-

The Open Source Program

09/26/2021 at 17:23 • 0 commentsSince the beginning, our aim was to create as much -real- impact as possible. Any Pediatric Exoskeleton is already a big deal which can surely benefit many children, but we couldn’t stop thinking that even if prices were accessible, there would always be someone we wouldn’t be able to get to.

We decided to propose an Open Source Model paired with a Sharing and Collaborating Program to ensure that the design wouldn’t just go into a repository where people wouldn’t really know what to do with it. An exoskeleton is a complex machine which can really make use of a bit of instruction and support in order to be successfully built and run. We want to help makers around the world really get into the technology, and we want to push collaboration beyond our own capabilities as well!

Because of the children-focused nature of Alice, and due to the fact that it operates with high levels of current with moving parts which could very well damage someone’s limbs if not operated properly, we provide free access to the codes, designs and reference material after a screening process which ensures only people with basic engineering experience and aptitude attempt to build and use the device. We want to make sure Alice helps children, and we want to make sure nobody is damaged through what we have made.

If you want to build your own exoskeleton, make sure to request full access through this link.

We have a growing community in Italy, Greece, the USA, Chile, México, India, Ecuador, and more; and we would love to have you with us!

See you there and until the next log! :)

-

Diving into Alice’s PID controller ( mood = nerd; )

09/26/2021 at 17:19 • 0 commentsAlice’s locomotion algorithm consists of a Finite-State Machine (FSM) that sets the desired kinematic trajectories for each motor. Once the kinematics in the form of joint angles are defined, PID speed regulators are activated controlling the motors’ speeds to move from the current position to the objective joint angles.

Figure 1. Block diagram of the controller, digital filters implementation and data acquisition.

The angle of the motors is indirectly obtained through potentiometers installed in the mechanical system. A mathematical mapping was constructed to convert the potentiometers’ voltage measurements to angles.

The speed is estimated through a second order approximation of the derivative. In addition, discrete third order Butterworth filters were designed and implemented for the angle and speed variables. The cutoff frequency of the filters was designed to be half the sampling frequency to avoid aliasing and still be able to recover signals within the desired spectrum, according to the Nyquist sampling rate.

Figure 2. Angular velocity (blue) with the motor in static state, and filtered velocity (red).

To calculate manipulations, the derivative of the error was computed using a second order approximation and a Butterworth filter was applied to them using the previously mentioned cutoff frequency. Additionally, an anti-windup incremental algorithm was used to saturate the Integral action of the PID, and general non-symmetrical saturations were also implemented over the total manipulation computed by the controller. Finally, constant non-symmetrical tuned values were added to the PID’s manipulations to decrease the effect of the dead-zone nonlinearity created by the static friction of the motors.

The following graph shows the efficacy of the control algorithm in achieving target speeds while alternating joint-movement direction.

Figure 3. Performance of PID velocity controller with different target speeds and during alternating motion. For slower speeds, velocity is maintained during longer periods of time; reaching time is also longer.

-

How we made our materials more resistant on a low budget.

09/26/2021 at 17:18 • 0 commentsWhen trying to find the balance between low-cost and strong materials we did some research about how we could make our 3D printed parts just resistant enough. We had heard about Carbon Fiber and thought about giving it a go. We studied the process and quickly realized it was a bit complex for us. We wanted to skip the molds and find an easier way. Maybe covering 3D printing parts?* After several attempts, we finally found the best way to do it. Now we’d like to share it with you.

- Keep in mind that Carbon Fiber sheets can be harmful to the skin, so it’s important to dress properly. You will need to cover every visible part of your skin so we recommend you wear gloves, a face mask (covering nose and mouth), glasses, and a coat.

- After you dress up and get your Carbon Fiber ready, we recommend you measure the pieces you want to cover and draw the area you need on the fiber marking it with tape. Use a penknife to cut the area, the tape will help to get the little fibers that form the sheet to stay together when you cut it.

- Prepare the epoxy resin following the indications of the specific brand you bought (the one we use requires 2 parts of resin and 1 part hardener solution). Take into account that the mixture starts getting hot minutes after combining (20 min for ours), so you need to make sure to work fast and to mix only the amount you will really use. We recommend buying from polyestershoppen.nl or getting West 105 + 205 epoxy resin and hardener.

- When you have your epoxy ready and the Carbon Fiber cut to size, we recommend you cover both sides of the Carbon Fiber sheet with epoxy. Afterwards, place it on top of the PLA part you want to reinforce. Add a bit more epoxy on it and make sure it touches the whole surface so that no bubbles are formed. We recommend reinforcing one side at a time.

- Let it rest for a whole day and after 24 hours you may cover the other side if needed. Make sure you don’t move or touch it while it’s drying to avoid leaving unwanted marks. After every side has been covered and the part has completely dried, you can now cut the excess and give it its final shape. We recommend using a Dremel or a similar rotative tool. Make sure you protect your skin, eyes, and mouth especially for this part. Carbon Fiber particles can be really sneaky and they itch a lot, potentially causing important problems in your lungs if you let them in, so make sure you take this warning seriously ! If you can work outside that would probably be better; try using a box or a bag as well to collect all of the dust.

Hope you liked our mini tutorial, If you have any suggestions or additional questions do let us know ! We are sure there’s room for improvement.

Remember you can build your own exoskeleton with us. Follow the link for more information in our website: http://www.indi.global/alice

* This idea came originally from Jeff Gorges at the University of Houston.

-

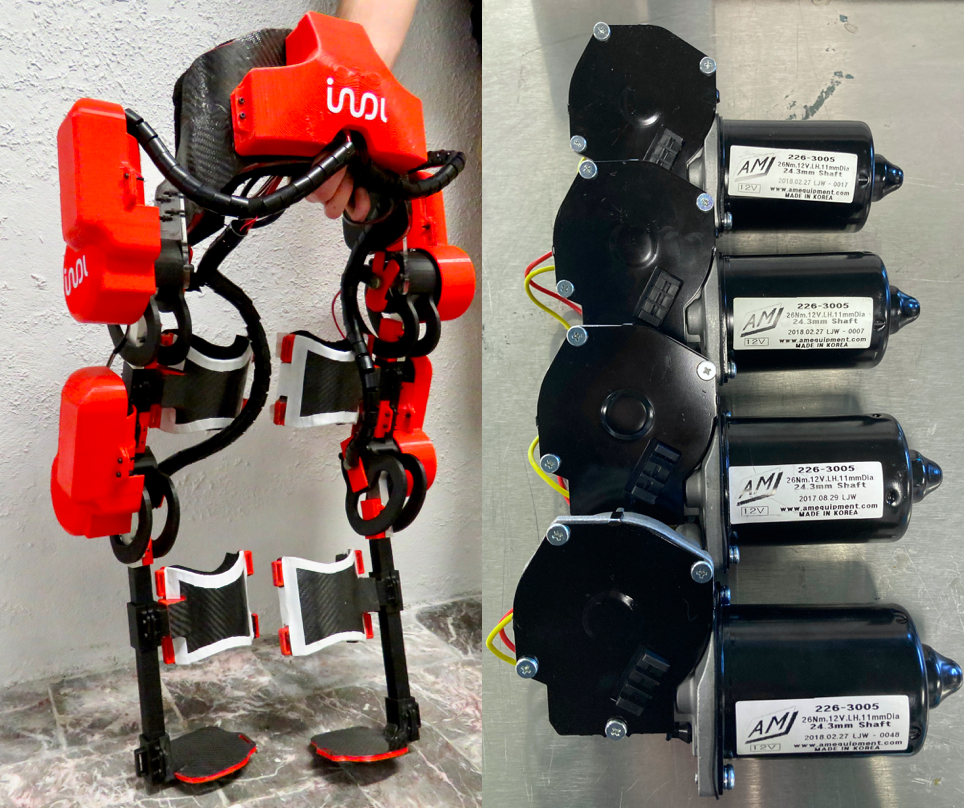

Talking Motors

09/26/2021 at 17:17 • 0 commentsDuring the building of the pediatric exoskeleton, some actuator evaluations were done in order to decide for the best option. The state-of-the-art Brushless DC motors by Maxon Group (Switzerland) joined with strain weave gears by Harmonic Drive LLC (United States) combinations were compared to DC Motors by SIEMENS (Germany) and AM Equipment (United States). Even though the state-of-the-art combination is undeniably better in performance, both SIEMENS and AM equipment 26Nm DC actuators were found to be appropriate exoskeleton implementations.

AM Equipment DC actuators were finally deemed the best option for continuous system production and deployment due to technological characteristics, price and overall product availability within the Mexican market.

Four actuators were used and covered hip and knee Degrees of Freedom; this reduced complexity and weight while maintaining minimum functionality required for standing and walking tasks.

We have been searching for different alternatives and similar motors to make sure people outside The US and especially in Europe have easier access to low-cost actuators but we haven’t been able to find other suppliers with similar options and reliability. Let us know if you find any !

![]()

Alice Open Source Exoskeleton 2021 Update

Open Source, Child-Focused Leg Exoskeleton for accessibility in developing communities.

Jesús Tamez-Duque

Jesús Tamez-Duque