-

Body beautiful

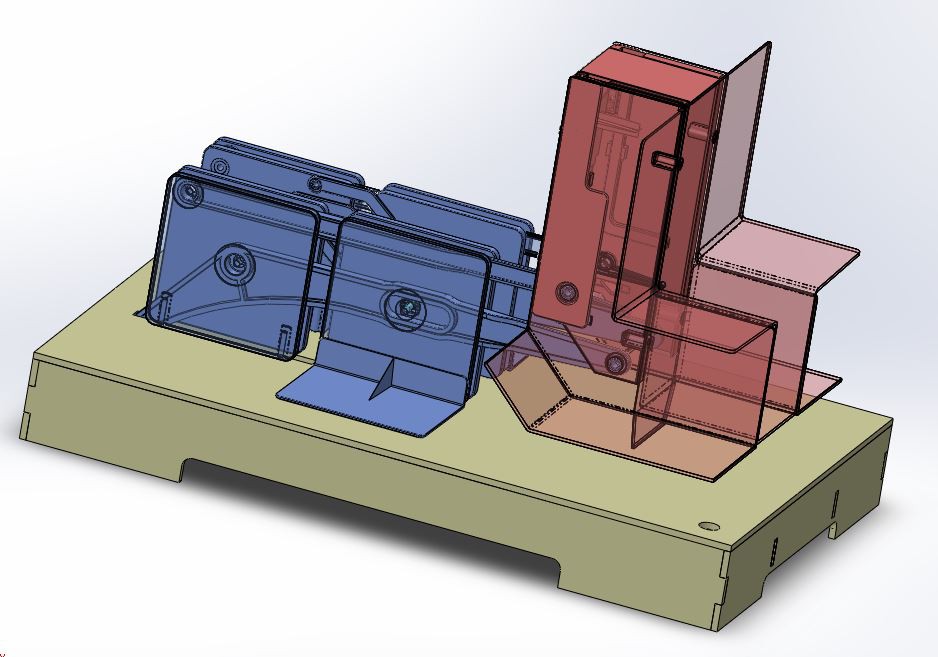

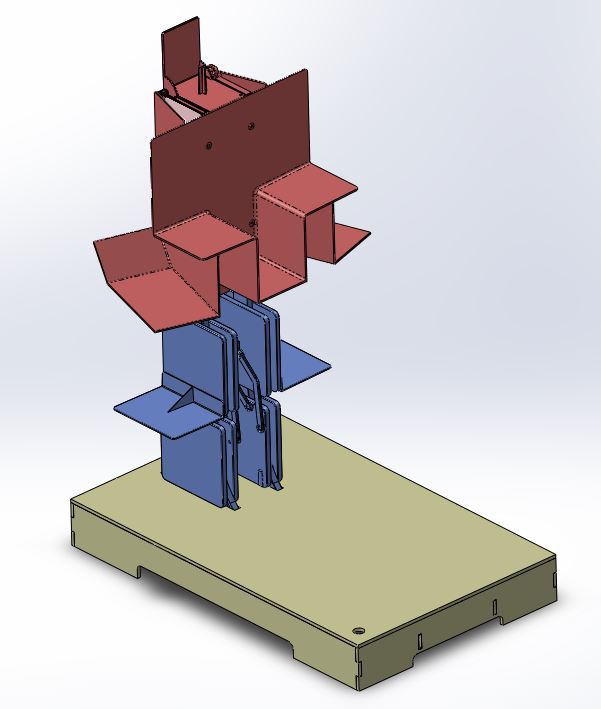

01/15/2017 at 01:32 • 0 commentsRecently I have been preparing the body parts for printing and assembly. Adding tolerances (gaps between parts) , beveling (removing square edges for cleaner prints) and adding little pegs with holes so the whole thing can be assembled with the same sized small screws.

I'm just waiting on some red and blue PLA filament to arrive to print some test parts and check all my guesses.

As we are creating something that will interact with food we need to be food safe. PLA is considered food safe (It's made from corn starch) and we will use food-safe petrolium jelly as a lubricant in all the joints.

-

Uplifting thoughts

01/02/2017 at 07:14 • 0 commentsWhere the original cake had 2 motors, the new cake will have only one.

This time instead of an expensive stepper motor I want to use a DC motor with a leadscrew (pictured below) because they are cheap ($5 from Ebay) and the control electronics, a DC motor controller shield, is also affordably prices on eBay.

The Cake, including icing, will weight an estimated 1.6kg (3.5lbs). But because of the leverage of the lifting arm the motor will have to move 3x that, 4.8kg (10.5lbs)

I hope to use no more than 6 AA batteries to power the electronic but there is a bit of trial and error to come after my parts arrive in a few weeks.

Naturally I will create a BOM (Bill of Materials) as the project progresses which will include a list of all the final electronics and links of where to buy them.

-

A Foundation

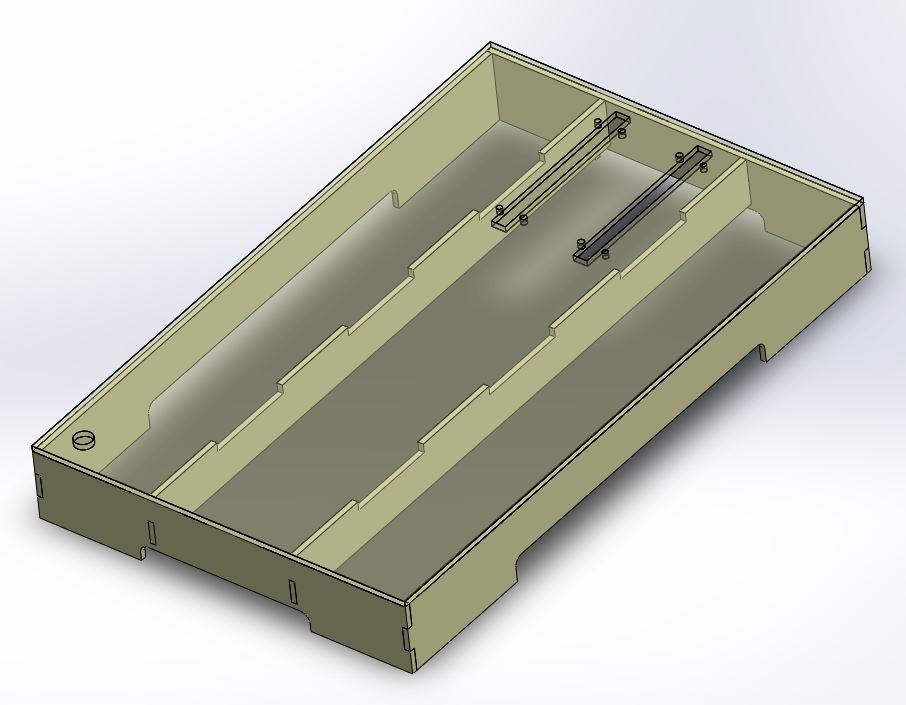

12/22/2016 at 15:17 • 0 commentsLets start from the ground up, the base. The original was made out of 8mm MDF because I wanted it to be a stable platform for the cake to move on. It certainly was stable but 8mm was total overkill.

This version will use 3mm MDF with 3D printed elements (not pictured) to strengthen the high stress area at the rear. Using 3mm MDF allows us to use affordable laser cutting services to have the pieces cut out and delivered cheaply.

I consider using 3D printing for the base but my 3D printer on has a 150x150cm (6x6") base. I would need to print in 6 different parts and screw them together and that all seemed a bit clunky to me.

MDF has a nice finish if you want to paint it (in food safe water colors of course) or will happily take an plastic adhesive-backed covering like the original has.

Transforming Birthday Cake

Birthday cake on a moving platform that sounds and transforms like Optimus Prime.

Russell Munro

Russell Munro