-

A major milestone: Part 5 of the Prusa conversion

3 hours ago • 0 commentsIt was a long way from the early prototypes in 2021 when the Hackaday Prize triggered the project, to a working 3D printer that converts plastic powder from failed prints into something new:

...but still not finished. I am currently working on a 3D printed gearbox for the extruder motor.

-

Old prints to raw material with a hacked mill

02/26/2025 at 08:55 • 0 commentsWith the converted Prusa getting closer to my everyday 3D printer, I need more raw material. I modified a commercial mill to a grinder with integrated sieve. The material throughput I get is definitively good enough, however there are still some things to improve:

-

More printing discloses weak points of the design

02/15/2025 at 07:20 • 0 commentsThe granule printer meanwhile works very well and I start doing more than just print tests and with that the weak points can be seen. I have to replace a too weak gearbox and must redesign the powder feed.

-

Meanwhile, close to a _normal_ printer

09/29/2024 at 15:21 • 0 commentsI have modified the mechanics of the Prusa again. This time I had an eye on better usability of the printer. Furthermore I am working on the automatic material feed. The parts needed for this were all printed from PLA powder. The machine gets closer to a printer that is almost like a _normal_ (filament) printer:

The full print of a small part is demonstrated in another video:

-

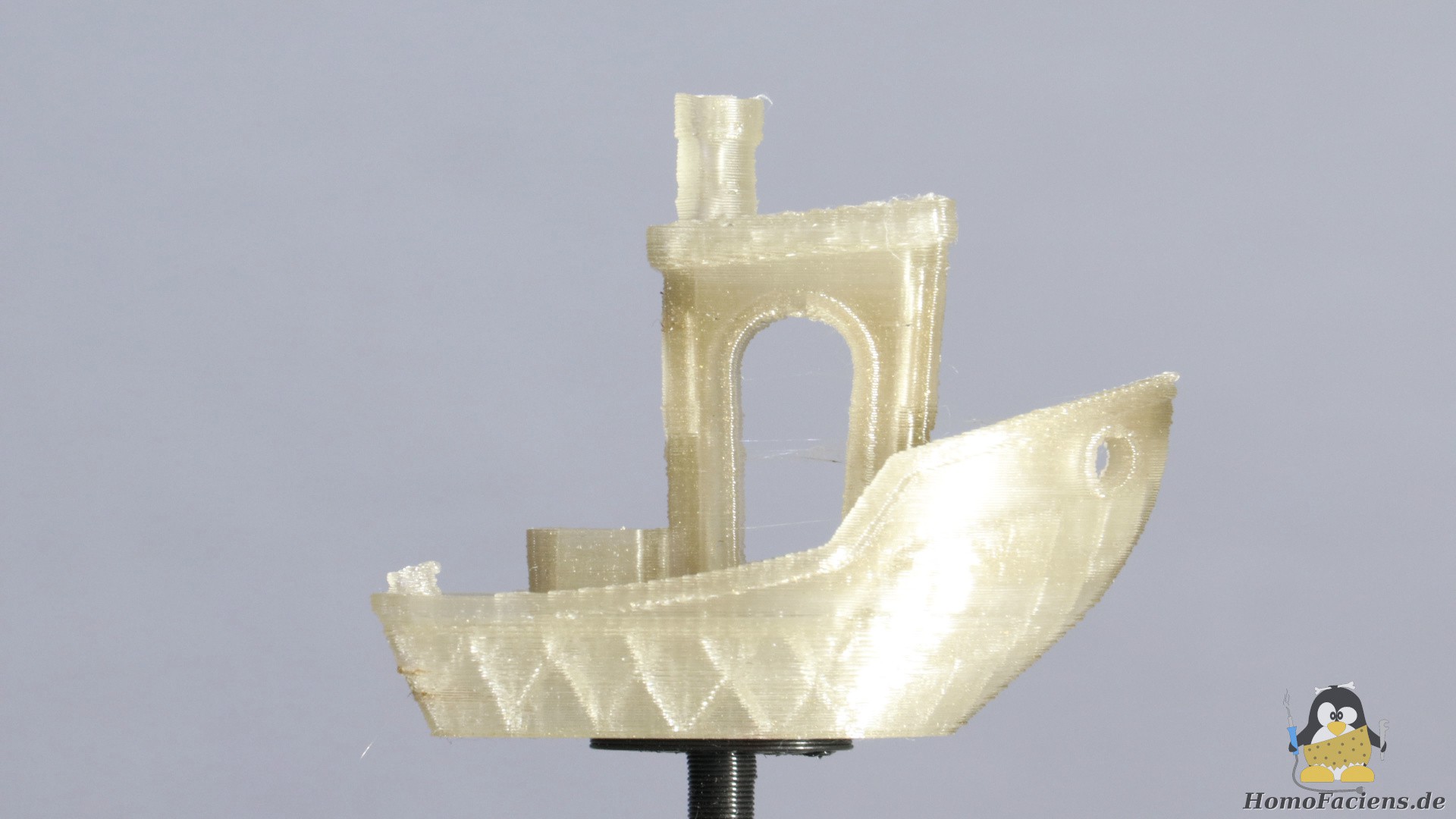

First 3D Benchy printed from PLA granules

09/07/2024 at 10:49 • 3 commentsThe load cell of the Prusa MK4 is implemented and so bed leveling works fine. Now that larger prints can be carried out, I have made a Benchy:

If you know a granule FDM printer that can make better looking Benchies, leave a comment!

![]()

![]()

![]()

![]()

-

Extruding PLA powder required changes in the design

07/22/2024 at 14:10 • 0 commentsI got some PLA powder and trying to print with this raw material didn't work with version 5.0 of my granule extruder. I had to shorten the extruder tube (again) and make some more changes to the hardware, but now printing with the powder works:

-

My Prusa MK4 no longer needs filament to print

06/07/2024 at 13:57 • 1 commentI am in the process of converting a Prusa MK4 to granule printing. Part 1 of the process shows how to build the core component, extruder V5.0 and first test prints:

-

A closer look at the auger screw(s) of my direct granules 3D printer

05/10/2024 at 11:40 • 0 commentsThe simplest component of my granule extruder must meet certain criteria to get a working 3D printer:

Next step: Converting a Prusa MK4 to direct granule printing.

-

Extruder V4.1: Rough build instructions and thermal optimization

04/27/2024 at 12:54 • 0 commentsI have been shrinking the tube of my extruder in order to reduce friction and so to get a better retract:

-

V4 of my granules Extruder has a full Metal Core

04/06/2024 at 10:05 • 0 commentsVersion 4 is made of a brass / stainless steel tube and has of course a simple wood screw an auger:

A 20 minutes test print of a tiny 27x25x12mm track link shows the capabilities of the new design:

Direct Granules Extruder, FDM prints from powder

Waste plastic turned into raw material for 3D printing.

Norbert Heinz

Norbert Heinz