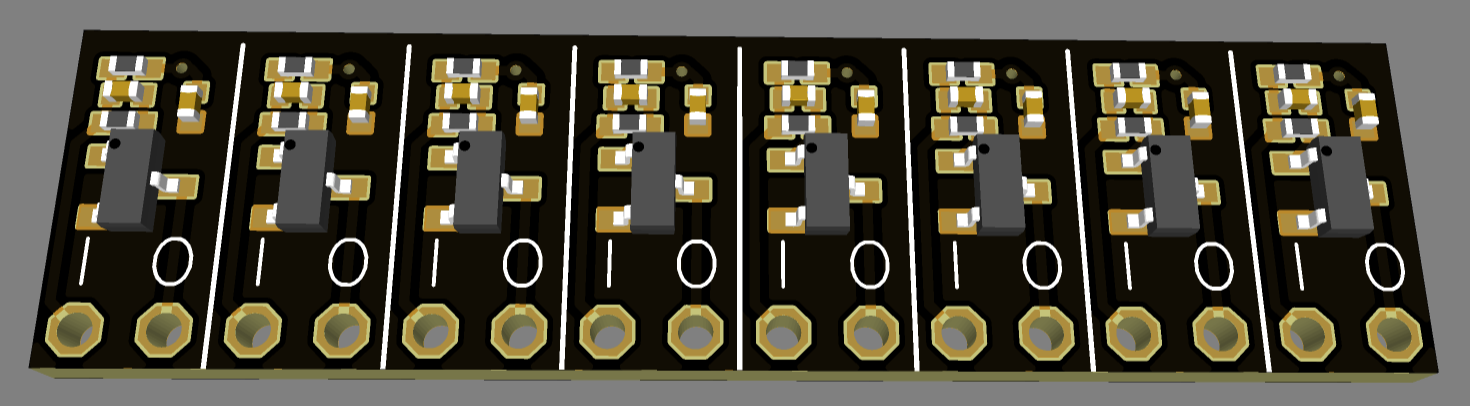

Here is an attempt in taking the strip concept and making it a bit smaller and easier to assmble.

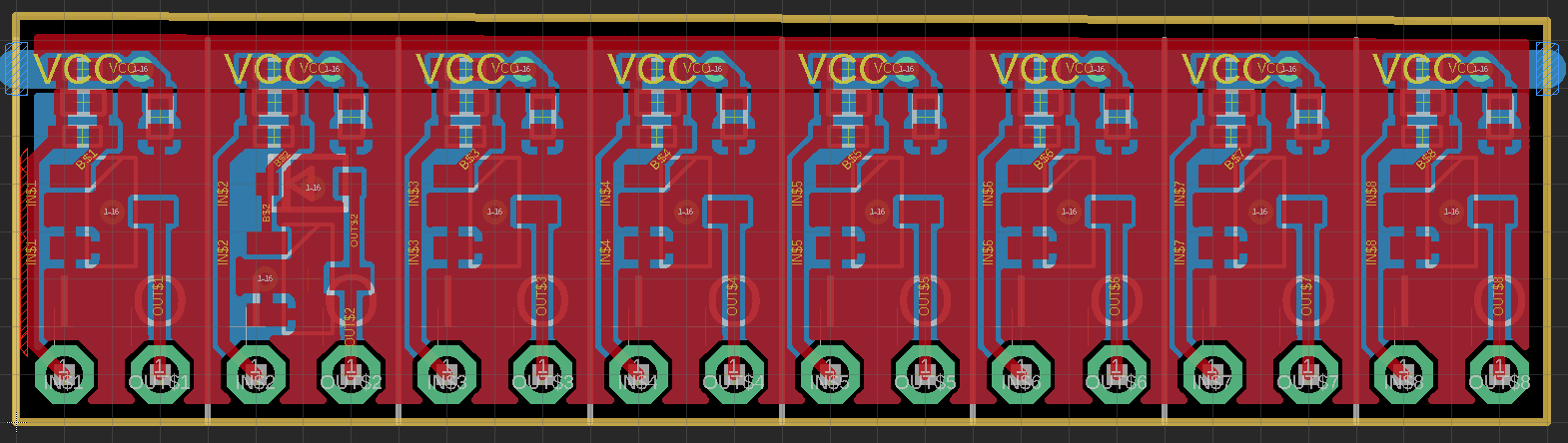

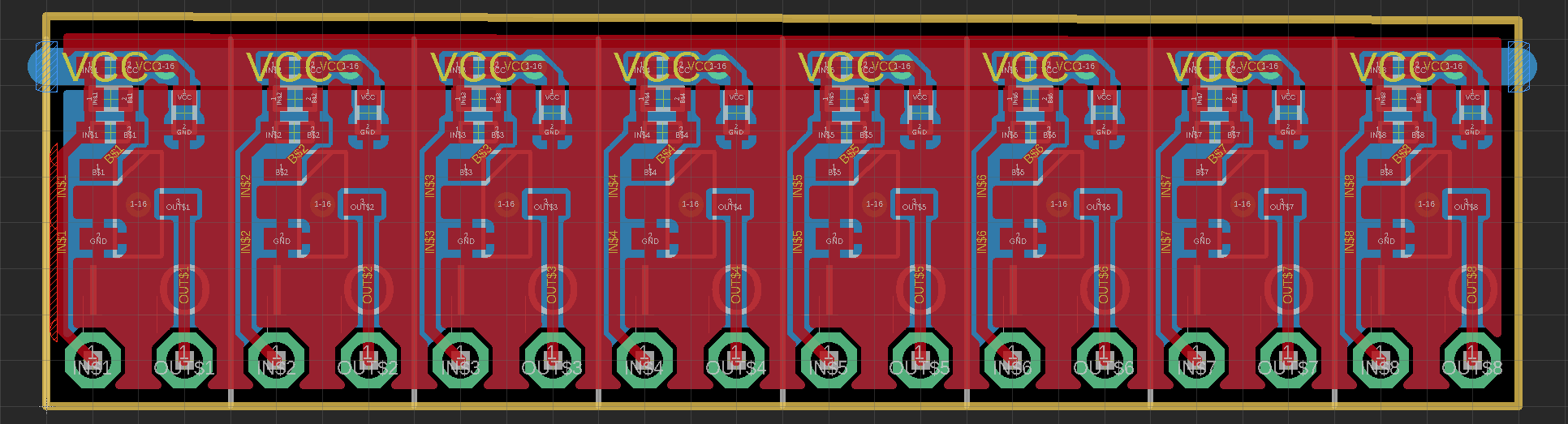

I moved all components to the top to allow automated assembly. If we use an assembly service anyways, we can switch all the passives to 0402 and save a lot of space. The VCC power rail is now routed on the rear side, while there is a large groundplane for GND on both sides of the PCB, that will also help with shielding.

This new arrangment allows reducing the strip width to 0.2". Each element is a single inverter with pull up at the input. Multiple inverters can be combined to form wide input NOR2 gates in RTL.

A base resistor bypass cap is added to improve switching speed. There is no space for a schottky clamp diode, but probably the parasitics of the wiring scheme on a breadboard will limit the achievable speed a bit anyways. Each element also has a decoupling capacitor.

Open and still unsolved: How to connect to the power lines?

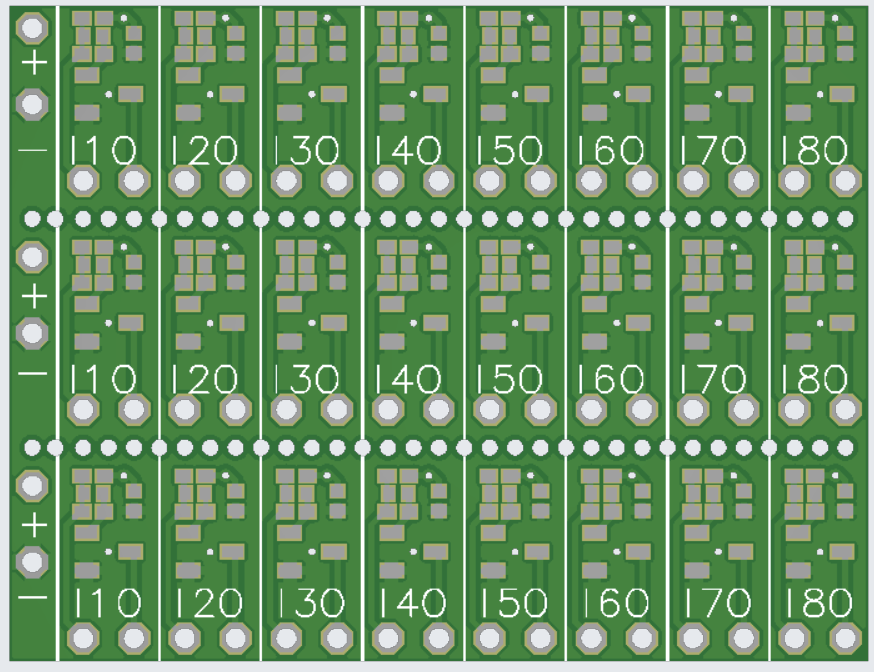

Some more renders below.

Edit: One could also fit a clamping diode in there. But then the text has to be moved to the rear side. Second from left:

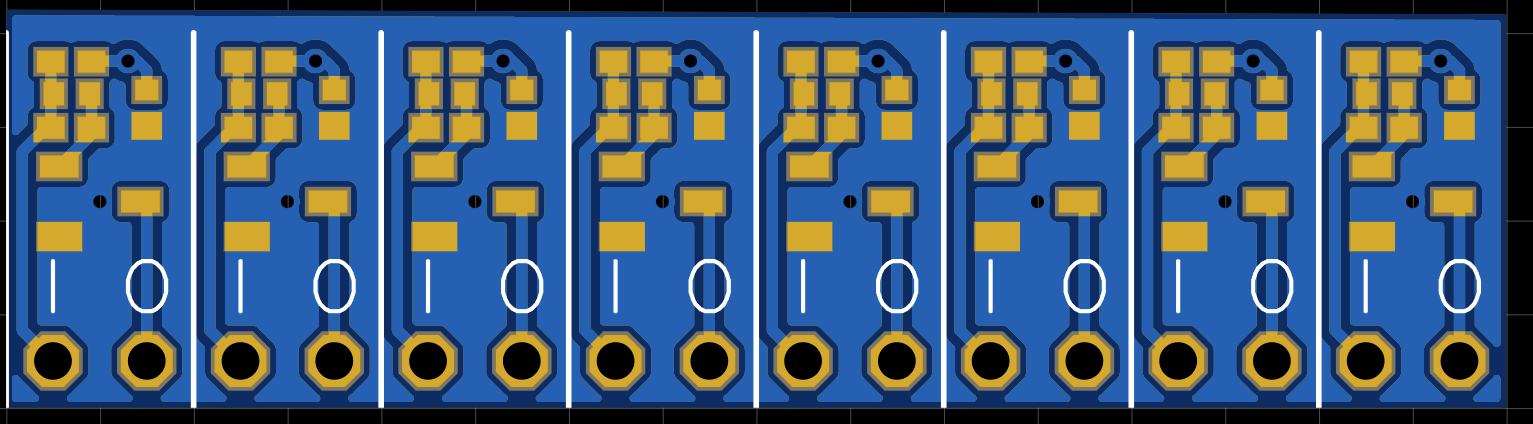

EDIT2: A version with drill-lines for easy separation

EDIT2: A version with drill-lines for easy separation

Tim

Tim

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

@Tim The "edit" seems to be only on one gate.

What package footprint did you use ?

Are you sure? yes | no

indeed. Just a test.

SOD-323

Are you sure? yes | no

nice :-)

Are you sure? yes | no

"How to connect to the power lines?" I contemplated this question already.

I imagined something like the "real" LED strips, which can be joined by soldering exposed pads. In our case, the pads can simply be exposed copper. A bit of resistor leg might also help.

But the corollary is : how do you break/cut the strip to a desired length ? V-groves ? microdrills ?

Are you sure? yes | no

>how do you break/cut the strip to a desired length ? V-groves ? microdrills ?

The design is probably too small for V-groves. But I made very small breakout boards before by separating them with microdrills on 0.8mm FR-4 thickness. You could simply cut them apart with scissors.

Are you sure? yes | no

I have an open order at JLCPCB and just added a few PCBs as above for testing without assembly. I can share some with you.

Are you sure? yes | no

Awesome !

Are you sure? yes | no

More strips per board could be achieved if you let go of the I and O marks, or even put them on the other side of the board :-)

Are you sure? yes | no

yeah, i though about that. Could flip the parts to the bottom. But then it is always better to be able to look at the components

Are you sure? yes | no

flip the marking to the bottom instead, it's the same, right ?

Are you sure? yes | no

"probably the parasitics of the wiring scheme on a breadboard will limit the achievable speed"

Why limit ourselves to breadboards ? ^_^

Are you sure? yes | no