OK, the first problem has occurred with using the DVD piece as my diffraction grating, even at 4.7G and 1540 lines per mm, and the DVD begin a name brand, doesn't mean a thing. There is no way around the random spacing errors created by the manufacturing process for a ruled grating type piece.

I thought by using the Schott glass filter (which is designed to reduce these effects at the detector,) would help, but it does not. Alignment is another problem, even though I have it designed so I can rotate it, it doesn't matter, the lines MUST be parallel, with little spacing error.

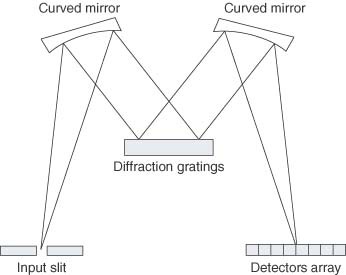

So I am going to have to use a Holographic diffraction grating square. the specs will be in the component list. I am going to use the Czerny-Turner configuration which is shown below:

This set up will just solve a lot of headache, especially since I have designed my own fiber optic mounts (FC/FC connectors.) I am still able to use my present set up for testing the fiber optic equipment I've built.

All this will still fit nicely within the enclosure with room to spare, so no worries there, just a slight rearrangement of components.

David H Haffner Sr

David H Haffner Sr

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Thanks, I'm getting the idea. The imprinting process on a large substrate will cause variations of the spacing, which won't have a noticeable impact on its function as a data medium.

Are you sure? yes | no

A holographic grating is a type of diffraction grating formed by an

interference-fringe field of two laser beams whose standing-wave pattern is

exposed to a polished substrate coated with photoresist. Processing of the exposed medium results a pattern of straight lines with a sinusoidal cross section.

Holographic gratings may exhibit less scattered light than ruled

gratings. Due to their sinusoidal groove profile, holographic gratings cannot

be easily blazed and their efficiency is usually considerably less than a

comparable ruled grating. However, an exception exists when the ratio of the

period to the wavelength is near one; in this case, a holographic grating has

virtually the same efficiency as the ruled version.

Holographic master gratings are replicated by a process identical to that used

for ruled gratings.

Are you sure? yes | no

The first day I had a CD in my hands I held it into the sunlight and thought that the diffraction looked interesting, but not "pure" enough to be usable. Same for EPROMs with an erase window. When I first saw diffracted sunlight on the ceiling from a DVD lying on the table I noticed that the the diffraction was more intense, but it never came to my mind to use it as a diffraction grate.

Enter your project (and others). I understand that the curvature of the gratings is tangential to the input slit (or vice versa), and thus will have systematic grating rate variations relative to the center of the (now cut) DVD. You've been writing about spacing errors, and in my understanding production errors and the systematic geometric error isn't quite the same.

Could you please explain what the production error is?

Are you sure? yes | no

Hey Thomas, the problem lies in the fact that DVD's and CD's have burned in pits from the master in which they are produced from, and since DVD's store more information they have a lot more burned in pits.

These pits are what is causing the diffraction, at 4.7G the pits are spaced very close together and are etched on Polycarbonate substrate, as with any manufacturing process no matter how precise, there will always be imperfections. The same holds true even for the highest quality ruled diffraction gratings purchased for hundreds of dollars, they have spacing errors too.

Its the physicality of it, that's why the holographic gratings are best for Raman spectroscopy, there is no physical burning or etching on the substrate.

I could have gotten away with still using the DVD piece, if all I wanted to do was fluorescence spectroscopy, but with Raman, the signals are too weak, and detection has to be very precise.

Are you sure? yes | no