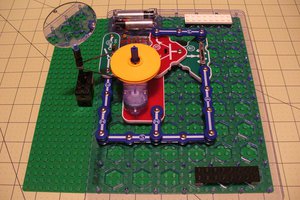

The design used 4 coils (AWG Gauge Magnet Wire 250' Enameled Copper Coil Winding) that were displaced 90 degrees in space from one another. The 4 coil bobbins were used in their entirety with 4 very large nuts and bolts. I obtained the largest bolts that came as close as possible to fitting as snugly as possible through the plastic coil bobbins. The 4 coils ran in series and were placed in correct polarity. This was done by tagging the coils North and South and connecting one coil with another accordingly as one would connect one magnet to another. Wire terminal connectors were used to connect the outer wires together. An armature that was used for the rotor was taken from a universal bathroom vent fan motor replacement electric motor. Some of its metal casings were used to balance and center the rotor on the wooden platform. What helped greatly to make the induction motor work was the type of capacitor used. Although it was recommended to use a pair of 200 micro farad non-polarized capacitors, I had chose to instead use a BB-2PR 600 Hz 4 ohm Bass Blocker recommended by Instructor Tim Callinan and his induction motor on YouTube which worked perfectly fine. A 24-volt AC transformer was connected to the circuit and was spliced to a polarized US 2-prong male-female extension power cord cable. A small fuse box was included in the circuit to help ensure that I did not accidentally blow a fuse. Finally, an on and off push button switch was also added to the circuit.

Click on link below to view completed project:

https://video.wixstatic.com/video/301c36_ce09beaa6d1f4f15bb7c911130b0887d/1080p/mp4/file.mp4

Additional notes:

Some of the coils will get warm after running longer than 10 minutes. If splicing wires using a two-prong extension cord, remember that if one is longer than the other, the smaller narrower prong is for the "hot" black wire and the larger wider one is for the "neutral" white wire. One may need to adjust the distance of the coils to the rotor in order achieve maximum speed or torque. The speed of rotation is approximately 800-1000 turns per minute which is about the speed of an average turning desk fan. Caution and safety should be maintained when using a standard AC outlet in order to run the 24-volt transformer.

Special thanks to:

Christine Mecklenborg in her “AC Induction Motor” video –

https://www.youtube.com/watch?v=UsT-qWAzTHg

RODALCO2007 in his “Open induction motor -- Home made field coils” video –

https://www.youtube.com/watch?v=BawBBc4IY38

(Where I obtained the design idea for the project as well as the circuit design)

Lidmotor in his “Homemade 12v AC induction motor” video-

https://www.youtube.com/watch?v=EhPdYRuqb0E

Tim Callinan in his “Build a simple AC Induction Motor” video –

G. Rosa

G. Rosa

Paul Fjare

Paul Fjare

Steve Schuler

Steve Schuler

Peter Buckley

Peter Buckley

Petar Crnjak

Petar Crnjak