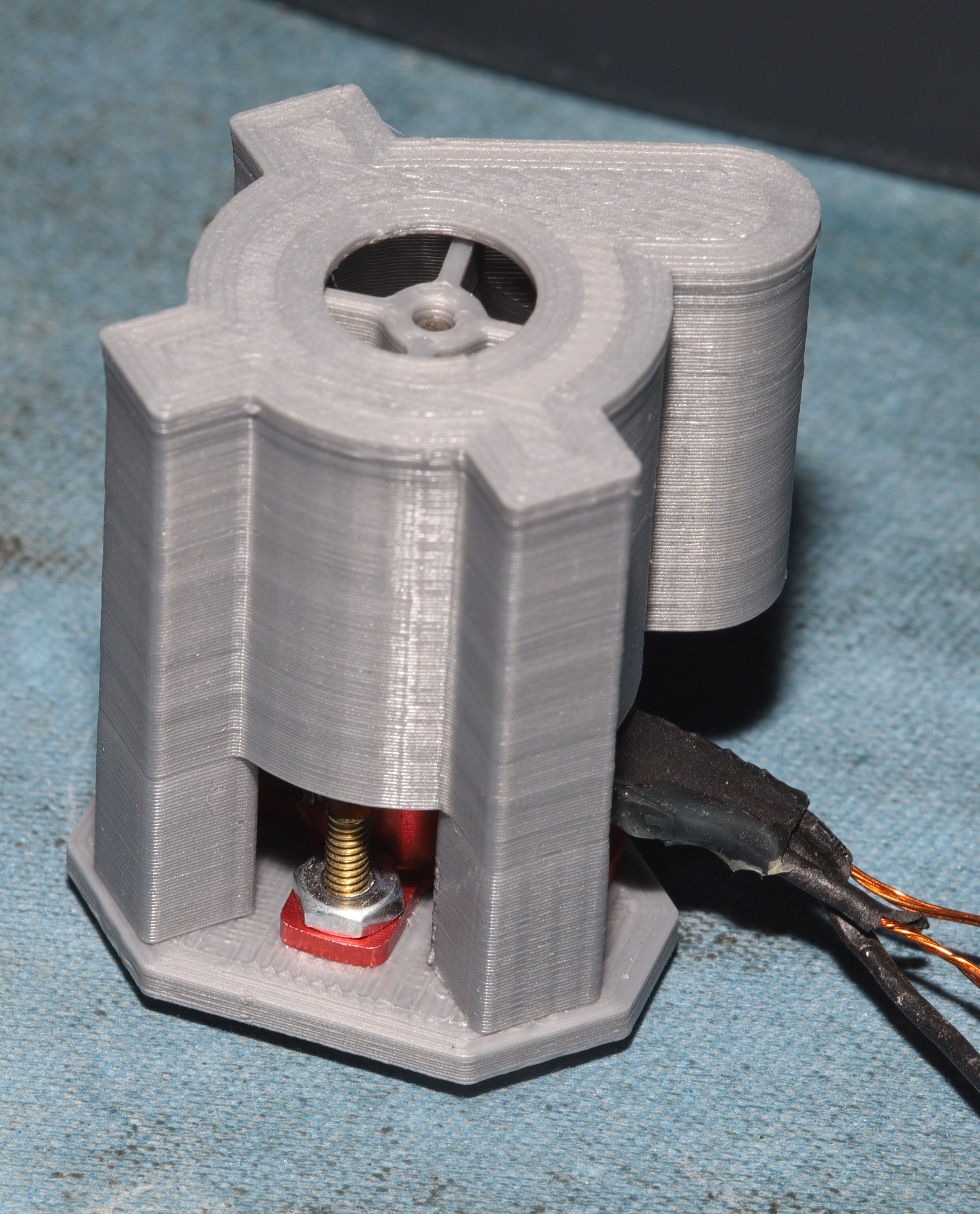

The internet is all over the place regarding lifespan of submerged motors & the lion kingdom has a large inventory of small brushless outrunners, so the decision was made to try submerging one & see what happens.

It actually pumped some water through the tube, while burning .5A 6V. The seal around the motor was lousy. As an outrunner, it needed a gap around the motor which water was more inclined to flow through than the tube. An inrunner could block flow around the motor, but they're a lot scarcer & more expensive.

The water picked up a lot of oil from the motor. It was surprising just how easy it was to make a pump from a brushless motor.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.