-

Project Update

10/30/2022 at 15:24 • 0 commentsJust a heads up, this project is still moving forward, slowly, my computer game consulting company IARItech.com has been busier than ever, taking up nearly all my time, along with the search for a new boat. That said, I have been making some progress, mostly on the emulator and debugger.

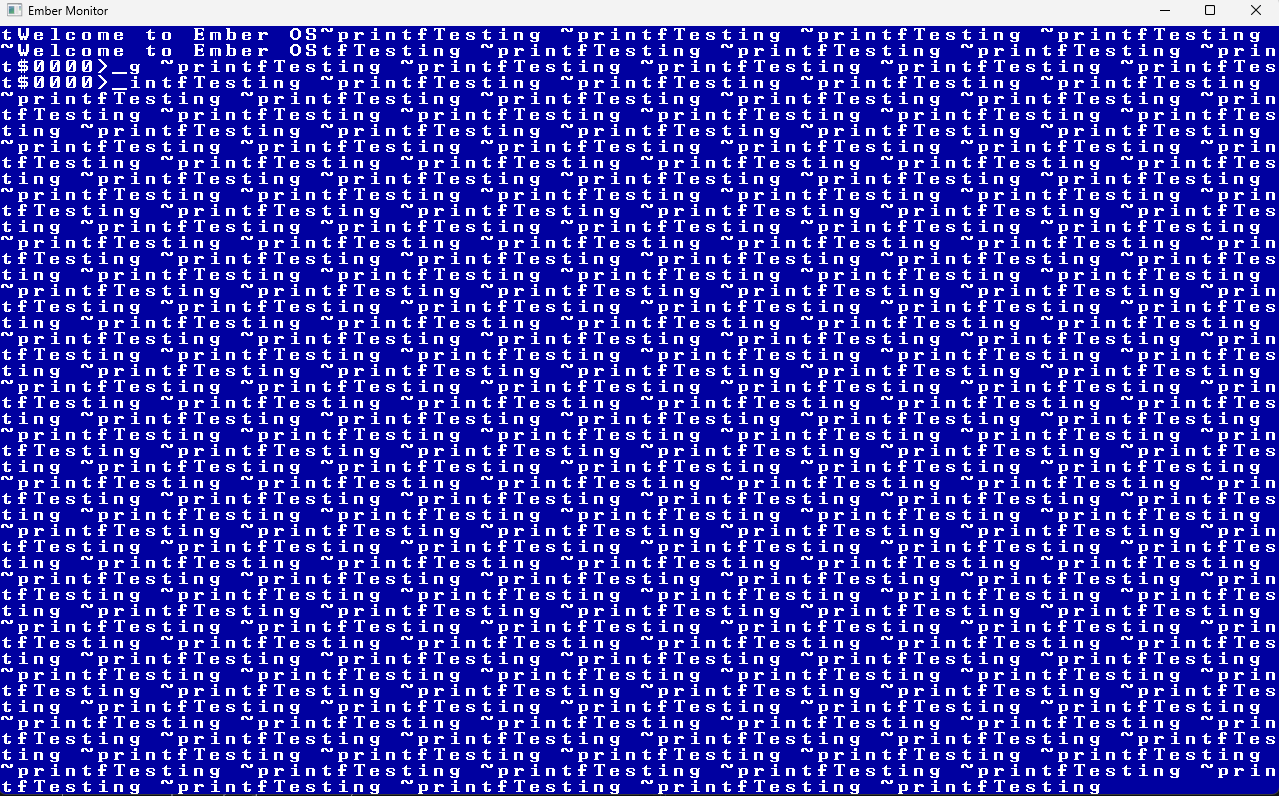

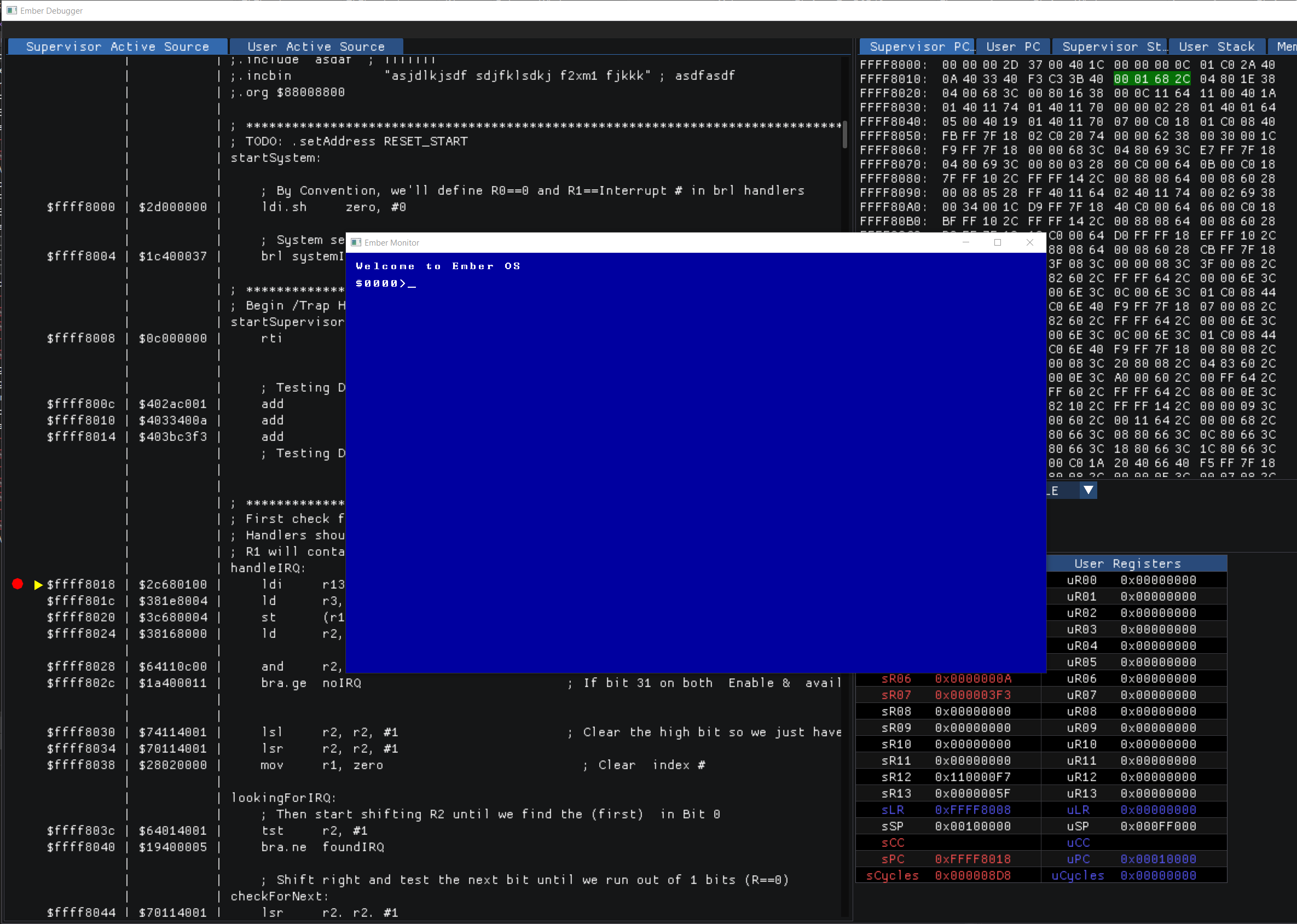

Ember Debugger Window I started working on a basic system monitor in Ember assembly, while also improving the assembler and debugger functionality as I go, then I got caught up with separating the integrated emulator and debugger into separate applications. Previously they were the same app, with the debugger being the emulator, and a separate window showing the output of the virtual machine.

Ember Emulator Window - Testing printf implementation I have now separated the two and I’m working on a socket-based network debugging protocol. The advantage will be that the emulator can run on a separate machine from the debugger. There are two scenarios that come into play here, one is running the emulator on a Steam Deck or other portable system, and the other is debugging Ember code directly on FPGA hardware, we’ll need a debugger that can connect to an FPGA fabric debugging harness, or possibly a debugger/monitor running as system software on the actual hardware.

-

Uploading llvm-mc elf to FPGA and Simulation

02/18/2022 at 20:20 • 2 commentsAfter a lot of pain and suffering(tm), I managed to get Vivado to update the bitstream to contain the contents of an Ember elf binary!

I honestly had no idea how convoluted integrating the assembler would be, but it appears to be working now, and each time I implement the design, the tool automatically adds the binary data to the BRAM initialization block so the program is on the FPGA when it starts. To get this working, I created a tcl script to update a mem file containing the binary data for simulation and implementation, and another to just patch the bit file if I'm just updating the assembly program (so I can just upload the patched bit file, not wait minutes for a new one to be implemented...)

Previously, I just built the instructions using {, , , } syntax in the memory definition, which is not a solution long term. It required a full re-synth/impl pass just the change a bit in the test program, and also, writing instructions required hand-constructing the opcodes. Now I can just write normal assembly in an editor, assemble it with llvm-mc, link it with llvm/lld, then run the scripts to patch the resulting elf file.

Previous method (in .sv file for BRAM module):

30'h00000000: data.mov <= '{OpCode::op_mov, WidthCode::w, MovReg::active, RegSet::gp, Reg::zero, MovReg::active, RegSet::gp, Reg::r2, 11'h000 }; 30'h00000001: data.mov <= '{OpCode::op_mov, WidthCode::w, MovReg::active, RegSet::gp, Reg::r2, MovReg::user, RegSet::gp, Reg::r3, 11'h000 }; 30'h00000002: data.mov <= '{OpCode::op_mov, WidthCode::w, MovReg::active, RegSet::system, SysReg::pc, MovReg::user, RegSet::gp, Reg::r4, 11'h000 }; 30'h00000003: data.sys <= '{OpCode::op_halt, 26'h0 }; 30'h00000004: data.mov <= '{OpCode::op_mov, WidthCode::h, MovReg::active, RegSet::gp, Reg::r2, MovReg::active, RegSet::gp, Reg::r1, 11'h000 }; 30'h00000005: data.mov <= '{OpCode::op_mov, WidthCode::sh, MovReg::active, RegSet::gp, Reg::r2, MovReg::active, RegSet::gp, Reg::r1, 11'h000 }; 30'h00000006: data.mov <= '{OpCode::op_mov, WidthCode::b, MovReg::active, RegSet::gp, Reg::r2, MovReg::active, RegSet::gp, Reg::r1, 11'h000 }; 30'h00000007: data.mov <= '{OpCode::op_mov, WidthCode::sb, MovReg::active, RegSet::gp, Reg::r2, MovReg::active, RegSet::gp, Reg::r1, 11'h000 };Assembly file version:

.org 0 _start: // MOV Test mov zero, r2 ; write nothing mov r2, ur3 ; user r3 to r2 mov pc, ur4 ; skip the following halt halt mov.h r2, r1 ; 16-bit (zero extended) r1 to r2 mov.sh r2, r1 ; 16-bit (sign extended) r1 to r2 mov.b r2, r1 ; 8-bit (zero extended) r1 to r2 mov.sb r2, r1 ; 8-bit (sign extended) r1 to r2 ...Making this work requires the use of the Vivado updatemem.exe tool (which replaces the data2mem.exe tool since about 2015 or so). It is not as simple to use, but once it works, it is quite useful.

Unfortunately, there is not a lot online about the newer tool (outside of the intended use with their MicroBlaze IP), but I managed to piece it together, mostly by looking at .mmi and .smi files people have made and posted online for their CPUs, which mostly use AXI busses also. If you are not using a Xilinx IP, or a core with AXI, you can't use their integrated ELF support, unfortunately. This site was particularly helpful if you are interested in the details of creating a .mmi file.

MMI and SMI Files

To use updatemem.exe, I first had to create a .mmi file, which describes where the BRAM is located on the FPGA, and how it is configured in the bitstream. Here is what I have for my very simple 4k test RAM (basically 1 32(+4p)-bit BRAM block on the Spartan7):

<MemInfo Version="1" Minor="5"> <Processor Endianness="Little" InstPath="my_bram"> <AddressSpace Name="my_local_bram" Begin="0" End="4095"> <BusBlock> <BitLane MemType="RAMB36" Placement="X0Y3"> <DataWidth MSB="31" LSB="0"/> <AddressRange Begin="0" End="1023"/> <Parity ON="false" NumBits="0"/> </BitLane> </BusBlock> </AddressSpace> </Processor> <Config> <Option Name="Part" Val="xc7s15ftgb196-1"/> </Config> <DRC> <Rule Name="RDADDRCHANGE" Val="false"/> </DRC> </MemInfo>Here is the slight variation for the .smi file...basically the same thing as the .mmi file, but instead creates a .mem file for simulation or synthesis, instead of patching the .bit file for the hardware:

<MemInfoSimulation Version="1" Minor="5"> <Processor Endianness="Little" InstPath="my_bram"> <AddressSpace Name="my_local_bram" ECC="NONE" Begin="0" End="4095"> <BusBlock> <BitLane MemType="RAMB36" MemType_DataWidth="32" MemType_AddressDepth="4095"> <DataWidth MSB="31" LSB="0"/> <AddressRange Begin="0" End="1023"/> <Parity ON="false" NumBits="0"/> <MemFile Name="mem/block_ram.mem"/> </BitLane> </BusBlock> </AddressSpace> </Processor> <Config> <Option Name="Part" Val="xc7s15ftgb196-1"/> </Config> <DRC> <Rule Name="RDADDRCHANGE" Val="false"/> </DRC> </MemInfoSimulation>This method is pretty fragile since if the FPGA implementation changes and uses a different BRAM block, this will fail and I'll have to update the files...right now it uses the single block at X0Y3 on the chip.

UpdateMem

The tcl script to call updatemem is super simple. You could parameterize things, but here I just hard-coded them for my testing. Once you have the .smi file above, just point it at the assembled .elf file and .bit file, then give it a name for the patched .bit file. For the -proc parameter, instead of some IP CPU, just set it to the same string as the InstPath in the .mmi file.

Now, in order to generate a new .mem file from my assembled .elf, I can run this script from the tcl Console in Vivado (first cd to the root directory of the Vivado project):

proc update_mem {src_name} { set filename "${src_name}" exec updatemem -meminfo mem/block_ram.smi -data ../../rtl/asm/bin/$filename -proc my_bram -force }The .mem file will look something like the following:

// // Mem file initialization records. // // Data File: C:/Development/Research/FPGA/ember/rtl/asm/bin/TestProgram.elf // Data File: The input elf file is: 32 address width. // // // Copyright 1986-2021 Xilinx, Inc. All Rights Reserved. // SW Build 3367213 on Tue Oct 19 02:48:09 MDT 2021 // updatemem v2021.2 (64-bit) // // Address Space Name: 'my_local_bram' // Data Bus: [31:0]. // Address Range: [4095:0] [0X0000000000000FFF:0X0000000000000000] // Address Depth: [1023:0]. // // Bus width = 32 bits, number of bus blocks = 1. @00000000 28001000 28051800 28232000 04000000 28840800 29040800 29840800 2A040800 28801000 29441800 28600800 28621000 28851000 29051800 29858000 2A058800 2C101234 2C10FFFF 2C901234 2C90FFFF 2D9000FF 2D9000FF 2D104567 2D108EEE 2E100067 2E1000FA 2C10FFFF 2C105678 2D10FF67 2D9000FF 2E1000F9 2E100039 40100000 41914001 45914001 45914001 42114002 46114001 46114001 421140FF 40900000 40914001 44914001 44914001 41114002 45114001 45114001 41117FFF 00000000 04000000

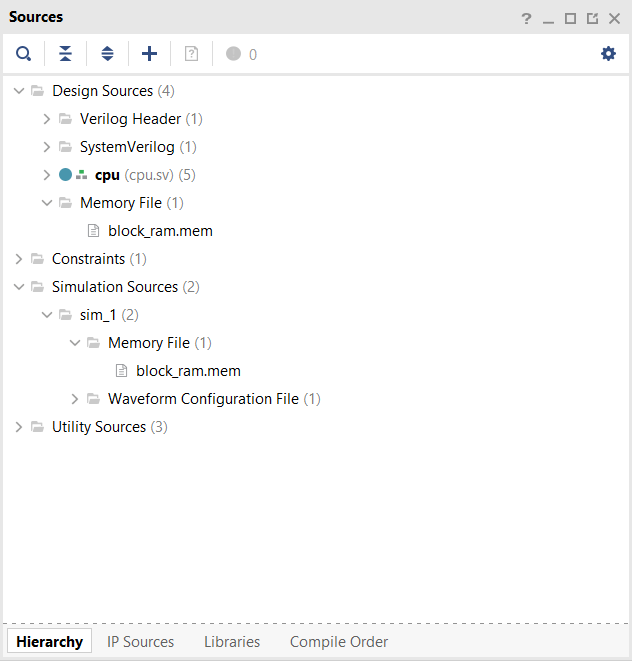

The .mem file needs to be added to BOTH the Design Sources (for Implementation) and Simulation Sources (for Vivado Simulation). You can add the same file to both. This will initialize both the FPGA and Simulation with the contents of the .mem file.

Then add some code in the HDL source like the following Verilog for inferred BRAM:

initial begin $readmemh("block_ram.mem", memory); endNo path is needed if you add it to sources. Then, when you run the simulation, Vivado will load this file and put the values in memory.

UpdateMem Patching

Once you generate a bitstream, you can patch the .bit file directly to just update the memory contents for a new .elf file. This is useful when you are not changing the CPU hardware implementation, but just want to update the program running on the CPU. This patch happens in just a few seconds, rather than minutes, or longer, for a full build.

This time use the .mmi file, and specify the original .bit file and a new filename for the patched .bit file:

proc update_elf {src_name} { set filename "${src_name}" exec updatemem -meminfo mem/block_ram.mmi -data ../../rtl/asm/bin/$filename -bit Ember.runs/impl_1/cpu.bit -proc my_bram -out Ember.runs/impl_1/cpu_programmed.bit -force }Be sure to upload the *_programmed.bit file, not the original file!

-

ALU, LDI, NOP, HALT at 100MHz - Part 2

02/08/2022 at 18:45 • 0 commentsI previously walked through and LDI instruction, this time we will look at how the stages of an Ember ALU instruction operate...from a high level at least. This implementation, while far from finished, does run at 100MHz currently, however, looking at the timing analysis in Vivado, some of the paths are getting quite close to the 10ns limit between clock cycles. The Z and N flag operations are the last to complete, since they rely on the result of the ALU op, so I'll have to take a look at those to see if I can change the logic around to get better inference.

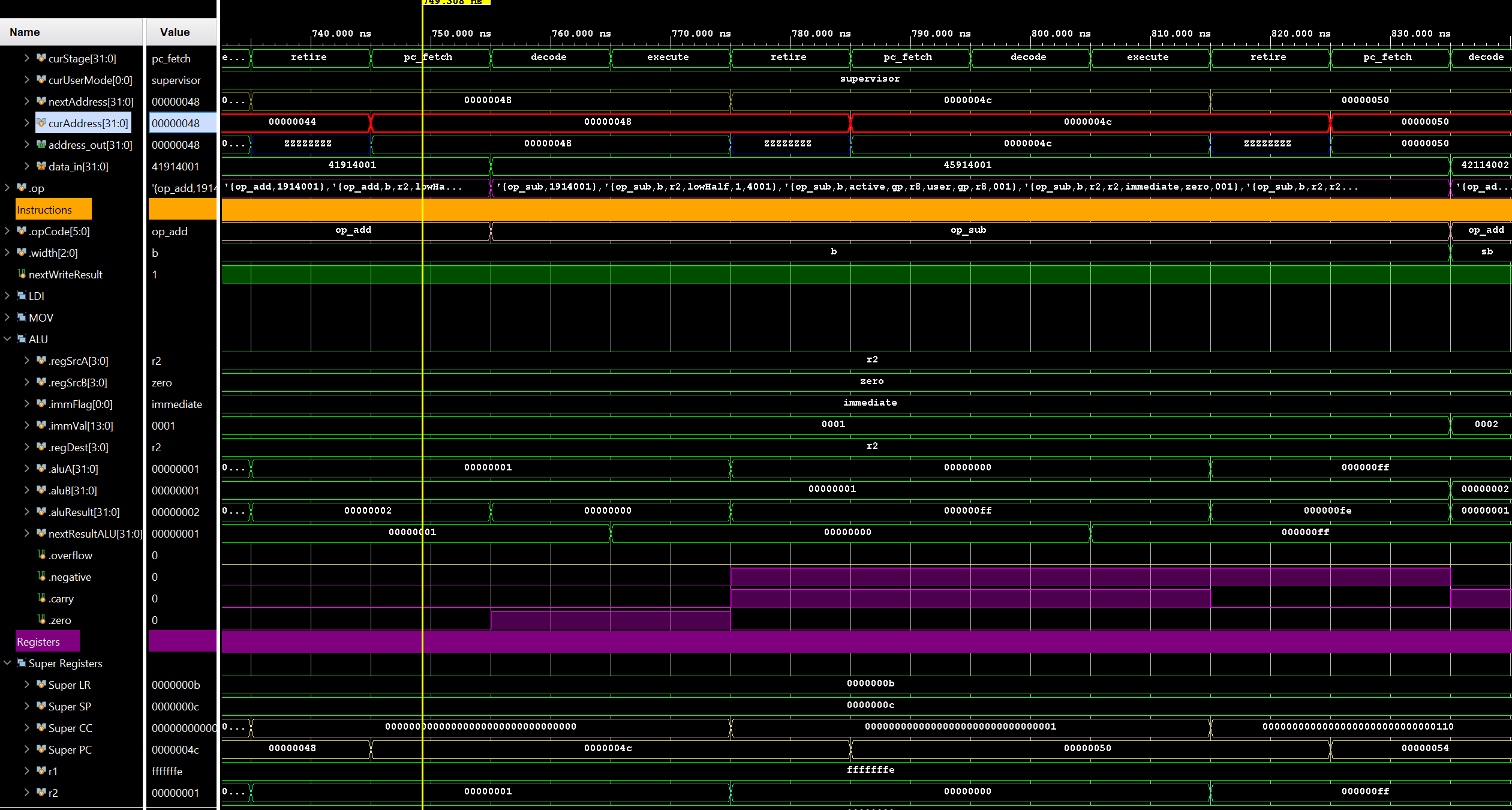

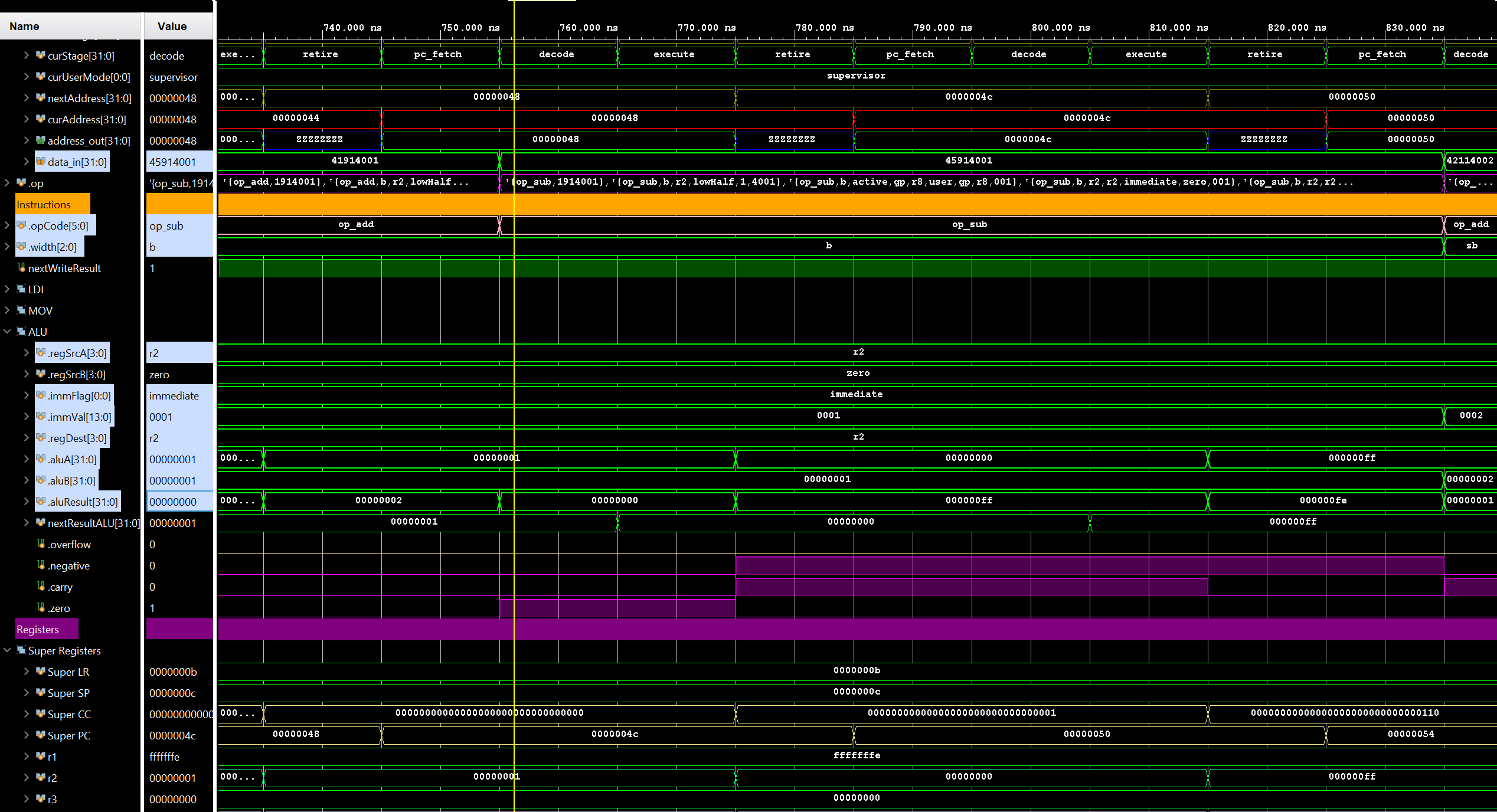

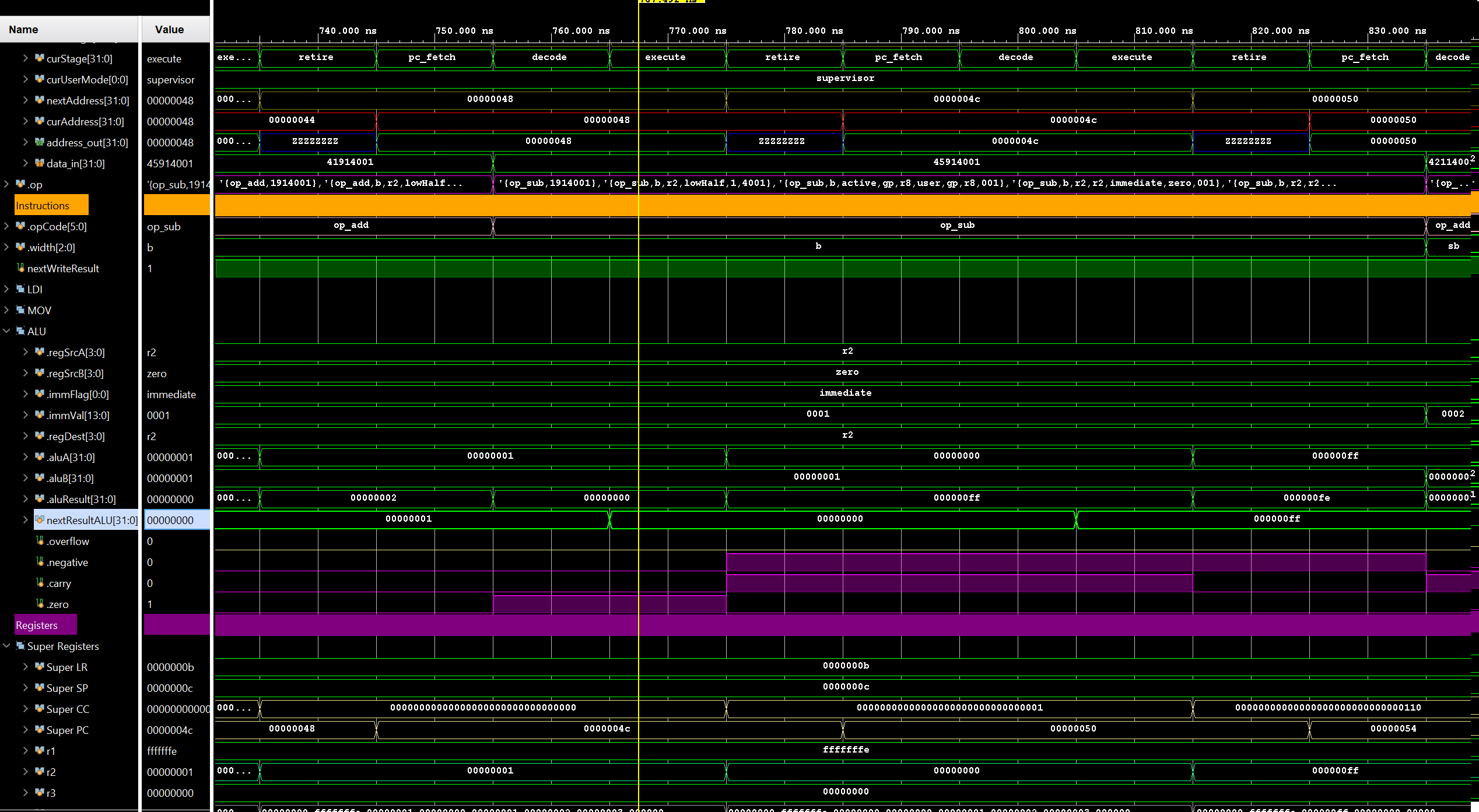

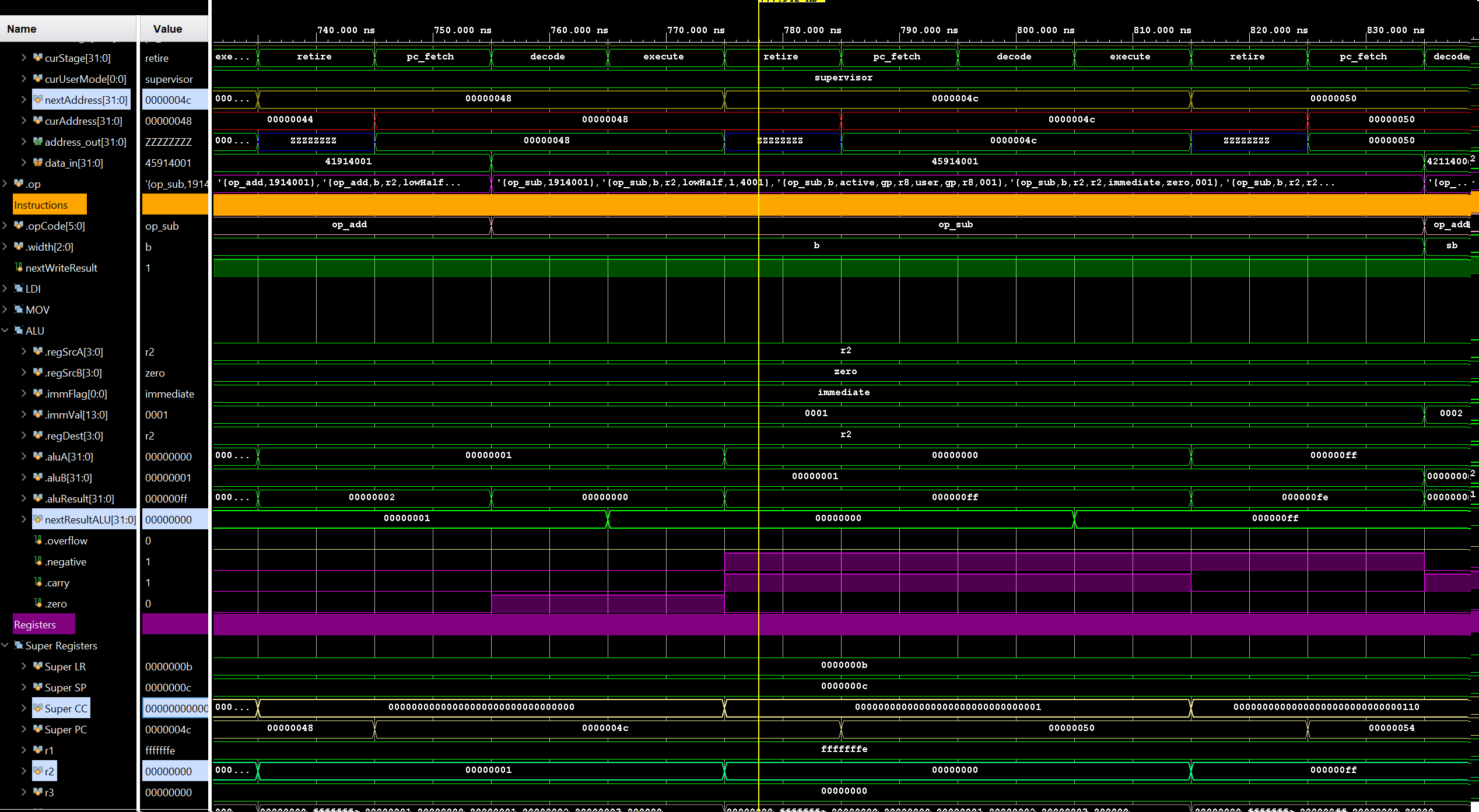

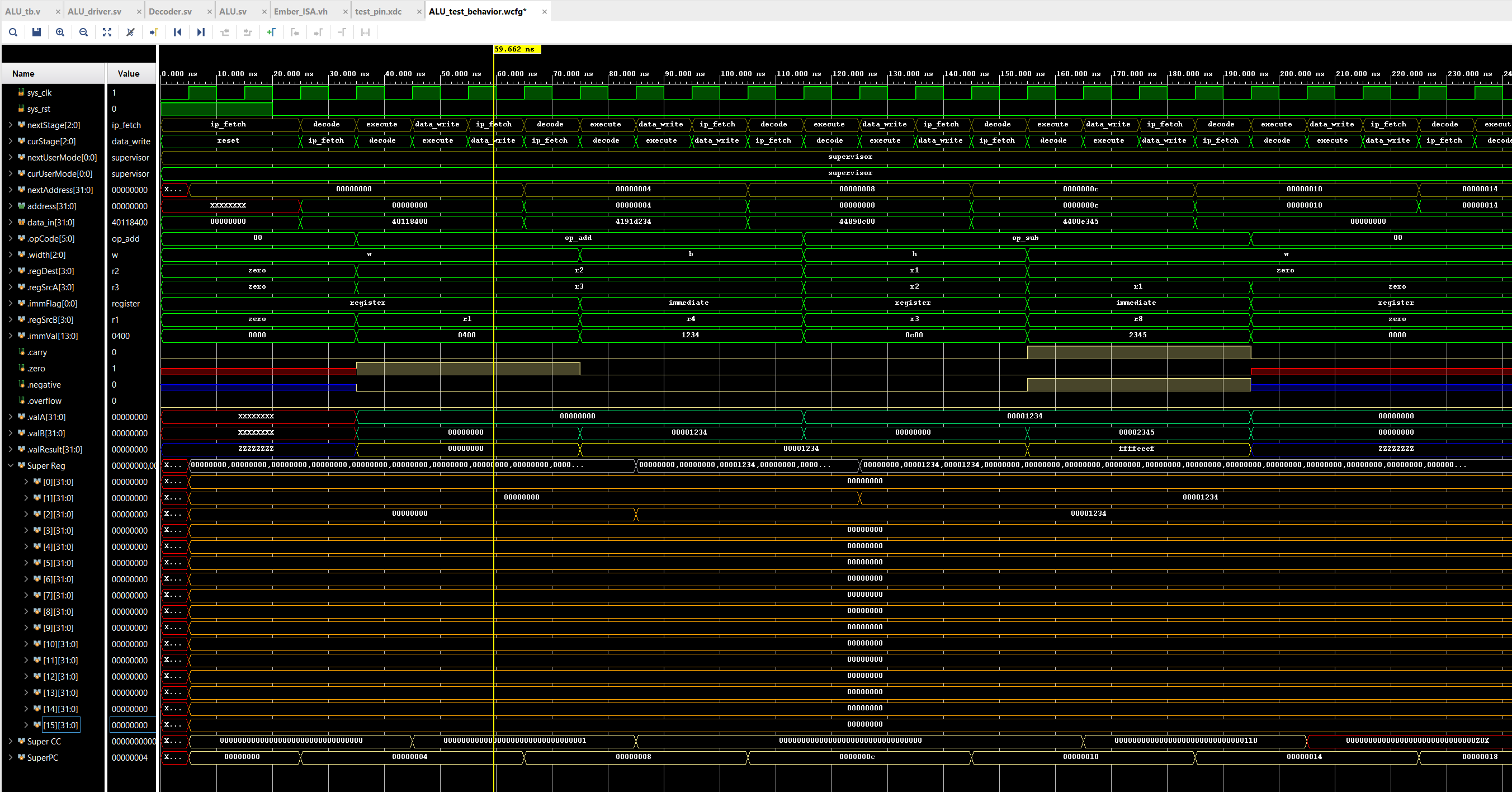

For now, let's look at the SUB instruction in the simulation timeline view.

As with any instruction, the first thing that happens in the pc_fetch stage is that curAddress (and thus address_out) is updated with the value of nextAddress, which was set in the retire stage of the previous instruction. In this case, the address to fetch is 0x00000048.

In the decode stage, we see that a sub.b instruction has been fetched by looking at the op.opCode and op.width values. Because of the b modifier, the width of the operation is 8-bit unsigned (zero-extended) byte. This means that both the input values and output of this instruction will be masked and then zero-extended. In addition, the processor ALU flags will be set based on the value of the 8-bit result.

If we examine the rest of the decoded instruction, we see that op.regSrcA is register r2, which currently has the value of 0x00000001. Also, op.immFlag is set, so the immediate value 0x01 contained in op.immVal is used for the second operand. This describes the following instruction in mnemonic format:

sub.b r2, r2, #1

The equivalent C would be:

uint32_t r2 = 1; r2 = (uint32_t)((uint8_t)r2 - (uint8_t)0x01);

In the execute stage of an ALU instruction, the CPU will latch the result registers to the values in the output. These include aluResult, which now has the value 0x00000000, as well as the ALU flags overflow, negative, and carry, which are all unset except zero, which is set since the output value is 0.

You might also note that after the execute stage, the address_out bus is released (represented by ZZZZZZZZ, or high impedance), since the value is data_in is no longer needed. In a real system, this would disable the memory read line on the CPU to allow other devices on the system bus to access memory if needed.

Finally, the retire stage is where the values of the flags and aluResult are written to the CPU registers, and we also update the nextAddress again to point to the next instruction.

Also notice that a bunch of values in the timeline change at this point, like the flags and operands, but we don't care since these only matter at the time they are latched into registers. Since they are always wired to the data_in register no matter what value is there, they become basically undefined when the address is not being driven by the CPU directly.

That covers the ALU instruction from the timeline view. I'm working hard on an ISA document, which I will post soon, and should make much of this more clear, and open for discussion.

-

ALU, LDI, NOP, HALT at 100MHz - Part 1

02/07/2022 at 01:37 • 0 commentsSuccess! The FPGA implementation can execute at least a few of the instructions at 100MHz on the Spartan Edge! Keeping in mind it's a simple test, running about 34 instructions: first, a bunch of LDI (Load Immediate) instructions load registers, then a combination of ALU instructions perform a sequence of ADD, SUB, etc. at various widths 8-bit, 16-bit, and 32-bit operations on registers, then NOP and a HALT, ending with the correct final results and flags. I can also step through the entire sequence of instructions one cycle at a time and watch the CPU stages, flags, and one register (r2) on the LEDs.

Here you see the final stage after running the test program. On the left 0b101 (stage 5 == HALT), then 0b010 (CPU Flags Carry/Negative/Zero so N flag set), and in red the low 8 bits of register r2 0b11111110 (-2 signed).

To see how I got here, we can look at the Logic Analyzer time view in Vivado. First, a few quick notes:

Currently, all implemented instructions take exactly 4 cycles, represented by the following Stages:

- pc_fetch - Request the next instruction from memory by promoting the value of the internal register nextAddress (which was set in the previous retire or reset stage) to curAddress, then assigning the memory bus address_out to that value for at least a cycle to load the instruction word

- decode - Load the new instruction word from the data bus data_in into the internal op register. All the appropriate connections to the ALU and other instructions are always wired, so they decode the result "immediately", available after only gate propagation delay in the same clock cycle.

- execute - Results of any operation (and appropriate flags and CPU states) are latched in internal registers. This is necessary especially in cases where one of the source registers is also the destination register location.

- retire - Write out latched results to the destination register, set processor flags, set nextAddress for the next pc_fetch.

There are also two others:

- reset - In this state while sys_rst is high

- halt - After executing a HALT instruction, stays in this state until sys_rst goes high. Useful for debugging/testing.

There are currently no wait/stall stages, as there are no memory or branch instructions so far, and I'm using Block RAM right now which always completes in 1 cycle, so we don't need to wait on a signal to read or write the memory value. Ultimately I will need to add these.

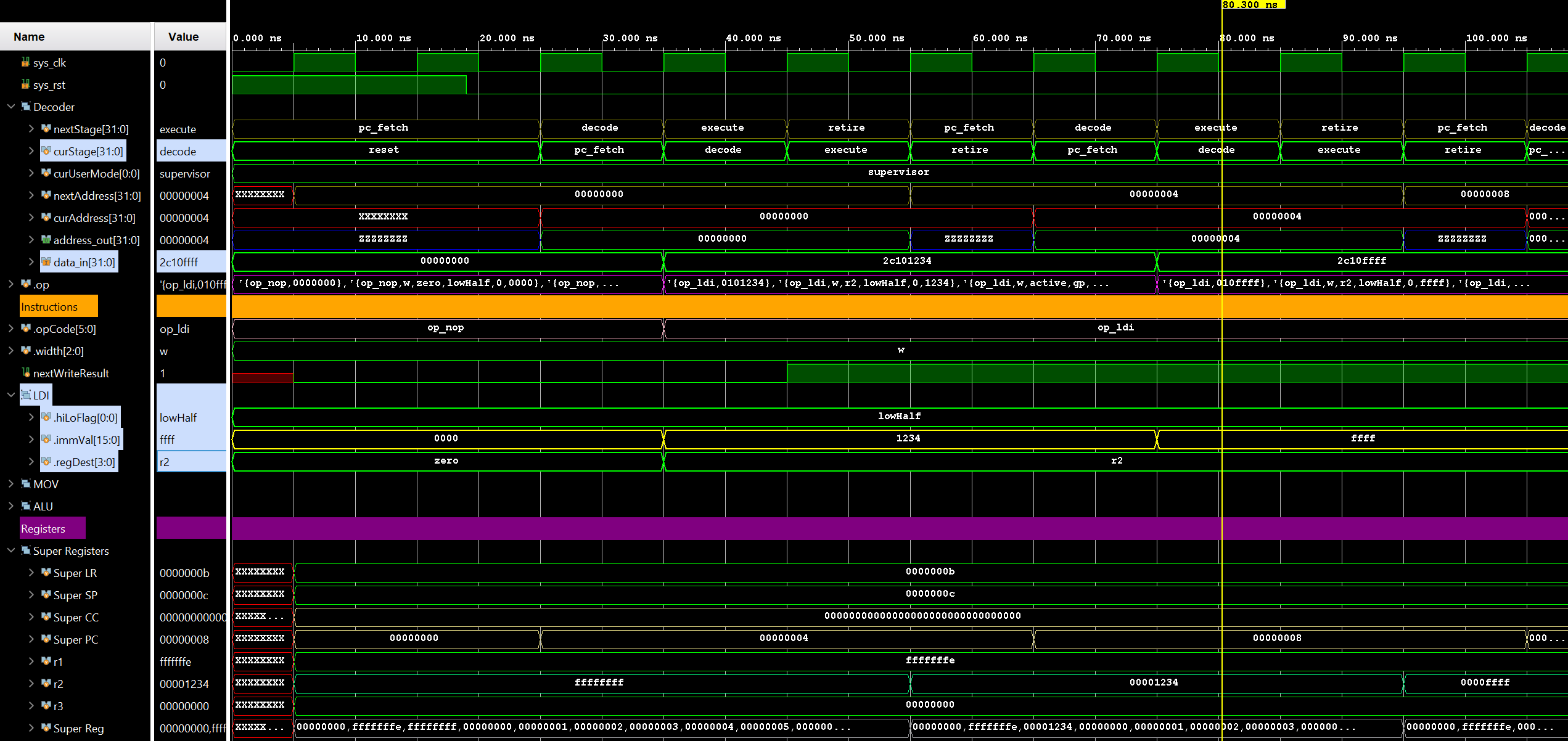

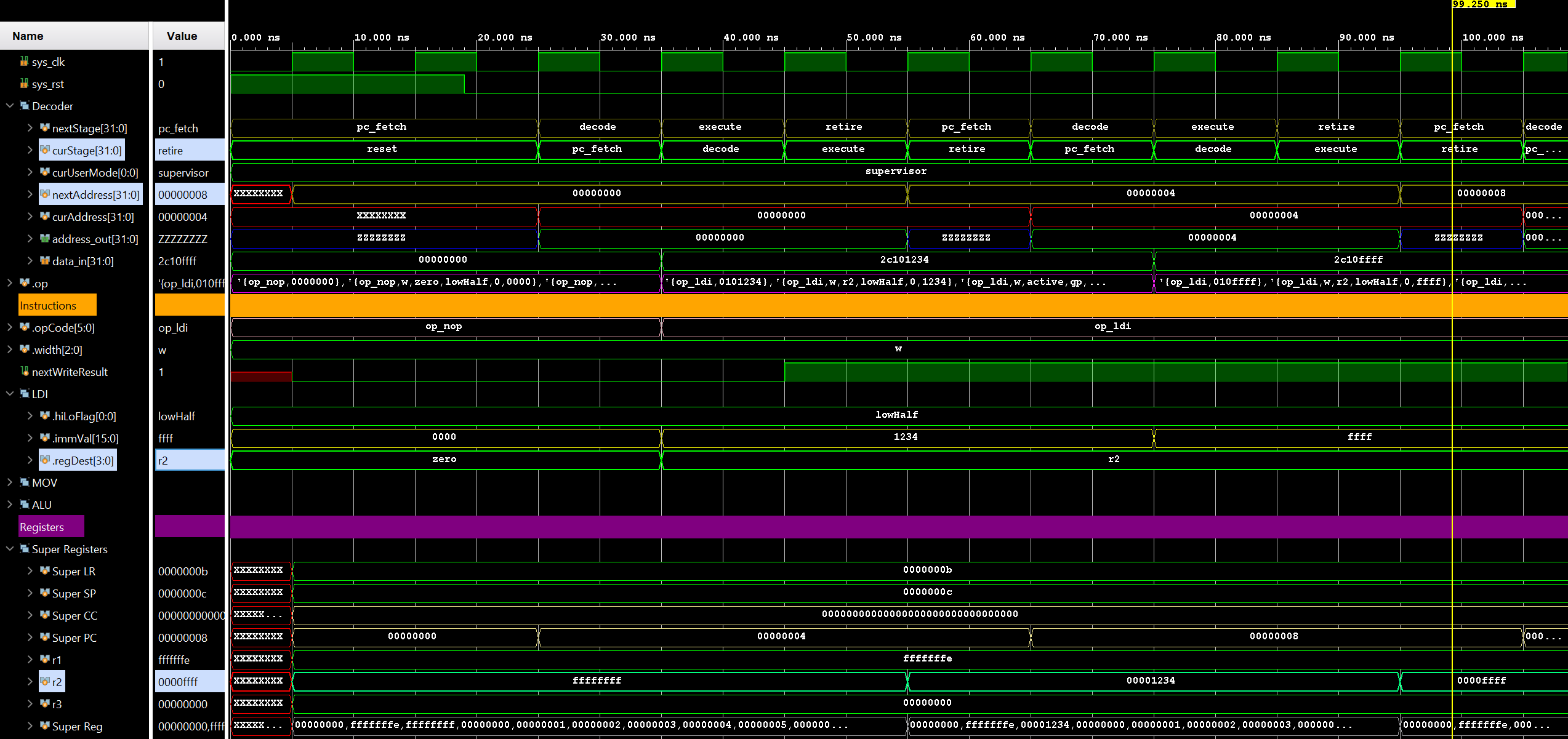

Now that you know what should be happening, let's look at it in the timeline. We will actually start on the last stage of the previous instruction indicated by the verticle line. Notice that nextAddress is incremented here to 0x00000004. If the previous instruction were a branch, it might have instead set the address to the branch target location at this point.

We now start the next instruction with the pc_fetch stage. Notice that the register curAddress is updated with the value of nextAddress, and address_out is wired to curAddress and the address 0x00000004 is sent out to BRAM.

One cycle later we are in the decode stage. Here we see that data_in now has the instruction word available, which is latched into the op register. This register is cleverly defined as a union of structs, each describing one type of instruction. These structs are in turn continuously wired to their respective logic so that when the 32-bit value is loaded into the register at the start of the decode stage, the results are computed for all possible instructions simultaneously in parallel in hardware. Only after we examine the opcode in the later cycles do we choose from the various results and write out only the information we need.

In this case, we have loaded an LDI instruction designated by op_ldi in the opCode field, so we can examine the LDI struct to see the contents of the instruction word. One bit labeled hiloFlag here determines if the 16-bit Immediate value immVal goes into the high or low 16-bits of the destination register (it is unset, or lowHalf in this case, immVal is 0xffff and the destination register is r2).

Nothing interesting happens in the execute stage for LDI, so we move on to the retire stage again. Here the CPU will write out the LDI result value of 0x0000ffff to register r2, update nextAddress to the value of the PC register (0x00000008), and finally increment PC to the next instruction address (0x0000000b).

This continues for the next 15 instructions, which are an assortment of LDI instructions to test different combinations of width, value, and registers. Then there is a similar sequence of ALU ADD/SUB instructions. I will cover those in the next update.

I am also working on an ISA document, but I'm only getting started...since I'm basically designing the CPU as I go...I hope to post more details on the instruction set and register architecture soon.

-

Progress on the ALU FPGA Design

01/28/2022 at 02:17 • 0 commentsI have made some great progress on the ALU in SystemVerilog in Vivado for the Spartan-7. I can now step through a sequence of ALU instructions, have them read from registers and immediate values, then save out the result to another register. The next step will be to add some additional instruction types to the decoder logic, probably memory load/store, and a few others like load immediate to have some data to operate on. Then I need to try stepping it on the FPGA hardware. For now, it is looking good in the simulator.

I decided to go with SystemVerilog ultimately. Originally, I wanted to do the whole implementation in Verilog, but after finding roadblocks and bottlenecks (a lot of it was due to being a programmer for decades, Verilog was just too limiting), it was becoming apparent it would be much harder to do.

Anyway, as you can see from the simulator image above, there are benefits to using SystemVerilog and going all in. I was able to define typedef enums for all my types and values. Then I defined a number of structures for each encoded instruction word, defining the bits in each instruction and assigning them enums. This way, I can just load the 32-bit instruction and set it to a typedef logic union, then use the structure members just like it was C code! It looks like it's just as optimal, way easier to read, and even more convenient to simulate.

If you look closely at the sequence in the image, you can see all the values with names like the pipeline state at the top, names of instruction opcodes, registers by name, etc. I can then change their colors as well. People complain all the time about the "closed" tools like Vivado, Quantus, and the like, but so far it has been working for me...we'll see as I get farther into things. I have to say it is slow when building for hardware though...you do need a fast machine or builds take forever...

I plan to write up something on the SV code at some point, but right now I'm having so much fun just coding it! :)

-

FPGA Test Harness

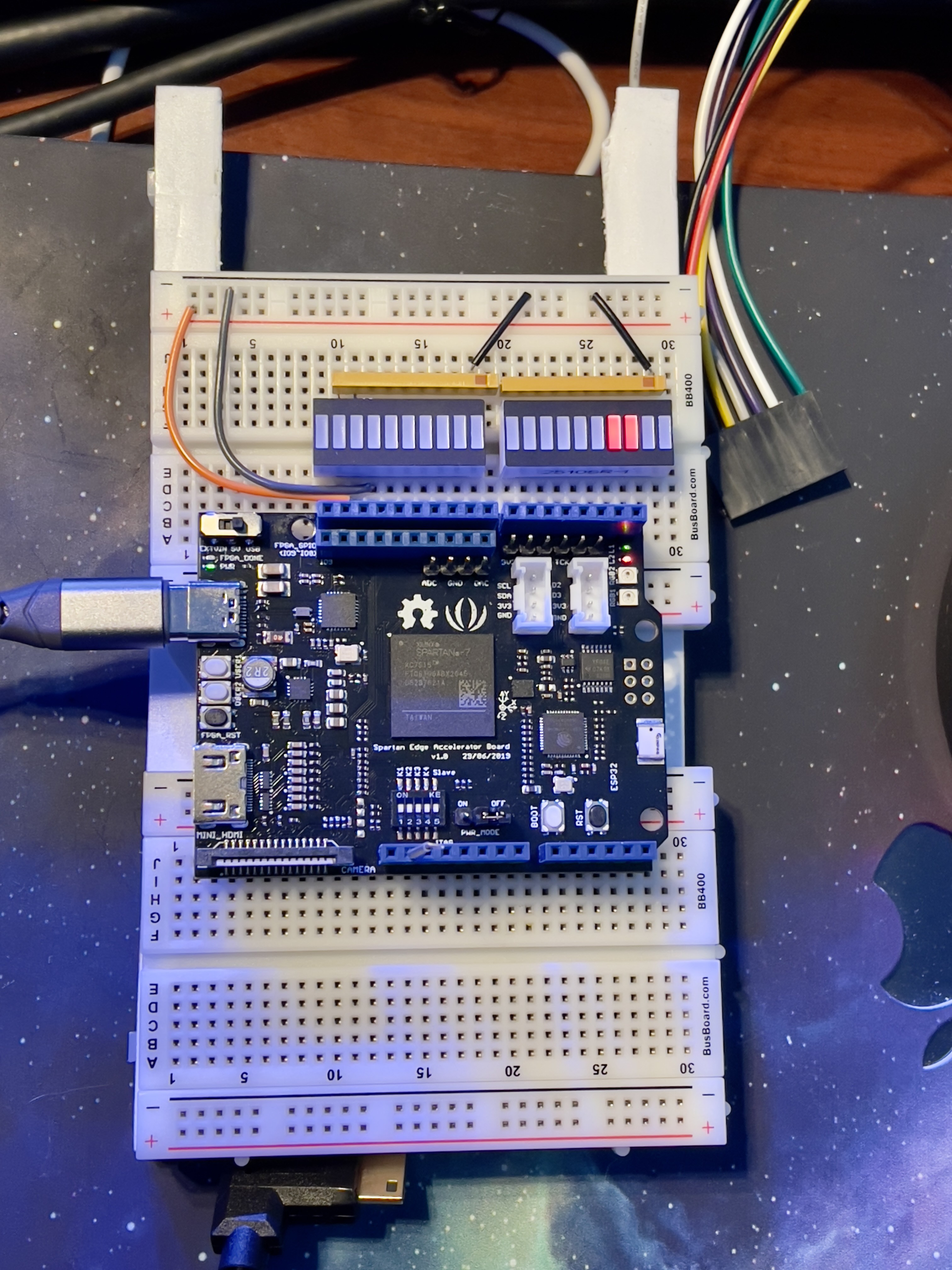

01/23/2022 at 21:16 • 0 commentsIn preparation for ALU development on the FPGA, I decided to hook up all the external pins of the Spartan Edge board to LEDs and switches so I can do at least a bit of debugging. Ultimately, once I have more of a working CPU, I can likely interact through the ESP32, I2C, or something. But for now, it will be more hands-on. First, though, I had to solder on the headers for various connections (using my brand new digital microscope!), as the Spartan Edge leaves those off initially as verious user options to install as needed.

The Spartan Edge board has various connections to the Spartan-7 FPGA and the ESP32 onboard. Many of the IO pins from the Spartan-7 are laid out and configured with resistors to be used with an Arduino Uno, and a few are directly wired. We have 14 pins from the Arduino Digital IO headers, and 10 pins from the FPGA directly. Unfortunately, the Analog pins are instead wired directly to the ESP32, which is all fine, but since we're not using that right now it isn't helpful.

One very unhelpful note is that there are NO 3.3v pins at all (at least on any of these headers) to get VCC_3v3 from the board! I did some checking, and the ONLY place you can get regulated VCC_3v3 from the board is the two Grove connectors, which are intended to be used for I2C or whatever, and the JTAG connector which I need in order to program the FPGA. I didn't have any Grove connectors, so I'll need to wait for them to come in later this week. Unfortunately, the pins are too small to get female jumper wires to stay put.

For now, I can at least set up the breadboard with some LEDs and switches. My first attempt was to just place the board directly on two short breadboards, which would be way cleaner, however, I soon realized that all the pins I need are on one side of the board, and if I run jumper wires to the breadboard, I can't use the top row of connections if the board pins are connected. So, on to plan B...

Now I have the FPGA board plugged into the breadboard, mostly just to hold it in place, as I am not currently using any of the analog or signal pins from that bottom Arduino header. I then run ribbons of IO pins to the breadboard. Initially, I'm running the Arduino 0-13 pins as output driving the LEDs in sets of 8, 4, and 2, and the 10 FPGA pins to switches in 8 and 2. Here they are just tied to Ground, since I don't have the VCC side wired yet, so the switched inputs float when not grounded...resulting in noise, but I can at least see they are working.

There are also some switches, two pushbuttons, and a few LEDs on the board if I need those. I figure I can use the pushbuttons to step through test cases.

Next up, get some ALU functionality coded up on the FPGA so I can step through some logic on the test connections.

-

HDMI "Mode 0" Text Output functional on the Spartan Edge FPGA

01/16/2022 at 18:58 • 0 commentsWhile I have been working on the emulator and assembler, I have also been playing around with the Seeed Spartan Edge FPGA. After watching an untold number of videos on You Tube, and reading through a few (unfortunately too few) GitHub projects, I have managed to implement an HDMI output example in Verilog for the Spartan 7 FPGA.

It currently only supports a single resolution at a time, set to 1280x720 for now. I have tentatively called "Mode 0" (the only one at this point really) as an 80x45 character text mode using a 16x16 bit ASCII font. For this test case, I store both the default VRAM contents (80x45 bytes) and the font (128x2x16...half the ASCII character set, plus 2 by 16 bytes for each character bitmap) in block RAM on the FPGA.

The next step for the FPGA project is to create some code to write data to the dual-port block RAM, so the HDMI output can display text. I figure the first step for that is to work on the ALU and CPU pipeline implementation. That will at least allow some part of reading and writing to memory. -

Display Output and Keyboard Interrupts Working in Emulator

01/15/2022 at 20:20 • 0 commentsI now have the emulator back to the point I was before I started integrating the LLVM assembler and linker! This means when the emulator is running it outputs to a virtual 1280x720 text display (80x45 16x16 characters for now) with a very simple monitor program that can read keyboard input. The display and keyboard controller work through CPU interrupts.

I will go into detail on how this works once I get my Medium Blog caught up. I'm still going through early design at this point at a very high level, but I will get way more detailed soon.

-

Quick Progress Update

01/10/2022 at 18:00 • 0 commentsBeen a while, thought I should just give a heads up. I have the emulator and LLVM assembler working now with nearly all the instructions, including branch and memory access. The debugger now supports stepping and breakpoints for supervisor-level code (think kernel/firmware)...need to add support now for user-level code (applications), then I can hook up the rendering and keyboard interrupts again (broken since the change from my hacky assembler days to LLVM)

I have also been making progress with the FPGA. I worked over the weekend to get a simple Mode0 HDMI output working. I can now at least fill the screen with the letter 'A'! I know, sounds like not much, but for me it's a milestone. I now need to get the Block RAM VRAM working, issues with clock timing I need to work out...then I can output text on the HDMI screen attached to the FPGA. Next step will be to start coding the ALU for the CPU.

Cheers, Tom

-

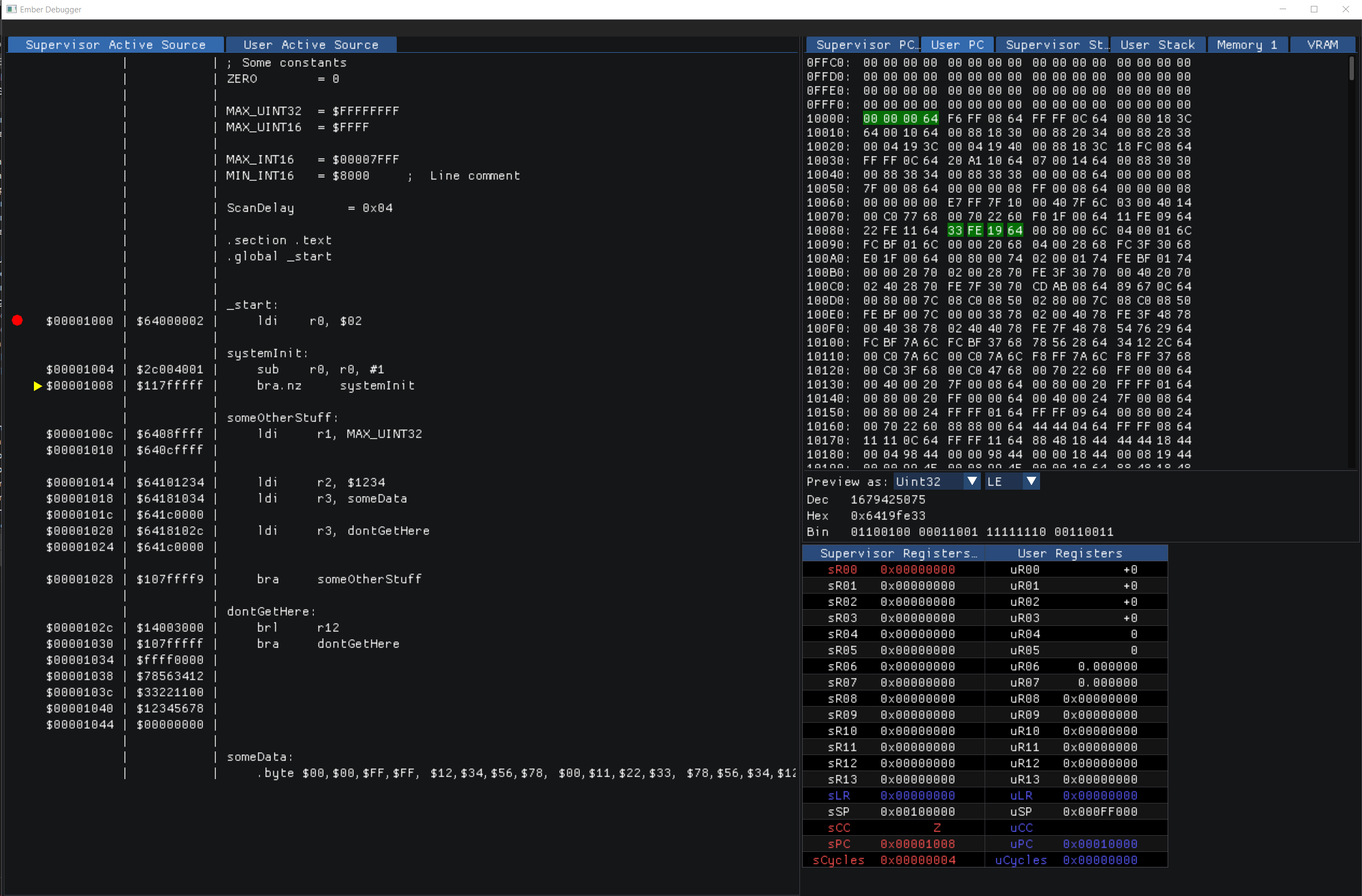

Emulator/Debugger now working with LLVM-produced *.elf files

12/23/2021 at 22:40 • 0 commentsWith a few days off for the holidays, I finally had some time to get the debugger working again. It now supports the common DWARF debugging standard segment that is contained in the ELF file written by LLVM-MC and LLD.

I originally coded it for the simple assembler that I wrote for the CPU, but the system quickly outgrew that and I decided to implement a "real" assembler. I ended up going with LLVM-MC over a separate assembler like VASM so I could more easily implement higher-level languages at some point. That was painfully complex, but it is now working, at least for a small subset of the Ember instruction set.

I can now set breakpoints, step through the code in the emulator, as well as view and edit registers and memory, directly in the emulator window.

Next, I need to finish up the instruction set ISA, add all the remaining instructions to the LLVM TableGen scripts, then update the emulator for the new instructions and I should be able to get working on some firmware/OS code.

Tom

Tom