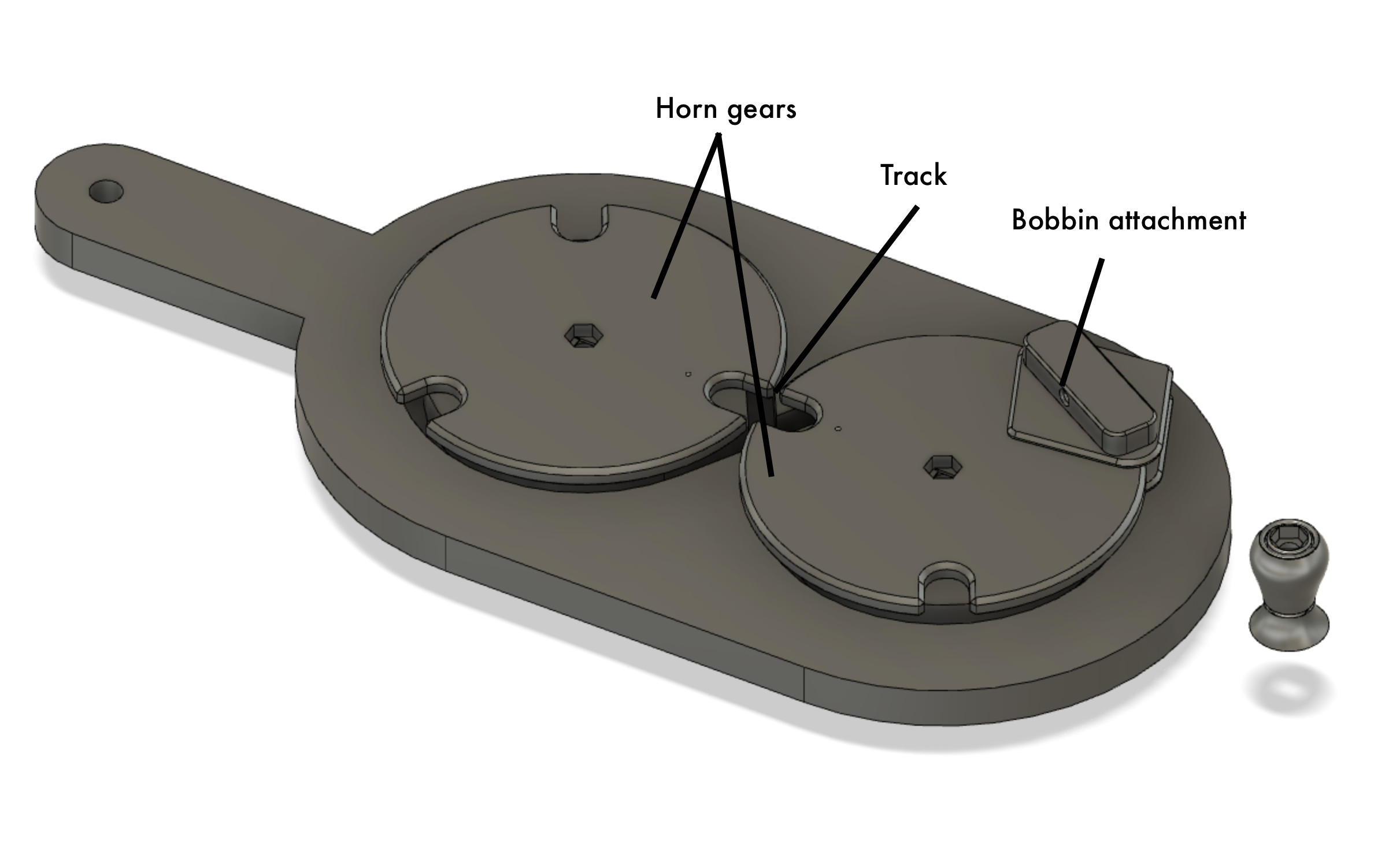

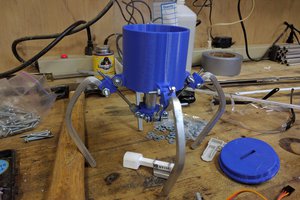

A braiding machine consists of spur gears, a frame with a track, horn gears, a foot (guide) for each bobbin carrier and the bobbin itself.

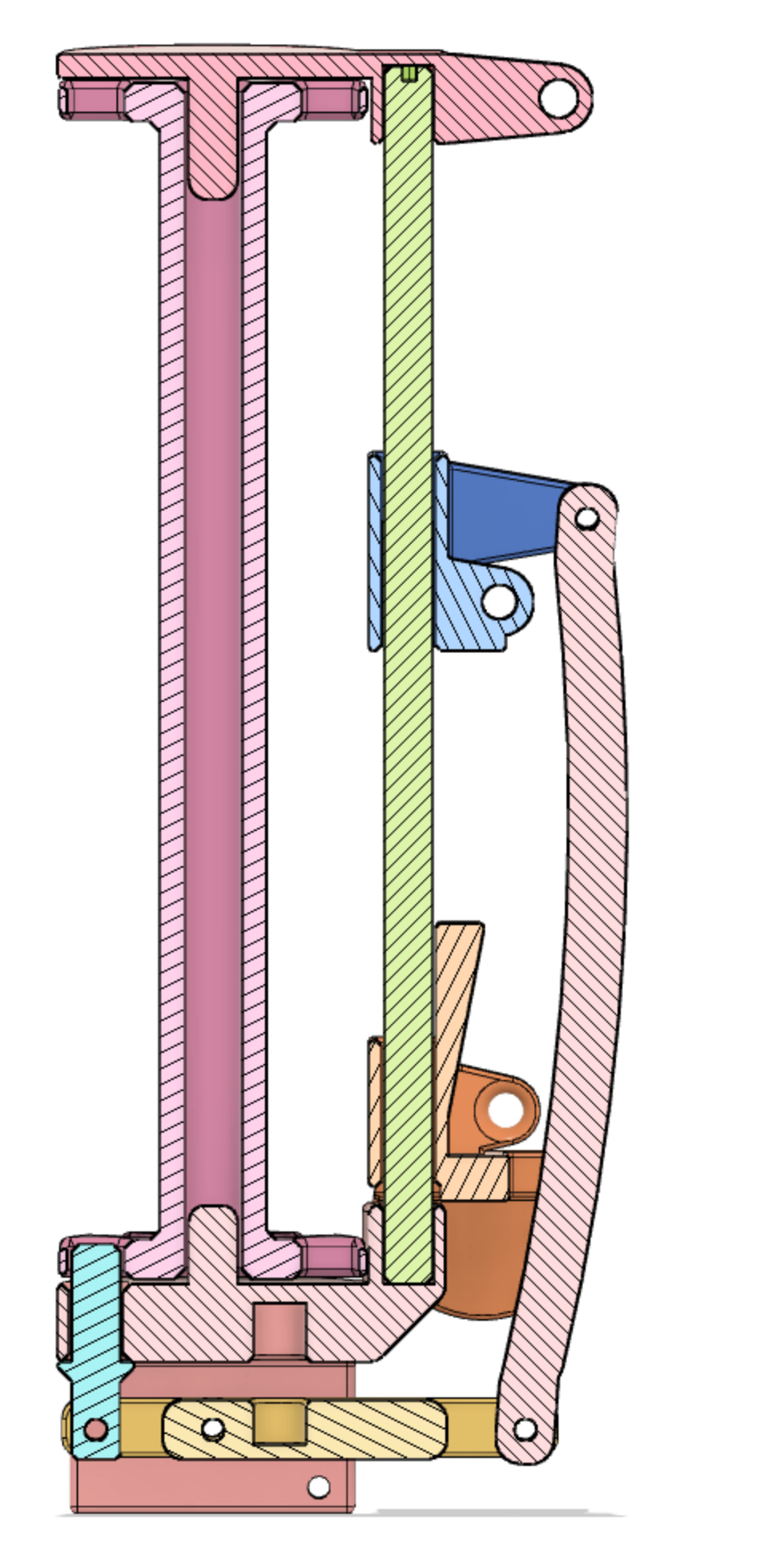

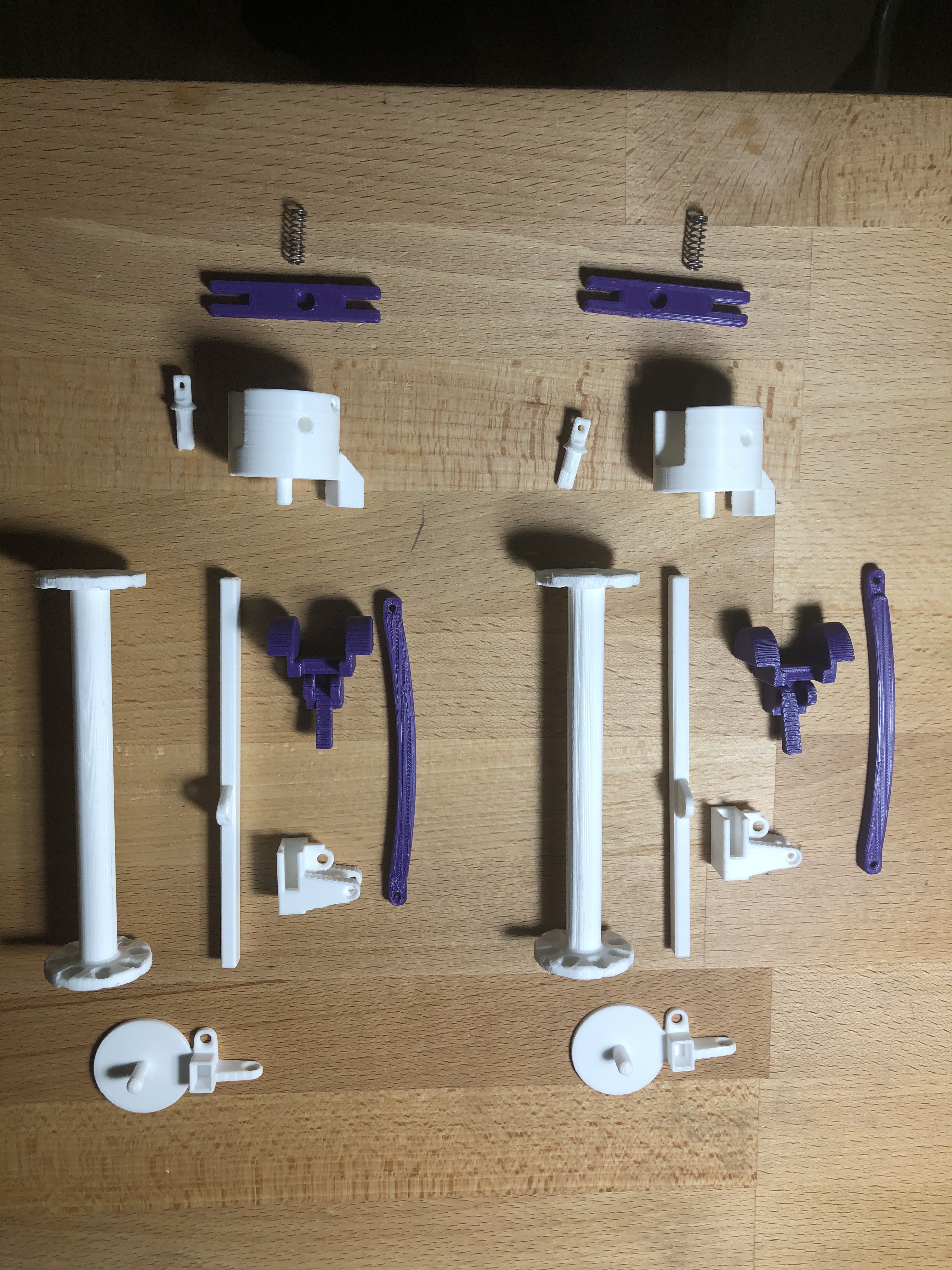

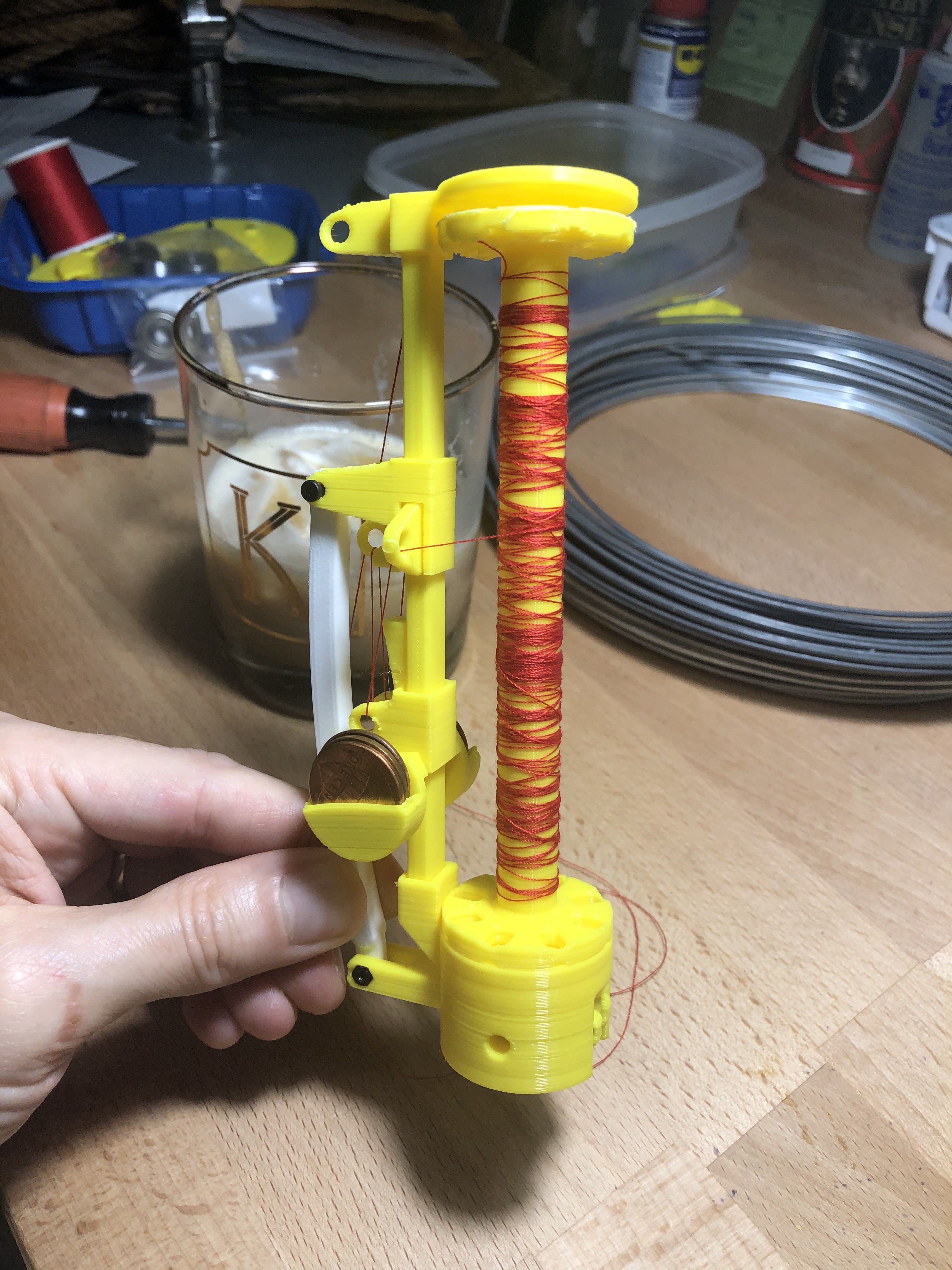

First, start by visualizing and understanding how the bobbins pass from one horn gear to another. I made a fidget spinner version to help me understand the basic functionality. Then, the bobbin carriers are actually more complex, since they have to keep a constant yarn tension, but release yarns when the tension gets too high. I studied images of commercial bobbin carriers and came up with a single-spring design (in contrast to a two-spring design in commercial units) by using gravity to maintain the primary yarn tension and then the spring for the bobbin release.

Watch the GIF above to see the fidget-spinner version in action showing how the horn gears pass the individual sections back and forth.

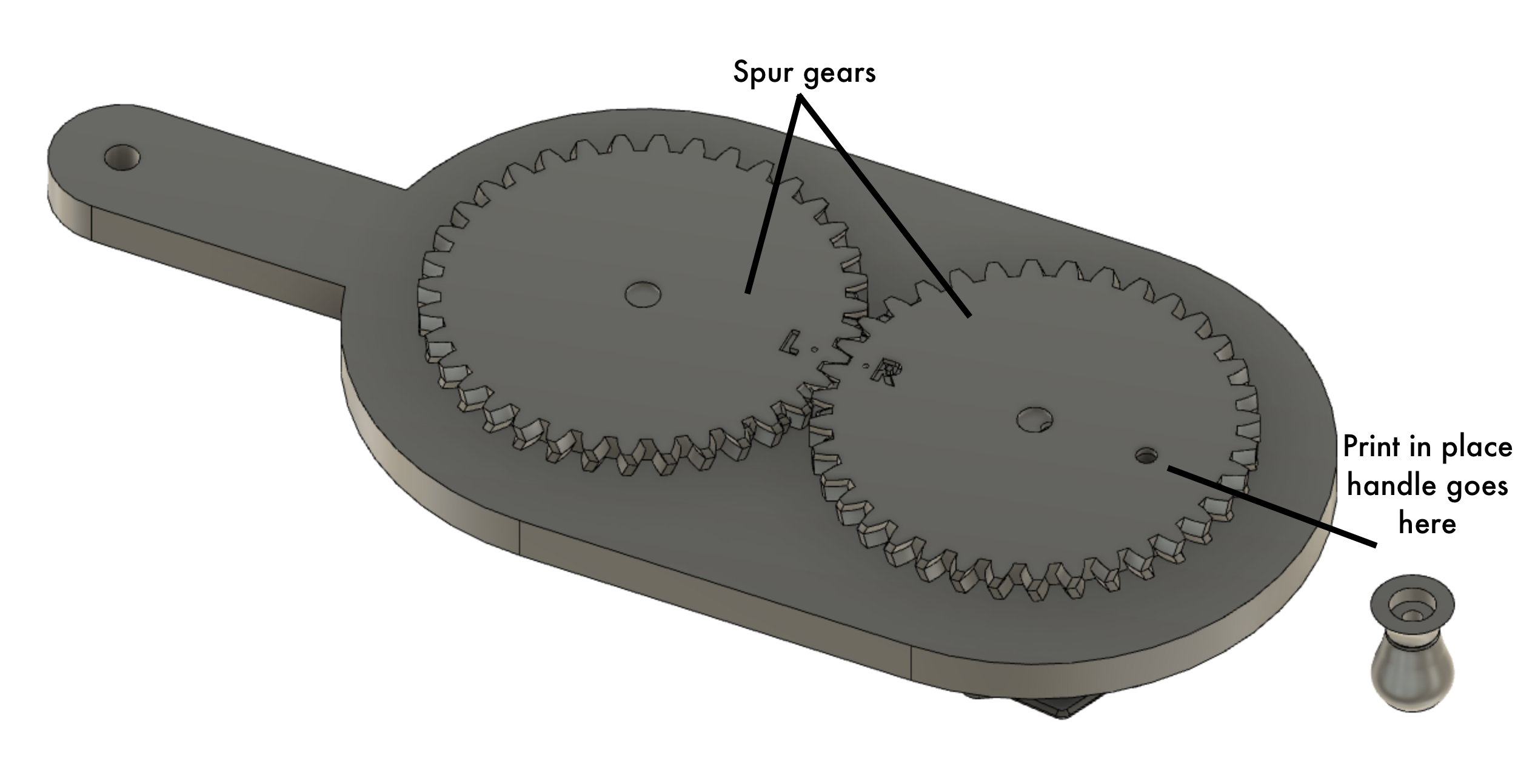

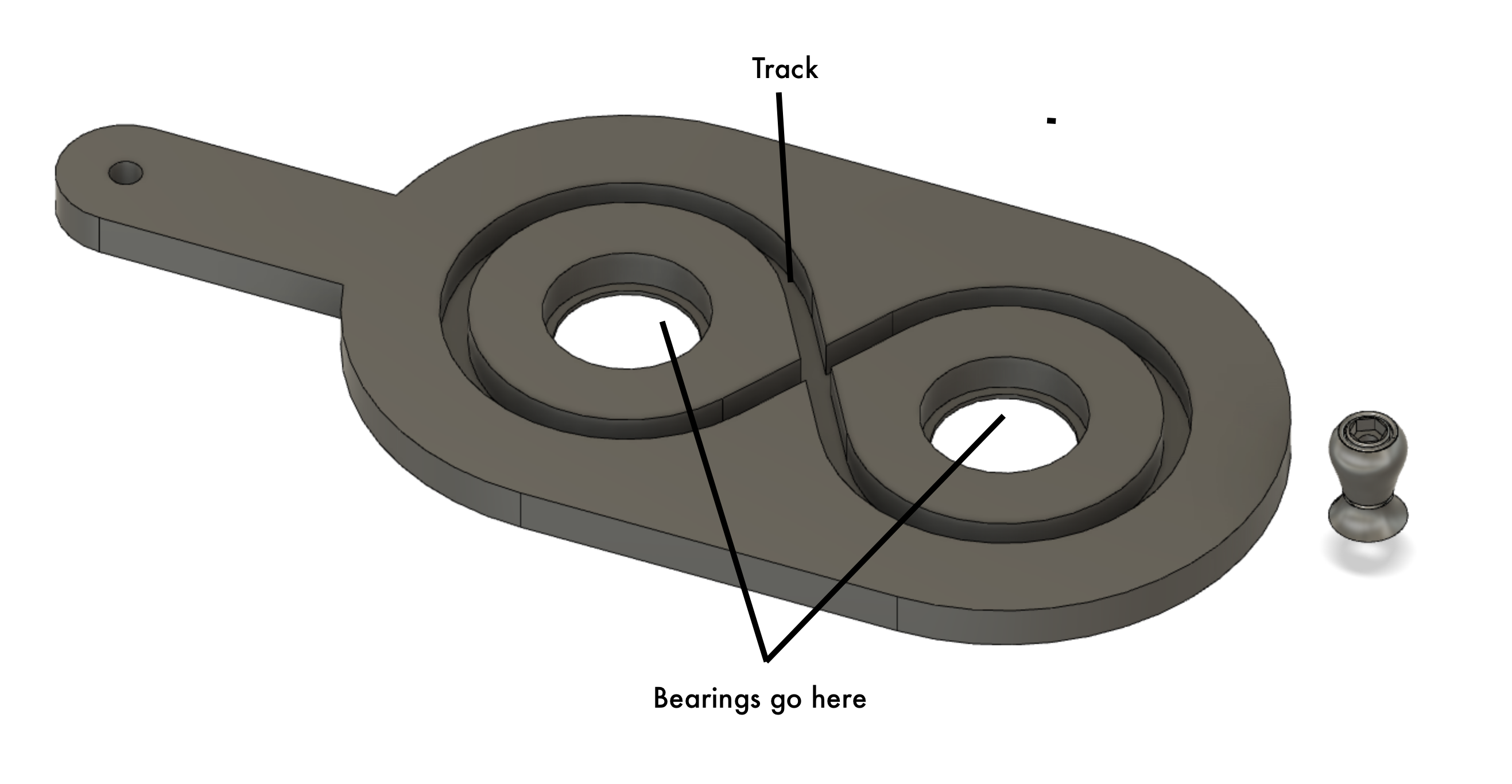

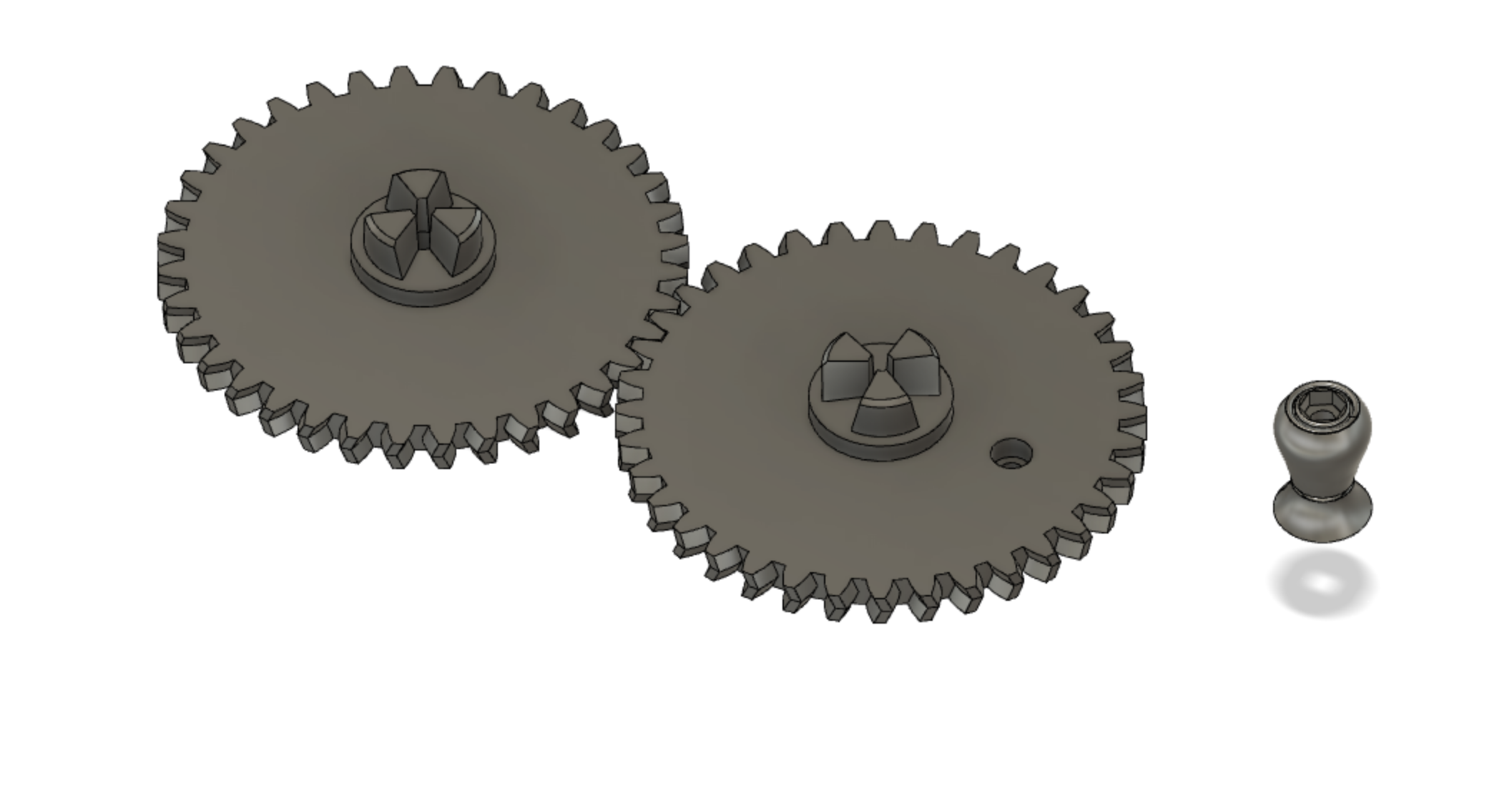

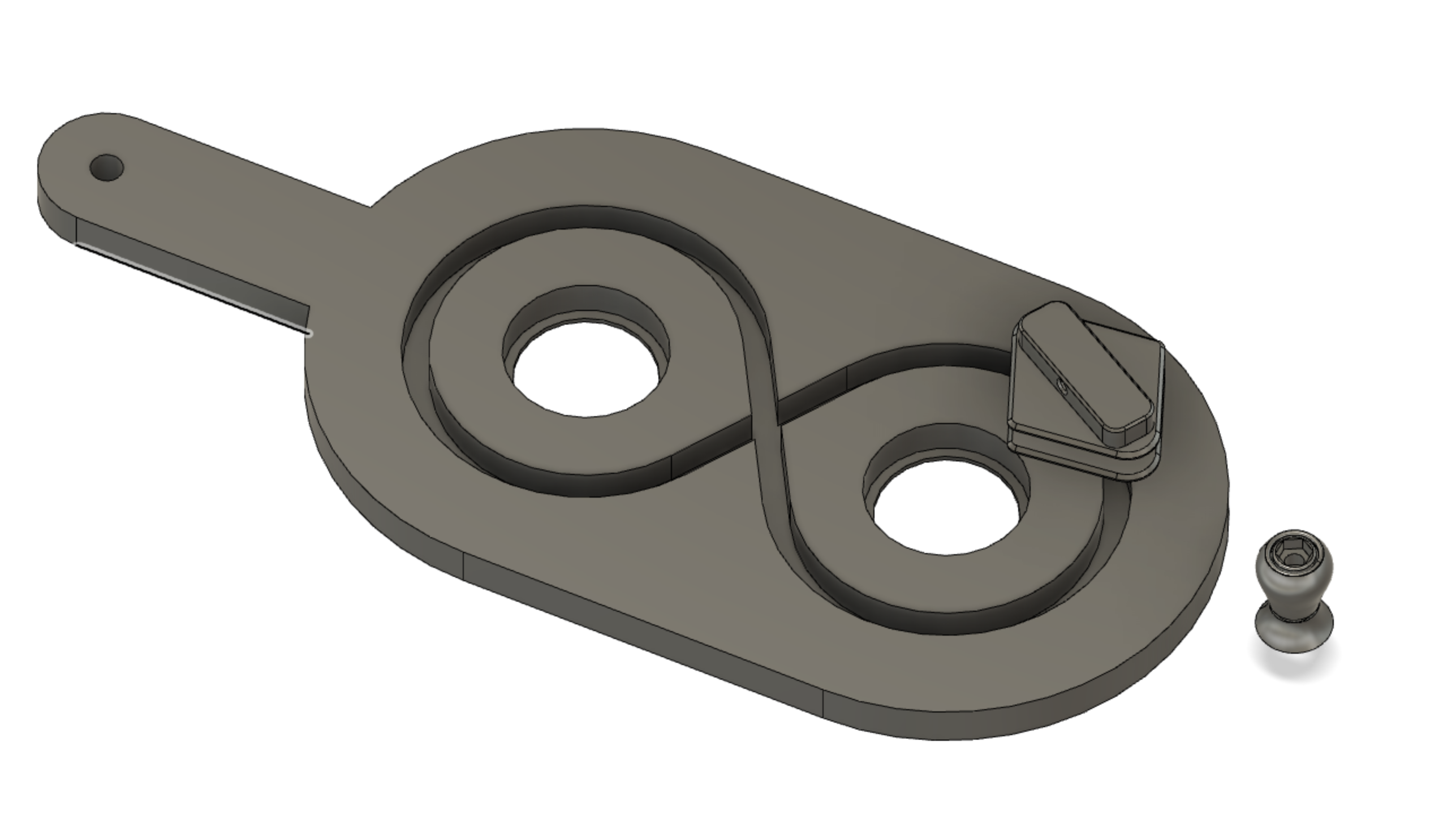

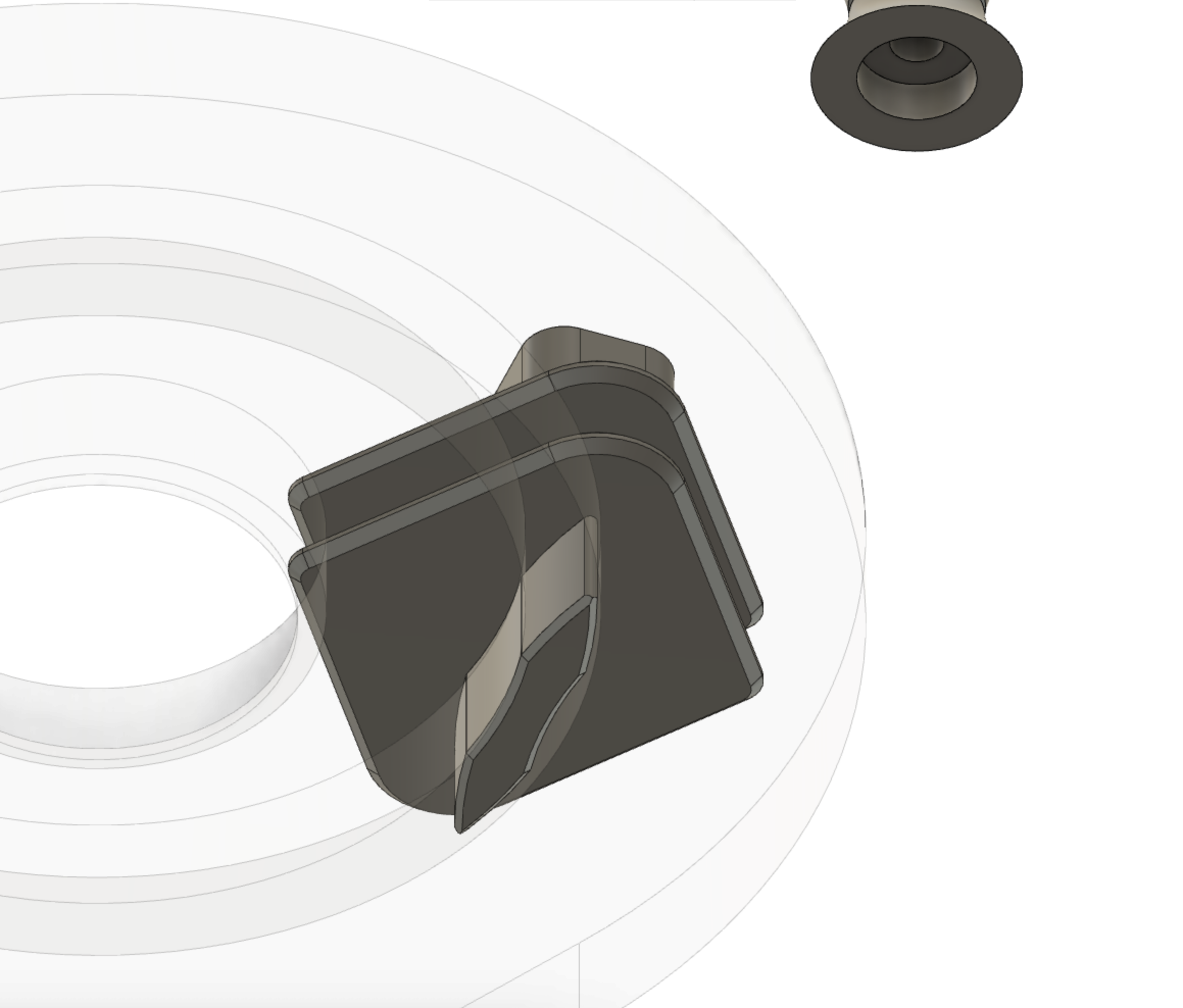

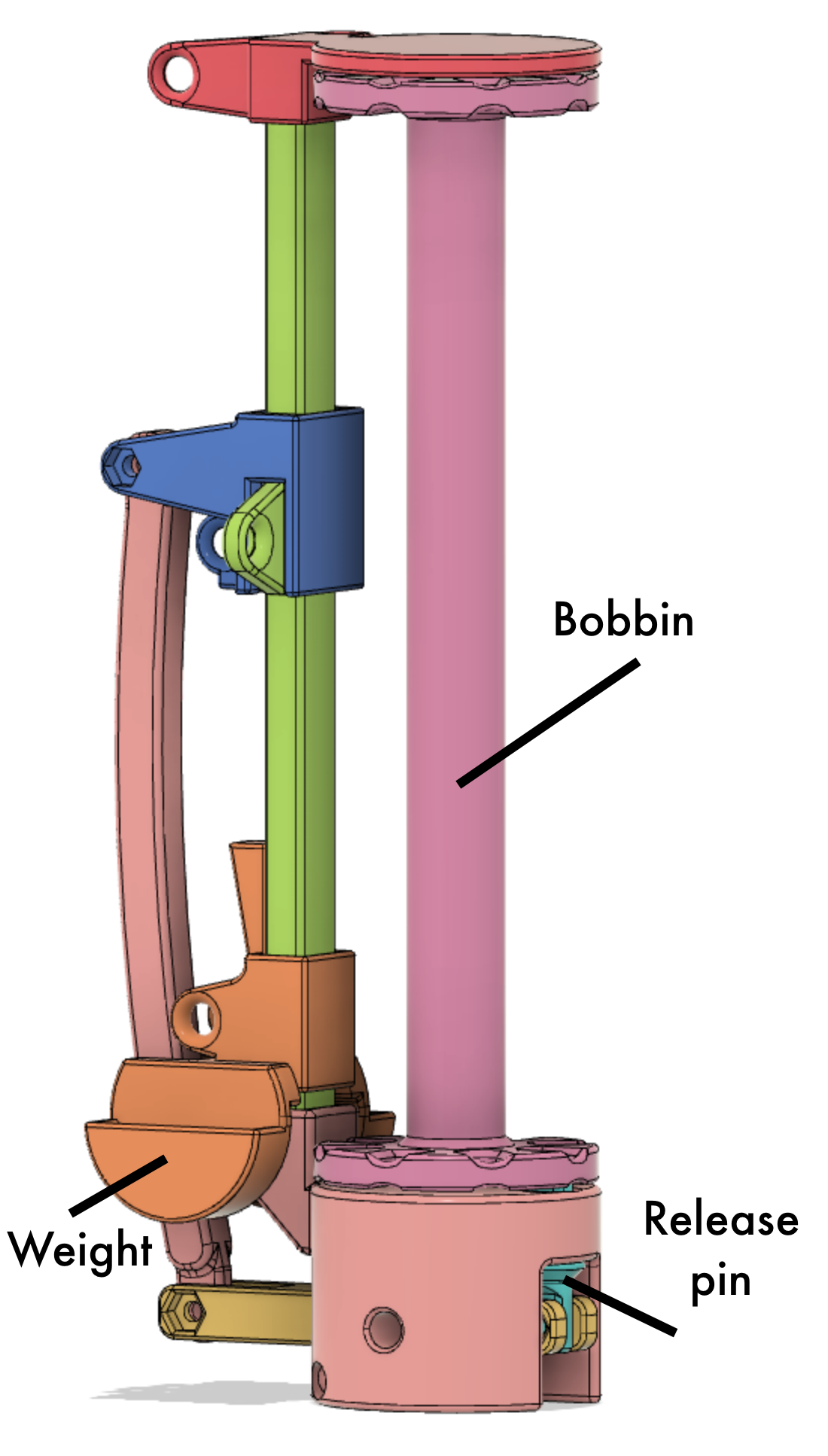

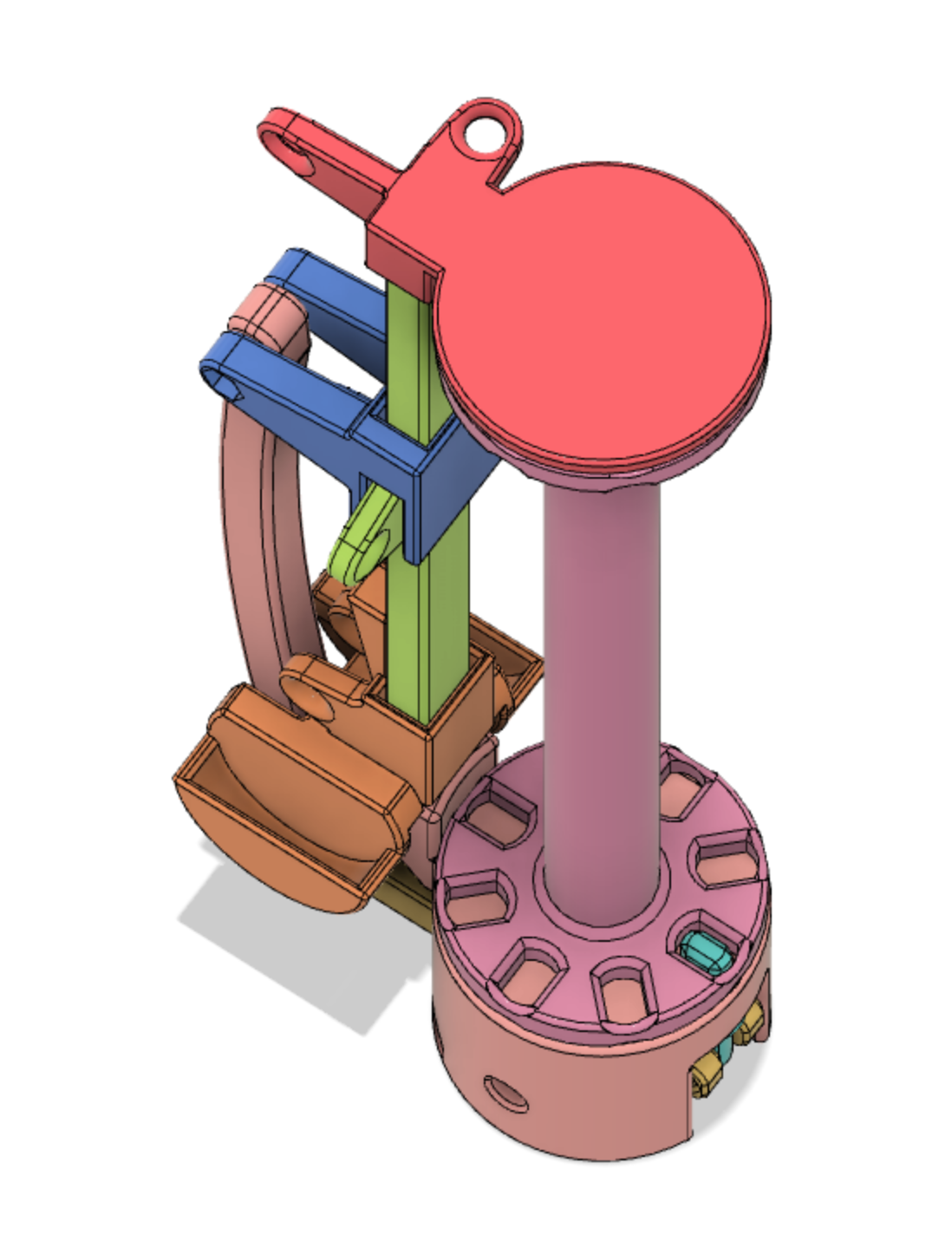

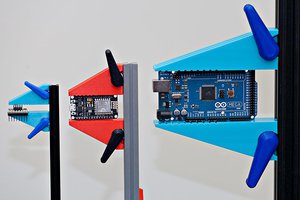

The spur gears are interconnected to each other and these spur gears are usually driven by a motor. The spur gears attach directly to a horn gear via a shaft passing through a bearing in the frame. The rotation of the spur gears drives the rotation of the horn gears. The horn gears grab the bobbin carrier and push it along the track and pass it to the next horn gear. The foot slides in the track and ensures that the bobbin carrier follows the correct path, carefully traversing the intersections of two tracks. The bobbin carrier contains a peg that is grabbed by the horn gear slot. The bobbin carrier rides on top of the horn gear. Also, the bobbin carrier has attachment points for a bobbin.

With the spur gear arrangement driving each adjacent gear, note that the horn gears next to each other will always rotate in opposite directions.

Here's a GIF of a braider with three bobbin carriers attached. This guide shows all the parts to make one of these.

kmatch98

kmatch98

Alex Anderson

Alex Anderson

Hi, very nice machine you have built there.

I have built a motorized braiding machine after old photos. The biggest problem is to keep the cord always under tension. I had also thought of a construction similar to your bobbin holder. I think this construction becomes a problem when the bobbins can be turned very easily and the weight unwinds the bobbin. Or have I overlooked something? Here you can see my braiding machine if you are interested:

YT: https://www.youtube.com/watch?v=xj4MgT5iLL0&list=PL9Jzxu1vDldMNZdv_c5Pis4F-nQ77MFtc